Tower concrete structure pointed roof formwork system and construction method

A technology of concrete structure and formwork system, which is applied to formwork/formwork/work frame, building structure, and on-site preparation of building components, etc., to achieve the effects of good molding quality, convenient processing and manufacturing, and ensuring structural safety and waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

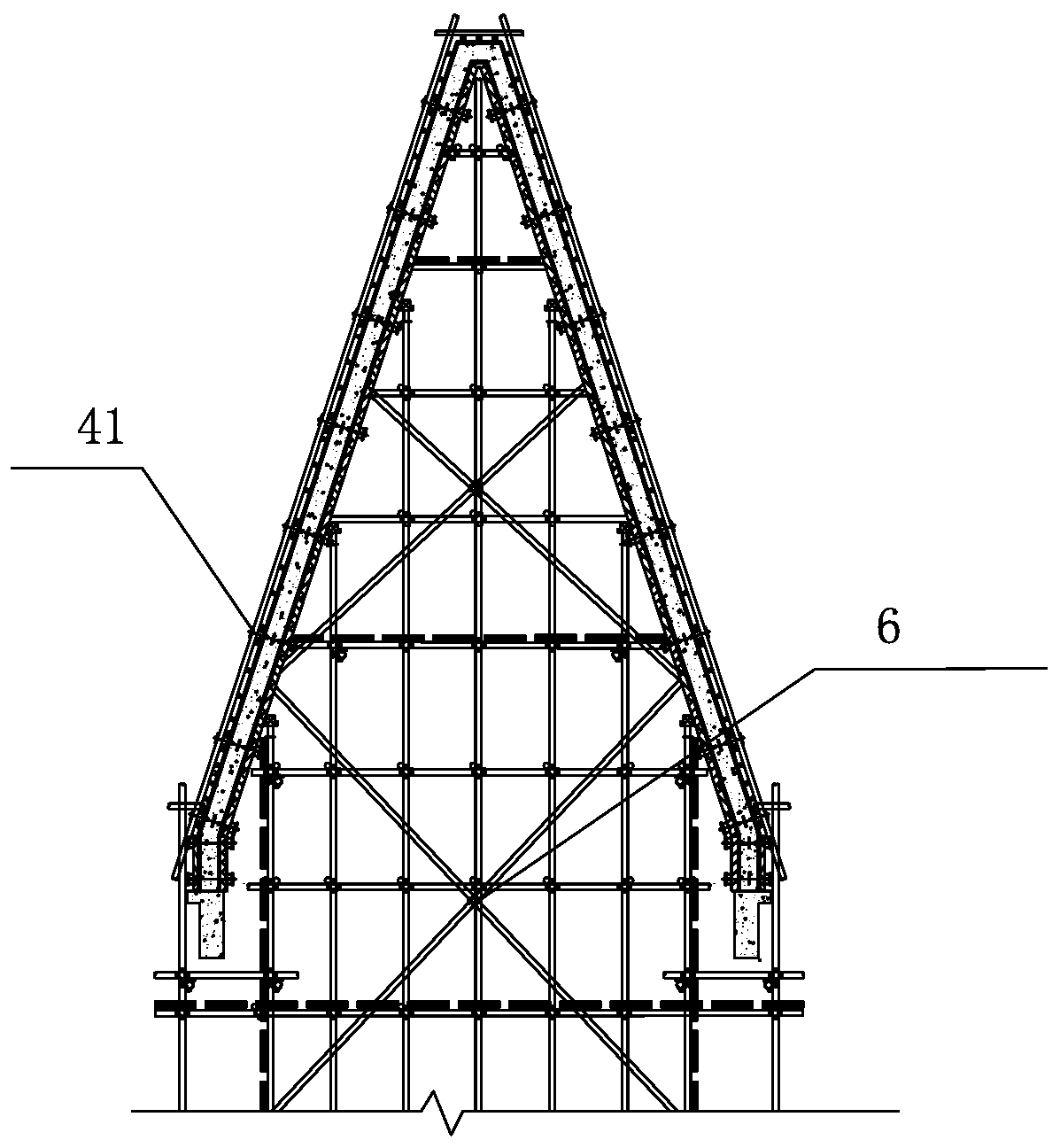

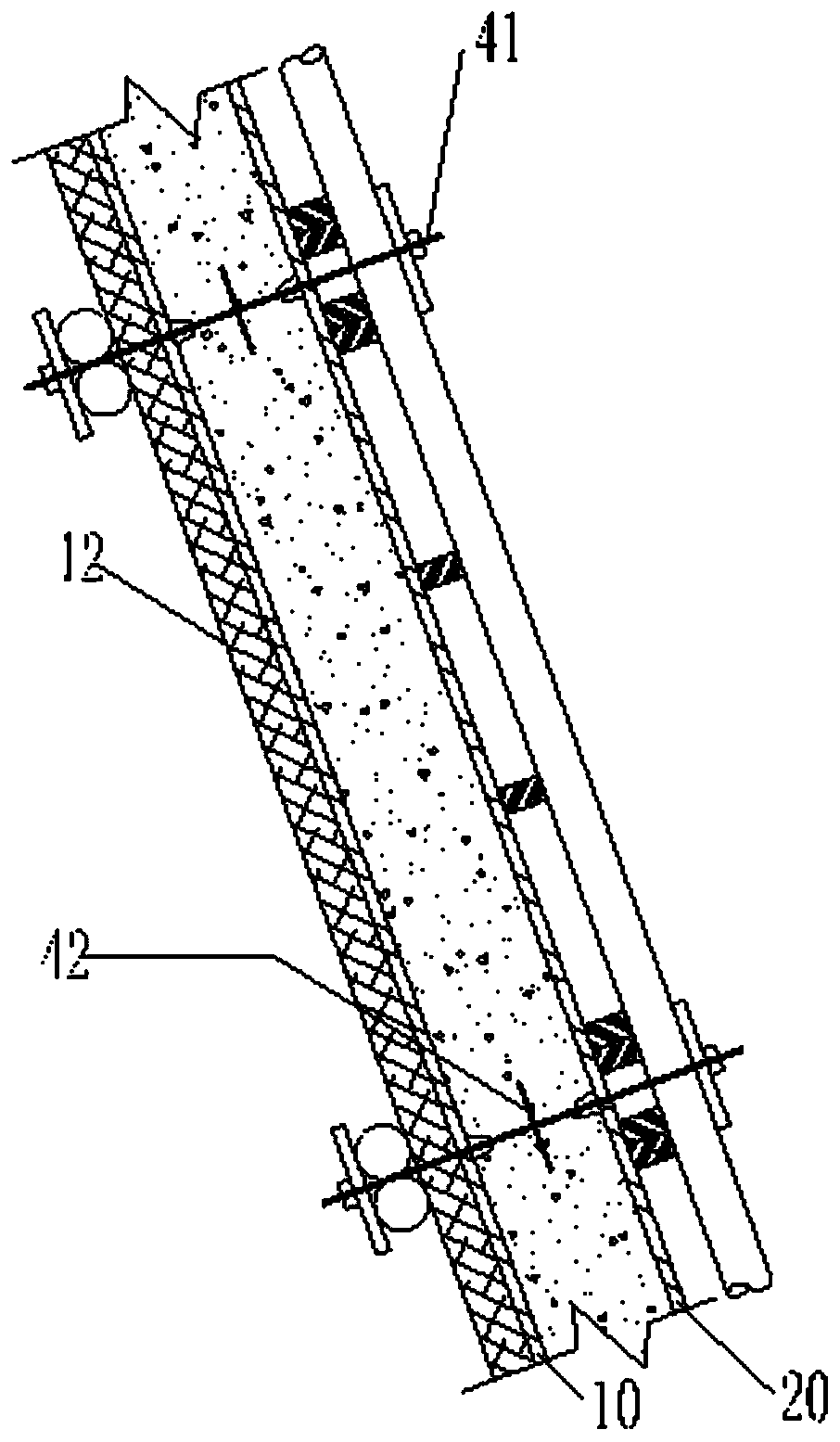

[0027] combine Figure 1 to Figure 3 The structural composition of the pointed roof formwork system of the tower concrete structure of the present invention is illustrated. The steep slope slope of the pointed roof in this embodiment is greater than 45°.

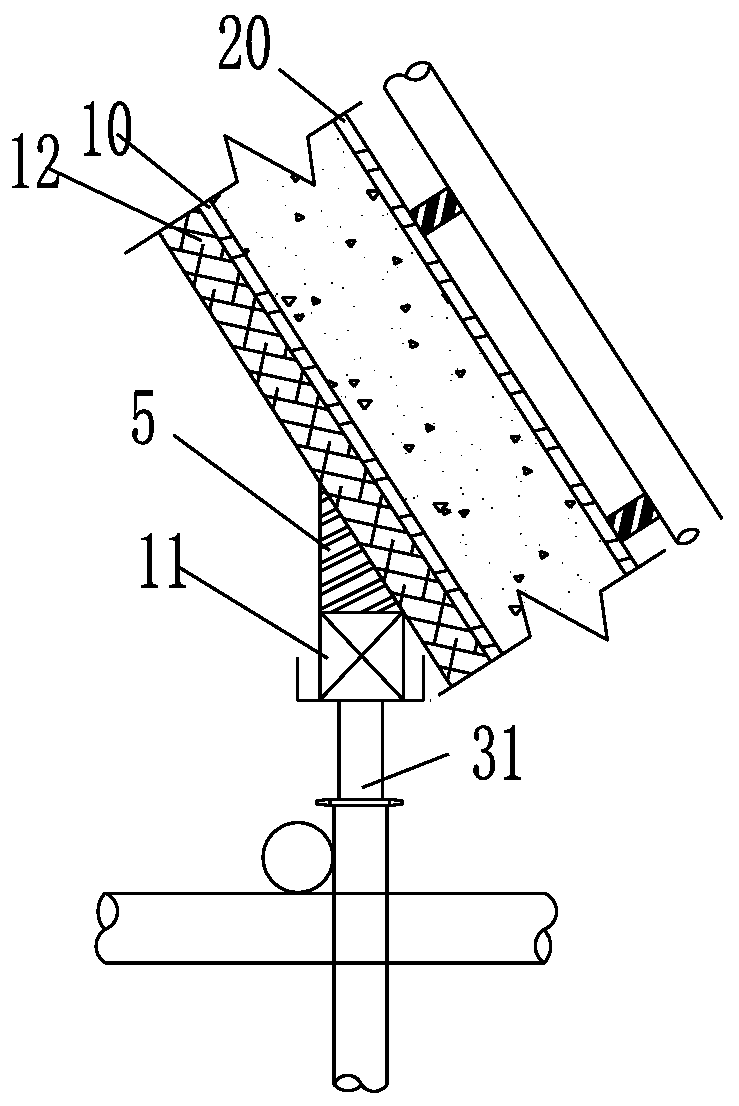

[0028] A formwork system for a pointed roof of a tower concrete structure, comprising a base formwork 10 and a surface formwork 20; the base formwork 10 is fixed by a full hall support bent frame 6, and the base formwork 10 has the same slope as the large-slope inclined roof of the pointed roof to be poured; the surface The layer formwork 20 is arranged in parallel above the bottom formwork 10, and the two are connected by fastening components to form a cavity. The thickness of the cavity is consistent with the thickness of the sloped roof. There is a pouring trough (not shown).

[0029] Specifically, the formwork system for the pointed roof of the tower concrete structure of the present invention is achieved by setting do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com