Cylindrical husk steaming machine

A chaff and drum-type technology, applied in the field of drum-type chaff steamers, can solve the problems of unsmooth cutting, long production cycle, and inability to rapidly cool, and achieve the effect of ensuring cutting and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

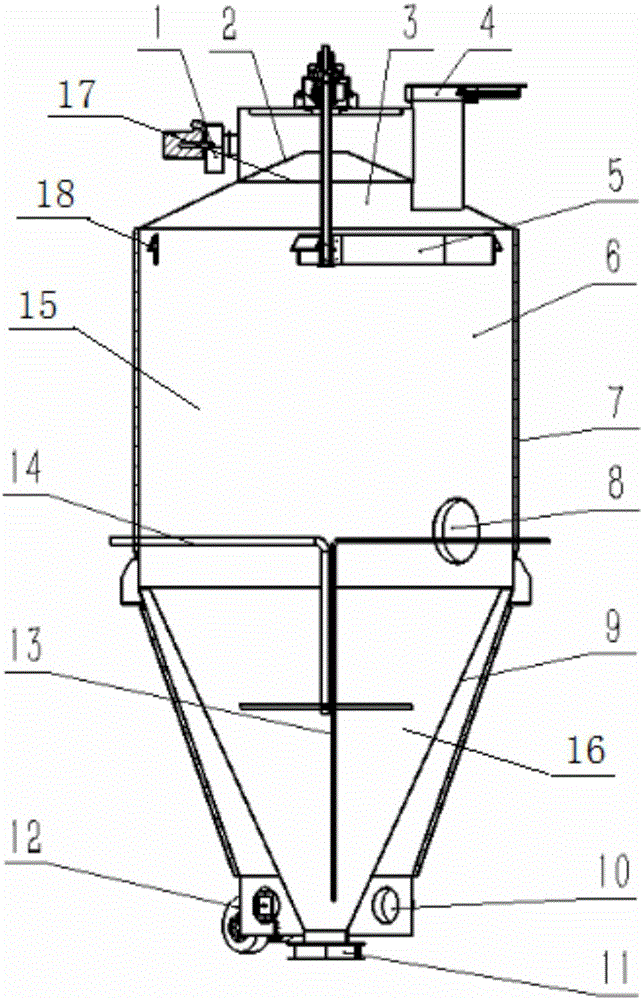

[0014] like figure 1 Shown, a kind of cylinder type rice husk steamer comprises exhaust fan 1, loam cake 3, cylinder 6, wherein said cylinder 6 comprises cylinder top 15 and cylinder bottom 16, and said cylinder top 15 is Cylindrical, the lower part of the cylinder 16 is a rounded frustum shape, the upper part of the cylinder 15 and the lower part of the cylinder 16 are connected to form the cylinder 6, and the walls of the upper part of the cylinder 15 and the lower part of the cylinder 16 are filled with insulation materials, so The lower end of the lower part 16 of the cylinder is provided with a discharge port, and the discharge port is provided with a discharge pneumatic gate 11, and the side of the lower end of the lower part 16 of the cylinder is provided with a cleaning hole 10 and a cold air hole, and the side wall of the lower part 16 of the cylinder is Connected with the cooling fan 12, an inner screen 9 is provided on the inner wall of the lower part 16 of the cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com