New and old mixed stemming manufacturing process and equipment applied to process

A production process and a technology for poppet mud, which is applied to the production process of new and old mixed poppet mud and the equipment used in the process, which can solve the problems of waste of resources, discarding of poppet mud, and easy drying up, so as to ensure blanking and reduce misalignment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

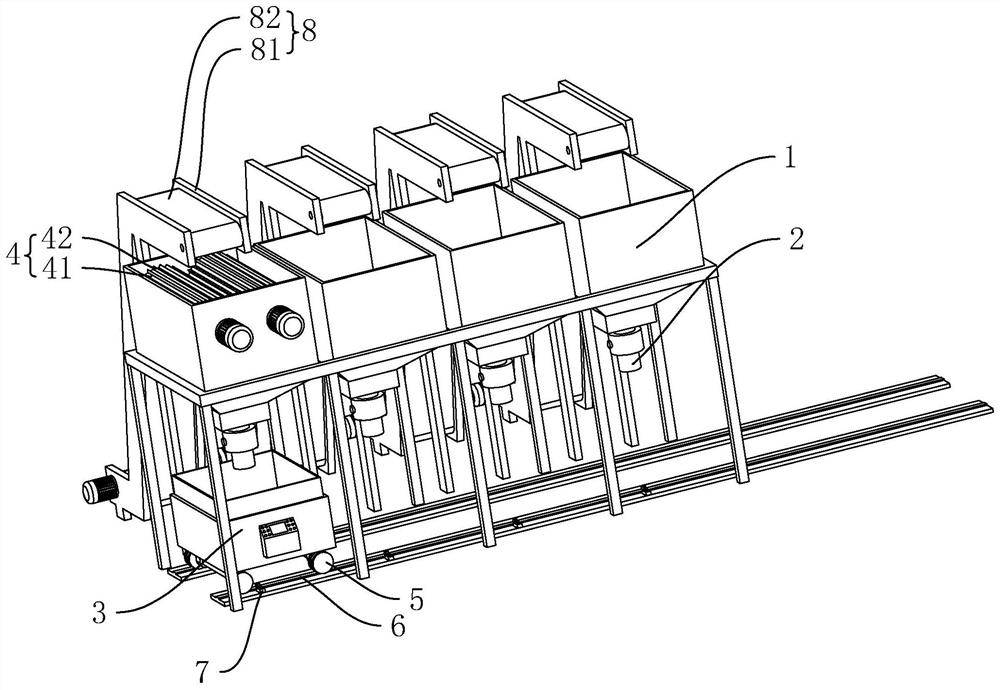

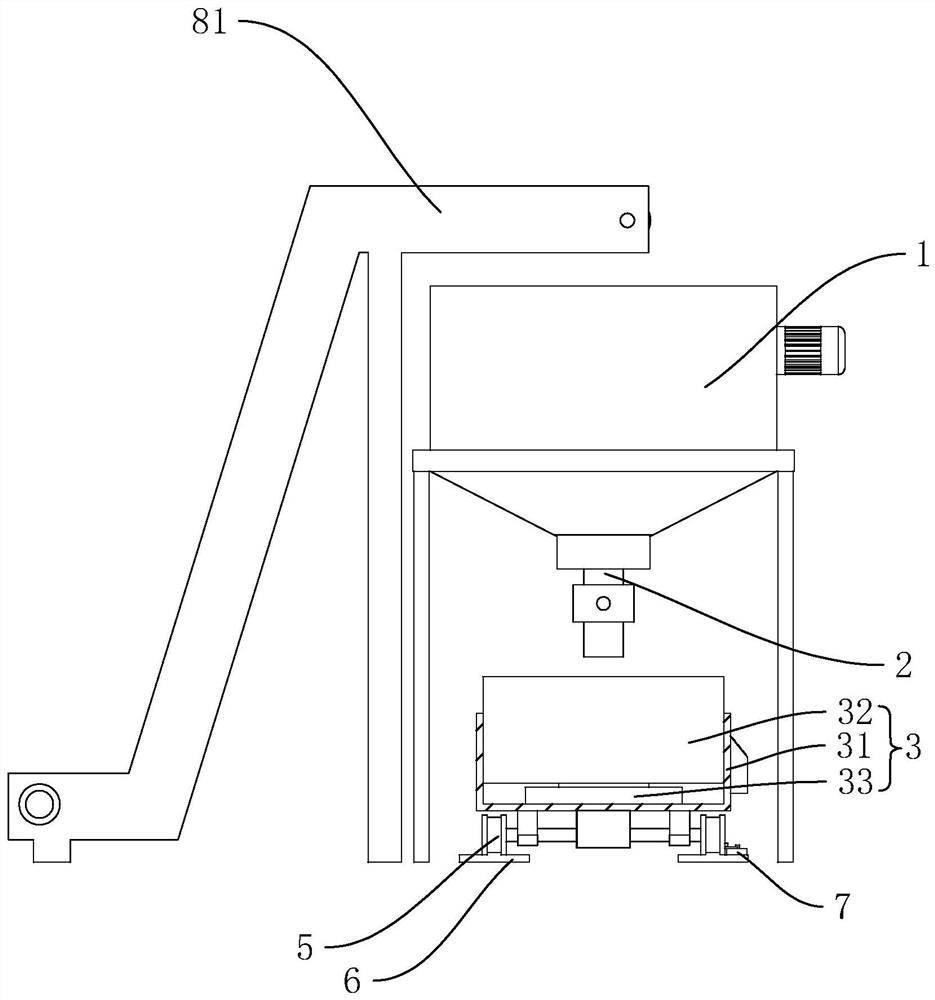

[0041] The following is attached Figure 1-3 The application is described in further detail.

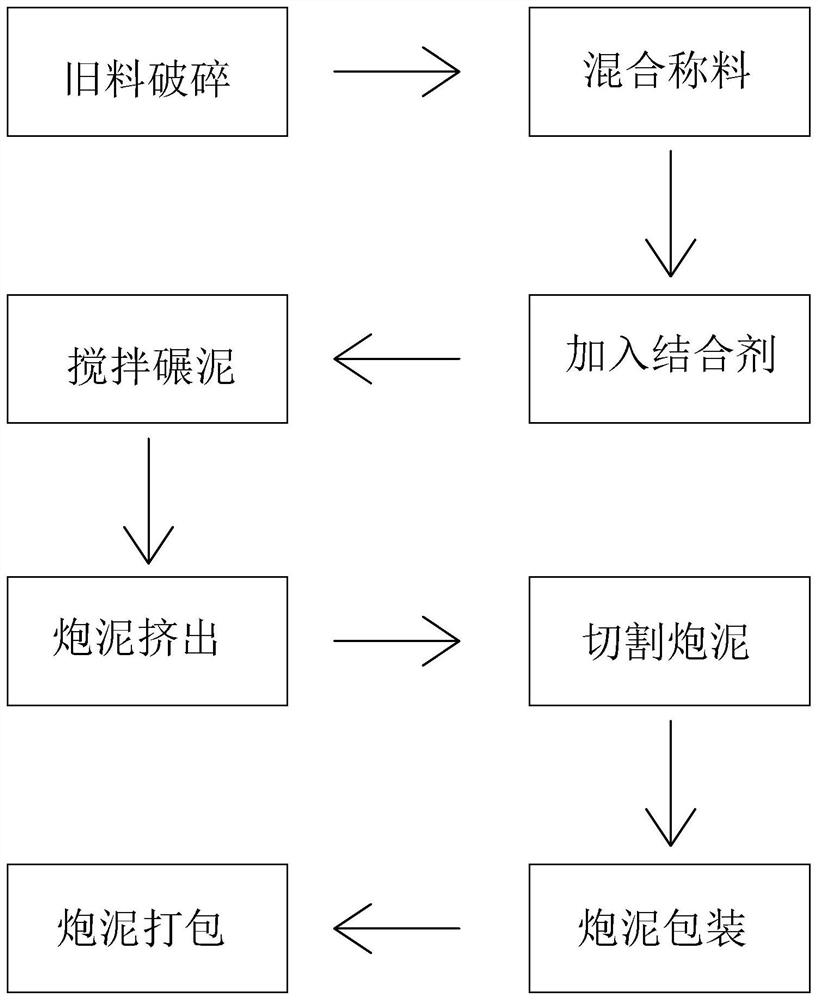

[0042] The embodiment of this application discloses a kind of new and old mixed gun clay production process, referring to figure 1 , including the following steps:

[0043] Step 1: Crushing the old material, crushing the dry clay until it is broken into powder, the powder clay can be easily mixed with the raw material of the clay;

[0044] Step 2: Mixing and weighing, weighing and mixing the crushed gun mud and the gun mud raw material in proportion, the gun mud raw material is mixed according to the normal production ratio of the gun mud, the crushed gun mud powder and the gun mud raw material According to the ratio of 1:2, the performance of the dry clay will be reduced. By adding a small amount of clay to the clay, it can save resources and ensure the quality of the clay in subsequent production. By crushing the dried clay and Mixing new materials to make new gun mud can reuse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com