Collection ring carbon brush holder

A collector ring and carbon brush holder technology, applied in current collectors, rotary current collectors, circuits, etc., can solve problems such as affecting motor operation, inability to provide electrical conductivity, and elastic fatigue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

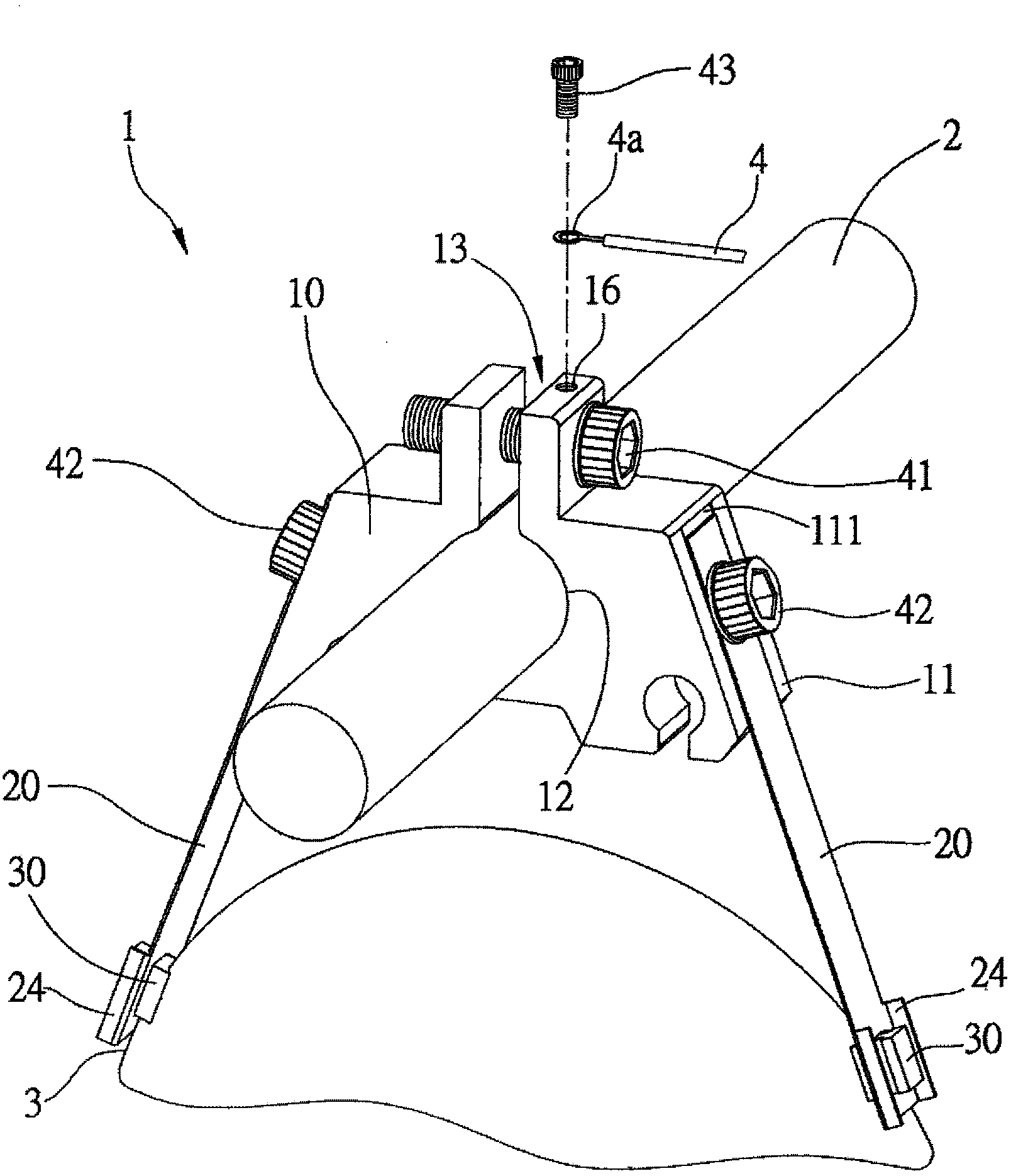

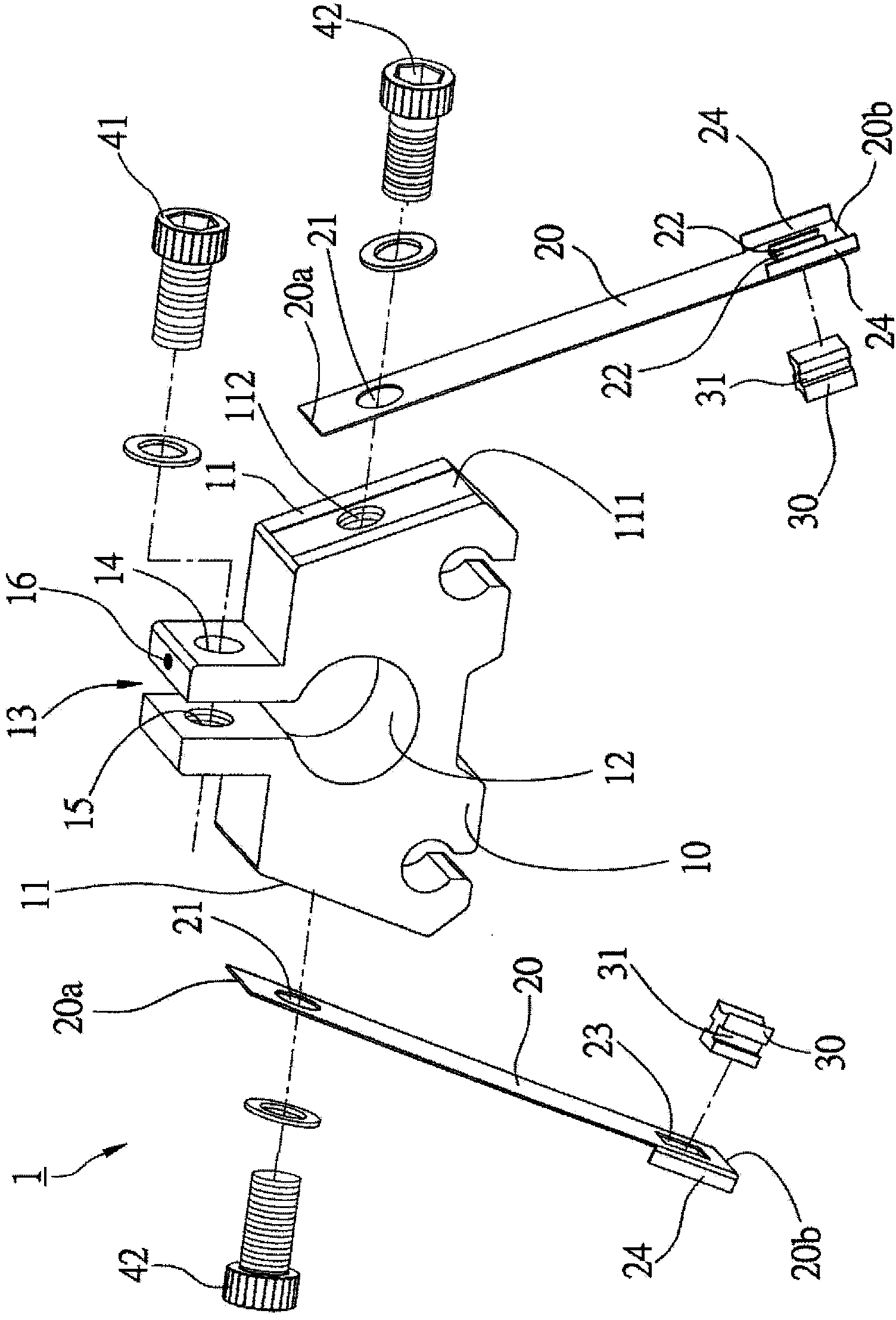

[0014] In order to illustrate the present invention more clearly, a preferred embodiment is given and detailed description is as follows in conjunction with the drawings, please refer to figure 1 and figure 2 As shown, the slip ring carbon brush holder 1 of a preferred embodiment of the present invention is located between a fixed shaft 2 and a slip ring 3 , and includes a joint seat 10 , two brackets 20 and two carbon brushes 30 . in:

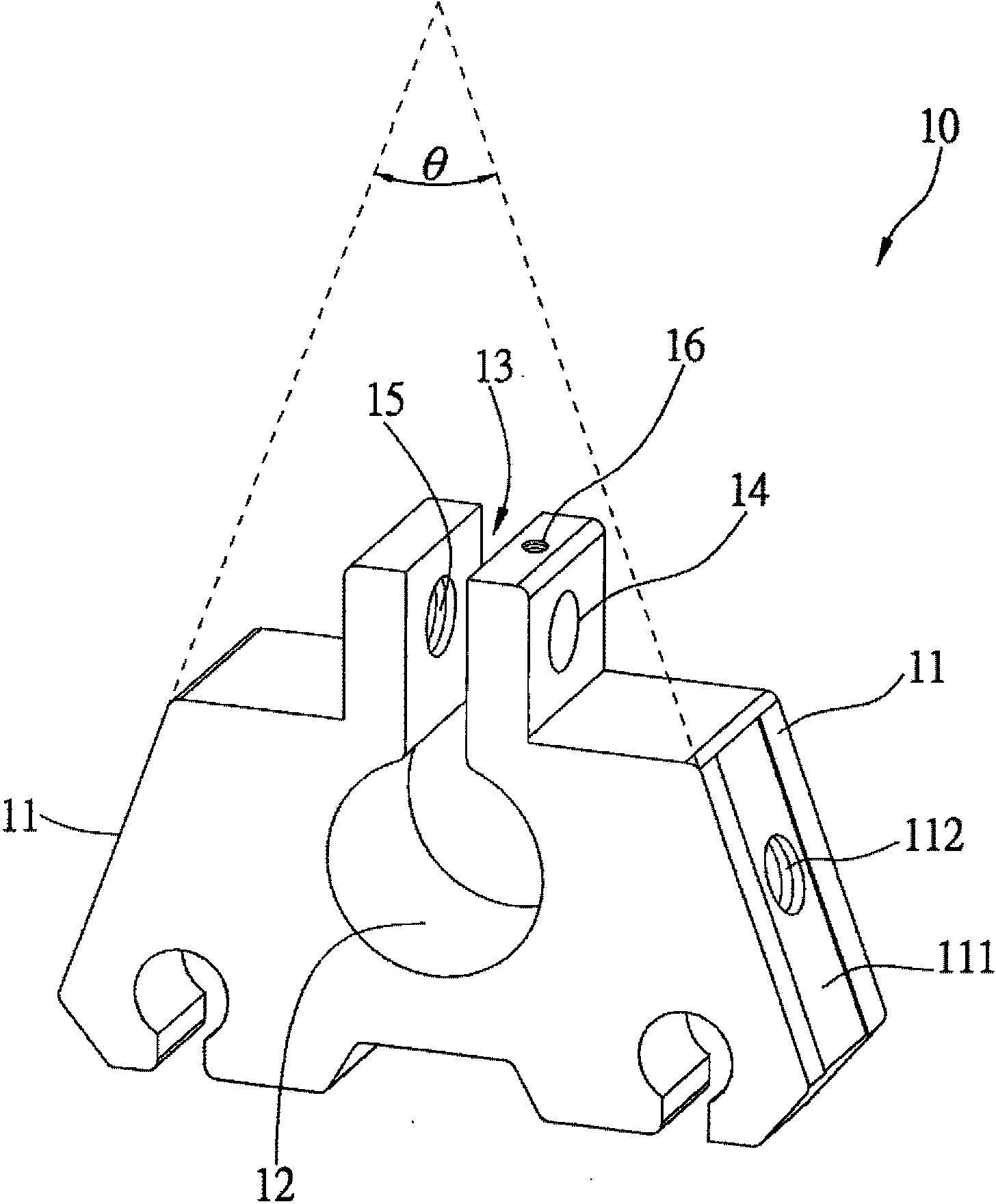

[0015] see image 3 , the joint base 10 is made of a conductor (such as copper) as a whole, and has two joint surfaces 11 , a shaft hole 12 , and a gap 13 connecting the shaft hole 12 and the outside of the joint base 10 . The two joint surfaces 11 are located on the opposite sides of the joint base 10, and the extension surfaces of the two joint surfaces 11 form an angle θ between 0° and 180° and extend downward and outward, wherein the angle θ It is better to be about 30 degrees as shown in this embodiment. In addition, a groove 111 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com