Dual power rotation deep inclined hole drill machine and processing method thereof

A dual-power, rotating direction technology, used in boring/drilling, metal processing equipment, drilling/drilling equipment, etc. The position is accurate, the precision is high, and the work efficiency is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

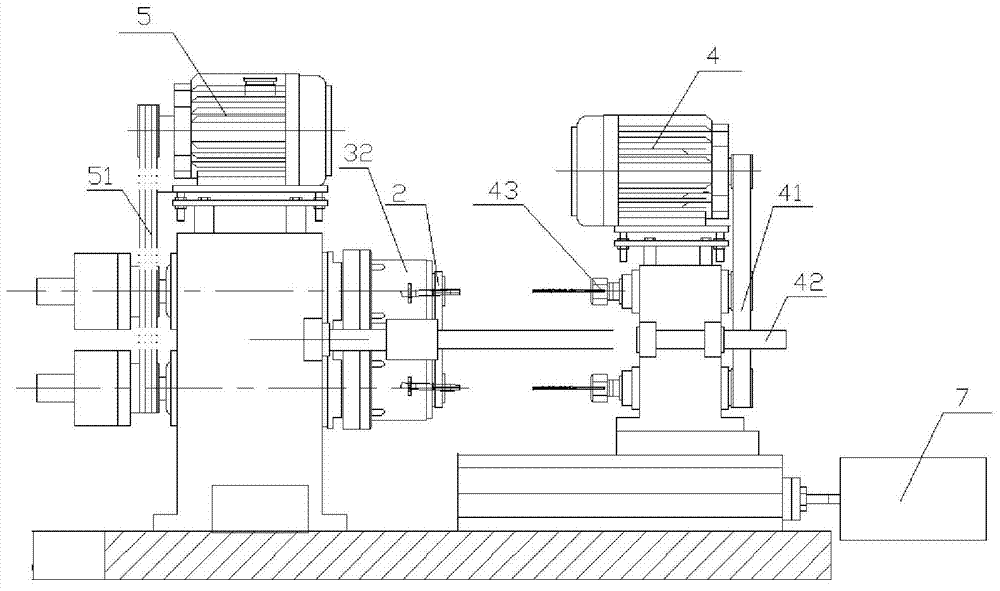

[0030] refer to Figure 1-Figure 8 To further illustrate the present invention, the following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

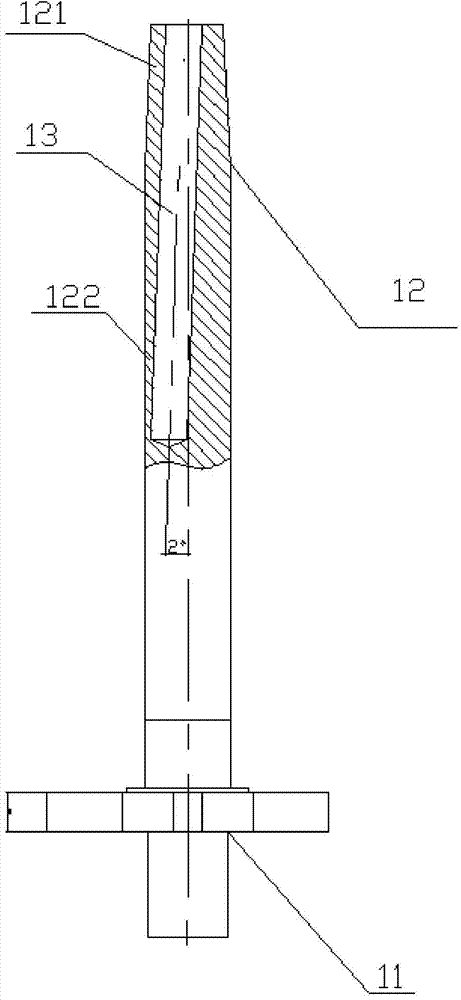

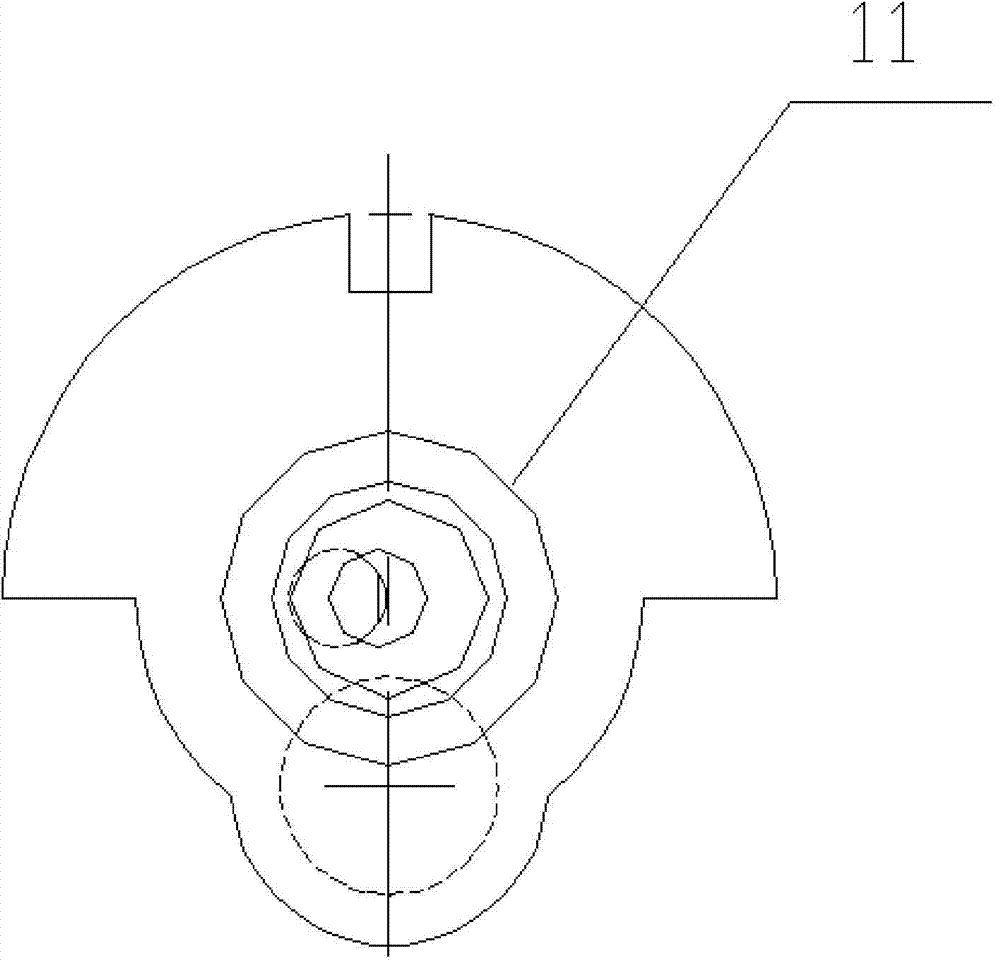

[0031] refer to Figure 2-Figure 3 : the workpiece to be processed includes a centrifugal part 11 and a major axis 12, and the major axis 12 includes a cylindrical A part 121 and a conical B part 122 connected to the A part 121, and in the processing process, it is necessary to drill the major axis 12 Get a deep inclined hole 13 that passes through the B portion 122 and partially penetrates into the A portion 121. The centerline of the deep inclined hole 13 intersects with the centerline of the major axis 12, and the formed acute angle is 2 degrees. At the same time, the deep inclined hole The hole center of 13 deviates nearly 0.5 mm from the center of the upper bottom surface of B part 122, the diameter of A part 121 is about 11 mm, the diameter of the upper bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com