Pulverized coal boiler capable of subcritically combusting lean coal

A pulverized coal boiler, subcritical technology, applied in steam boilers, combustion equipment, indirect carbon dioxide emission reduction and other directions, can solve the problems of insufficient combustion, high sulfur content, waste of energy, etc. Avoid the effect of coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

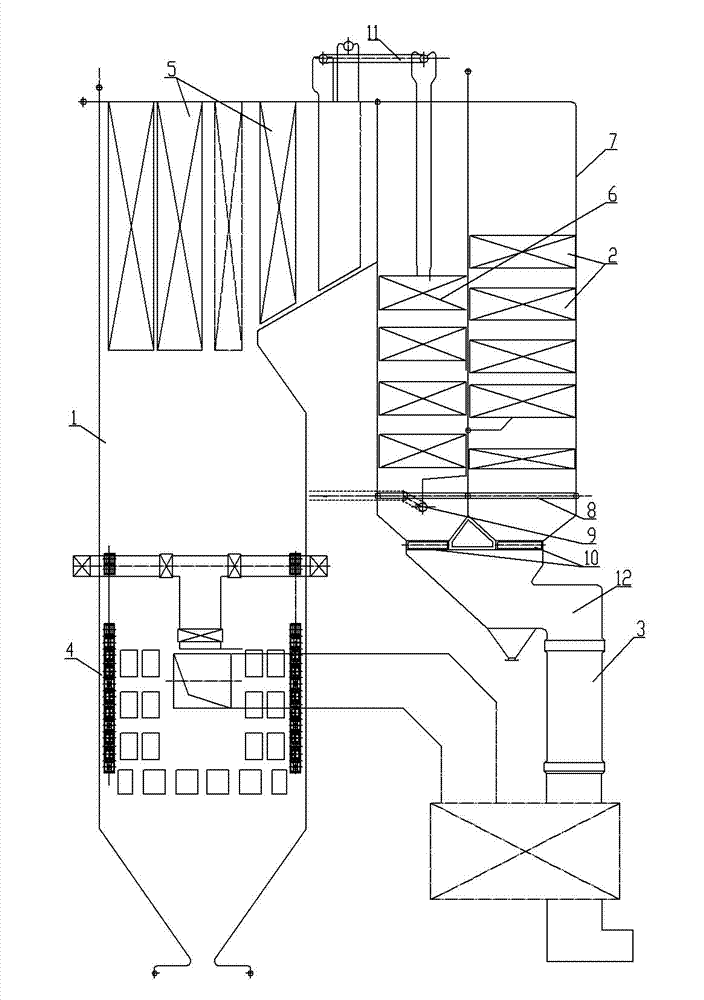

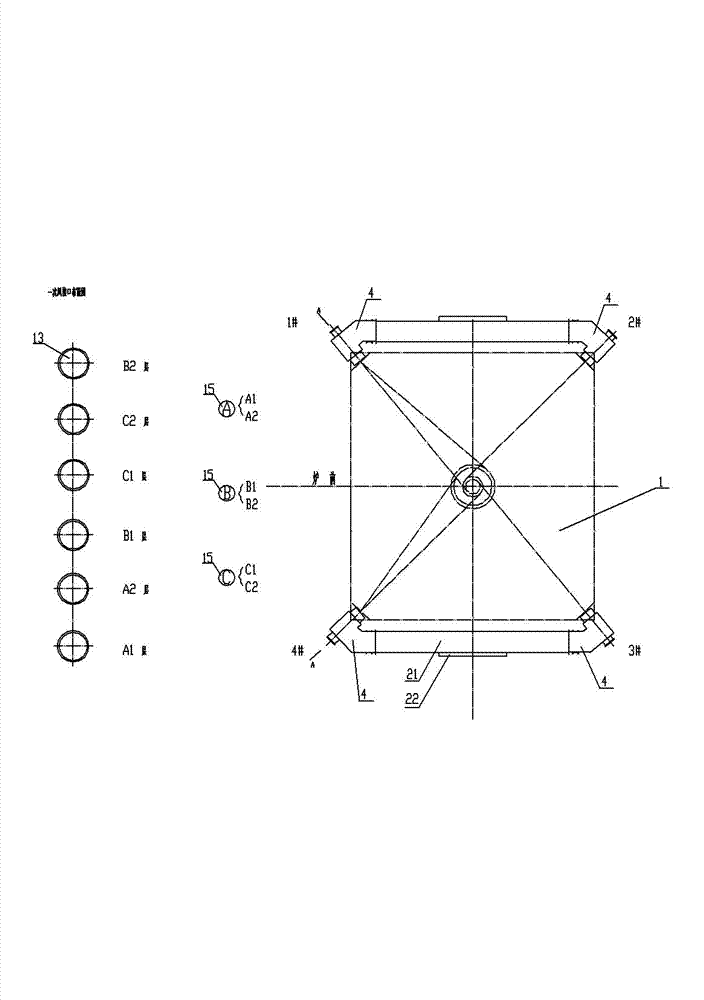

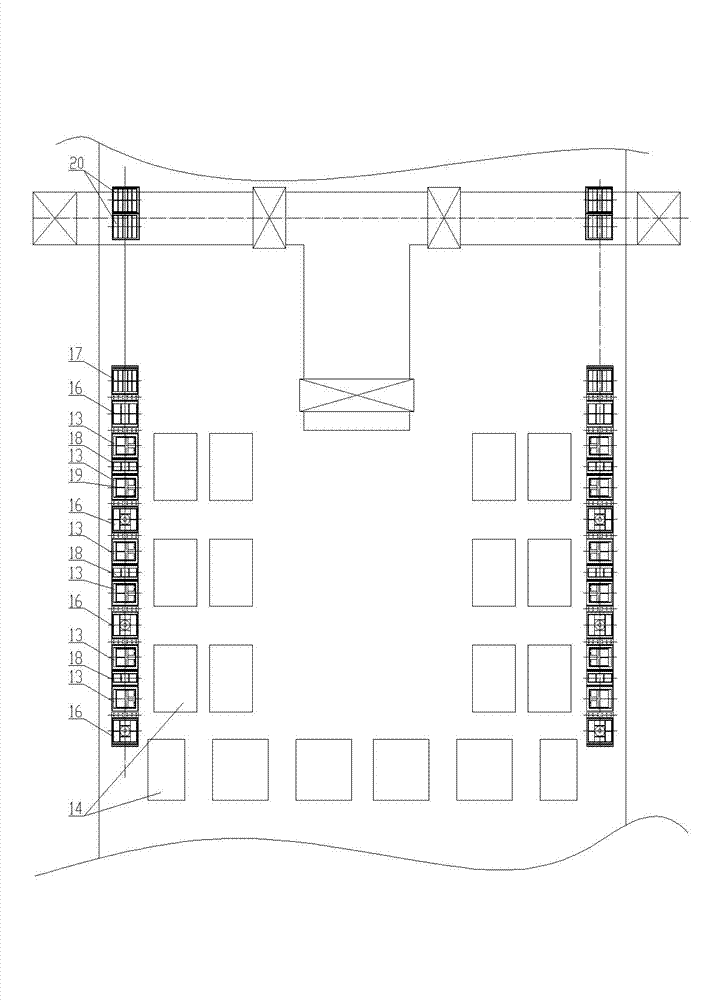

[0018] See figure 1 , figure 2 , image 3 , Figure 4 , which includes a furnace 1, a superheater, an economizer 2, and an air preheater 3. A burner 4 is arranged in the furnace 1. The superheater includes a high-temperature superheater 5 and a low-temperature superheater 6. A high-temperature superheater is installed above the furnace 1. 5, the upper part of the furnace 1 is connected to the shaft flue 7, and the two sides of the shaft flue 7 are separated. A superheated steam inlet pipe 8 is provided, and an accident water spray desuperheater 9 is installed on the superheated steam inlet pipe 8, which is used as an emergency water spray to protect the superheater; the shaft flue 7 is located at the low temperature superheater 6 and the economizer 2 The flue gas temperature-regulating baffles 10 are respectively arranged under the , the high-temperature superheater 5 and the low-temperature superheater 6 are respectively connected to the micro-spray desuperheater 11, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com