Dyeing and finishing process for polyester blended fiber fabric

A fiber fabric, polyester-cotton blended technology, applied in the direction of textile material processing, fiber type, fiber treatment, etc., can solve the problems of insufficient aesthetic feeling, poor printing and dyeing performance, monotonous style, etc., to improve the strength and appearance of the fabric. The ability of fabrics to absorb dyes, the effect of increasing dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

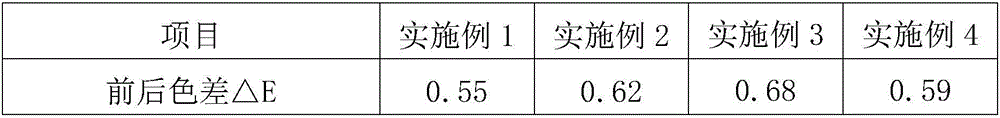

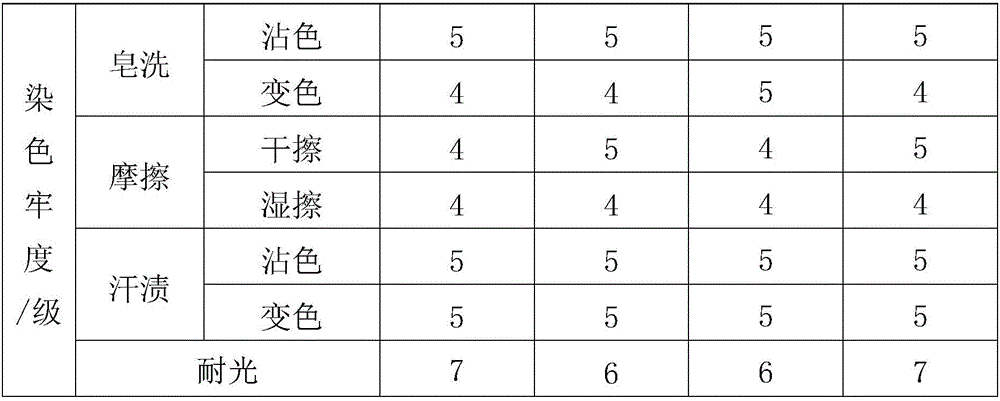

Examples

Embodiment 1

[0020] In the present embodiment, a kind of dyeing and finishing process of polyester-cotton blended fiber fabric comprises following process:

[0021] S1, pre-treatment, immerse the polyester-cotton blended fabric in the bleaching liquid, and treat it at 105°C for 30 minutes. The bleaching liquid includes: refining agent 1g / L, caustic soda 5g / L, hydrogen peroxide 6g / L, hydrogen peroxide stabilizer 1g / L, after washing with water, immerse in the enzyme treatment solution, and treat at 70°C for 60min. The enzyme treatment solution includes: 0.5g / L pectinase, 3g / L cellulase, 0.5g / L glacial acetic acid, agent 2g / L, dry after hot washing;

[0022] S2, mercerizing and setting, padding the fabric pretreated by S1 with lye at room temperature, the concentration of lye is 180g / L, applying tension, stretching, rinsing, steaming at 110°C to remove alkali, washing at 80°C, Add acetic acid solution with an amount of 6g / L to neutralize, squeeze water, and pre-set after drying. The pre-sett...

Embodiment 2

[0026] In the present embodiment, a kind of dyeing and finishing process of polyester-cotton blended fiber fabric comprises following process:

[0027] S1, pre-treatment, immerse the polyester-cotton blended fabric in the bleaching solution, and treat it at 115°C for 15 minutes. The bleaching solution includes: refining agent 3g / L, caustic soda 2g / L, hydrogen peroxide 10g / L, hydrogen peroxide stabilizer 0.5g / L, after washing with water, immerse in the enzyme treatment solution, and treat at 80°C for 30min. The enzyme treatment solution includes: pectinase 1g / L, cellulase 1g / L, glacial acetic acid 1g / L, penetrant 1g / L, dry after hot washing;

[0028] S2, mercerizing and setting, padding the fabric pretreated by S1 with lye at room temperature, the concentration of lye is 200g / L, applying tension, stretching, rinsing, steaming at 100°C to remove alkali, washing at 90°C, Add 3g / L acetic acid solution to neutralize, squeeze water, and pre-set after drying. The pre-setting tempera...

Embodiment 3

[0032] In the present embodiment, a kind of dyeing and finishing process of polyester-cotton blended fiber fabric comprises following process:

[0033] S1, pre-treatment, immerse the polyester-cotton blended fabric in the bleaching solution, and treat it at 110°C for 20 minutes. The bleaching solution includes: 2g / L refining agent, 3g / L caustic soda, 8g / L hydrogen peroxide, hydrogen peroxide stabilizer 0.7g / L, after washing with water, immerse in the enzyme treatment solution, and treat at 75°C for 45min. The enzyme treatment solution includes: pectinase 0.7g / L, cellulase 2g / L, glacial acetic acid 0.7g / L, Penetrant 1.5g / L, dry after hot washing;

[0034] S2, mercerizing and setting, padding the fabric pretreated by S1 with lye at room temperature, the concentration of lye is 190g / L, applying tension, stretching, rinsing, steaming at 105°C to remove alkali, washing at 85°C, Add 4.5g / L of acetic acid solution to neutralize, squeeze water, and pre-set after drying. The pre-setti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com