Piston type pneumatic control valve

An air-controlled valve and piston-type technology, applied in valve details, multi-way valves, valve devices, etc., can solve problems such as cumulative errors, affecting transmission efficiency, and internal parts stuck, achieving small deviations, good sealing effects, and easy assembly The effect of small deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

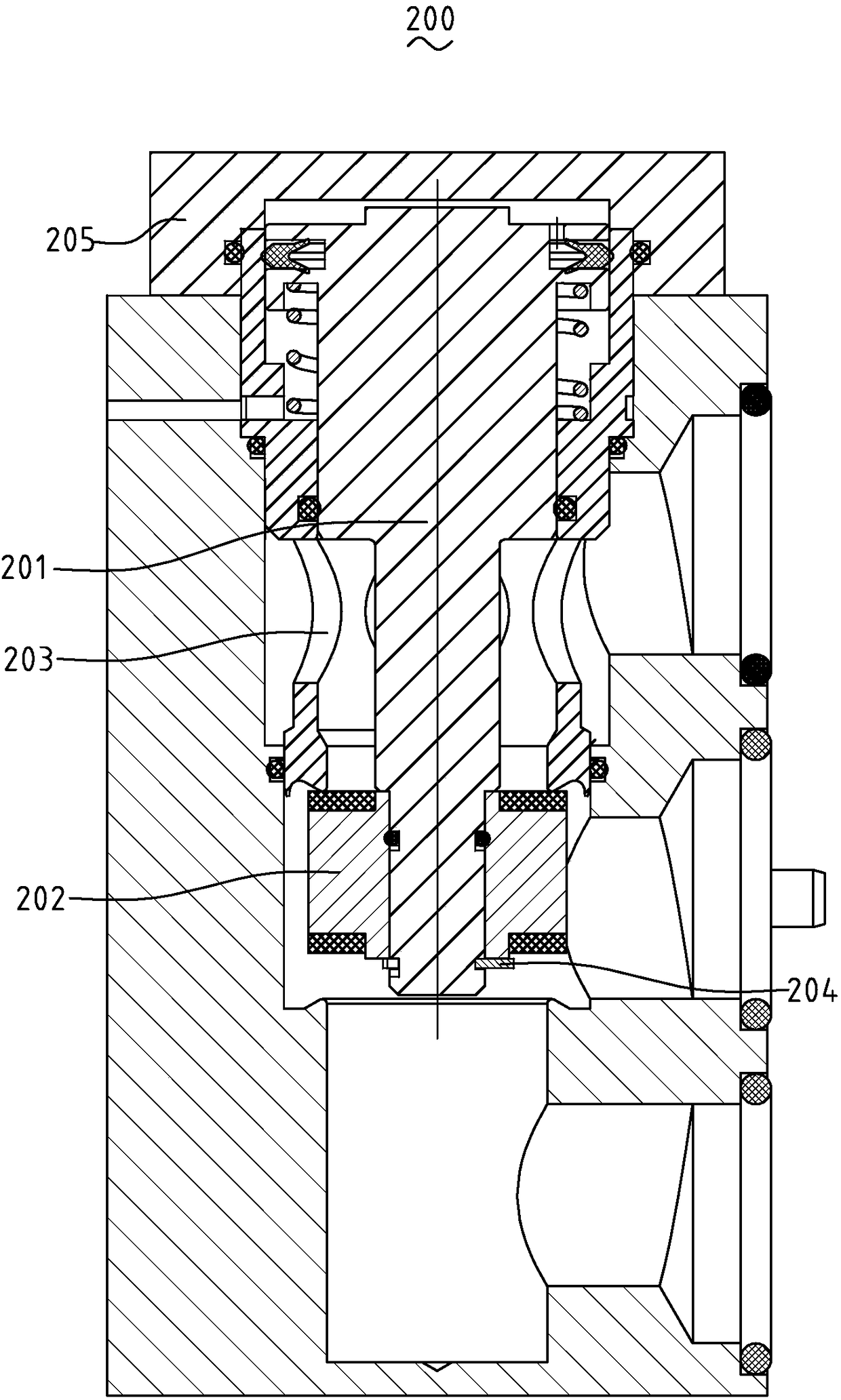

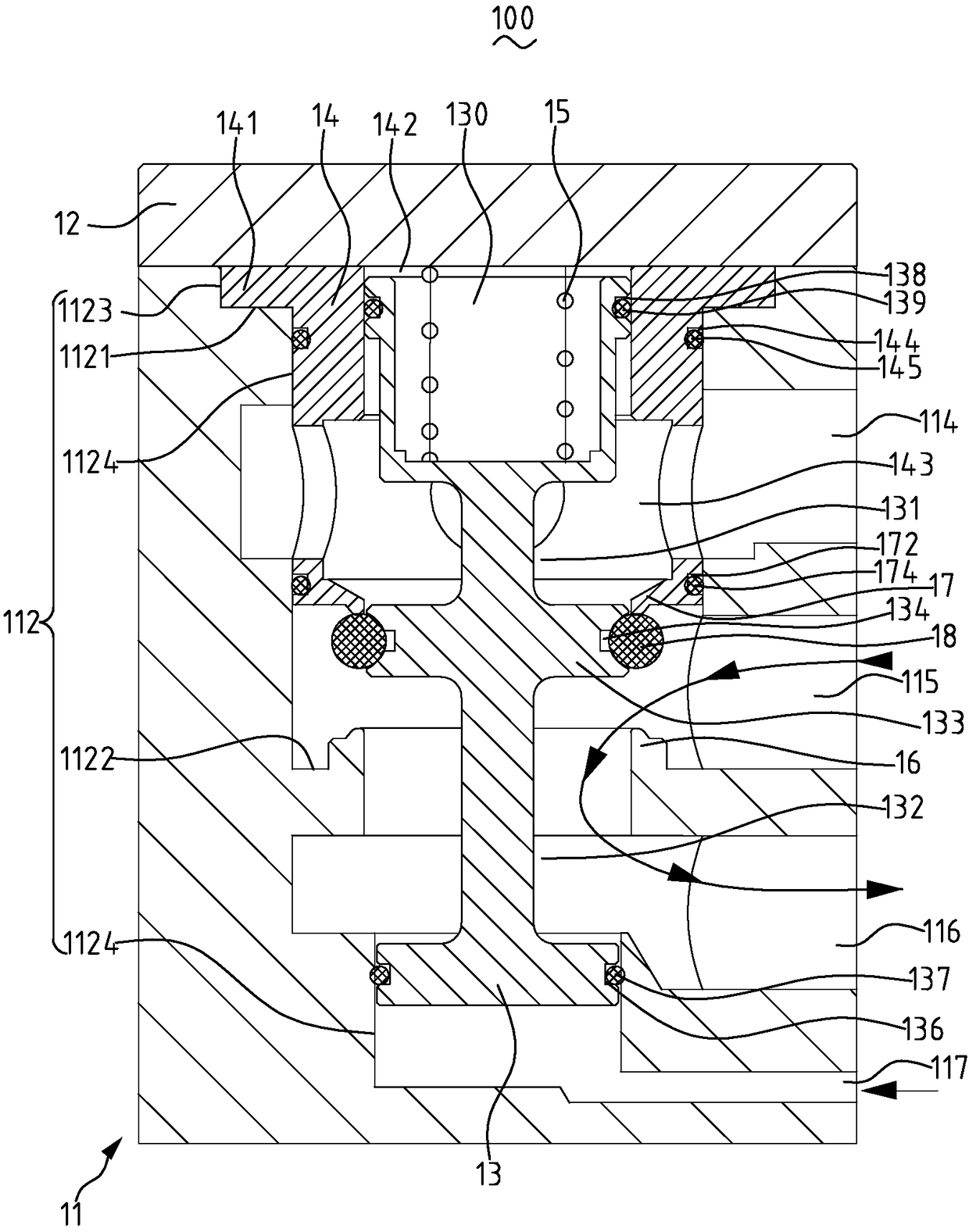

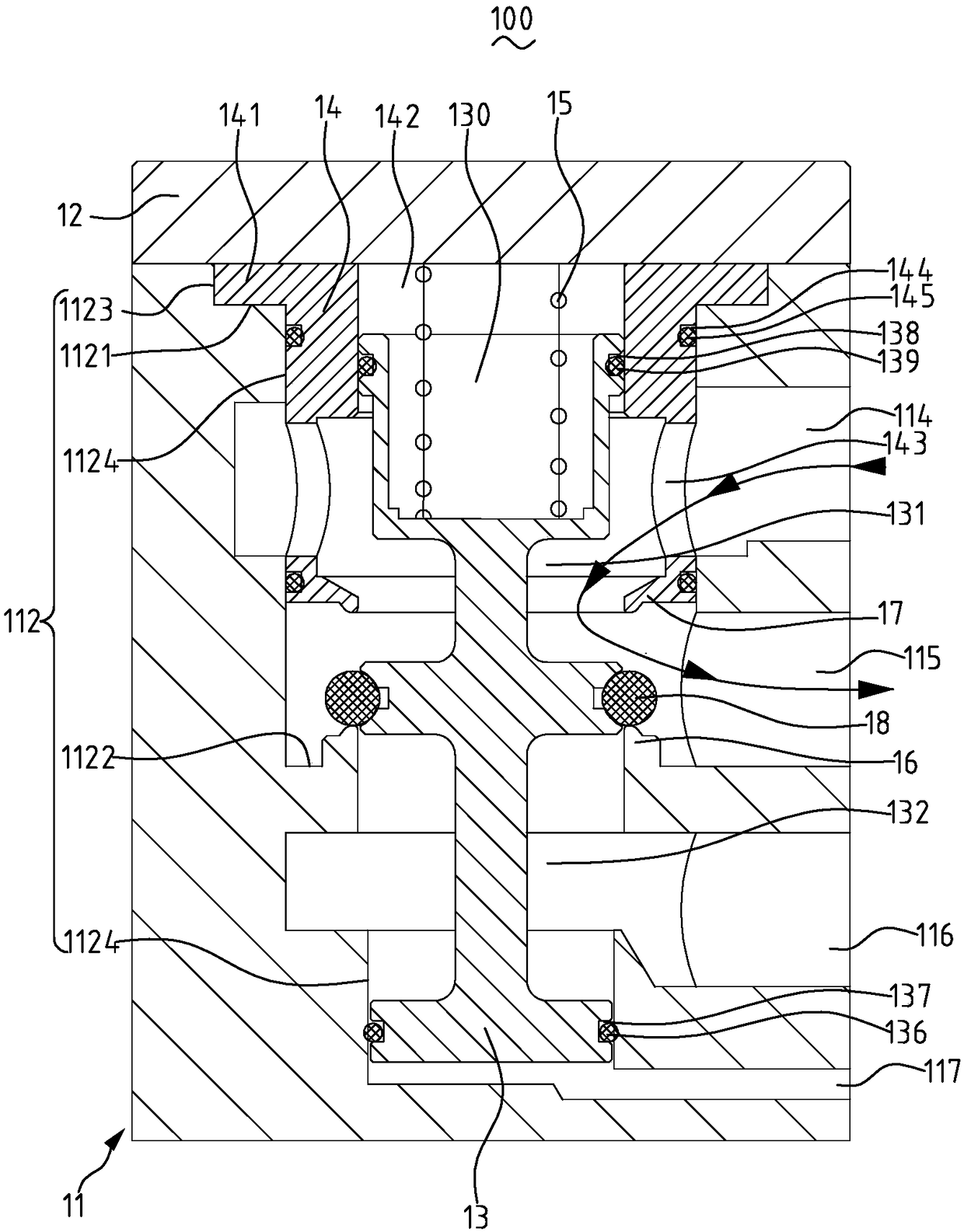

[0020] figure 2 It is a schematic diagram of the structure of the piston air control valve of the present invention in the normal ventilation position, image 3 It is a structural schematic diagram of the piston air control valve of the present invention in the forced release position. Specifically, see Figure 2 to Figure 3 , The piston-type air-operated valve 100 of the present invention includes a valve body 11 , a valve cover 12 , a valve stem 13 , a guide valve seat 14 , a spring 15 , a lower valve port 16 , an upper valve port 17 , and a sealing ring valve core 18 . The piston air control valve 100 changes the pressure change at the lower end of the valve rod 13 through the control port 117 to switch on and off the compressed air to re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com