Wallboard cutting device not prone to deflection

A wallboard, difficult technology, applied in metal processing and other directions, can solve the problems of deflection of the cutting part and the impact of product quality, and achieve the effect of ensuring quality and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

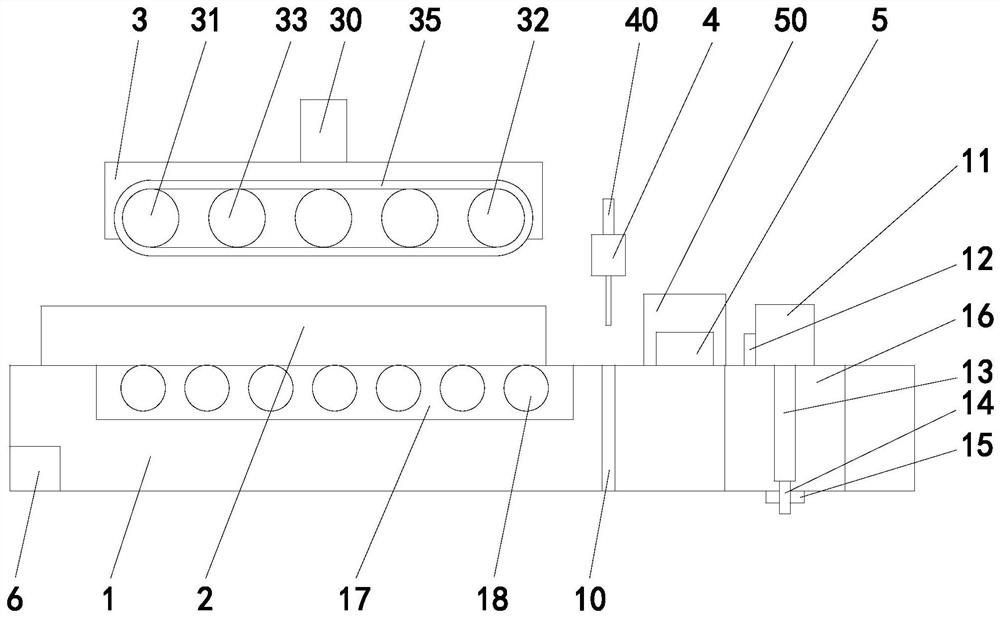

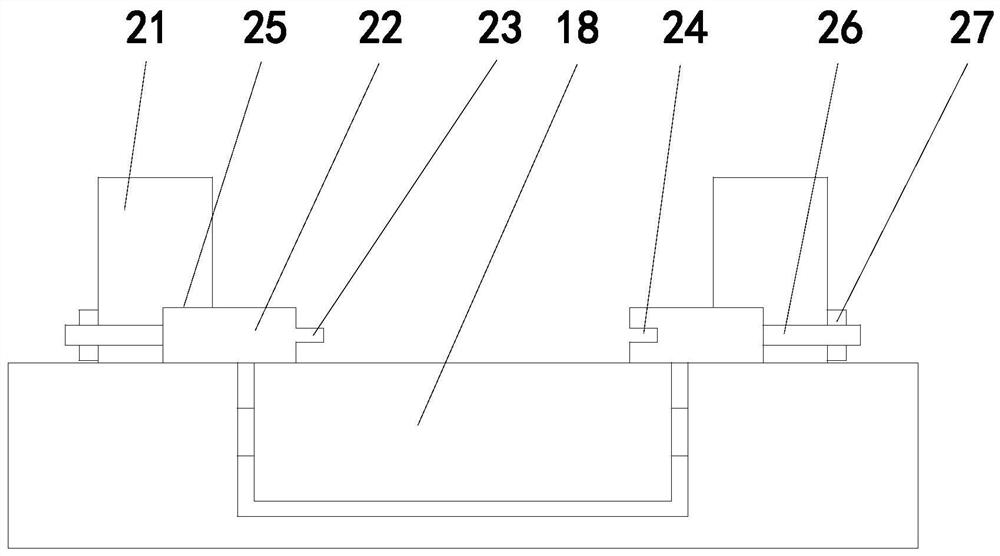

[0016] refer to figure 1 and figure 2 , a wall panel cutting device that is not easy to deflect in the present invention, including a cutting table 1, a guide plate 2, a first lifting device 30, a mounting frame 3, a feeding belt 35, a limit plate 11, a pressure sensing device 12, a cutting machine 4. The second lifting device 40 and the control device 6. The cutting table 1 is provided with two strip-shaped guide plates 2. The two guide plates 2 are parallel to each other. The length direction of the guide plates 2 is in line with the moving direction of the wallboard. parallel, the opposite sides of the two guide plates 2 are respectively provided with a groove 24 and a convex strip 23, the groove 24 is matched with the male head of the wallboard, the convex strip 23 is matched with the female groove of the wallboard, and the cutting table 1 A mounting frame 3 is arranged above, and the mounting frame 3 links to each other with a first lifting device 30. The driving shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com