Novel bus duct

A busway and busbar technology, applied in the field of busway trunk system and new busway, can solve the problems of low strength of busway cover, affecting project quality, inconvenient construction, etc., to reduce the possibility of dust entering the busway, The effect of improving safety performance and improving the use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

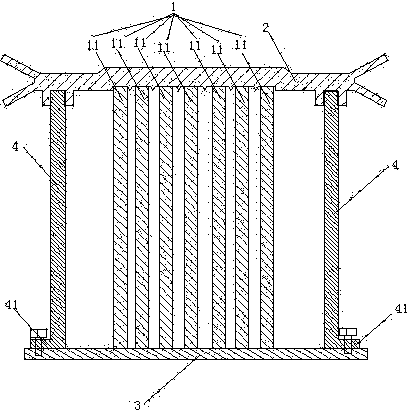

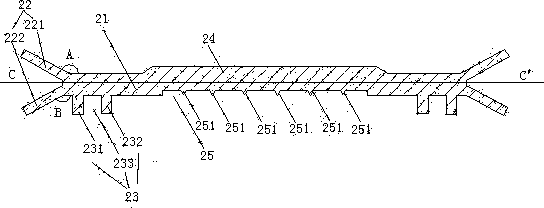

[0015] As shown in the figure, it specifically relates to a new type of busway, including a busbar 1, which is characterized in that the top of the busbar 1 is provided with a cover plate 2, the bottom is provided with a bottom plate 3, and side panels 4 are provided on both sides. The cover plate 2 has an integral structure, including a cover plate body 21, and a dust-proof mechanism 22 is respectively provided at both ends of the cover plate body 21. The dust-proof mechanism 22 is symmetrically arranged, and the dust-proof mechanism 22 includes an upper Dust-proof plate 221 and lower dust-proof plate 222, the upper dust-proof plate 221 and the lower dust-proof plate 222 are all inclined, with the horizontal line C-C' as the axis of symmetry, the upper and lower dust-proof plates 221, 222 are axially Symmetrically distributed; the angle A between the upper dustproof plate 221 and the cover body 21 is 160 degrees, and the angle B between the lower dustproof plate 222 and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com