Claw assembly with long service life and production process thereof

A manufacturing process and long-life technology, applied in the field of nuclear reactor control system components and component manufacturing, can solve problems such as unsatisfactory service life, and achieve the effects of high spray welding speed, large selection of alloys, and precise dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Such as Figure 1 to Figure 4 As shown, a manufacturing process of a long-life claw assembly for the manufacture of parts with friction between the claw assembly of the nuclear reactor control rod drive mechanism during operation, including sequential blanking, rough machining and surface The step of processing the wear-resistant layer, the blanking step is to process the blanks of each part according to the design requirements;

[0039] The step of processing the wear-resistant layer on the surface is spray-welding the wear-resistant layer on the surface of each blank, wherein the spray-welding wear-resistant layer includes the following steps carried out in sequence:

[0040] A. Preheating, the preheating is heating each blank to 300-400°C;

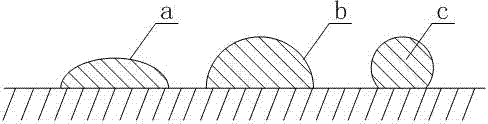

[0041] B. Powder spraying and remelting. The powder spraying is carried out with an oxyacetylene flame. The powder spraying includes a solder powder spraying process and a heat melting process with at least one frequency and the...

Embodiment 2

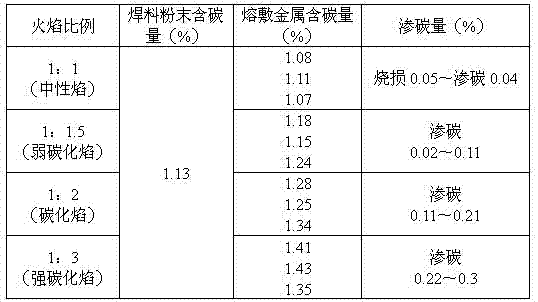

[0061] The present embodiment is further limited on the basis of embodiment 1, as Figure 1 to Figure 5 As shown, as a further implementation of Example 1, the heat source used in the remelting step is an oxyacetylene flame, and the oxyacetylene flame used in the remelting step is a neutral flame, a weak carbonization flame or a carbonization flame, and the oxyacetylene The ratio of the length of the flame core to the inner flame is between 1:1 and 1:2. In this embodiment, the length ratio between the flame core and the inner flame of the oxyacetylene flame is limited between 1:1 and 1:2. The reason is the same as that in Embodiment 1. In fact, it is to limit the mixing ratio of oxygen and acetylene as combustion gases. .

[0062] In the remelting step, the included angle between the oxygen acetylene flame and the surface of the cladding layer used in the remelting step ranges from 60° to 75°. In the process of spraying and welding the wear-resistant layer, the two-step meth...

Embodiment 3

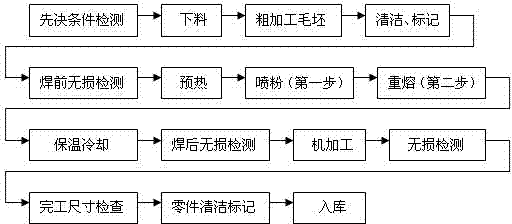

[0070] The present embodiment is further limited on the basis of embodiment 1, as figure 1 As shown, this embodiment provides a preferred manufacturing process route of the claw assembly, and the prerequisite detection is carried out before blanking; the steps of rough machining and surface machining of the wear-resistant layer include cleaning and marking steps; pre-welding steps are carried out before the preheating step For non-destructive testing, the cooling step is thermal insulation cooling. The subsequent cooling step also includes post-welding non-destructive testing, machining, non-destructive testing after machining, finished dimension inspection, part cleaning and marking, and storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com