A special aluminum-manganese alloy powder formula for 3D printing and its preparation method and printing method

An aluminum-manganese alloy, 3D printing technology, used in additive manufacturing, process efficiency improvement, additive processing, etc., can solve the problems of high cost, component segregation, low output, etc., and achieve high corrosion resistance and mechanical properties. The effect of low anisotropy and low metallurgical defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

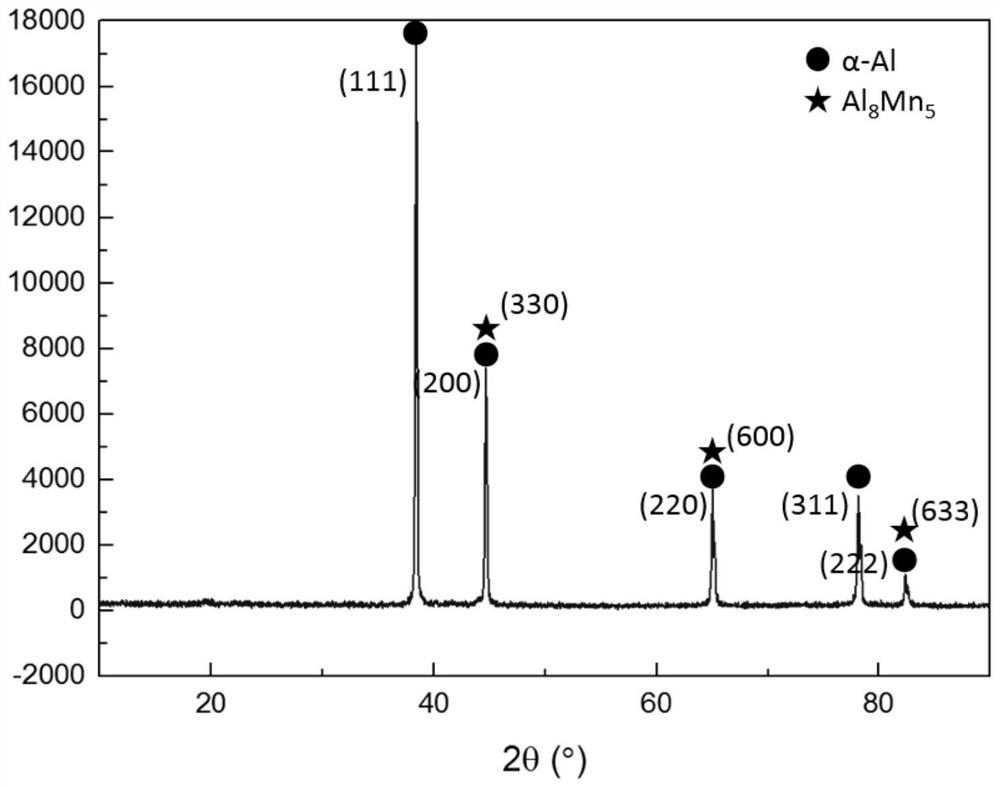

[0033] Aluminum-manganese alloy for SLM printing, containing the following components in mass percentage: Mn: 4.2wt%, Sc: 0.6wt%, Zr: 0.2wt%, Mg: 0.8wt%, Fe: 0.2wt%, Si: 0.2 wt%, Cu: 0.1wt%; Zn: 0.1wt%, the rest is Al.

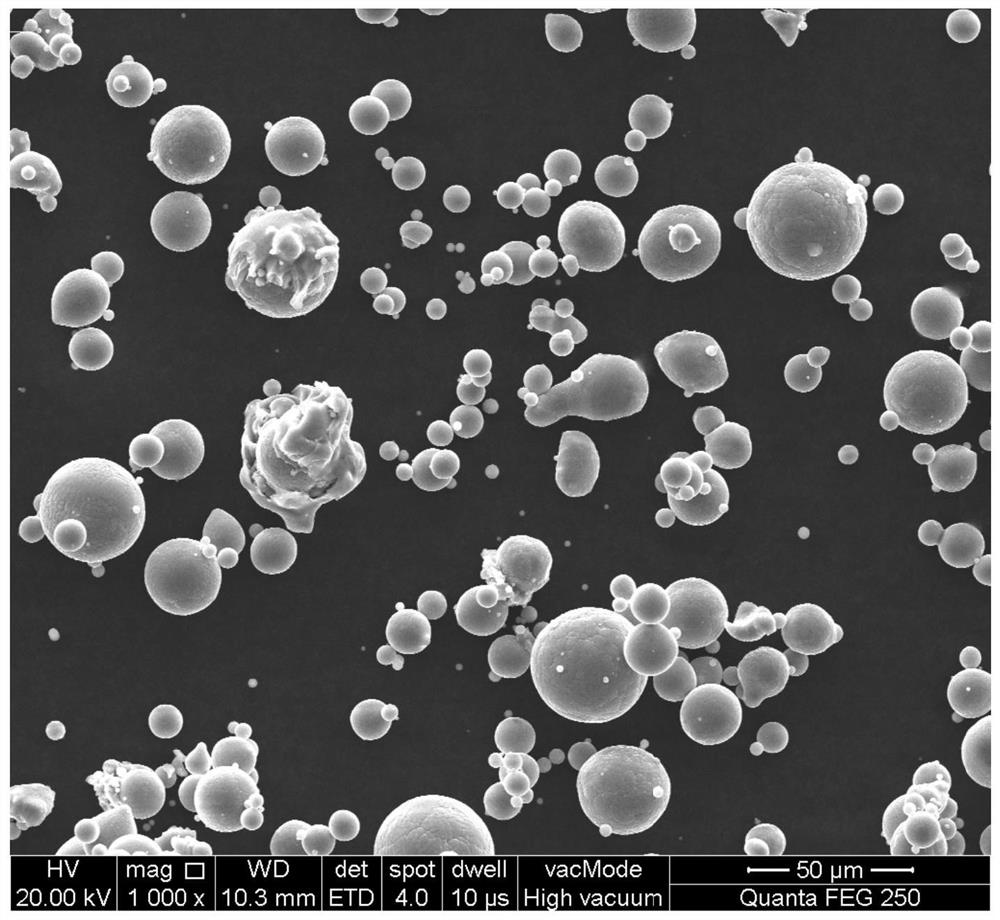

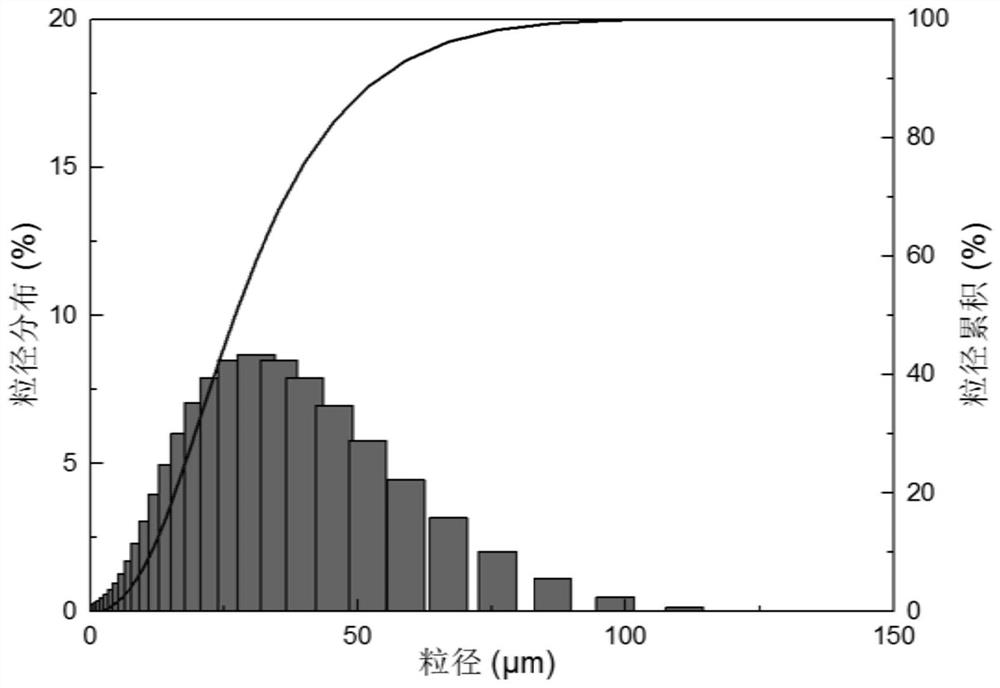

[0034] The aluminum-manganese alloy powder for 3D printing with the above ingredients is prepared by vacuum melting, and then using argon atomization to make powder: the melting temperature is 850°C, and the pressure in the melting furnace is 0.5MPa; then the metal is melted using argon as the medium The droplets are atomized, and the atomization pressure is 7MPa. The particle shape of the prepared powder is spherical, and the powder below 250 mesh is sieved, which can be used for SLM printing.

[0035] In a vacuum drying oven, the sieved powder was dried at 90°C for 8 hours, and the heating temperature of the substrate was increased to 250°C during printing.

[0036] The above 3D printing aluminum alloy powder fiber laser SLM printing process is laser power...

Embodiment 2

[0038] Special rare earth aluminum alloy for SLM printing, containing the following components in mass percentage: Mn: 2.5wt%, Sc: 0.3wt%, Zr: 0.1wt%, Mg: 1.2wt%, Fe: 0.2wt%, Si: 0.2 wt%, Cu: 0.1wt%; Zn: 0.1wt%, the rest is Al.

[0039] The preparation method of the aluminum-manganese alloy powder for 3D printing with the above ingredients is as follows: put the powder into an induction melting furnace for vacuum melting and then use argon atomization to make powder: the melting temperature is 900 ° C, and the pressure in the melting furnace is 0.6 MPa; then use Argon gas is used as the medium to atomize metal droplets, and the atomization pressure is 8.5MPa. The particle shape of the prepared powder is spherical, and the powder below 250 mesh is sieved, which can be used for SLM printing.

[0040] Dry the sieved powder at 90°C for 8 hours in a vacuum drying oven, and increase the heating temperature of the substrate to 300°C during printing.

[0041] The 3D printing aluminu...

Embodiment 3

[0048] Embodiment 3 (comparative example):

[0049] Special rare earth aluminum alloy for SLM printing, containing the following components in mass percentage: Mn: 6.5wt%, Sc: 1.3wt%, Zr: 0.8wt%, Mg: 1.5wt%, Fe: 0.5wt%, Si: 0.2 wt%, Cu: 0.1wt%; Zn: 0.1wt%, the rest is Al.

[0050] The preparation method of the aluminum-manganese alloy powder for 3D printing with the above ingredients is: vacuum melting, and then using argon atomization to make powder: the melting temperature is 900°C, and the pressure in the melting furnace is 0.6MPa; then using argon as the medium to melt the metal The droplets are atomized, and the atomization pressure is 8.5MPa. The particle shape of the prepared powder is spherical, and the powder below 250 mesh is sieved, which can be used for SLM printing.

[0051] In a vacuum drying oven, the sieved powder was dried at 90°C for 8 hours, and the heating temperature of the substrate was increased to 300°C during printing.

[0052] The 3D printing alumi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com