Technique for producing precision castings of zirconium and zirconium alloy pumps/valves

A technology of precision castings and process methods, which is applied in the field of precision castings for valves and the production of zirconium and zirconium alloy pumps to achieve stable performance, less internal defects, and normal use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

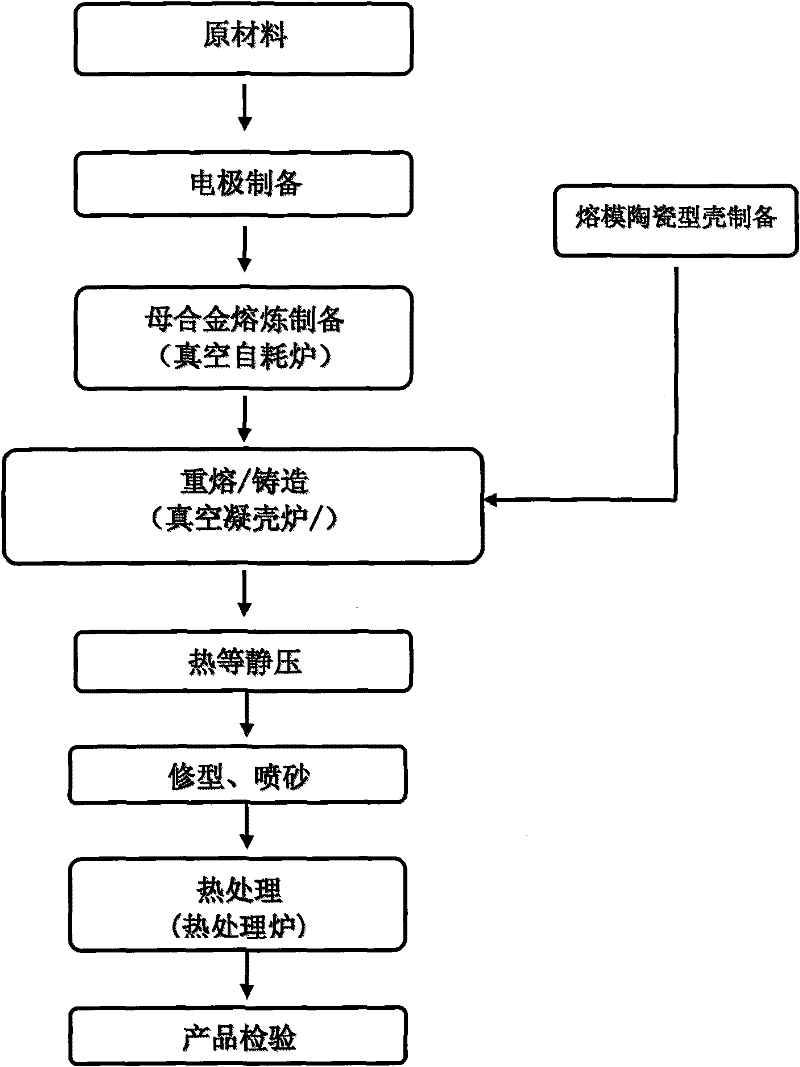

Image

Examples

preparation example Construction

[0017] 4. Preparation of ceramic moulds: Firstly, wax is taken into the mold with a wax injection machine (process requirements: pressure 0.2-1 MPa, pressure holding time 2-6 minutes); the wax type is coated, sanded, Drying and waxing process to make ceramic type;

[0018] 5. Casting: Put the ceramic type and spare electrode into the vacuum shell solidification furnace, and pour (process requirements: vacuum degree <0.01 Pa, melting current 14000-26000A, time 4-15min);

[0019] 6. Hot isostatic pressing: Hot isostatic pressing of castings (process requirements: temperature 900-1260 degrees Celsius, pressure 100-160 MPa, holding time 0.5-2h);

[0020] 7. Refurbishment and sandblasting: repair and sandblast the casting after hot isostatic pressing (process requirements: spray pressure 0.05-0.4 MPa, nozzle diameter Ф25-Ф70);

[0021] 8. Heat treatment: heat treatment after sandblasting (process requirements: temperature 500-600 degrees Celsius, holding time 0.5-2h, cooling metho...

Embodiment 1

[0024] Alloy pump, the alloy is composed of the following chemical components by weight percentage: Zr+Hf~99.2, Fe+Cr~0.20, H~0.005, N~0.025, C~0.05, 0~0.14, the impurities contained in the alloy meet the standards performance requirements. Each chemical composition is made into an alloy by the traditional alloy preparation process, that is, Zr702 alloy. According to the process shown in the figure, the alloy casting data prepared according to the weight ratio of the above chemical composition are as follows:

[0025] Dimensional accuracy of castings: ≤±0.1%;

[0026] Internal quality of castings: no cracks and inclusions, no continuous distribution of porosity and pores,

[0027] Individual porosity and pore size: ≤0.5mm;

[0028] Mechanical properties of castings:

[0029] σ b ≥483MPa, σ 0.2 ≥342MPa, δ 5 ≥12%

Embodiment 2

[0031] Alloy valve, the alloy is composed of the following chemical components by weight percentage: Zr+Hf~99.4, Fe+Cr~0.19, H~0.005, N~0.024, C~0.05, O~0.15, and the impurities contained in the alloy meet the standards performance requirements. The chemical components are made into an alloy by traditional alloy preparation process, that is, Zr702 alloy, which can be used in the production of various common valve casting equipment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com