Powder metallurgy preparation method of graphene reinforced aluminum-based composite material

A composite material and reinforced aluminum-based technology, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problems of inability to satisfy the dispersion of graphene, complicated preparation process, and poor strengthening effect at the same time, and achieve excellent reinforcement effect, combined with Good and conducive to the effect of large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

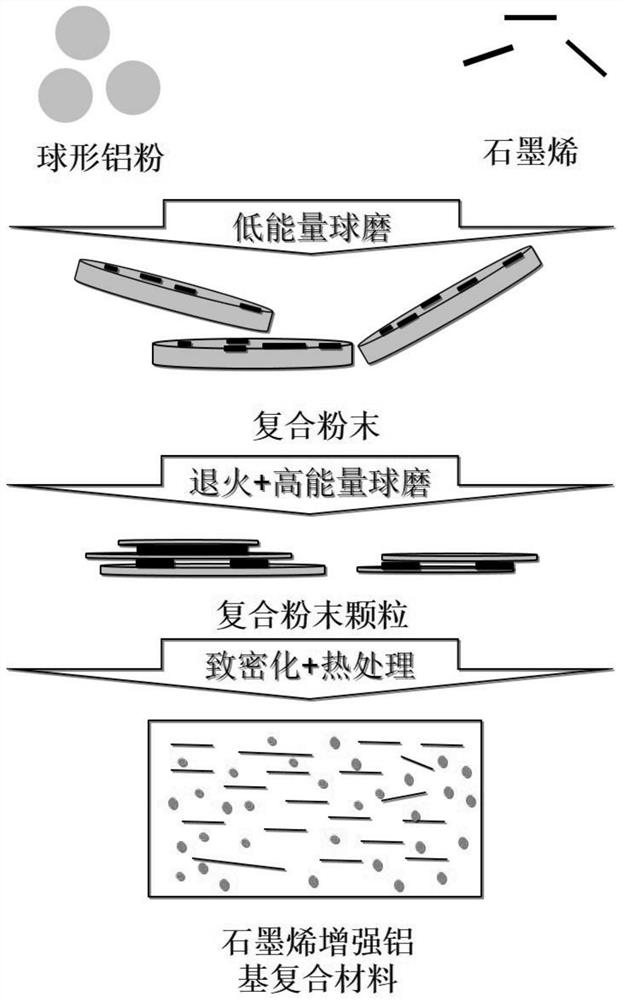

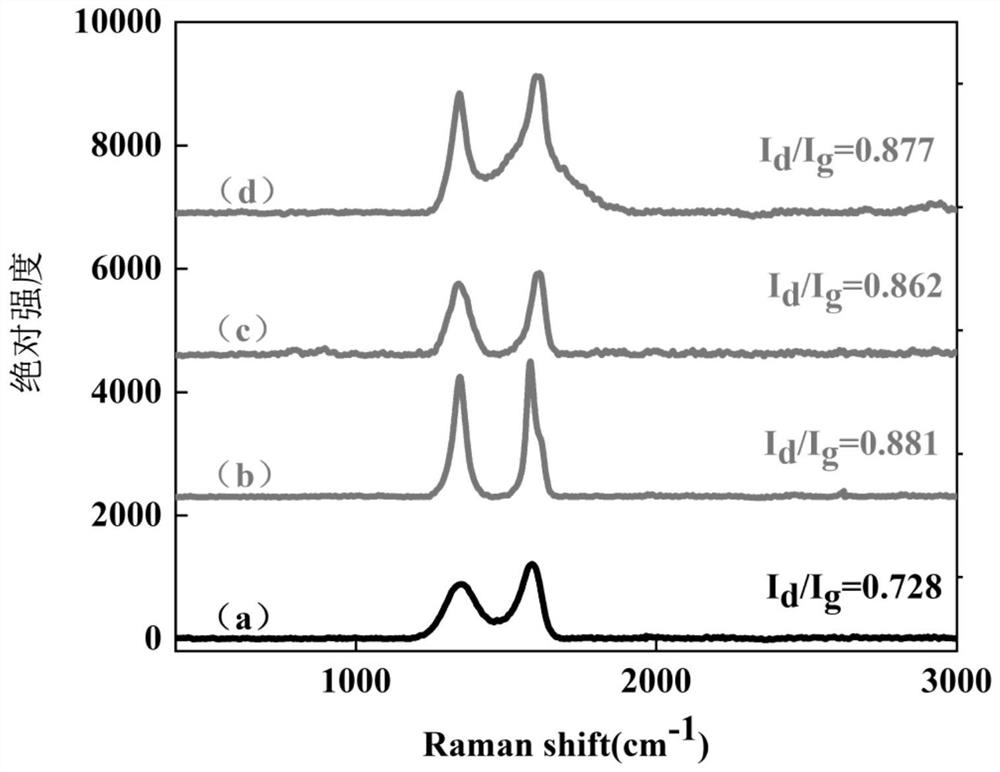

[0041] This implementation provides a kind of preparation method of graphene reinforced aluminum matrix composite material (containing graphene 0.3wt.%), such as figure 1 As shown, the steps are as follows:

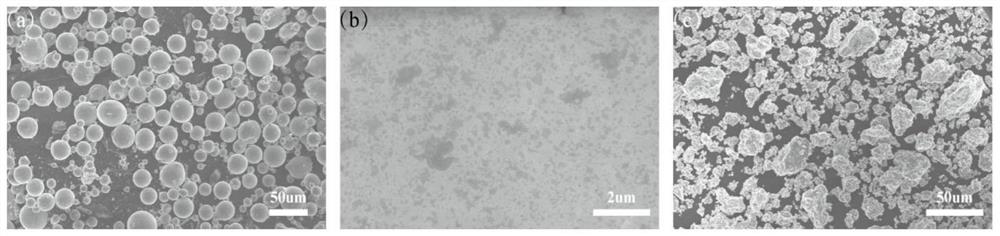

[0042] Get 49.85g, 10 μ m pure aluminum powder (spherical powder) and 0.15g graphene and place in the stirring ball mill, take ethanol as solvent, add 2g phthalate coupling agent as ball milling process control agent, take stainless steel ball as ball milling medium, The ball-to-material ratio was 20:1, and the graphene / aluminum composite powder was obtained by ball milling at a speed of 100 rpm for 10 hours. After suction filtration and drying, vacuum annealing was carried out at 200°C for 2 hours. figure 2 (a) is the original spherical aluminum powder, figure 2 (b) is the dispersion diagram of graphene on the surface of aluminum sheet after 10h stirring ball milling.

[0043] The annealed graphene / aluminum composite powder is placed in a planetary ball mill, and 2g ...

Embodiment 2

[0049] This implementation provides a kind of preparation method of graphene-enhanced aluminum matrix composite material (containing graphene 0.6wt.%), and the steps are as follows:

[0050] Take 49.7g, 10μm pure aluminum powder and 0.3g graphene and place them in a stirring ball mill, use ethanol as solvent, add 2g phthalate coupling agent as ball milling process control agent, use stainless steel balls as ball milling medium, the ball to material ratio is 20:1, ball milled at a speed of 100 rpm for 10 h to obtain graphene / aluminum composite powder, and after suction filtration and drying, vacuum annealed at 200°C for 2 h.

[0051] The annealed graphene / aluminum composite powder is placed in a planetary ball mill, and 2g of stearic acid is added as a ball milling process control agent. Under the protection of argon, stainless steel balls are used as a ball milling medium, and the ball-to-material ratio is 20:1. The composite particles were obtained by ball milling at a speed ...

Embodiment 3

[0054] This implementation provides a kind of preparation method of graphene-enhanced aluminum-magnesium-silicon-based composite material (containing graphene 0.4wt.%), the steps are as follows:

[0055] Take 49.8g, 35μm 6061 aluminum alloy powder and 0.2g graphene, put it in a planetary ball mill, add 2g stearic acid as a ball milling process control agent, under the protection of argon, use stainless steel balls as the ball milling medium, the ball to material ratio 20:1, ball milled at 120 rpm for 6 hours to obtain graphene / aluminum alloy composite powder, and vacuum annealed at 200°C for 2 hours.

[0056] Put the annealed graphene / aluminum alloy composite powder in a planetary ball mill, add 2g of stearic acid as a ball milling process control agent, under the protection of argon, use stainless steel balls as the ball milling medium, and the ball-to-material ratio is 20:1 , and ball milled at a speed of 250 rpm for 15 min to obtain composite particles.

[0057] After cold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com