Patents

Literature

196results about How to "Optimize chemical composition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Degradable polymer filmcoated controlled release fertilizer, preparation thereof and special filmcoated material

ActiveCN101323545AHas the ability to degradeAchieve friendlyFertilizer mixturesControl releasePolyol

The invention discloses a polymer coated released fertilizer and a preparation method thereof and a special coating material thereof. The coating material comprises isocyanate, polyol, degradable functional monomer, an aid agent of coating and a chain extender, wherein, the mol ratio between the isocyano group in the isocyanate and the hydroxyl group in the polyol is 1:2 to 2:1 and the mass of the degradable functional monomer is 1 percent to 20 percent of the mass of the coating material. The coated released fertilizer provided by the invention consists of a core and a karyotheca, wherein, the core is granule fertilizer and the karyotheca is prepared from the coating material, and the mass of the karyotheca is 2 percent to 10 percent of the mass of the core. The coating material has good film forming and water resisting performance and can be degraded in nature. The hardness and the elasticity of the material can be adjusted by changing the mixure ratio of the coating material so as to prepare released fertilizers with different releasing periods.

Owner:CNSG ANHUI HONG SIFANG FERTILIZER IND CO LTD

Boron-containing titanium-based amorphous solder for braze welding Si3N4 ceramic and preparation method thereof

The invention relates to braze welding Si3N4 ceramics containing the boron Ti-based amorphous solder and the preparation method thereof, and belongs to the brazing material in the field of amorphous state and metallurgy. The ingredients of the brazing material consist of the following according to the mass percent: Zr of 12.0-28.0 percent, Ni of 12.0-28.0 percent, Cu of 12.0-28.0 percent, and B of 0.05-0.5 percent, and the remains is Ti. The melting scope of the brazing material ranges 1,150K to 1,250K, and the brazing temperature is from 1,273K to 1,373K. The Ti-Zr-Ni-Cu-B amorphous braze vacuum braze welding Si3N4 ceramics, which is produced by the rapid solidification technology, has superior high-temperature performance to Ag-Cu-Ti solder and Ti-Zr-Ni-Cu solder. The tie-in high-temperature bend strength reaches 145MPa under 673K DEG,108MPa under 773K DEG, and still 93MPa under 873K DEG.

Owner:JIANGSU UNIV OF SCI & TECH

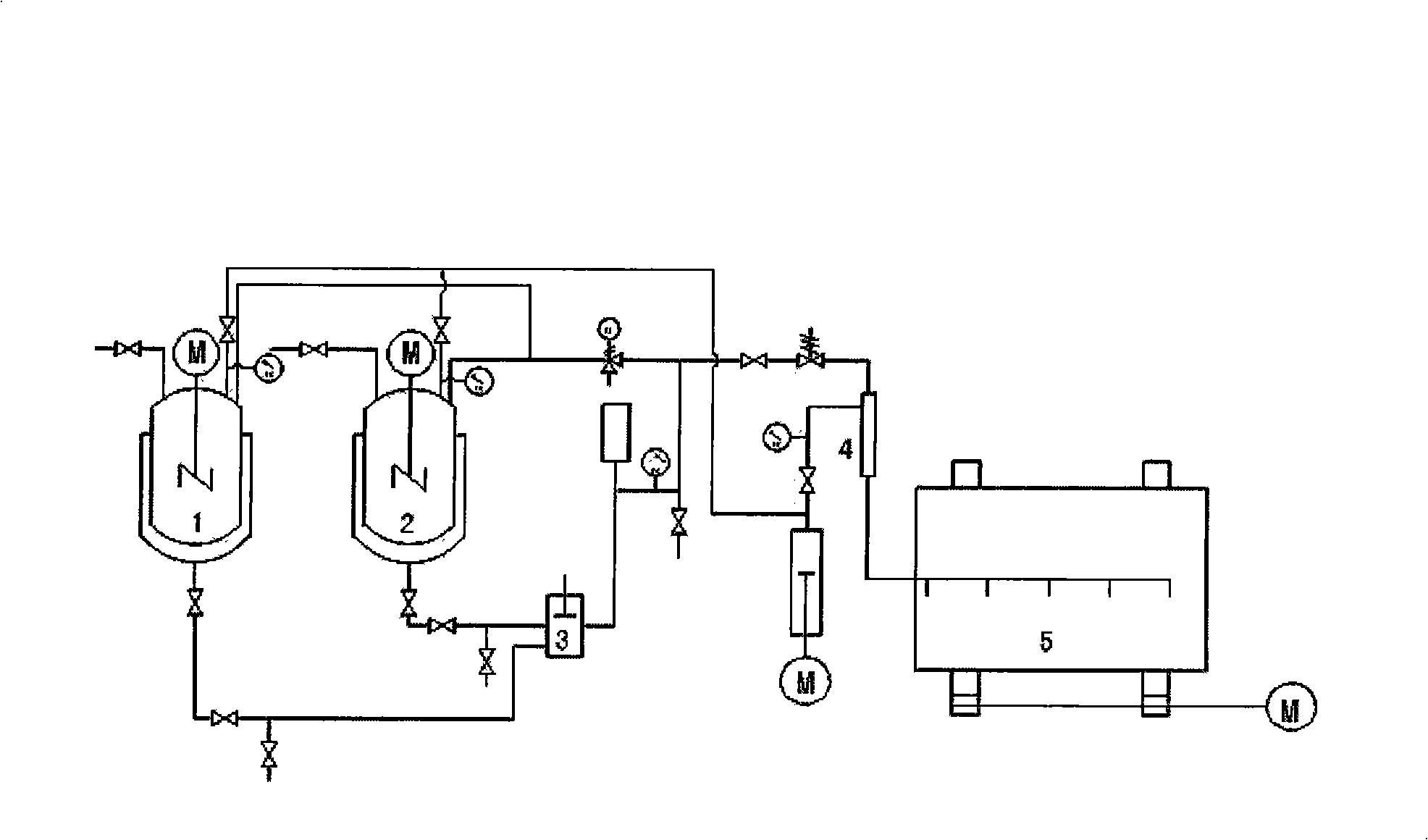

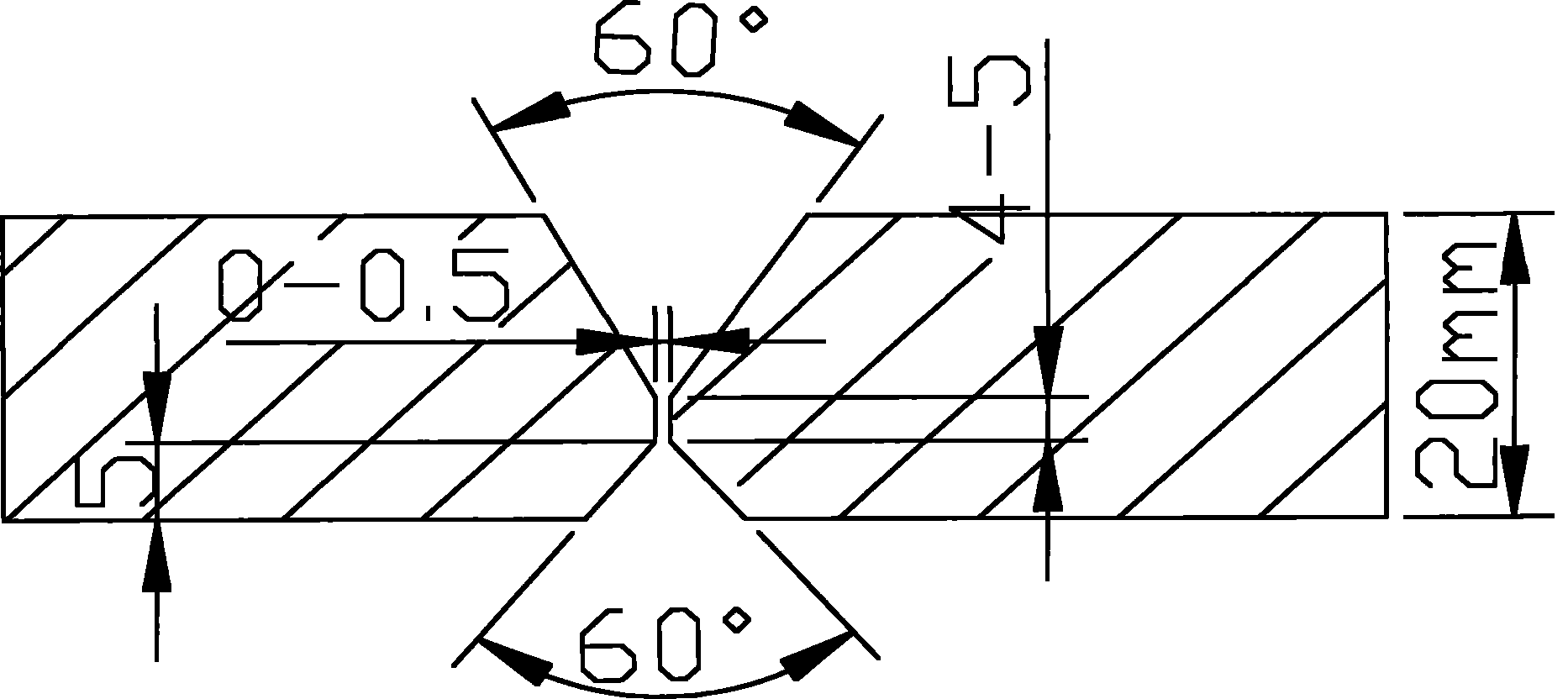

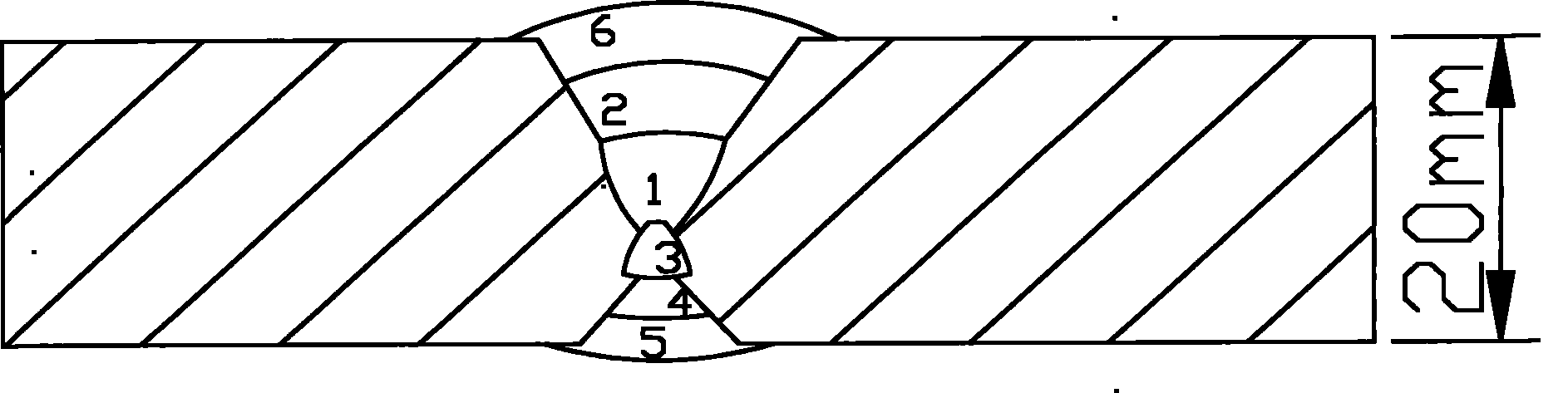

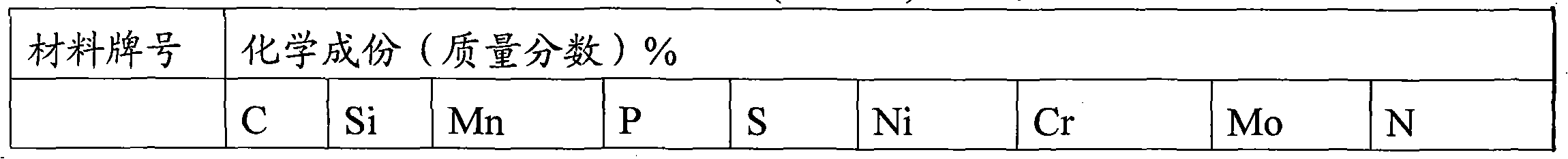

Two phase stainless steel submerged-arc welding SAW welding procedure

ActiveCN101913012AGood academic performanceImprove corrosion resistanceArc welding apparatusMechanical propertyWeld line

The invention relates to an economic and practical submerged arc welding procedure applicable to welding of common two phase stainless steel 022CrNi5Mo3(S31803 and S2205). The invention is characterized in that the procedure includes the following steps: 1) the performance characteristics of two phase stainless steel are researched; 2) welding material is selected and welding procedure is determined; 3) welding edge preparation is carried out; 4) clean-up and final inspection are carried out on the surface of work piece to be welded; 5) submerged arc welding is carried out on the common two phase stainless steel. The invention is based on research of chemical constituents and performance characteristics of common two phase stainless steel, economic and practical domestic submerged arc welding material combination applicable to common two phase stainless steel and reasonable submerged arc welding procedure are selected, and the invention has the advantage that efficient welding of two phase stainless steel is realized by adopting high line energy submerged arc welding. Welding of common two phase stainless steel is carried out by adopting the invention, the chemical constituents of welding line can be ensured to meet standard requirement, ferrite content of welding joint (including welding line and heat affected zone) is controlled to be 30-65%, and the welding joint has good mechanical properties and pitting corrosion resistance.

Owner:NANJING BAOSE

Fruit flavor for cigarettes and application of flavor

InactiveCN104388191AOptimize chemical compositionImprove smoking qualityTobacco preparationEssential-oils/perfumesActive enzymeFreeze-drying

The invention discloses a fruit flavor for cigarettes and application of the flavor. The fruit flavor for cigarettes is prepared by naturally fermenting, filtering, centrifuging, and freeze-drying edible fruits and sugar as raw materials. The fruit flavor is rich in active enzyme, reducing sugar, amino acid, vitamin, trace elements and minerals and the like and can be used in tobacco leaf or shredded stem feeding process. The fruit flavor for cigarettes is simple to manufacture, safe and environmentally friendly and has good application prospects; by the fruit flavor, the internal quality of the cigarettes can be significantly improved.

Owner:CHINA TOBACCO YUNNAN IND

Edible fungi culture medium and preparation method thereof

InactiveCN102942410AHigh biotransformation rateIncrease nutritional contentFertilizer mixturesFiberSucrose

The present invention discloses an edible fungi culture medium and a preparation method thereof. The preparation method comprises: (1) carrying out a pretreatment on giant knotweed rhizome drug residue, wherein the pretreatment comprises adding water to giant knotweed rhizome drug residue and carrying out enzymolysis; and (2) preparing an edible fungi culture medium, wherein the treated giant knotweed rhizome drug residue is added with quick lime, gypsum, sucrose, cottonseed hulls and wheat bran, and uniform stirring is performed. According to the edible fungi culture medium, a resveratrol mass fraction is more than or equal to 0.1%. a crude protein mass fraction is more than or equal to 6%, a nitrogen-free extract mass fraction is more than ore equal to 30%, and a crude fiber mass fraction is more than or equal to 30%. According to the present invention, a complex enzyme preparation is adopted to carry out fermentation and enzymolysis to improve components of the giant knotweed rhizome drug residue, such that the components are applicable for cultures of pleurotus eryngii, cap fungus, coprinus comatus and other edible fungi.

Owner:JISHOU UNIVERSITY

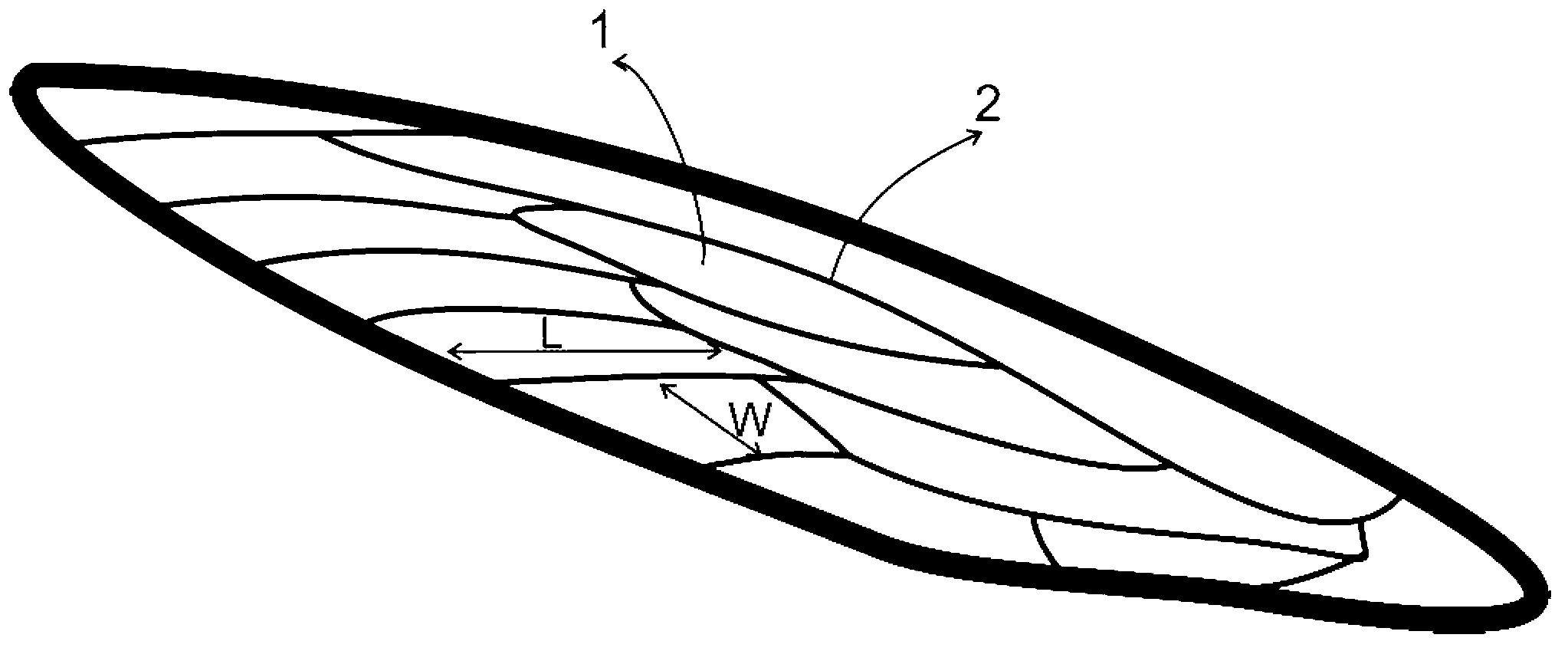

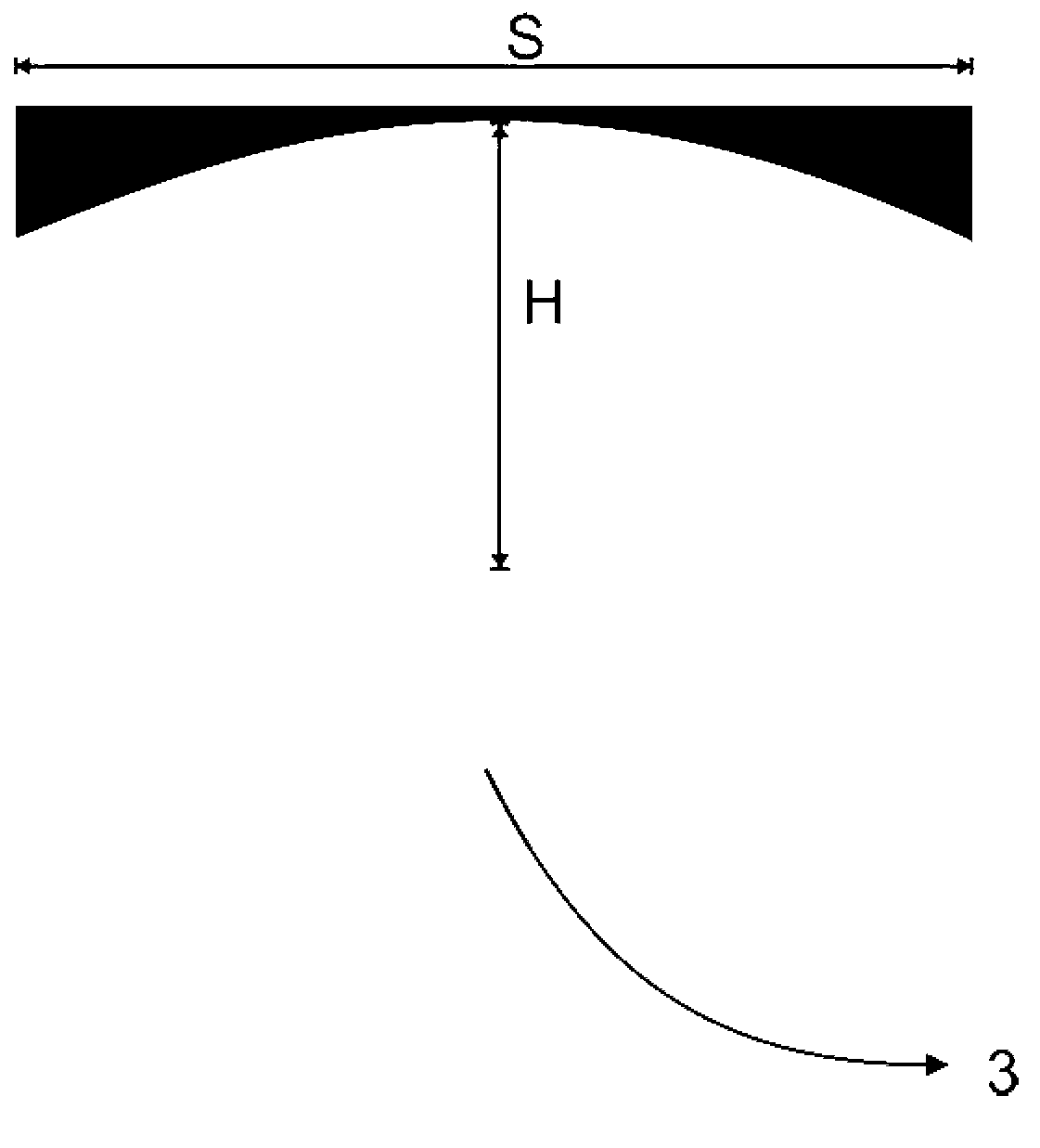

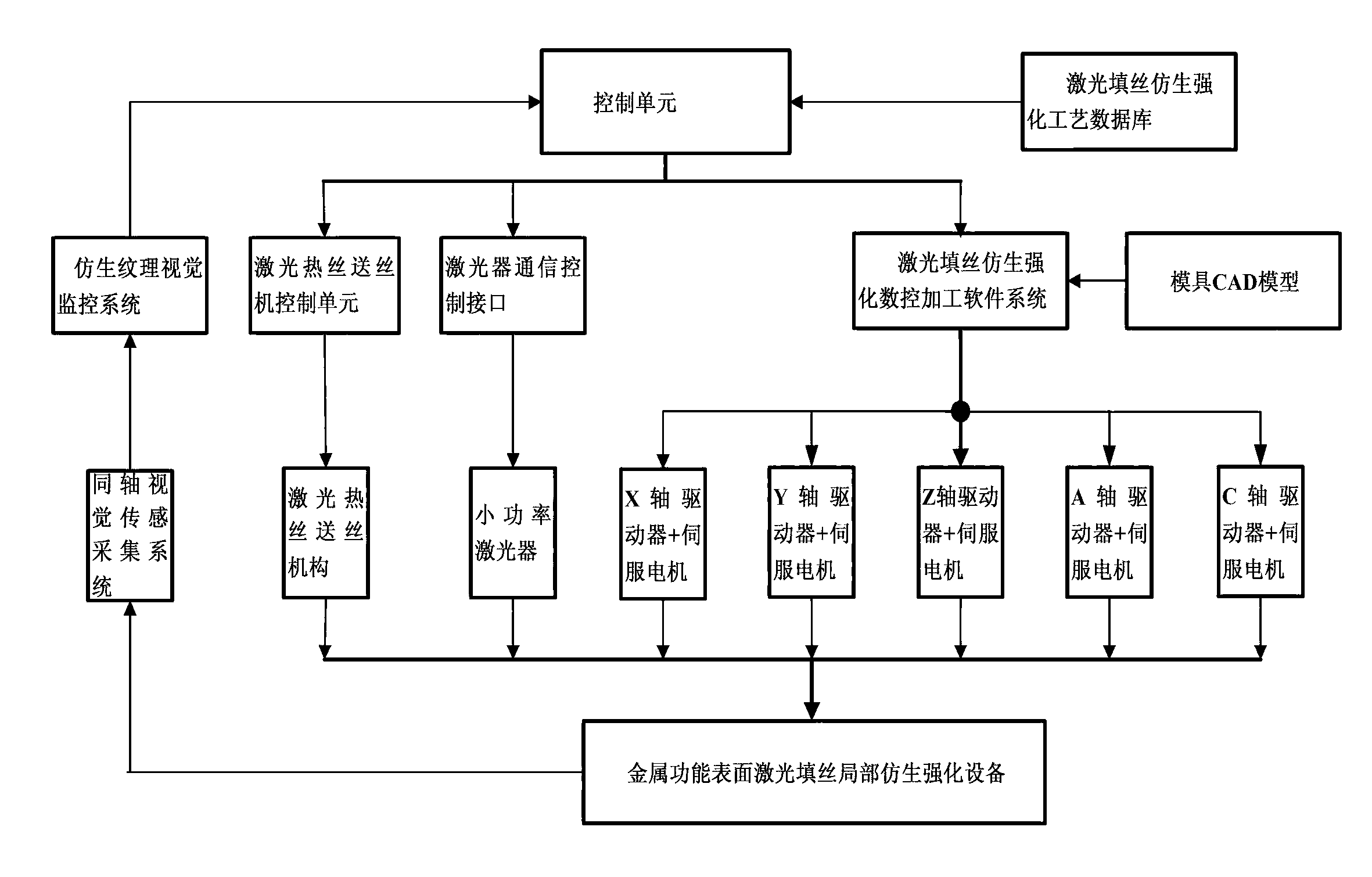

Laser wire-filling local bionic-texture manufacturing method and equipment for metal functional surfaces

InactiveCN103252582AImprove toughnessReduce microcracksLaser beam welding apparatusFive freedomsCost performance

The invention relates to laser wire-filling local bionic-texture manufacturing method and equipment for metal functional surfaces, belongs to the field of processing of metal materials and aims to provide a technical method and a manufacturing device which are capable of effectively improving thermal fatigue resistance and wear resistance on the metal functional surfaces. For different metal base materials, by combining the automatic wire filling technology with the vision sensing and small-power laser technology, a novel method for manufacturing bionic texture on metal functional spatial curved surfaces is provided. In order to implement the mentioned technical method, strengthening equipment composed of a control unit, a vision system, an adjustable temperature heating wire feeding machine, a laser and a five-freedom-degree numerical-control worktable is researched, thermal fatigue resistance and wear resistance of the metal functional surfaces are effectively improved, cost performance is good and production efficiency is high.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

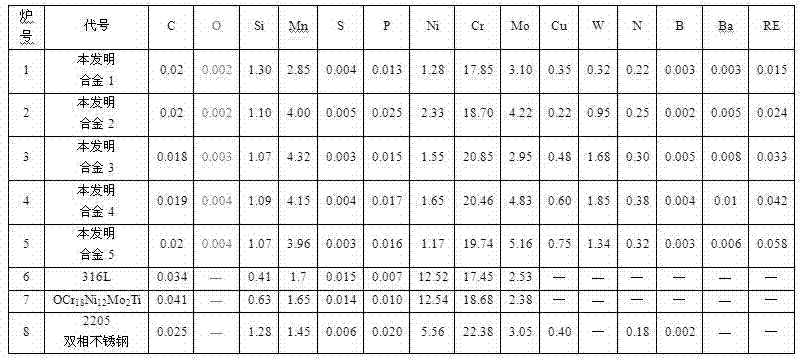

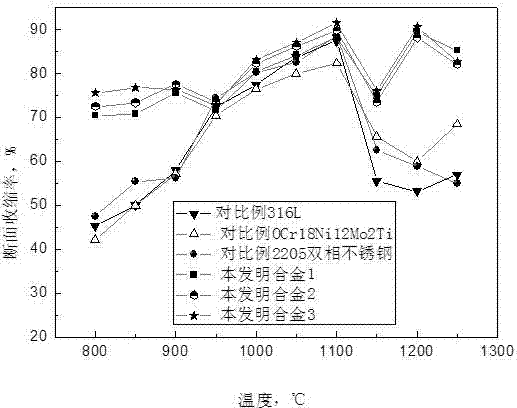

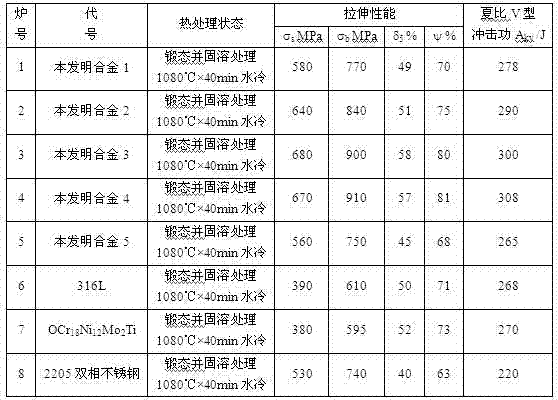

Nickel-saving rare-earth/barium-containing biphase stainless steel alloy material and preparation method thereof

The invention relates to a nickel-saving rare-earth / barium-containing biphase stainless steel alloy material and a preparation method thereof. The alloy material is composed of the following components in percentage by mass: at most 0.025% of C, at most 0.005% of O, at most 0.006% of S, at most 2.00% of Si, at most 0.025% of P, 2.00-5.00% of Mn, 17.0-21.0% of Cr, 1.0-2.5% of Ni, 0.1-2.0% of W, 0.1-1.0% of Cu, 2.0-5.5% of Mo, 0.2-0.40% of N, 0.001-0.01% of B, 0.0005-0.01% of Ba, 0.01-0.2% of lanthanum-cerium mixed rare earth RE and the balance of Fe. The preparation method comprises the following steps: smelting, casting, cast ingot or casting blank cogging, hot rolling and solution treatment. The method has the advantages of nickel saving and low production cost, obviously enhances the mechanical strength, and improves the hot working properties, corrosion resistance and the like.

Owner:JIANGSU XIHU SPECIAL STEEL

Prepn. contg. composite enzyme for improving quality of tobacco

InactiveCN1692846AAccelerates the natural aging processShorten the natural aging cycleTobacco treatmentAmylaseYeast

Owner:ENZYME ENG INST SHAANXI PROVINCE ACAD OF SCI

Baking method for upper leaves of flue-cured tobacco

ActiveCN105942569APromote maturityReduce labor intensityTobacco preparationCooking & bakingChemical composition

The invention discloses a baking method for upper leaves of flue-cured tobacco. The baking method comprises the following steps: outbreak of a fire, a yellowing stage, a color fixing stage and a stem drying stage; and before baking, the material needs to be processed, including material collecting, tobacco weaving and tobacco filling. According to the invention, the baking condition of the upper leaves of the flue-cured tobacco can be controlled by controlling the heating rate and the temperature stabilizing time in baking, thus achieving an optimal effect. The baking method is capable of effectively reducing the labor strength in tobacco leaf harvest, promoting degradation and transformation of macromolecule substances in tobacco leaves, promoting the coordination of aroma substances and internal chemical components, improving aroma taste, reducing the ash hanging and stiffing proportion of upper leaves, and improving appearance quality.

Owner:YUNNAN TOBACCO CORP QUJING BRANCH

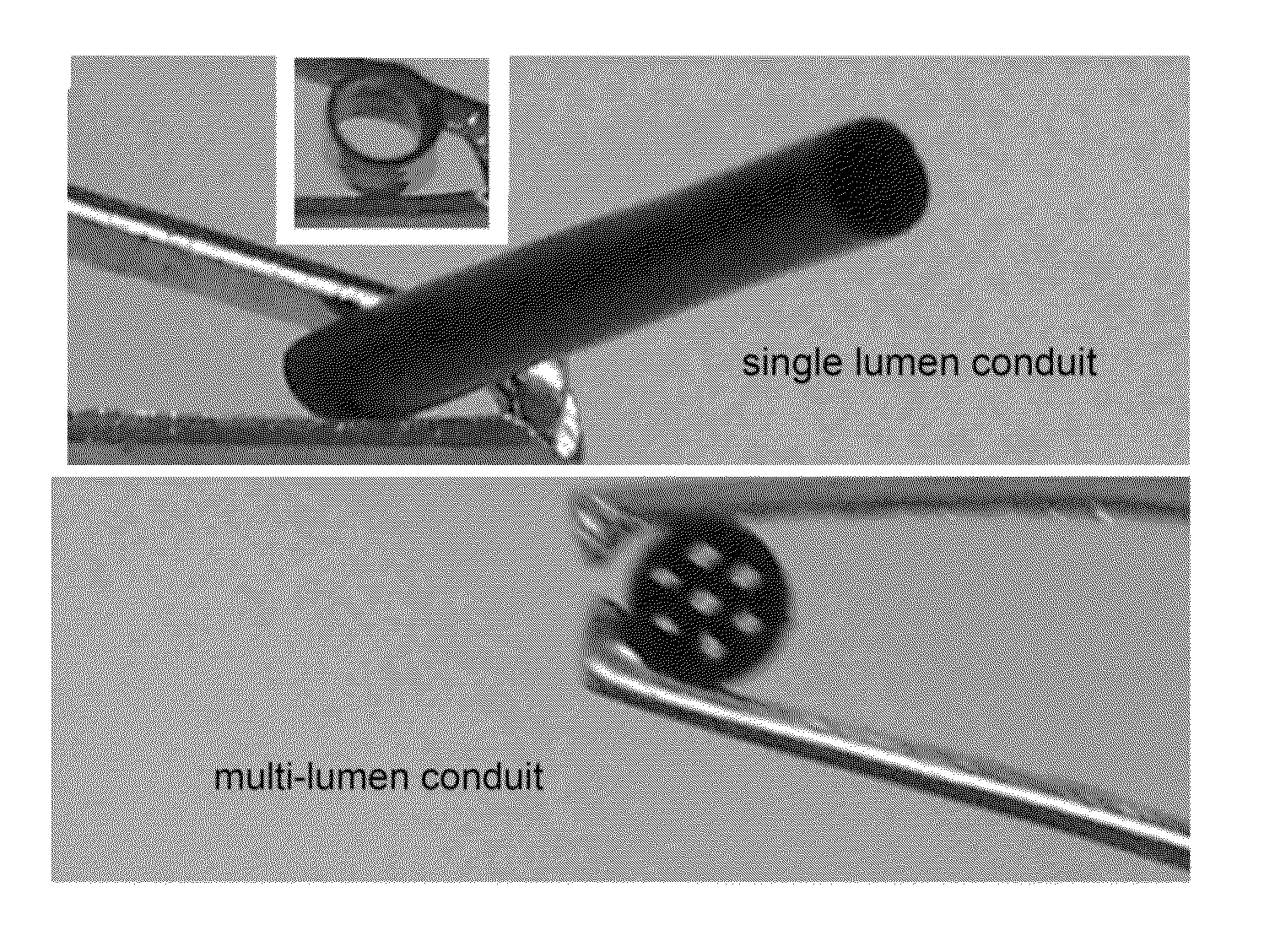

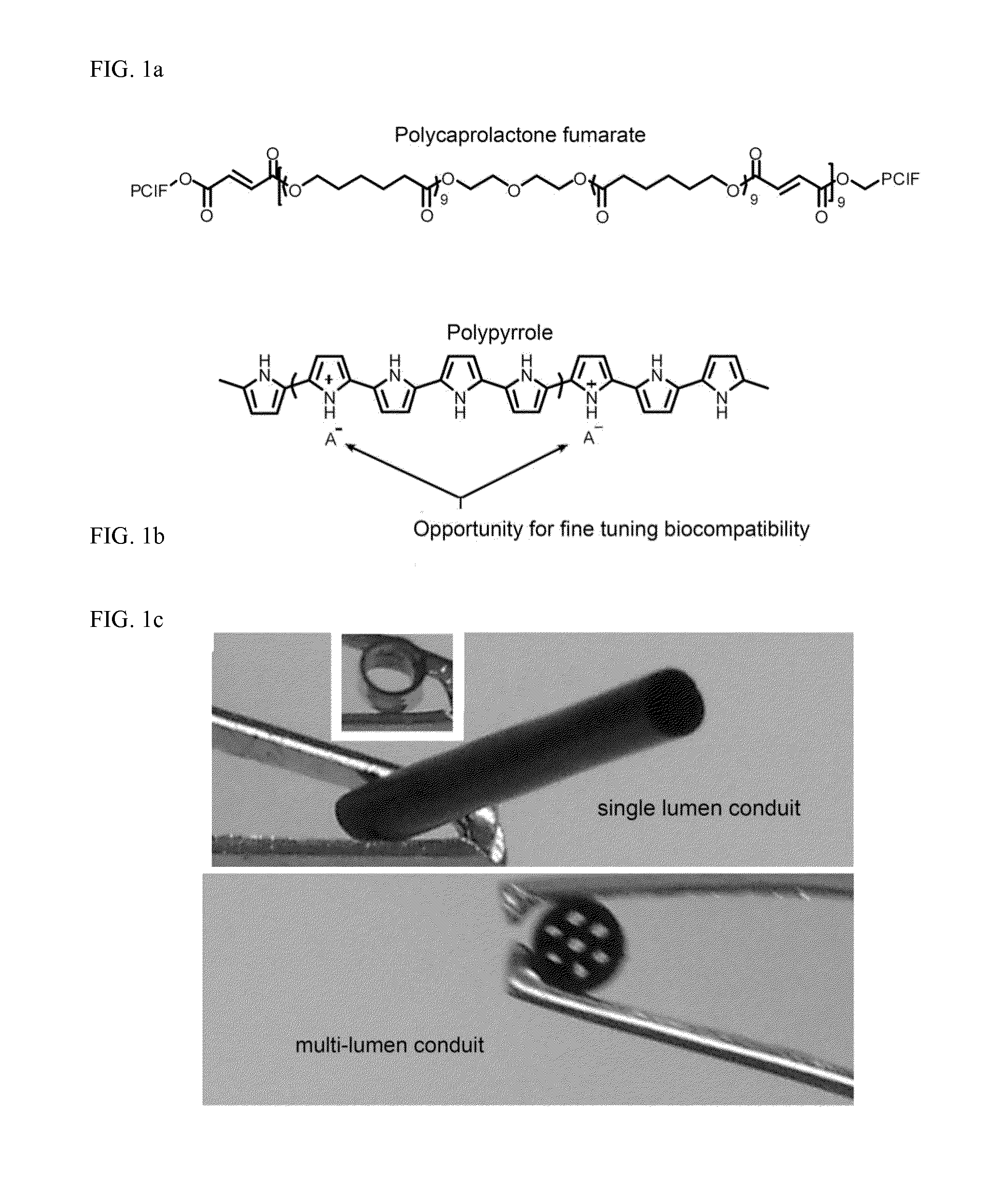

Conductive polymeric composites of polycaprolactone fumarate and polypyrrole for nerve regeneration

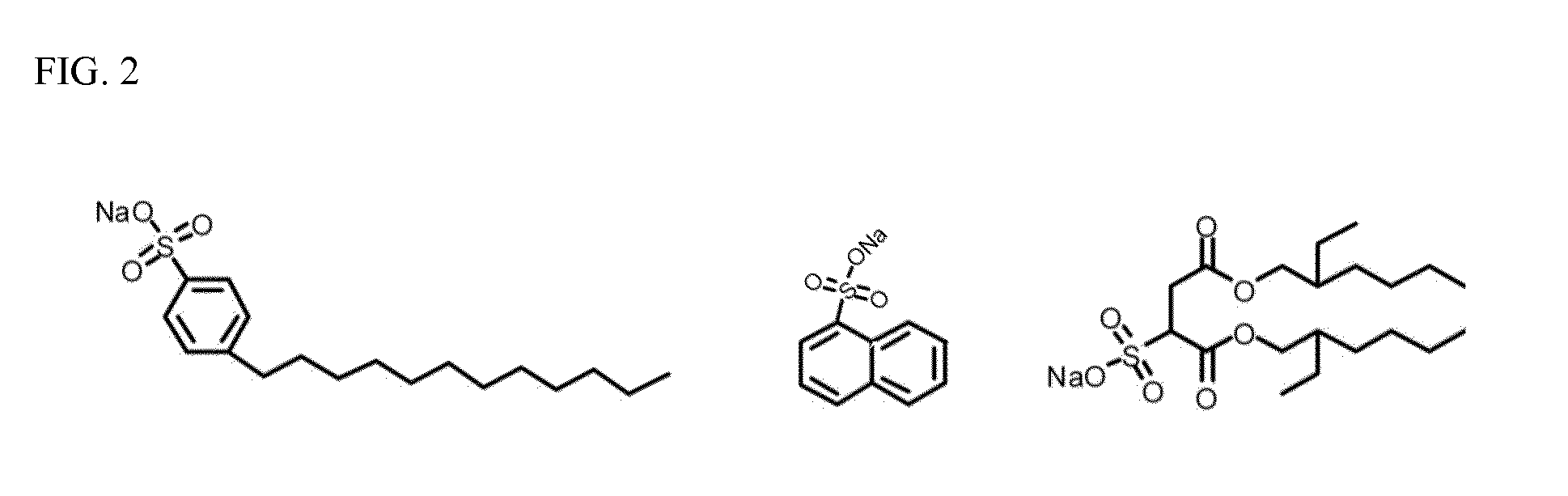

InactiveUS20130331869A1Optimize chemical compositionEnhance cell viabilitySpinal electrodesOrganic active ingredientsConductive polymerBiocompatibility Testing

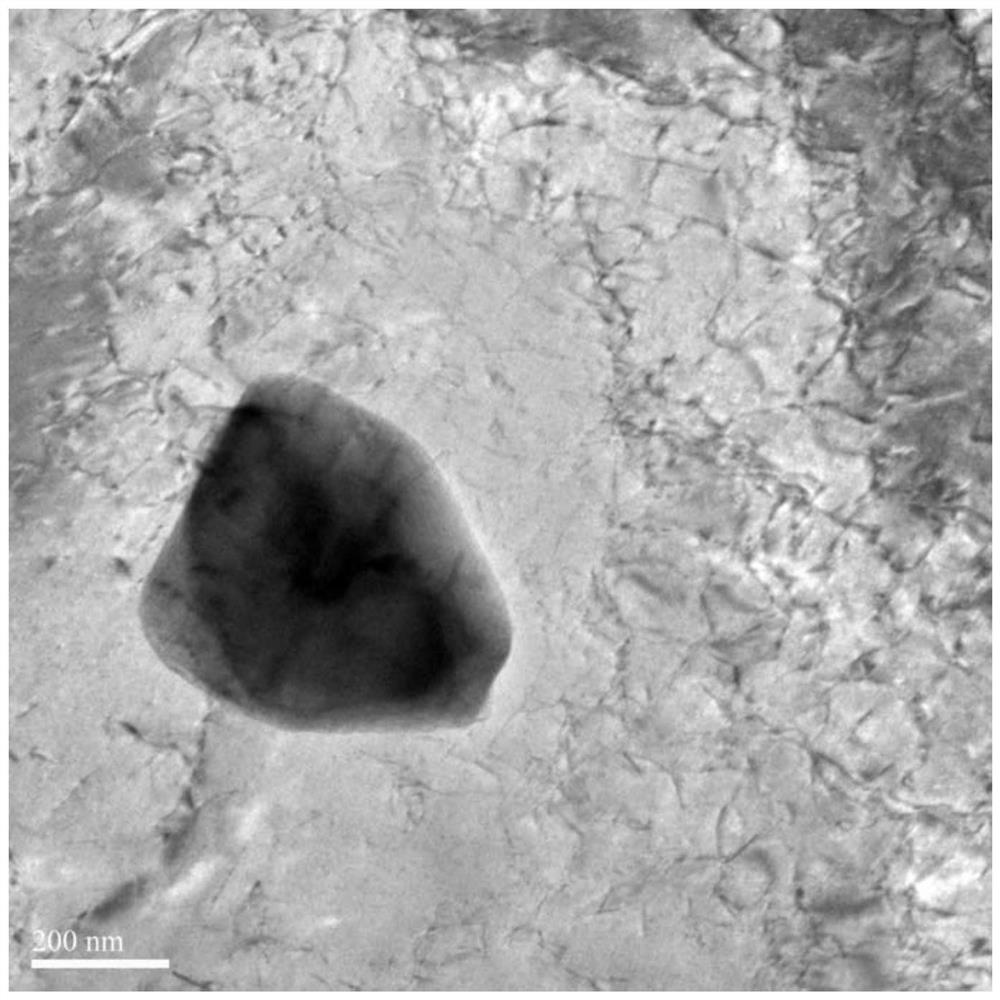

A novel electrically conductive polymer composite composed of polycaprolactone fumarate-polypyrrole (PCLF-PPy) for applications in nerve regeneration is disclosed. The synthesis and characterization of PCLF-PPy and in vitro studies showing PCLF-PPy supports both PC12 cell and Dorsal Root Ganglia neurite extension. PCLF-PPy composite materials were synthesized by polymerizing pyrrole in pre-formed scaffolds of PCLF resulting in an interpenetrating network of PCLF-PPy. PCLF-PPy composite materials possess electrical conductivity up to 6 mS cm−1 with compositions ranging from 5-13.5 percent polypyrrole of the bulk material. Surface topographies of PCLF-PPy materials show microstructures with a RMS roughness of 1195 nm and nanostructures with RMS roughness of 8 nm. PCLF-PPy derivatives were synthesized with anionic dopants to determine effects on electrical conductivity and to optimize the chemical composition for biocompatibility. In vitro studies using PC12 show PCLF-PPy composite materials induce a higher cellular viability and increased neurite extension compared to PCLF. PCLF-PPy composites doped with either naphthalene sulfonic acid or dodecyl benzene sulfonic acid are determined to be the optimal materials for electrical stimulation. In vitro studies showed significant increases in percentage of neurite bearing cells, number of neurites per cell and neurite length in the presence of ES compared to no ES. Additionally, extending neurites were observed to align in the direction of the applied current. Electrically conductive PCLF-PPy scaffolds possess material properties necessary for application as nerve conduits. Additionally, the capability to significantly enhance and direct neurite extension by passing electrical current through PCLF-PPy scaffolds renders them even more promising as future therapeutic treatments for severe nerve injuries.

Owner:MAYO FOUND FOR MEDICAL EDUCATION & RES

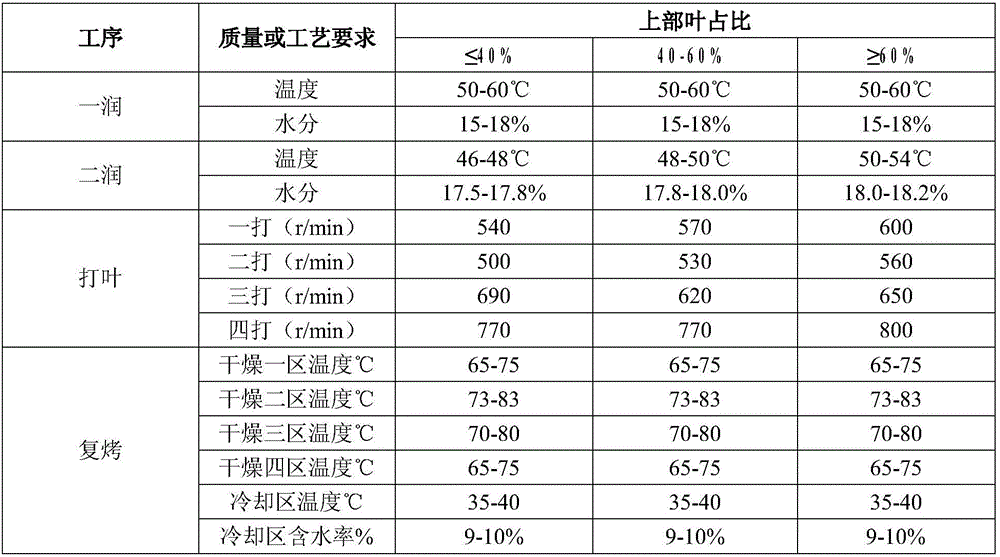

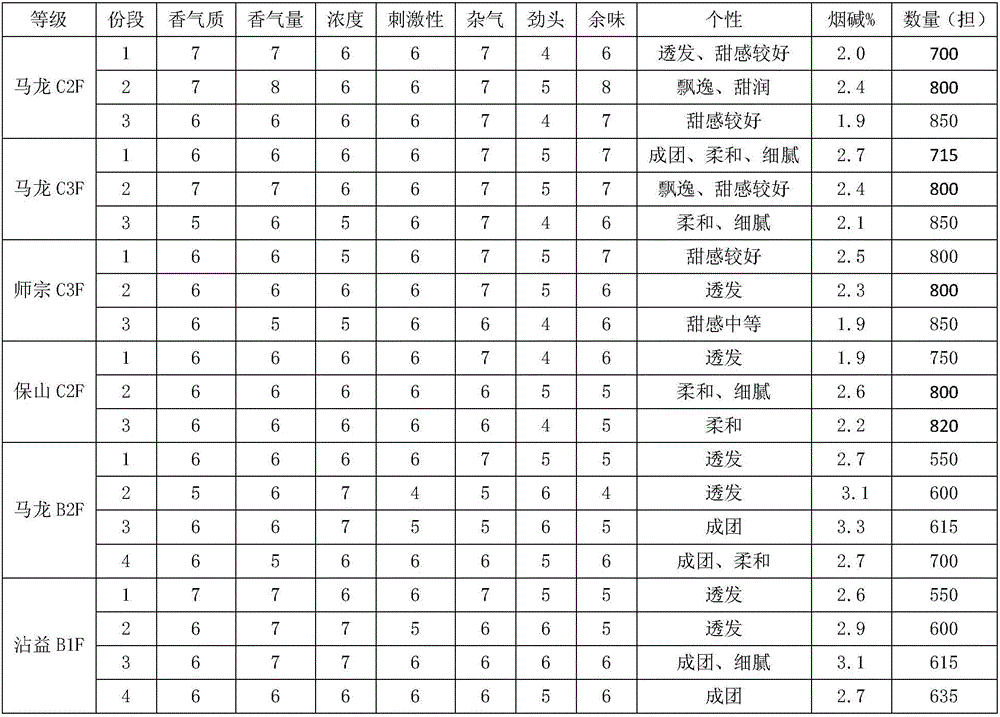

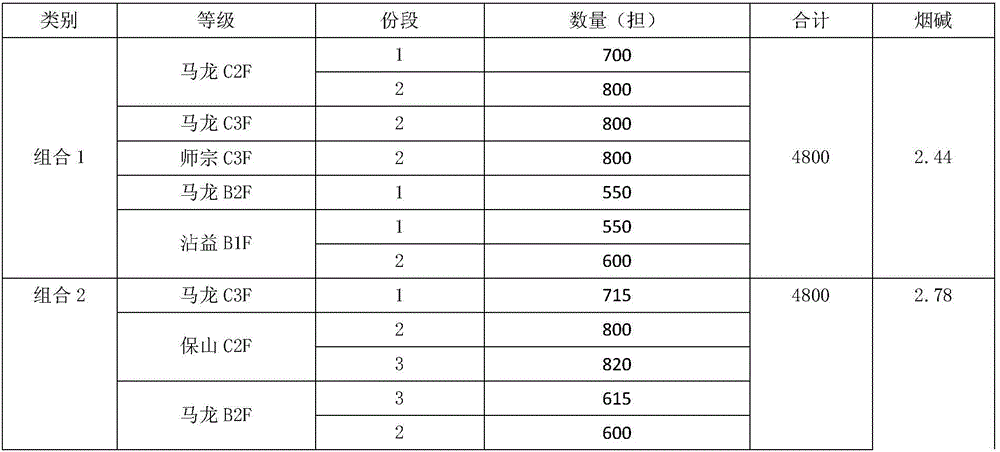

Threshing and re-drying processing method of high-grade tobacco leaf raw materials

ActiveCN106617251AGuaranteed uniformity and stabilityStable product quality styleTobacco preparationChemical compositionEngineering

The invention provides a threshing and re-drying processing method of high-grade tobacco leaf raw materials. According to the method, tobacco leaves on the upper portion and in the middle serve as the raw materials and divided into multiple segments according the lengths of the leaves, and the total weight and the nicotine content of each segment of tobacco leaf of each portion are determined; before feeding and threshing, multiple threshing combined formulas are formed through matching according to the total feeding amount and the content of chemical components, wherein the addition amount of the tobacco leaves in the middle portion in each formula is not smaller than 30%, and the same segments of tobacco leaves of the same portion are added into the same formula; the content of the tobacco leaves on the upper portion and the nicotine content in each formula are calculated, a threshing and re-drying formula meeting feeding requirements is determined for feeding, and then threshing and re-drying start according to an existing threshing and re-drying technology to obtain the combined high-grade tobacco leaf raw materials. The method guarantees uniformity and stability of the tobacco leaves obtained after threshing and re-drying, and can provide the good-quality and uniform tobacco leaf raw materials for high-end brand cigarettes.

Owner:HUBEI CHINA TOBACCO IND

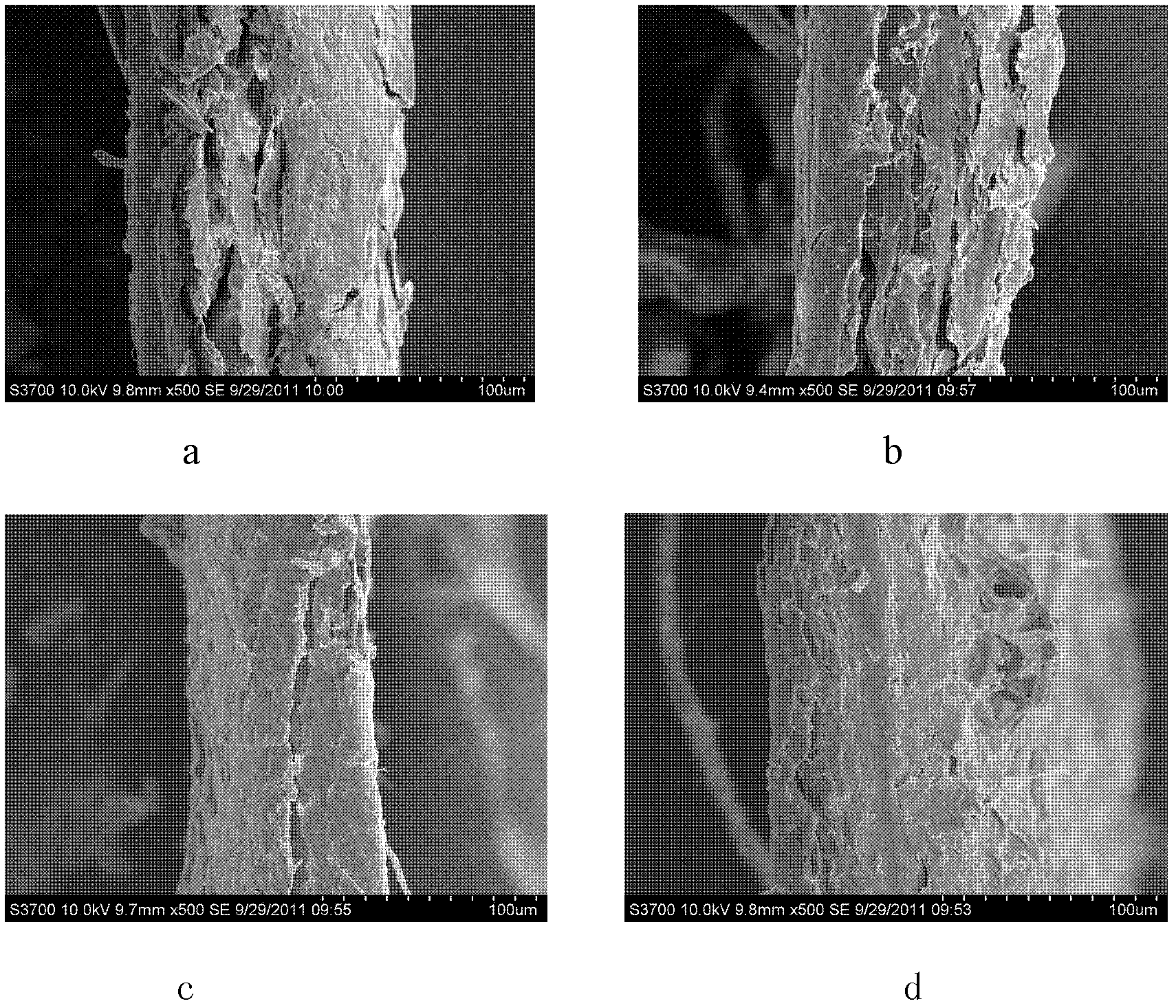

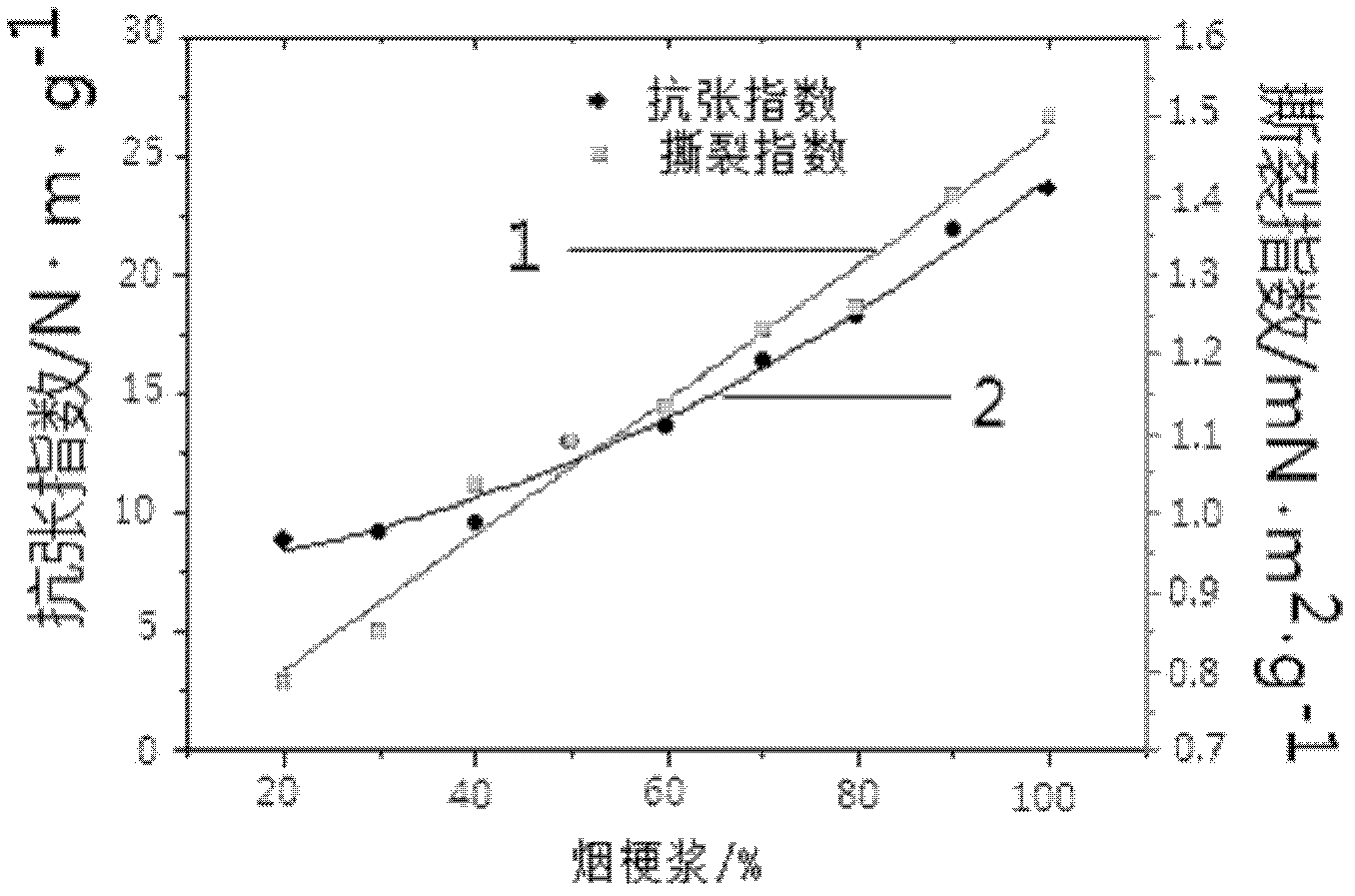

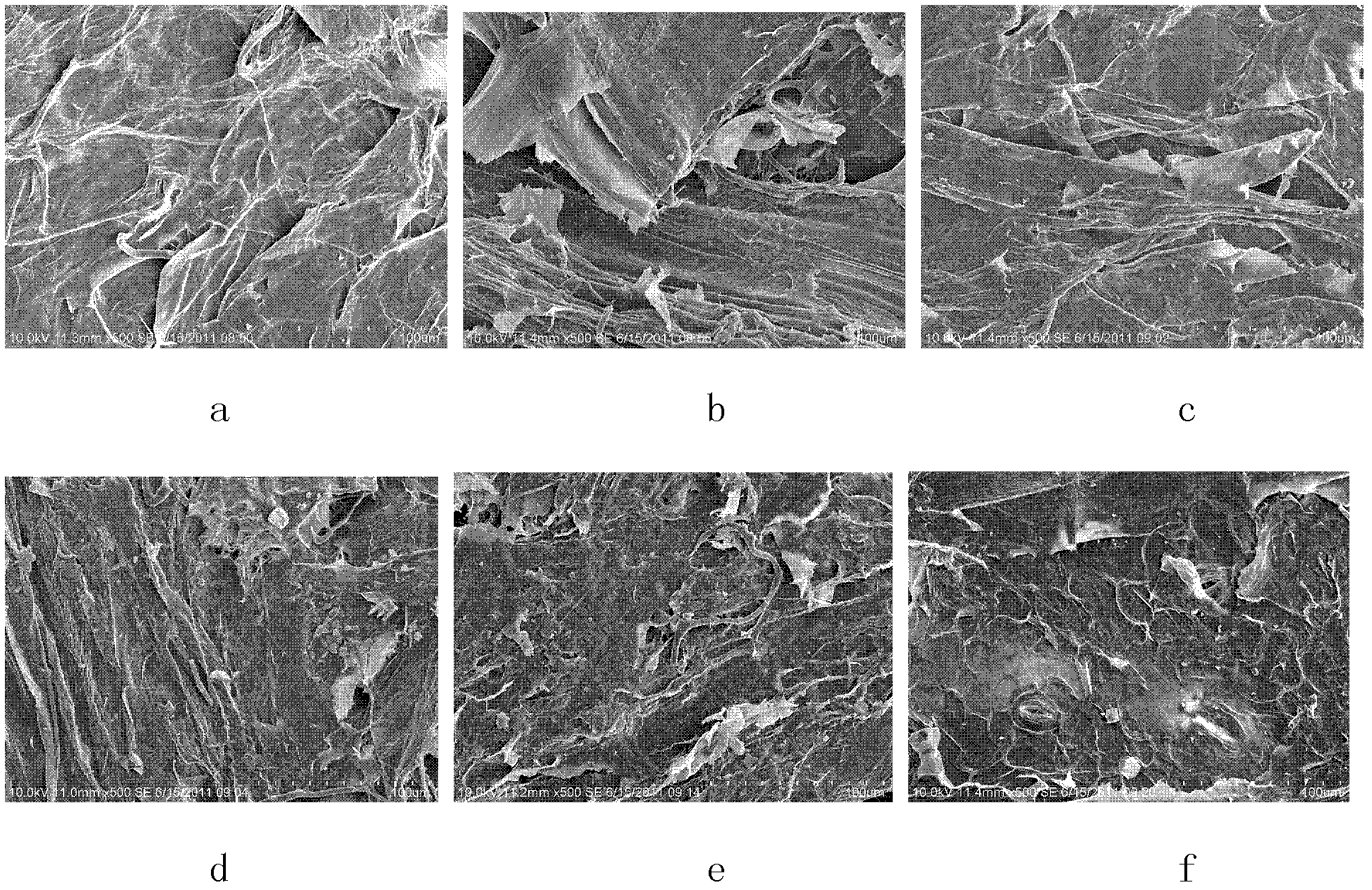

Preparation method of reconstituted tobacco from tobacco stem and tobacco powder

ActiveCN102599636AUnderstanding of physical propertiesOptimize chemical compositionTobacco preparationProduction lineChemical composition

The invention discloses a preparation method of reconstituted tobacco from tobacco stem and tobacco powder by papermaking method. The method comprises soaking to extract tobacco stem and tobacco powder, and filtering to obtain extractive solution and residue; subjecting the residue to pulping, sheet-making, squeezing and drying to obtain sheet base; and coating the extractive solution on the sheet base. The invention performs systematic research on squeezing process, provides suitable squeezing process conditions, effectively improves physical properties, chemical composition, tensile index, tearing index, bulkiness, density, air permeability, filling value, wettability and permeability of tobacco sheet base, comprehensively improves surface properties and interior structure of sheet base, and improves operation performance and effectiveness of tobacco sheet base production line.

Owner:CHINA TOBACCO GUANGDONG IND +1

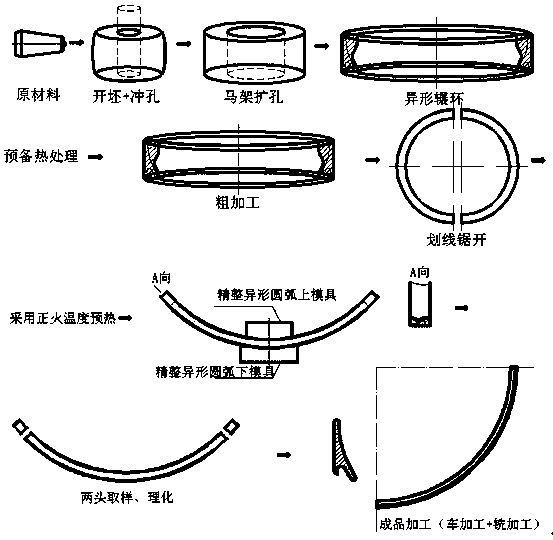

Low-alloy high-strength high-impact-energy extra-large special-shaped ring forging and forging method thereof

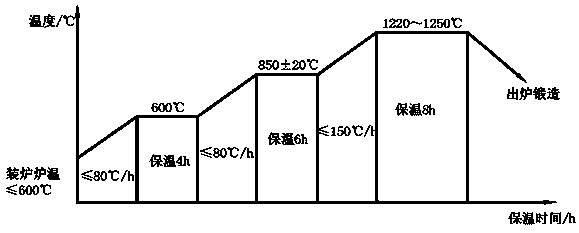

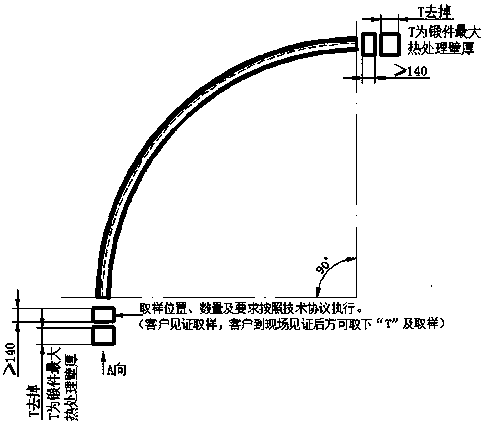

ActiveCN108914015AOptimize chemical compositionAvoid wastingMetal-working apparatusFurnace typesChemical compositionManufactured material

The invention discloses a low-alloy high-strength high-impact-energy extra-large special-shaped ring forging. Low-alloy high-strength steel comprises, by weight, 0.08-0.12% of C, 0.5-0.6% of Mn, lessthan or equal to 0.006% of P, less than or equal to 0.006% of S, 0.5-0.65% of Si, 1.4-1.5% of Cr, 0. 55-0.65% of Mo, 0.1-0.2% of Ni, less than or equal to 0.15% of Cu, less than or equal to 0.04% of V, 0.03-0.04% of Nb, 0.02-0.04% of Al, less than or equal to 0.01% of Sn, less than or equal to 0.01% of As, less than or equal to 0.0012% of Sb and the balance Fe and impurities, then through nozzle cold sawing, riser collection, riser heat chopping, then three times of upsetting and two times drawing, broaching chambering, special-shaped ring rolling, preparatory heat treatment, rough turning, sawing, preheating and arc finishing. In this way, chemical compositions of raw materials are optimized, a reasonable matching heat treatment system is adopted, the stability of the impact work can be improved through maximum simulated post-weld heat treatment of the materials, the product once inspection pass rate is increased to 100%, energy waste caused by rework and repair is avoided, the production cycle is shortened, the manufacturing cost is reduced, and the competitiveness of enterprises is improved.

Owner:AVIC EXCELLENCE FORGING WUXI

Large-thickness rack steel plate directly produced by continuous casting billet and manufacturing method of large-thickness rack steel plate

The invention relates to a large-thickness rack steel plate directly produced by a continuous casting billet. The steel plate takes Fe as a base component and further comprises the following chemical components by mass percent: 0.10% to 0.16% of C, 0.15% to 0.35% of Si, 0.95% to 1.25% of Mn, less than or equal to 0.010% of P, less than or equal to 0.005% of S, greater than or equal to 2.4% and less than or equal to 3.0% of Cr+Mo+Ni+Cu, greater than or equal to 0.08% and less than or equal to 0.13% of Al+V, less than or equal to 0.007% of N and 0.001% to 0.002% of B. A manufacturing method of the large-thickness rack steel plate comprises the following steps of KR molten iron pretreatment, converter smelting, LF (ladle furnace) refining, RH refining, continuous casting, casting billet covering for slow cooling, casting billet clearing, heating, high-pressure water descaling, rolling control, straightening, accumulation slow-cooling or slow cooling under a control condition and tempering. The steel plate is high in strength, good in plasticity, high in Z-direction performance and high in low-temperature toughness. In addition, the steel plate is simple and convenient in production process and low in cost.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Curing process of Yunyan 87 in biomass energy curing barn

The invention discloses a curing process of Yunyan 87 in a biomass energy curing barn. A three-segment curing process in the prior art is improved, and according to the characteristics and quality oftobacco leaves of the flue-cured tobacco variety Yunyan 87, the following steps are designed; the curing process comprises the steps of tobacco weaving loading, building fire temperature controlling,tobacco leave yellowing, tobacco leave color fixing and tobacco leave stem drying. The curing process has the advantages of being easy to operate and high in operability, keeping color fixing stability and loose structure of the tobacco leaves, and greatly improving the oil content and aroma quantity; the cured tobacco leaves are yellow, bright, soft and fragrant, and the style and characteristicsof the sweet and fragrant type tobacco leaves are more obvious.

Owner:贵州省烟草公司六盘水市公司

High-temperature amorphous solder for soldering Si3N4 ceramics

InactiveCN101823188AGood flexibilityImprove wettabilityWelding/cutting media/materialsSoldering mediaRoom temperatureFlexural strength

The invention discloses high-temperature amorphous solder for soldering Si3N4 ceramics, belonging to the technical field of soldering materials. The high-temperature amorphous solder of the invention for soldering the Si3N4 ceramics comprises the following components by weight percent: 35.0% to 45.0% of Ti, 20% to 30% of Zr, 0.1% to 0.3% of B and Cu in balancing amount, wherein the melting temperature of the solder ranges from 1,100K to 1,200K, and the soldering temperature thereof is 1,223K to 1,373K. The Si3N4 ceramics is prepared by vacuum-soldering the Ti-Zr-Cu-B high-temperature active amorphous solder on the basis of the rapid solidification technology, and the maximal room-temperature strength of the Si3N4 ceramics reaches 245MPa; and the high-temperature performance thereof is much higher than that of the Ag-Cu-Ti solder and Ti-Zr-Ni-Cu solder, particularly, the high-temperature bending strength of the ceramic connector is 165.5MPa at the testing temperature of 673K.

Owner:JIANGSU UNIV OF SCI & TECH

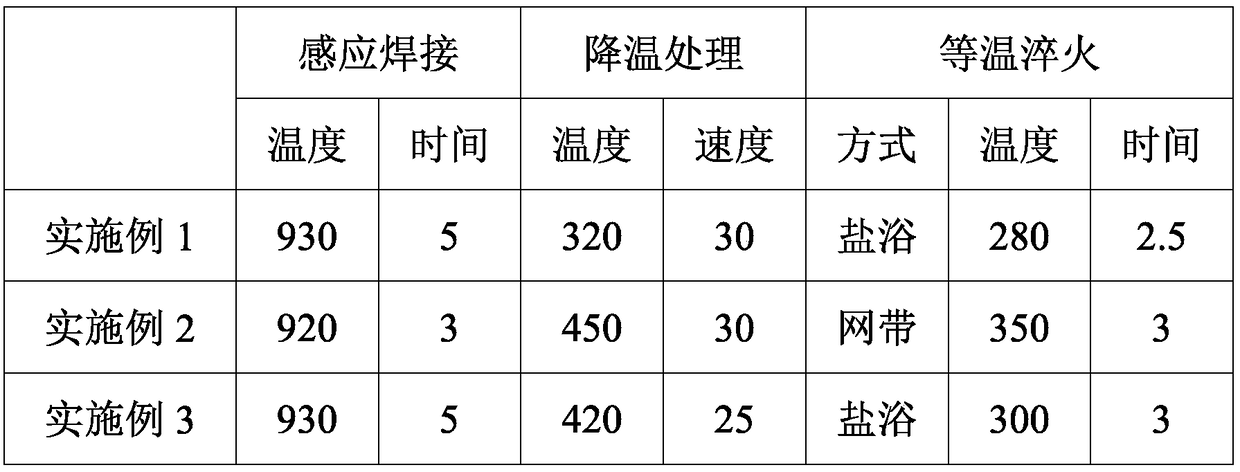

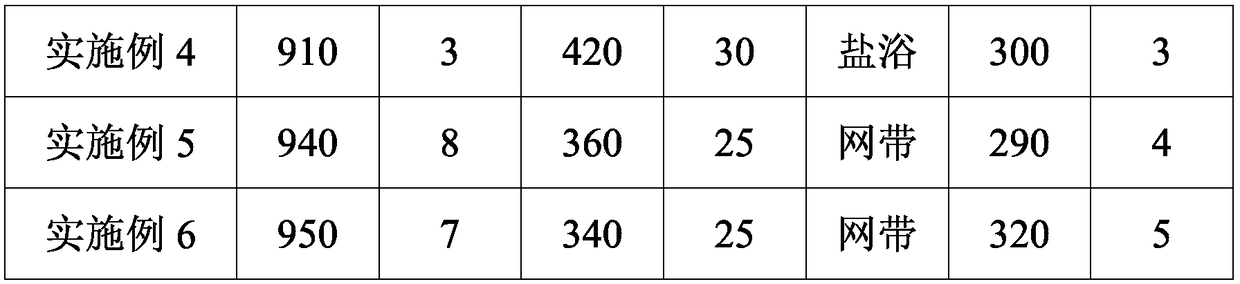

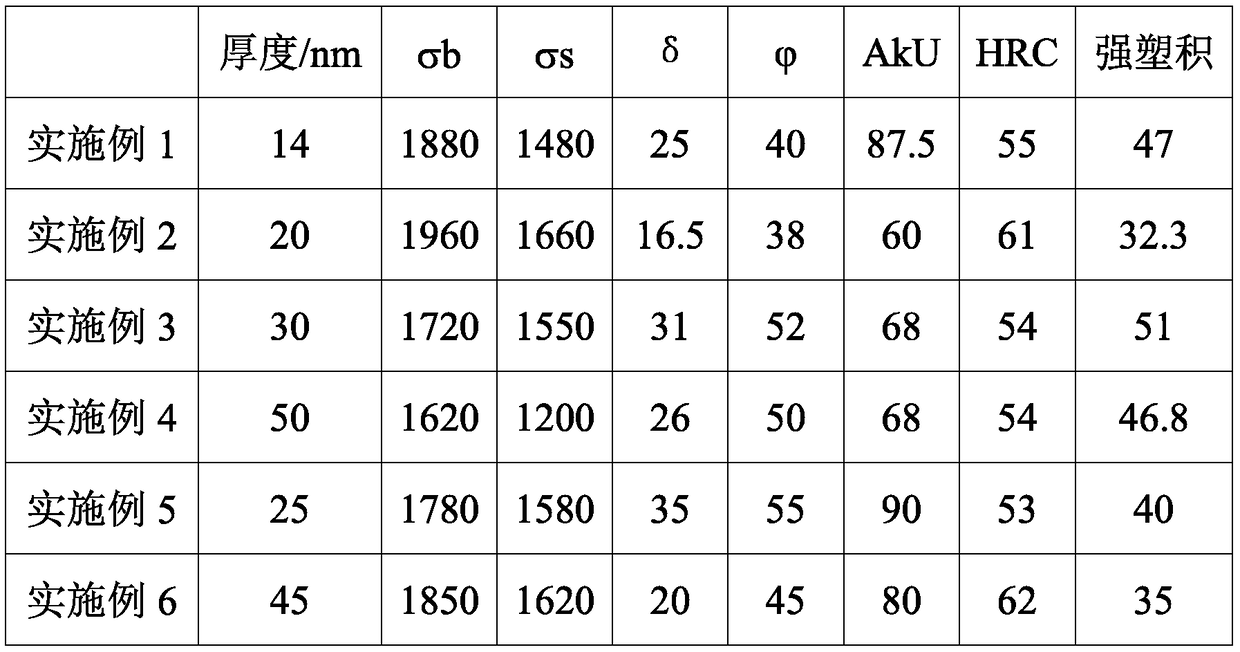

High performance cutting pick and manufacturing method thereof

InactiveCN108977631AOptimize chemical compositionHigh hardnessFurnace typesHeat treatment furnacesRaw materialMicrostructure

The invention provides a high performance cutting pick and a manufacturing method thereof, the high performance cutting pick comprises a tooth tip and a tooth body. The tooth body is high-strength, high-toughness and high-wear-resistance steel. The chemical components are as following by weight percent, 0.30 to 0.40 of C, 2.30 to 2.50 of Si, 2.20 to 2. 60 of Mn, 0.80 to 1.50 of Cr, 0.35 to 0.45 ofMo, 0.01 to 0.1 of Re, 0.02 to 0.04 of Nb, less than 0.01 of S, less than 0.01 of P, and the rest of Fe. After raw materials are refined and cast to obtain steel ingots or subjected to continuous casting to obtain continuous casting billets, after being rolled into round steel, cutting and annealing are conducted, and finally a cutting pick body is obtained by cold forging. The tooth tip is prepared from cemented carbide and welded to the tooth body by medium frequency induction heating. After cooling, austempering treatment is conducted, and finally discharging and air-cooling to room temperature are conducted. The finally obtained tooth body has tensile strength sigma b of 1700 to 2000MPa, yield strength sigma s of 1100 to 1520MPa, elongation delta of 16 to 35%, section shrinkage phi of45 to 55%, impact work Aku of 55 to 90 J, hardness HRC of 53 to 62, and strong plastic product of 32 to 51 GPa.%. The microstructure of the tooth body is a nano-carbide-free bainite-martensitic multiphase organization, and the thickness of a substructure slat is 10 to 50 nm.

Owner:鄂尔多斯市神东天隆矿山机械有限责任公司 +1

Silicon-manganese-chrome-molybdenum low-alloy steel excavator bucket tooth and production technique thereof

InactiveCN103614652AImprove toughnessExtended service lifeSoil-shifting machines/dredgersFurnace typesManganeseHardness

The invention provides a silicon-manganese-chrome-molybdenum low-alloy steel excavator bucket tooth and a production technique thereof. The silicon-manganese-chrome-molybdenum low-alloy steel of the excavator bucket tooth comprises 0.26-0.36 wt% of C, 0.80-1.20 wt% of Si, 0.80-1.20 wt% of Mn, 1.00-1.30 wt% of Cr, 0.30-0.40 wt% of Mo, at most 0.02 wt% of P, at most 0.02 wt% of S, greater than 0 and smaller than and equal to 0.50wt% of Ni, and the balance of Fe. The production technique is composed of a casting technique and a heat treatment technique. The silicon-manganese-chrome-molybdenum low-alloy steel excavator bucket tooth produced by the method is a bainitic structure, and has the advantages of favorable mechanical properties, high hardness, high toughness, high wear resistance, high tensile strength and long service life.

Owner:HENAN LIDE METAL MATERIALS

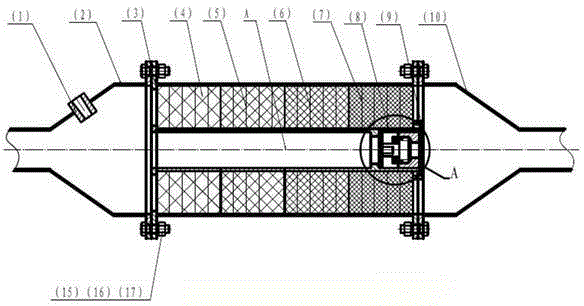

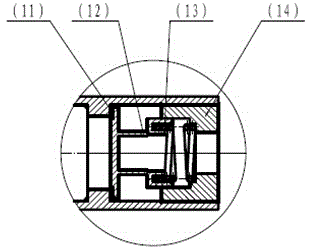

Efficient tail gas particle purification system of mining rubber-tyred vehicle

ActiveCN104594981ALow costImprove purification effectExhaust apparatusSilencing apparatusExhaust pipeMetal foam

The invention belongs to the technical field of tail gas emission of transportation equipment of mining rubber-tyred vehicles for underground coal mines and particularly relates to an efficient tail gas particle purification system of a mining rubber-tyred vehicle. The efficient tail gas particle purification system solves the problem that in the running process of existing mining rubber-tyred vehicles for underground coal mines, tail gas particle emission performance exceeds standards seriously. The efficient tail gas particle purification system of the mining rubber-tyred vehicle comprises an exhaust pipe and an exhaust tail pipe and further comprises a tail gas particle purification device and a display and warning system, the tail gas particle purification device comprises an exhaust safety device and a tail gas particle catcher arranged between the exhaust pipe and the exhaust tail pipe, the tail gas particle catcher comprises multiple levels of catcher bodies arranged in a shell in sequence, the catcher body of each level is formed by stacking a plurality of metal foam sheets, the metal foam sheets are made of Fe-Cr-Al in a firing mode, have different hole diameters and have the thicknesses of 3 mm-5 mm, and the hole diameters of the metal foam sheets in the levels of catcher bodies gradually decrease.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

Rust-resistant hot rolled ribbed bar and production process thereof

The invention discloses a rust-resistant hot rolled ribbed bar and a production process thereof. The chemical components of the ribbed bar comprise C, Si, Mn, V, Cr, P and S, wherein the percentages by weight of the chemical components are as follows: 0.20-0.25% of C, 0.40-0.60% of Si, 0.90-1.10% of Mn, 0.010-0.020% of V, 0.15-0.25% of Cr, not larger than 0.042% of P, not larger than 0.040% of S and the balance of iron and unavoidable impurities. The production process mainly comprises the following steps: (1) preparation of blast furnace molten iron; (2) top-blown converter smelting; (3) LF furnace molten steel refining; (4) continuous casting; (5) rolling steel production; (6) cooling treatment. The rust-resistant hot rolled ribbed bar disclosed by the invention has the advantages that the chemical components of the ribbed bar are optimized, the addition amount of alloy elements is adjusted, the alloy cost is greatly reduced, the rolled cooling strength is reduced, the mechanical properties of the bar are guaranteed, damage of the strong water penetration cooling process on iron oxide coating on the surface of the ribbed bar after rolling is avoided as well, and the rust resistance of the ribbed bar is guaranteed.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Aluminium alloy plate for battery case and battery case made thereof

ActiveCN101373818AImprove pressure resistanceImprove solderabilityJackets/cases materialsCell lids/coversAluminium alloyUltimate tensile strength

This invention provides an aluminum alloy plate of battery shell for simultaneously enhancing compression strength and laser welding performance, and battery shell manufactured with this aluminum ally plate, namely, an aluminum alloy of battery shell composed of Si: 0.10-0.60 mass%, Fe: 0.05-0.60 mass%, over 0.70-below 1.0 mass%, Mn: 0.10-1.80 mass%, Mg: over 0.70-1.50 mass%, Zr: over 1.10-below 0.20 mass%, Ti: 0.03-0.25 mass%, surplus Al and unavoidable impurity, and aluminum alloy plate of battery shell manufactured with the chemical formulation and to be aged after manufacture.

Owner:NIPPON LIGHT METAL CO LTD

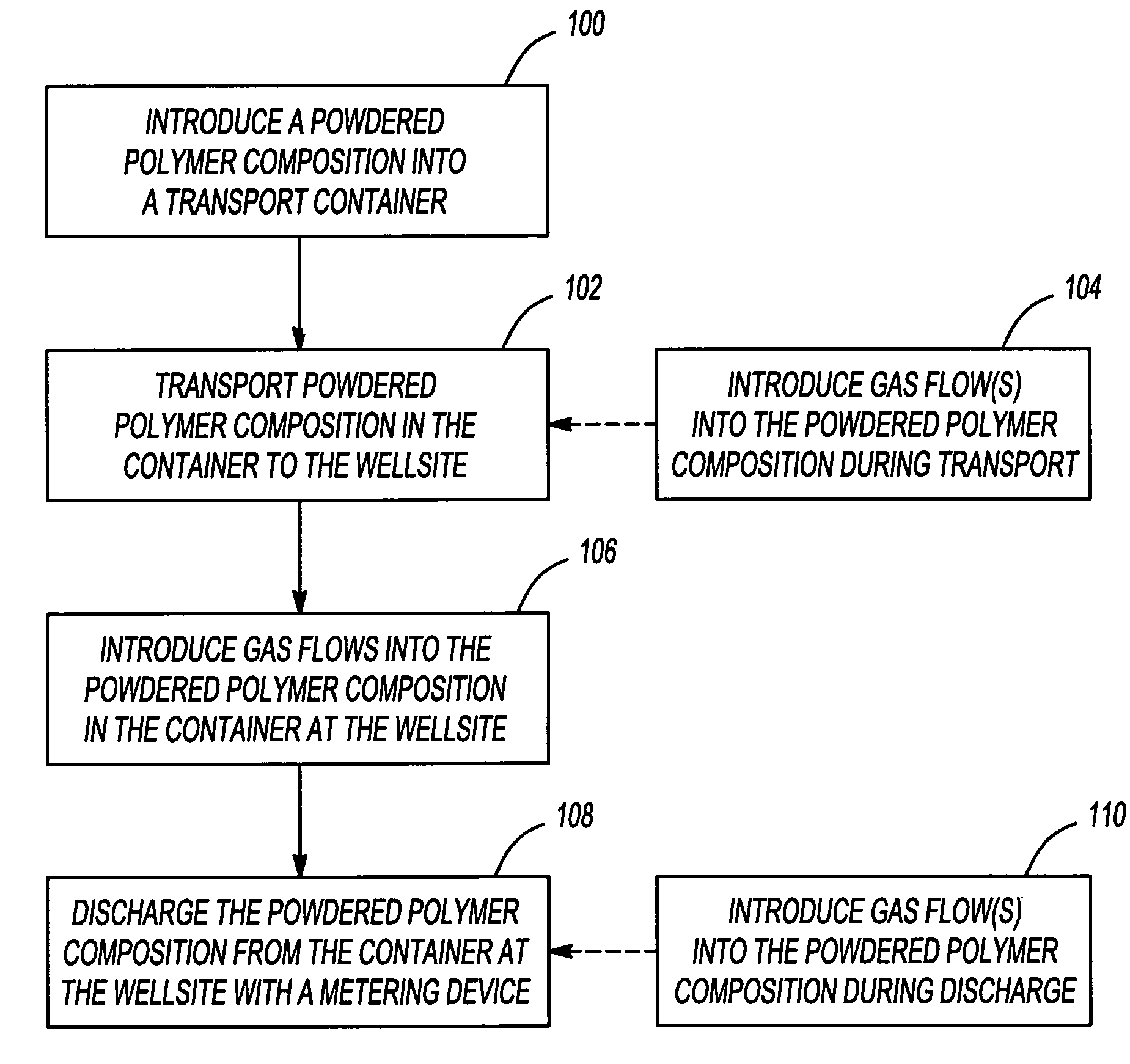

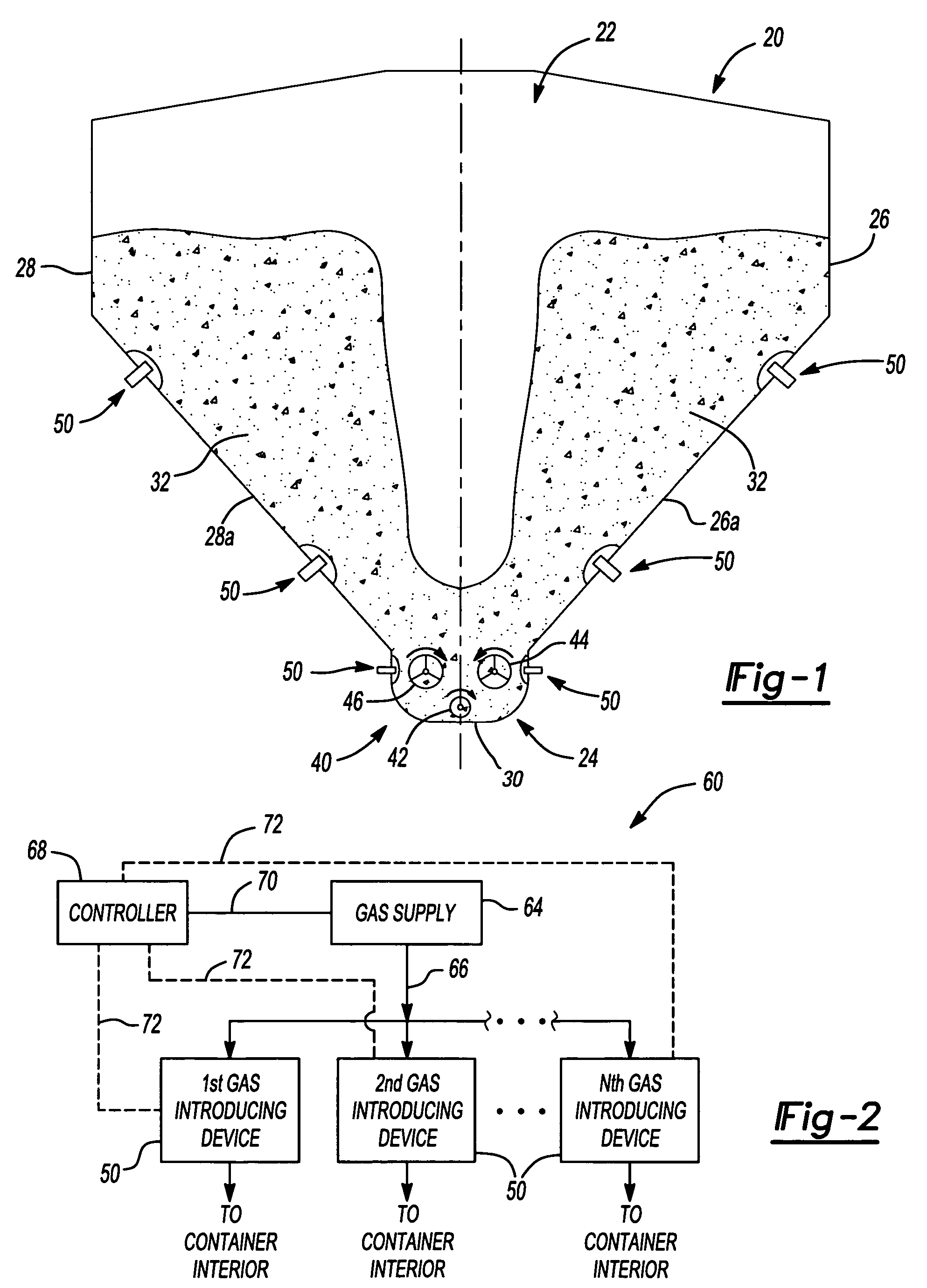

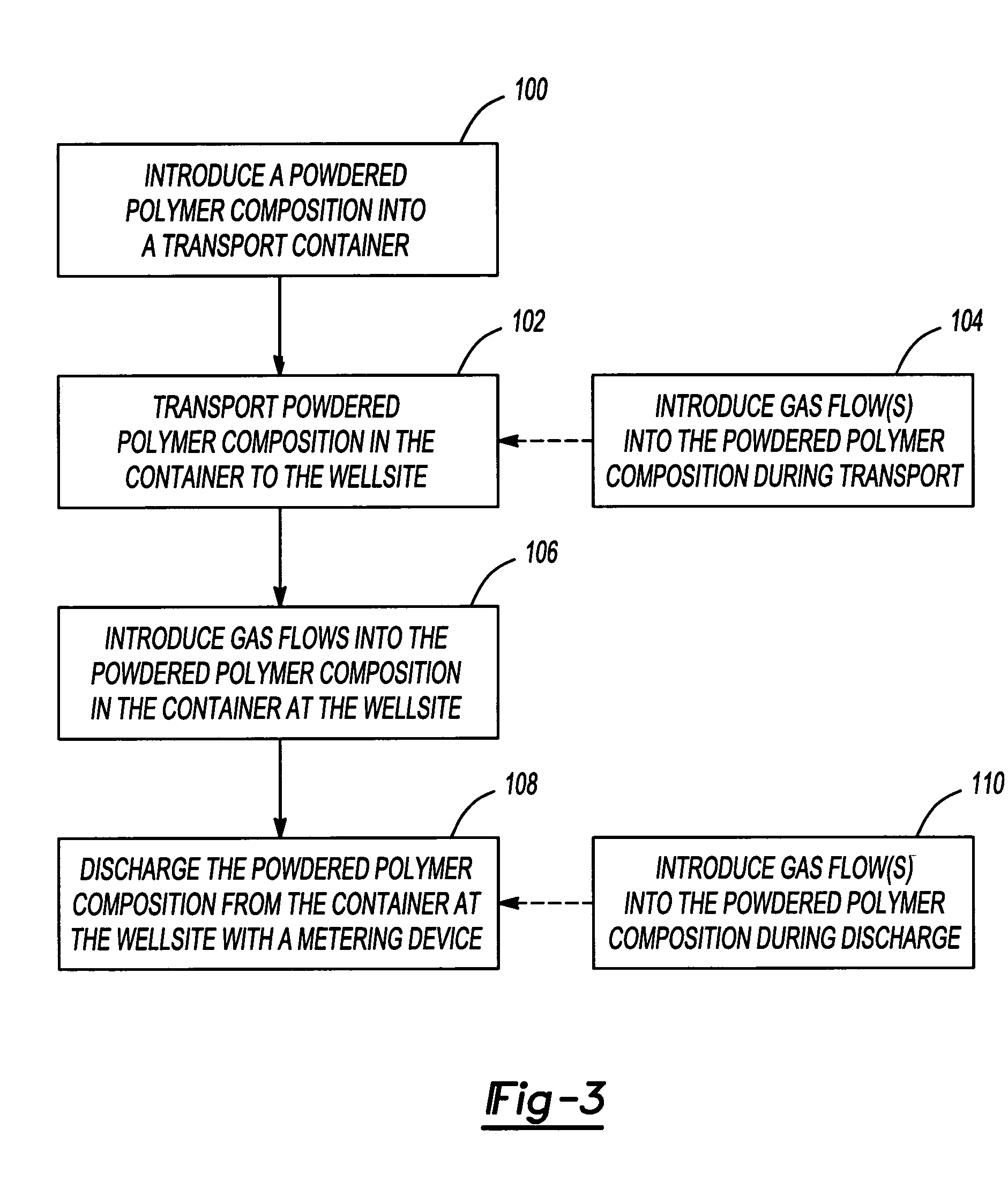

Method of supplying a powdered chemical composition to a wellsite

InactiveUS7540308B2Reduce disadvantagesPrevent the powder chemical composition from adequately flowingFluid removalSolid materialChemical compositionMaterials science

A method of conditioning a compacted polymeric powder to a flowable and meterable state. The polymeric powder is compacted during transport such that the flowability is hindered. To increase flowability, gas is introduced into the polymeric powder to condition the same to an improved flowable and meterable state.

Owner:SCHLUMBERGER TECH CORP

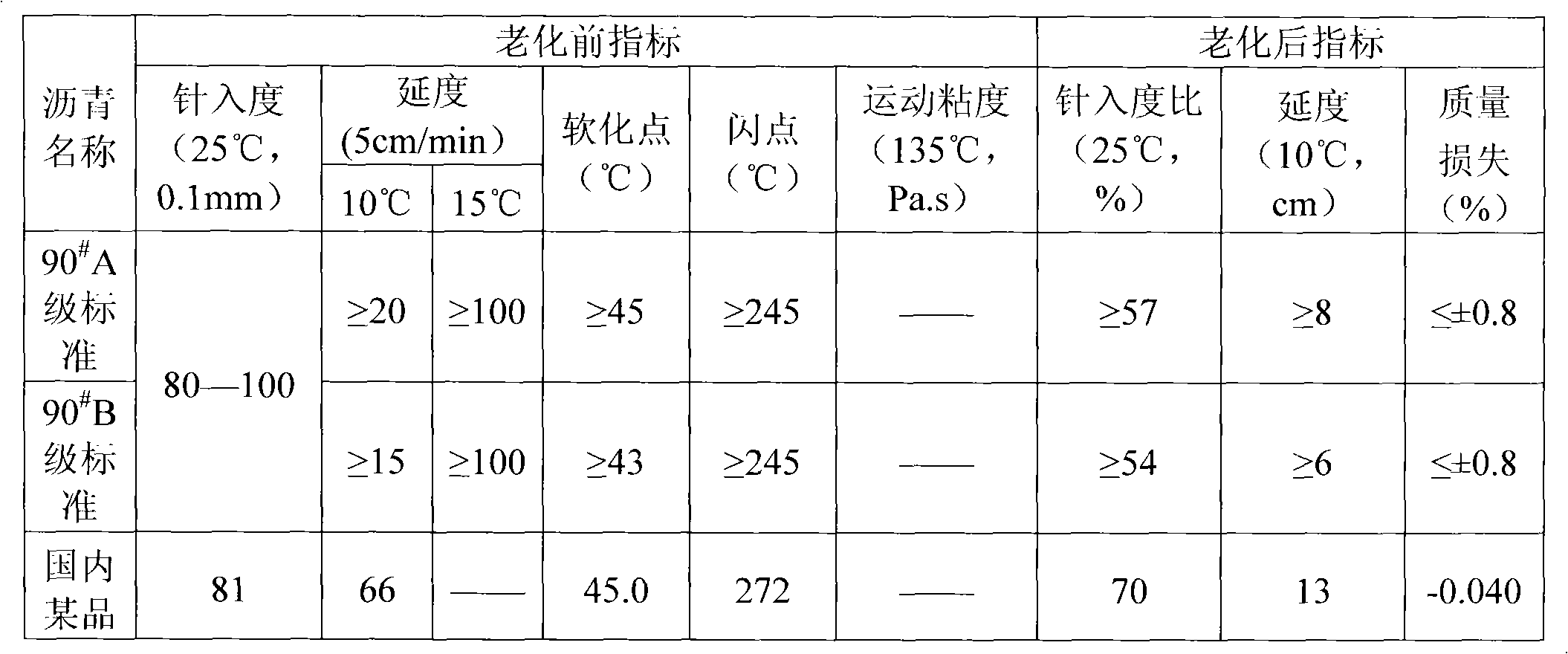

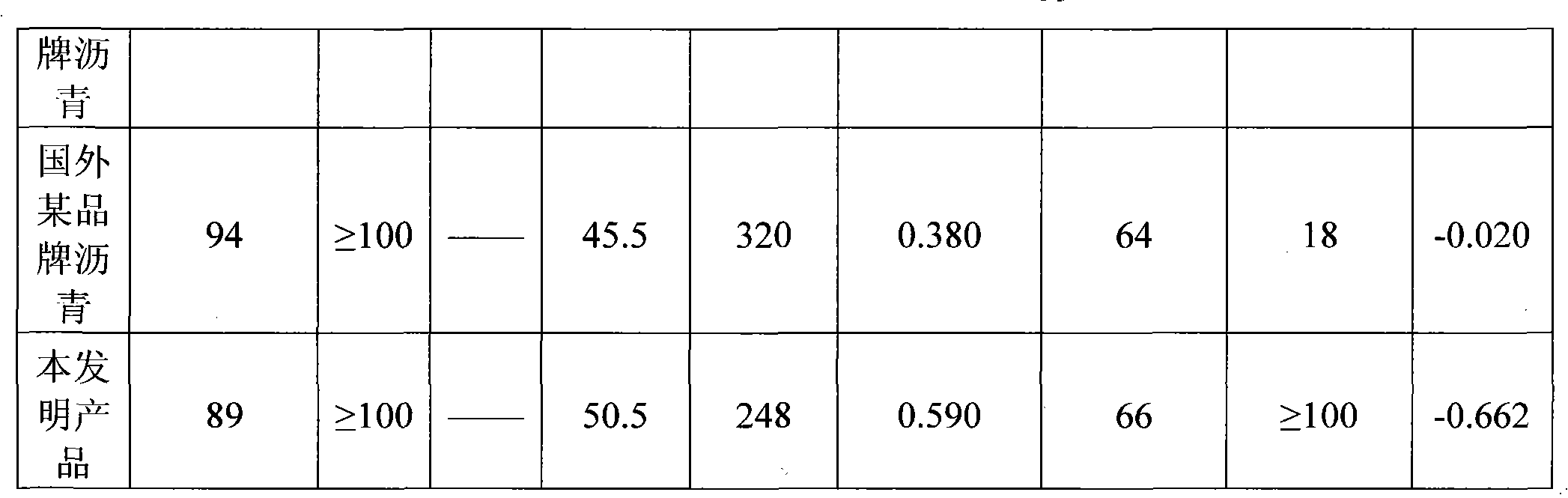

High-quality pavement petroleum asphalt material and preparation method thereof

ActiveCN101629021AImprove flexibilityImprove low temperature performanceBuilding insulationsBituminous materialsPetroleum

The invention discloses a high-quality pavement petroleum asphalt material and a preparation method thereof, belonging to the pavement engineering material technical field. The petroleum asphalt material is prepared from the raw materials according to the parts by weight: 80-95 parts of main asphalt, 5-20 parts of formulated asphalt, 0.01-2 parts of macromolecular crosslinking agent and 0.001-0.25 part of heat stabilizer. The invention adopts chemical crosslinking, heat stabilizer and the combination of cutting and milling to promote the matching of the four components of asphalt to be further optimized and develop in the direction of forming stable colloid structure, improving the pavement performance of the formulated asphalt material and increase the stability of the formulated asphalt product. The invention makes full use of the vacuum residue of residual oil and heavy crude which are treated through vacuum deep extraction and increases the use value so as to reach the effect of resource recycling and environmental protection.

Owner:XIAN ZHONGLI ASPHALT CO LTD

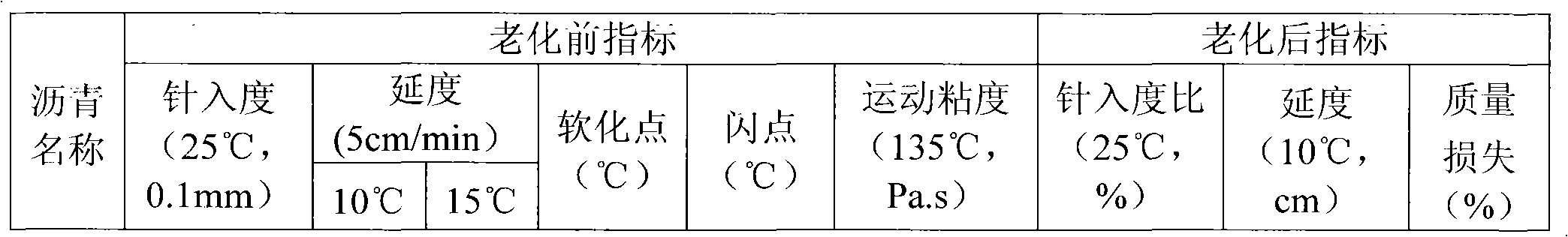

Aluminum alloy composite foil and preparation method thereof

ActiveCN107755427AImprove mechanical propertiesAccelerated corrosionAuxillary arrangementsMetal rolling arrangementsAlloy compositeSoldering

The invention relates to aluminum alloy composite foil and a preparation method thereof. The aluminum alloy composite foil is composed of a core material and two layers of skin materials located on the upper and lower faces of the core material. The core material comprises the components of, by mass, no more than 0.4% of Fe, no more than 0.7% of Si, no more than 0.1% of Cu, 1.1%-1.6% of Mn, no more than 0.03% of Mg, 2.0%-2.5% of Zn, 0.05%-0.15% of Cr, 0.02%-0.08% of Ti, other elements and the balance Al, wherein the single mass percentage of the other elements is less than 0.05%, and the totalmass percentage of the other elements is less than 0.15%. Each skin material comprises the components of, by mass, no more than 0.3% of Fe, 7.5%-9.5% of Si, 0.25%-0.45% of Cu, no more than 0.1% of Mn, no more than 0.03% of Mg, no more than 0.1% of Zn, no more than 0.05% of Cr, no more than 0.05% of Ti, other elements and the balance Al, wherein the single mass percentage of the other elements isless than 0.05%, and the total mass percentage of the other elements is less than 0.15%. The prepared aluminum alloy foil has good mechanical performance and corrosion resistant performance, after soldering, the grain size of the core material is large, and the corrosion depth is small.

Owner:YINBANG CLAD MATERIAL

High-temperature resistant hydrophobic material and preparation method thereof

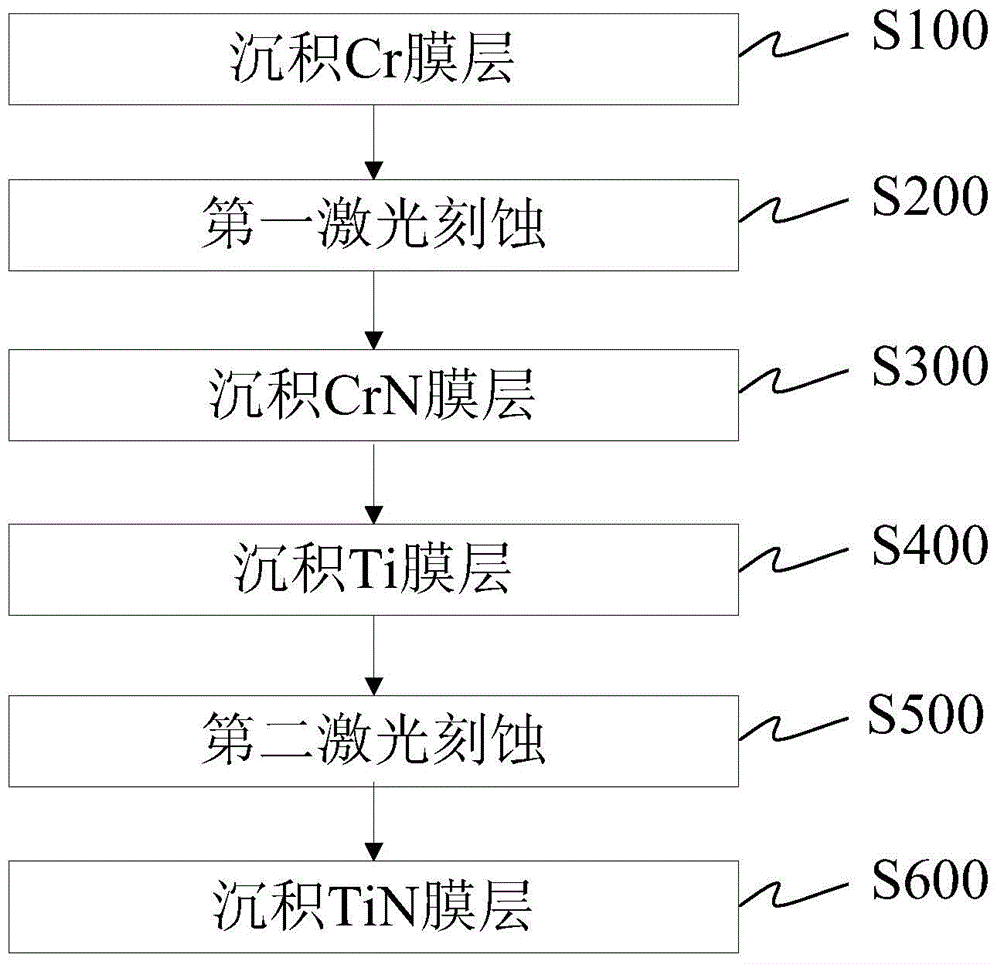

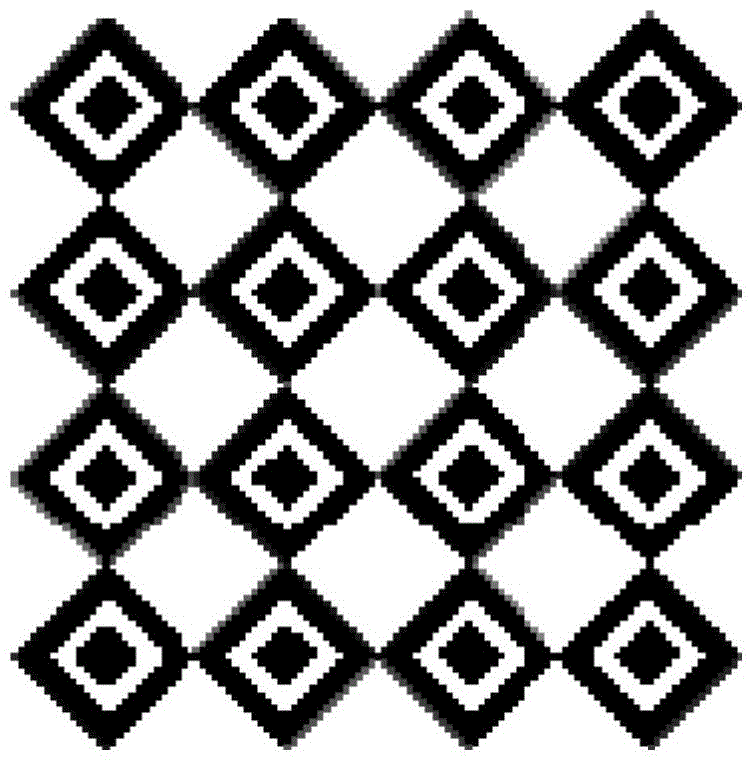

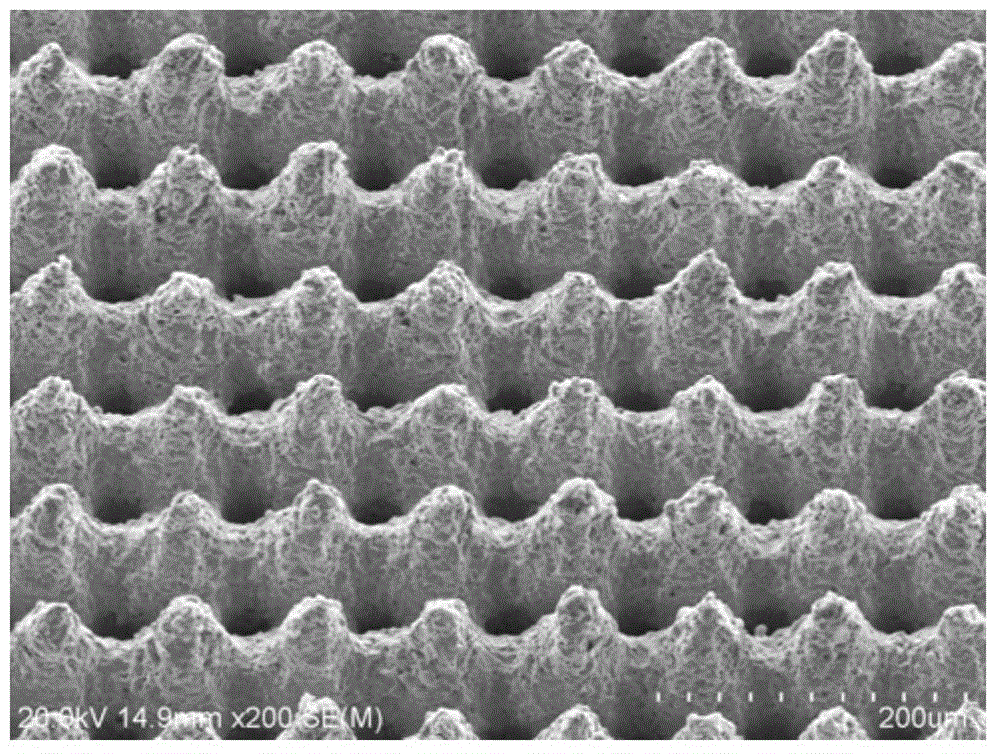

ActiveCN104818454AHigh strengthImprove antioxidant capacityVacuum evaporation coatingSputtering coatingLaser etchingHot Temperature

The invention discloses a high-temperature resistant hydrophobic material and a preparation method thereof; and the preparation method of the high-temperature resistant hydrophobic material adopts a magnetic filter cathode vacuum arc discharge method to deposit multiple film layers on the surface of a workpiece, and adopts a laser etching method to etch a texture on the surface of the workpiece after the deposition of the film layers, wherein the film layer deposition step and the texture etching step are alternately performed. The coating layers, prepared by the method, can improve the high-temperature oxidation resistance of materials while improving the surface hydrophobic performance of metal materials, and are excellent in mechanical performance, high in strength and long in service life. The method adopts the laser etching technology to continuously improve chemical components in the coating layers and local metallurgy state to form specific texture while using the magnetic filter cathode vacuum arc discharge technology to prepare the film layers, so that the oxidation resistance of the coating layers is further improved through the alternately distributed multilayer components.

Owner:BEIJING RES INST OF AUTOMATION FOR MACHINERY IND

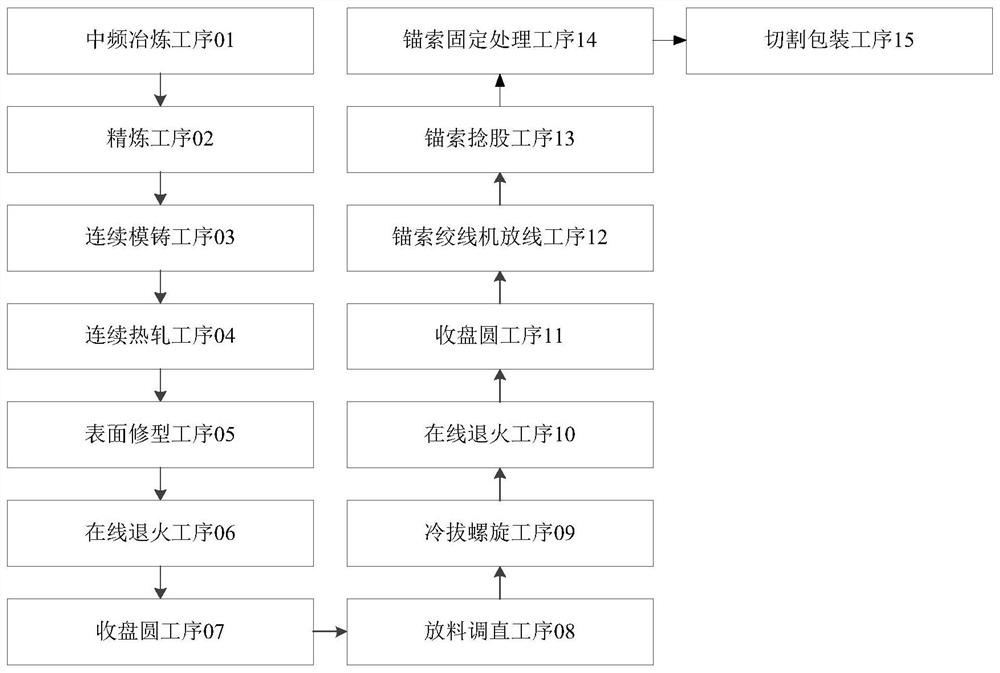

NPR anchor cable material and production method thereof

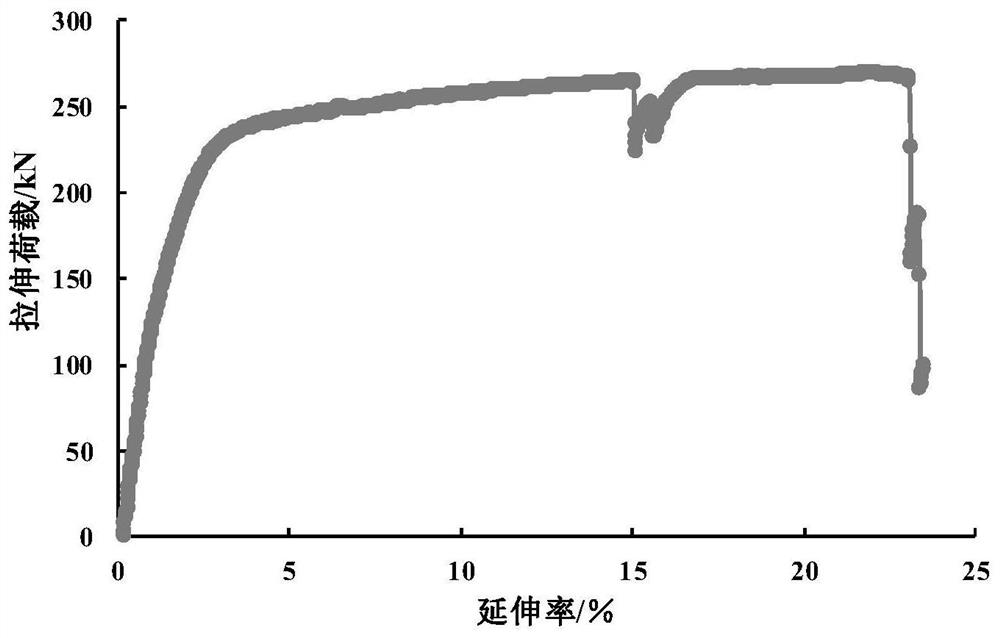

InactiveCN111763890AImprove mechanical propertiesImprove hydrogen embrittlement performanceAnchoring boltsEngineeringUltimate tensile strength

The invention discloses an NPR anchor cable material and a production method thereof. The components of the NPR anchor cable material include, by weight, 0.4-0.8% of C, 15-22% of Mn, 1-5% of Al, 0-1%of NPR crystals, 0-0.3% of Ni, 0-0.3% of Si, 0-0.001% of S, 0-0.001% of P and the balance Fe and inevitable impurity elements. The NPR anchor cable material and the production method thereof can effectively solve the problems that an anchor cable material in the prior art cannot adapt to instant large deformation of surrounding rock under the action of impact force, and the carrying protection capability is lost as the yield strength of the anchor cable material is instantly reached under the action of an impact load.

Owner:何满潮 +2

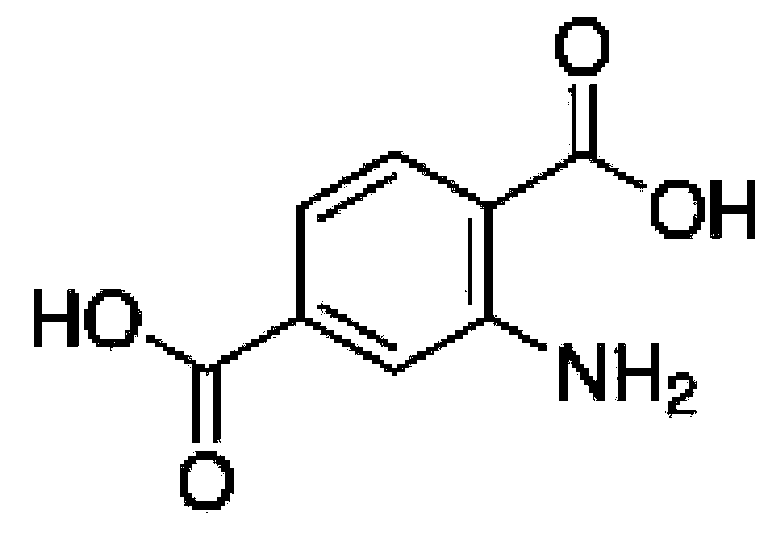

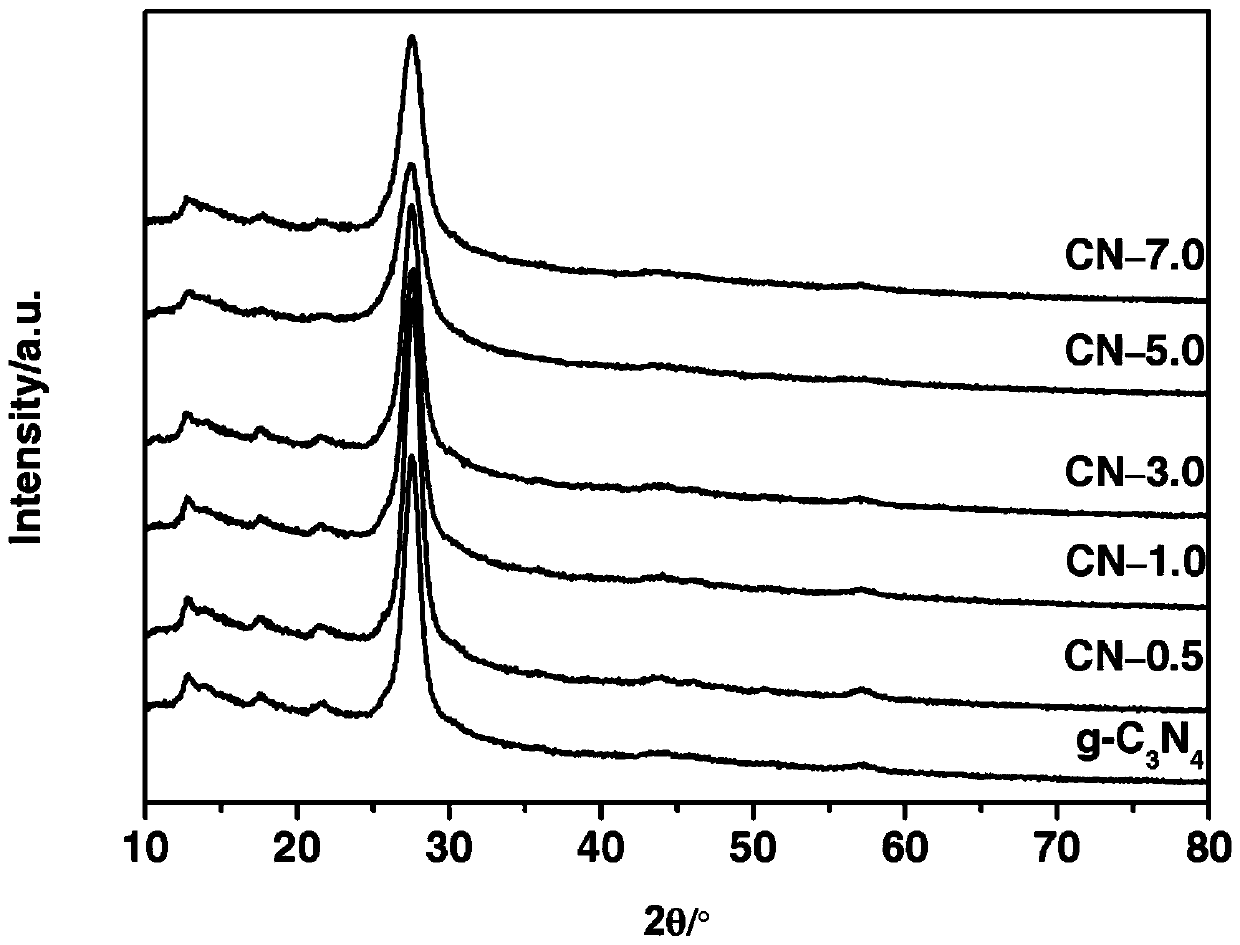

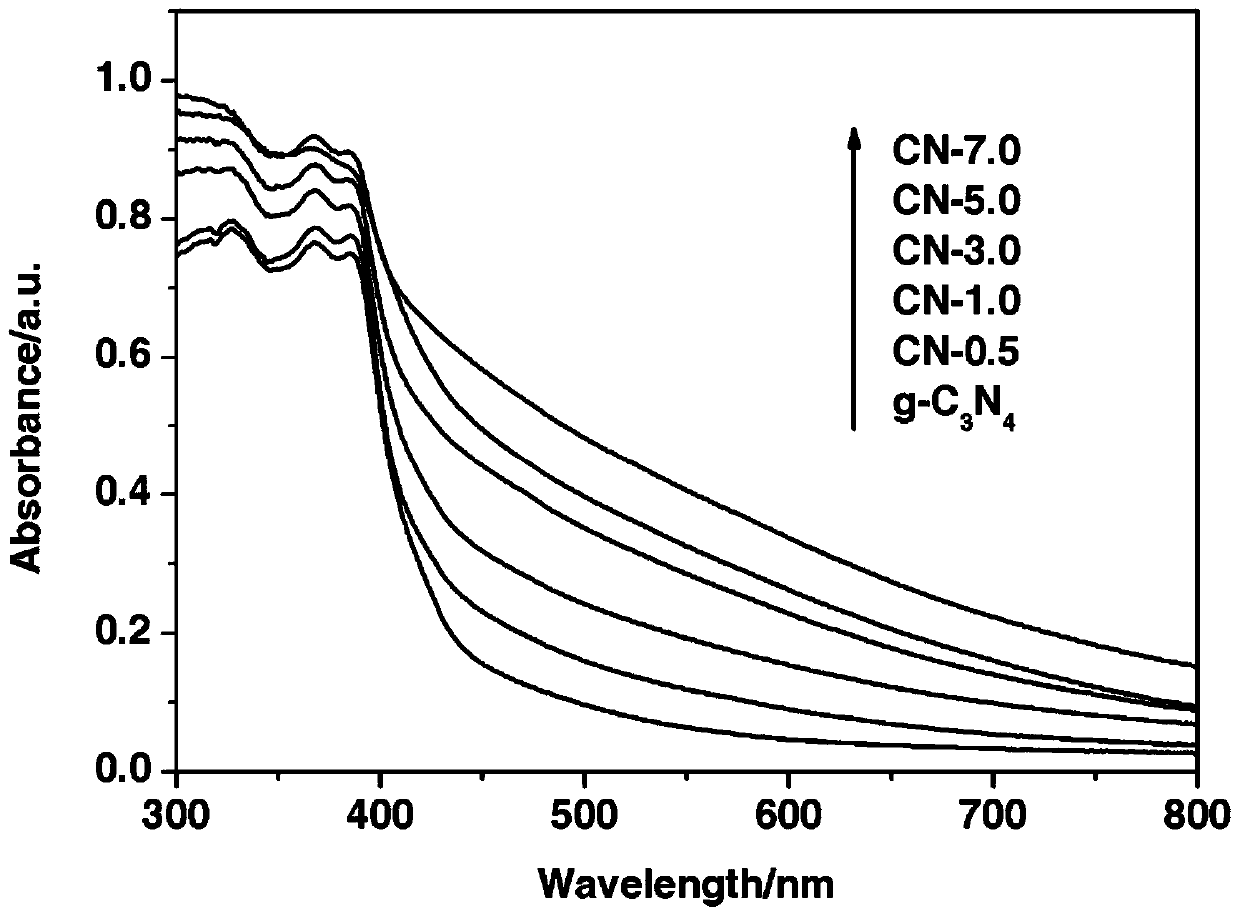

Method for preparing graphite-phase carbon nitride visible-light-induced photocatalyst through copolymerization of 2-aminoterephthalic acid and amine compound

ActiveCN109876841AOptimize chemical compositionImprove separation efficiencyCatalyst activation/preparationHydrogen productionCarbon nitrideGraphite

The invention relates to a method for preparing a graphite-phase carbon nitride visible-light-induced photocatalyst by copolymerization of 2-aminoterephthalic acid and an amine compound. The method comprises the following steps: uniformly mixing the amine compound and the 2-aminoterephthalic acid to obtain mixed powder, and calcining the mixed powder at 520-600 DEG C to obtain the graphite-phase carbon nitride visible-light-induced photocatalyst. The preparation method is simple, and the obtained novel graphite-phase carbon nitride has better visible light catalytic hydrogen production performance compared with original carbon nitride.

Owner:XI AN JIAOTONG UNIV

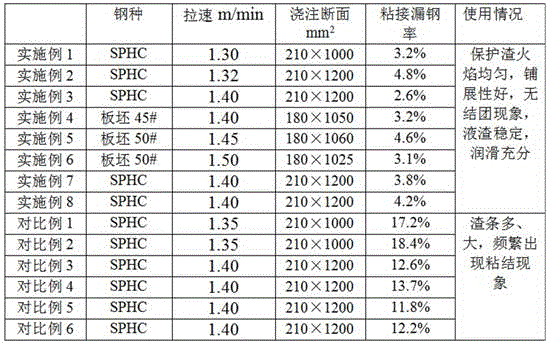

Continuous-casting mold flux for decreasing sticking steel breakouts and preparation method thereof

The invention discloses a continuous-casting mold flux for decreasing sticking steel breakouts and a preparation method thereof. The continuous-casting mold flux for decreasing the sticking steel breakouts comprises the following chemical components of, by weight, 32.5-35.5 percent of SiO2, 29.5-31.5 percent of CaO, 1.5-3.0 percent of MgO, 2.2- 3.0 percent of Al2O3, 0.5-1.5 percent of Fe2O3, 11.0-13.0 percent of Na2O, 10.0-12.0 percent of F-, 3.0-4.0 percent of C solid and the balance unavoidable impurity, wherein the binary basicity is 0.87 to 0.93; a melting point is 1050 to 1070 DEG C; and the viscosity below 1300 DEG C is 0.115Pa*S to 0.135Pa*S. In the practical application of the mold flux, a flame in a crystallizer is uniform; the spreadability is better; caking and agglomerating phenomena do not exist; a melt cinder is stable; the lubrication is sufficient; and the rate of the sticking steel breakouts can be decreased to below 5 percent from original 10 to 20 percent.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

Revitalizing essence comprising prezatide copper acetate and production method thereof

InactiveCN109364005AKeep moistGuaranteed to be smoothCosmetic preparationsToilet preparationsBetaineRadix Ophiopogonis

The invention discloses arevitalizing essence comprising prezatide copper acetate. The revitalizing essence is prepared from the following raw materials in parts by weight: 0.5 to 2 parts of opuntia streptacantha stem extract, 2 to 6 parts of glycerinum, 0.3 to 0.7 part of phenoxyethanol, 1 to 2 parts of hydrolyzed sodium hyaluronate, 2 to 6 parts of radix sophorae extract, 3 to 8 parts of radix ophiopogonis root extract, 3 to 6 parts of trehalose, 1 to 3 parts of moisturizing factors, 1 to 3 parts of lavender oil, 0.1 to 0.3 part of aminomethyl propanol, 1 to 2 parts of 1,2-hexanediol, 1 to 3parts of butanediol, 0.5 to 1 part of glycine betaine, 0.5 to 1 part of PCA sodium, 0.5 to 0.8 part of urea, 0.7 to 1.2 parts of peptide-1 copper, 1 to 2 parts of smithsonite extract, 2 to 4 parts ofxanthan gum, 0.3 to 0.8 part of p-hydroxyacetophenone, 1 to 3 parts of PEG-40 hydrogenated castor oil, and 80 to 100 parts of water. By adopting the revitalizing essence comprising the prezatide copper acetate and the production method thereof, the slack skin is tightened by adding the prezatide copper acetate (peptide-1 copper) in the skincare product, the resilience is improved, the moisturizing effect of the skincare product can be greatly improved by virtue of the opuntia streptacantha stem extract, and the revitalizing essence is non-irritating to the skin and is convenient for people touse.

Owner:朝日化妆品(深圳)有限公司

Method for improving moisture retaining performance of paper-making reconstituted tobaccos with modified tobacco stem extract

ActiveCN106579536AOptimize chemical compositionImprove qualityTobacco preparationChemical compositionAlcohol

The invention provides a method for improving the moisture retaining performance of paper-making reconstituted tobaccos with modified tobacco stem extract. The method comprises the following steps: adding ammonium hydroxide into tobacco stem extract to adjust the pH value of the system; adding sugar, amino acid and polyhydric alcohols, uniformly stirring and mixing, heating to a certain temperature, reacting for 1.5 hours, and cooling for later use; and adding the mixed liquid obtained in reaction into the paper-making reconstituted tobaccos as a coating solution, and keeping the reacting temperature at 130 DEG C. The method adopts the chemically modified tobacco stem extract to improve the chemical composition of the tobacco stem extract for the first time, so that the moisture retaining performance of the paper-making reconstituted tobaccos can be remarkably improved; and the reacting temperature is critical to the reaction, varieties and proportions of the reacting product obtained at over low or over high temperature are entirely different, and the quality and moisture retaining performance of flakes can be improved by the reaction product, namely modified tobacco stem liquid only when a proper reacting temperature is selected. The method is easy and feasible to operate, has the advantages of wide raw material source and low cost, and can remarkably improve the quality of paper-making reconstituted tobaccos.

Owner:CHINA TOBACCO JIANGSU INDAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com