Degradable polymer filmcoated controlled release fertilizer, preparation thereof and special filmcoated material

A coating material and controlled-release fertilizer technology, which is applied in the field of new degradable polymer-coated controlled-release fertilizers, can solve the problems of low utilization rate of coating raw materials, affect the controlled-release performance, and low mixing degree, and achieve a good environment. The effect of degradability, economical and feasible preparation process and high degree of operation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

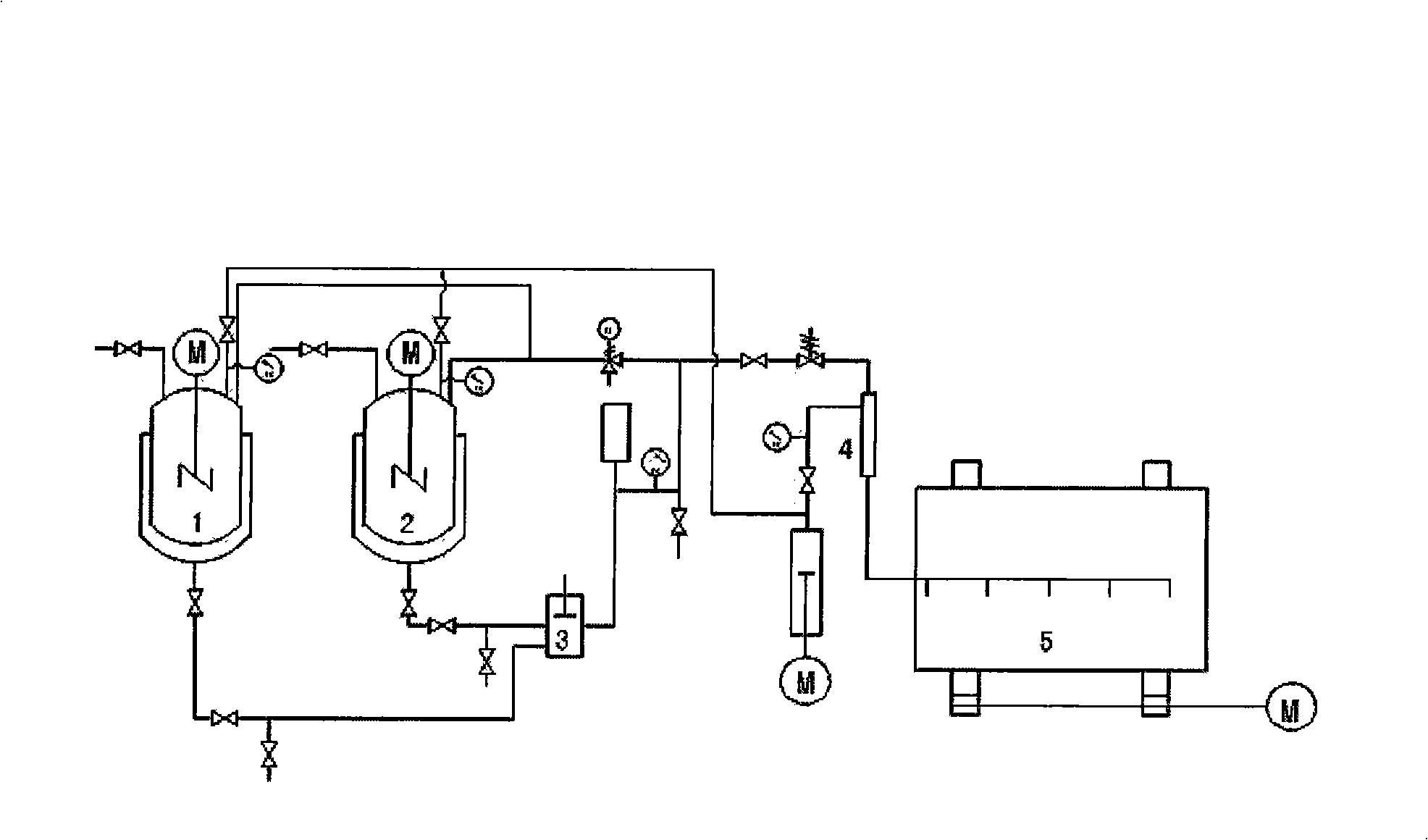

Image

Examples

Embodiment 1

[0059] Weigh 10 kg of large granular urea with a particle diameter of 3 mm, place it in the drum, turn on the heating switch of the drum, and preheat the fertilizer until the temperature is constant at 85° C. Weigh 150 g of diphenylmethane diisocyanate (MDI), add 60 g of paraffin (film-forming agent), and place it in a heating kettle to melt and keep the temperature at 75°C. Weigh 210g of polyether polyol series (Type 635 of Jingzhou Longhua Petrochemical Company), 20g of 2,3-butanediol (chain extender), 20g of tannin (degradable functional monomer), and place in a heating kettle to melt at constant temperature 90°C. Then open the vent valve of the proportional pump, and then open the pump inlet valve, so that the two-component liquid is mixed through the high-efficiency mixer, adjust the pressure of the pump to 0.1Mpa, and the total spray rate is 0.15 liters / minute, and start spraying. After continuous spraying for 3 minutes, stop spraying, keep warm at 90° C., react for 8 m...

Embodiment 2

[0061]Weigh 10Kg of the 16-16-16 Russia Akon compound fertilizer, place it in the drum, turn on the heating switch of the drum, and preheat the fertilizer until the temperature is constant at 85°C. Weigh 100 g of hexamethylene diisocyanate (HDI), add 80 g of rosin ester (film-forming agent), and place it in a heating kettle to melt at a constant temperature of 75°C. Take by weighing castor oil 260g, 1,4-butanediol 20g (chain extender), regenerated cellulose 30g (degradable functional monomer), and add 0.1g diethylenetriamine (catalyst), place heating kettle The medium melting temperature is 80°C. Then open the air release valve of the proportional pump, and then open the pump inlet valve to mix the two-component liquids. After mixing by the high-efficiency mixer, adjust the pump pressure to 0.1MPa, and the total spray rate to 0.15 liters / minute, and start spraying. Spray continuously for 12 minutes each time, then keep warm for 4 minutes and continue spraying until the coatin...

Embodiment 3

[0063] Weigh 10Kg of 15-15-15 Sacofu compound fertilizer, put it in the drum, turn on the heating switch of the drum, and preheat the fertilizer until the temperature is constant at 85°C. Weigh 200 g of toluene diisocyanate (TDI), add 140 g of sulfonated paraffin (film-forming agent), and place it in a heating kettle to melt at a constant temperature of 70°C. Take polybutylene adipate 420g, 1,6-hexanediol (chain extender) 40g, chitosan (degradable functional monomer) 65g, and add 0.1g stannous octoate (catalyst), place Melt in a heating kettle at a constant temperature of 80°C. Then open the vent valve of the proportional pump, and then open the pump inlet valve to mix the two-component liquid through the high-efficiency mixer, adjust the pump pressure to 0.1MPa, and the total spray rate to 0.075 liters / minute, and start spraying. Continuous spraying for 6 minutes, until the coating solution is completely sprayed, stop spraying, keep warm at 90°C for 10 minutes, cool down, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com