Enterococcus azikeevi EO-07 and application thereof in ethylene oxide degradation

A technology of ethylene oxide and enterococcus, applied in the direction of bacteria, microorganism-based methods, methods using microorganisms, etc., can solve the problems of high biological toxicity, complex microenvironment of microbial degradation pool, and influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

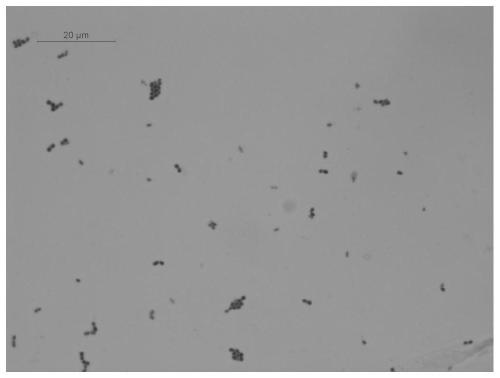

[0068] Enrichment, screening and identification of EO-07 original strain

[0069] Weigh 10.0 g of sludge sample, add 100 mL of 0.03 mol / L phosphate buffer, mix and clarify for 120 min, and remove large particles of sediment. Take 1mL of the suspension and add 10mL of enrichment enrichment liquid medium (containing 100mg / L low concentration of ethylene oxide), put it on a shaker for oxygen consumption enrichment culture at 200r / min, and incubate at 37°C for 24-48h Observe the growth.

[0070]This example enrichment enrichment liquid medium (Sabouraud liquid medium): Glucose 40g, casein trypsin digest, gastric enzyme digest of animal tissue equal mix 10g, pH5.4~5.8, distilled water 1000mL, aliquot to 500mL Erlenmeyer flasks, 250mL for each Erlenmeyer flask. Sterilize at 121°C for 20 minutes and cool to room temperature. Take out the ice box from the refrigerator, and place the reagent pure ethylene oxide on the ice box. Use a sealed syringe to draw 28 μL of ethylene oxide li...

Embodiment 2

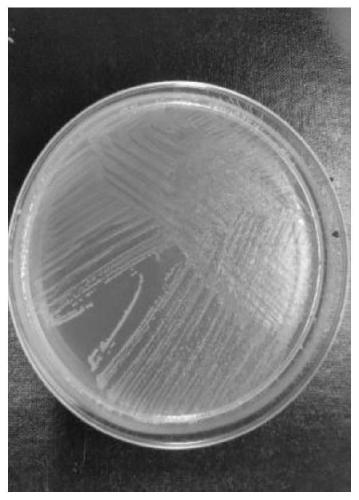

[0086] Ethylene oxide-induced domestication of EO-07 original strain

[0087] Ethylene oxide tolerance-induced acclimatization: using the streaking method, inoculate EO-07 original strains in a 100mg / L ethylene oxide-tolerant acclimatization medium, and culture at a constant temperature of 37°C for 48 hours; select the one with the largest colony radius on the plate Single colony, subculture to 200mg / L ethylene oxide tolerance acclimatization medium, 37 ℃ constant temperature culture for 48h; select the single colony with the largest colony radius on the plate, subculture to 500mg / L ethylene oxide tolerance and acclimatization culture medium at a constant temperature of 37°C for 48 hours; select the single colony with the largest colony radius on the plate, subculture to a tolerance acclimatization medium containing 800 mg / L ethylene oxide, and cultivate at a constant temperature of 37°C for 48 hours to obtain high-concentration ethylene oxide tolerance Receptor species.

[0...

Embodiment 3

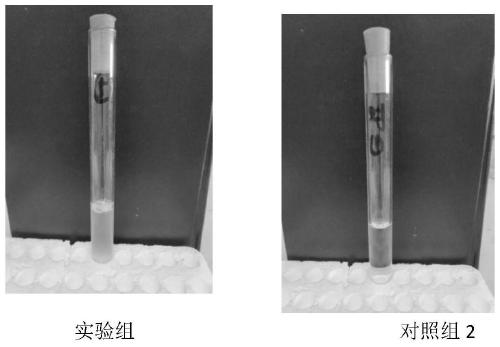

[0094] Identification of Ethylene Oxide Degradation Effect of EO-07 Strains

[0095] Microbial culture and activation: Take out EO-07 strains and EO-07 original strains from the -80°C refrigerator, take 10 μL and inoculate them into 100 mL Sabouraud liquid medium, culture at 37°C, 200 rpm, for 48 hours. The number of bacteria in the culture solution is 10 10 ~10 12 cfu / mL.

[0096] Sabouraud liquid medium: Glucose 40g, casein trypsin digest, animal tissue gastric enzyme digest equal mixture 10g, pH5.4~5.8, distilled water 1000mL, divided into 500mL Erlenmeyer flasks, each Erlenmeyer flask 250mL. Sterilize at 121°C for 20 minutes and cool to room temperature.

[0097] Sabouraud's liquid induction medium: 10g of peptone, 1000mL of distilled water, aliquoted into 400mL, sterilized at 121°C for 20min, cooled to room temperature for storage. Before use, add 160 mg of ethylene oxide with a sealed syringe to make a liquid medium containing no carbon source but containing 400 mg / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com