Stone paper corrugated board and manufacturing method thereof

A technology of corrugated cardboard and stone paper, which is applied in the field of stone paper corrugated cardboard and its manufacturing, can solve problems such as not proposed and limitations of corrugated cardboard, and achieve the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

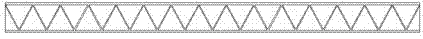

[0037] Embodiment 1: the manufacture of U-shaped stone paper composite corrugated cardboard

[0038] 1. Stone paper raw material granulation U-shaped stone paper composite corrugated cardboard with 75 parts of natural inorganic mineral powder (mainly composed of calcium carbonate, also includes calcium sulfate, barium sulfate, mica powder, zinc oxide, dolomite powder, talcum powder, Silicon oxide, etc.) as the main raw material, with 20 parts of HDPE (high-density polyethylene), 2.3 parts of modifiers (including 0.8 parts of aluminate, 1 part of JL-G modifier, 0.5 parts of stearic acid), 2.1 parts Parts of processing aids (including 0.6 parts of polyvinyl ester CH-4, 1.5 parts of paraffin wax 56#), 2 parts of functional aids (calcium carbonate modified whitening agent). In this stage, the raw material of stone paper corrugated board is manufactured into pellets. First, 75 parts of natural inorganic mineral powder (including calcium carbonate, calcium sulfate, barium sulfate, ...

example 2

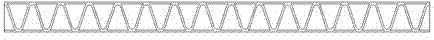

[0042] Example 2: Manufacture of UV type stone paper composite corrugated board

[0043] The manufacture of UV-type stone-paper composite corrugated board is basically the same as that of the U-shaped stone-paper composite corrugated board in Example 1 above. The differences can be explained in two parts: raw materials and manufacturing process.

[0044] In terms of raw materials, UV-type stone paper composite corrugated cardboard uses 80 parts of natural inorganic mineral powder (the main component is calcium carbonate, and also includes calcium sulfate, barium sulfate, mica powder, zinc oxide, dolomite powder, talcum powder, silicon dioxide, etc.) As the main raw material, with 20 parts of HDPE, 2.3 parts of modifiers (including 0.8 parts of aluminate, 1 part of JL-G modifier, 0.5 parts of stearic acid), 2.1 parts of processing aids (including 0.6 parts of polyethylene Ester CH-4, 1.5 parts of solid paraffin wax 58#) and 2.1 parts of functional additives (1.5 parts of titani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com