Patents

Literature

81results about How to "No white pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Degradable polymer filmcoated controlled release fertilizer, preparation thereof and special filmcoated material

ActiveCN101323545AHas the ability to degradeAchieve friendlyFertilizer mixturesControl releasePolyol

The invention discloses a polymer coated released fertilizer and a preparation method thereof and a special coating material thereof. The coating material comprises isocyanate, polyol, degradable functional monomer, an aid agent of coating and a chain extender, wherein, the mol ratio between the isocyano group in the isocyanate and the hydroxyl group in the polyol is 1:2 to 2:1 and the mass of the degradable functional monomer is 1 percent to 20 percent of the mass of the coating material. The coated released fertilizer provided by the invention consists of a core and a karyotheca, wherein, the core is granule fertilizer and the karyotheca is prepared from the coating material, and the mass of the karyotheca is 2 percent to 10 percent of the mass of the core. The coating material has good film forming and water resisting performance and can be degraded in nature. The hardness and the elasticity of the material can be adjusted by changing the mixure ratio of the coating material so as to prepare released fertilizers with different releasing periods.

Owner:CNSG ANHUI HONG SIFANG FERTILIZER IND CO LTD

Material capable of completely biodegrading and preparation method thereof

The invention relates to a material capable of completely biodegrading, containing the following parts by weight:100 of polyester resin, 5-100 of polylactic resin and the multipolymer thereof, 10-80 of compounding converted starch, 10-60 of inorganic fillers and 0.1-0.9 of resin acceptor, wherein the polyester resin is at least one of polybutylene succinate resin, polybutylene adipate resin and the multipolymer thereof. The invention also provides a preparation method of the material. The material capable of completely biodegrading can combine the advantages of each component and has high intensity, modules, elongation at break and toughness, good heat resistance, and the like, thereby meeting the property requirements of a plurality of plastic products in the market and in particular products, such as non-returnable containers, mess kits, agricultural films, and the like, which cause serious white pollution, retaining the complete biodegradability of the material and reducing the production cost under the precondition of no influence on the property requirement.

Owner:深圳市未名北科环境材料有限公司 +1

Blow molded polyvinyl alcohol membrane and production method thereof

The invention provides a polyvinyl alcohol membrane. The polyvinyl alcohol membrane is produced through blow molding of melt-processible polyvinyl alcohol resin, the tensile strength of the polyvinyl alcohol membrane is not lower than 20 MPa, the melt-processible polyvinyl alcohol resin comprises effective amounts of polyvinyl alcohol, a plasticizer, soft water and a processing assistant, the degree of polymerization (DP) of the polyvinyl alcohol is 1000-3500, the degree of hydrolysis (DH) of the polyvinyl alcohol is greater than 72 (mol)% and is smaller than 99.9 (mol)%, the plasticizer is at least one of glycerol, polyethylene glycol and triethylene glycol di-2-ethylhexoate, and the processing assistant is at least one of talcum powder, silica, oleamide and saturated aliphatic dicarboxylate. The method has the advantages of simple process, less device investment, small occupied area, and realization of blow molding of normal-temperature, medium-temperature and high-temperature water soluble membranes. The method is mainly used for producing double-layer membranes, and the membranes can be directly processed to produce various water-soluble bags, and the water-soluble bags are used in the field of medium and low end packaging application, and can be used as a pesticide and chemical engineering product inner packaging liner bag, a hospital washing packaging bag and a refuse bag.

Owner:CHINA PETROCHEMICAL CORP +2

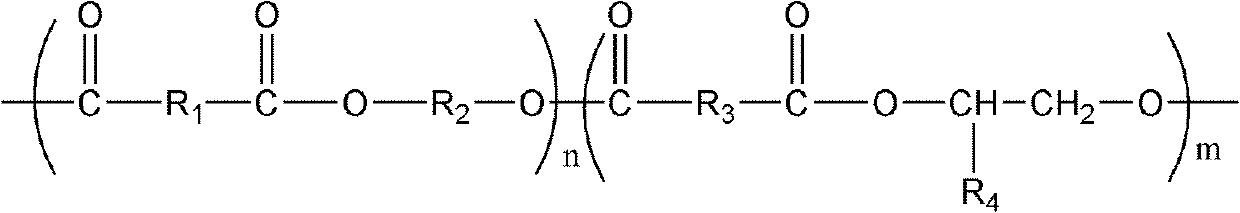

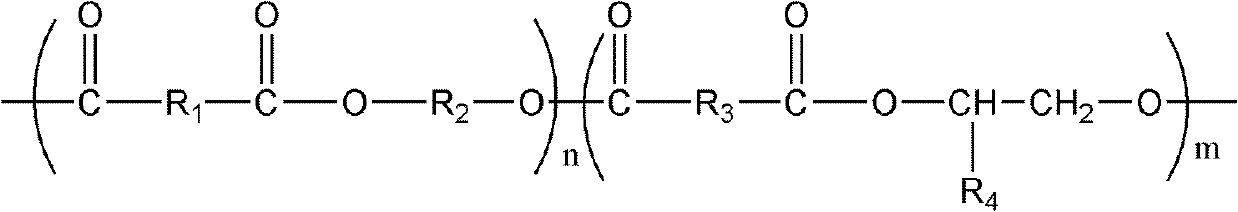

Biodegradable polyester and its preparation method

The invention belongs to the field of polymer material technology, and discloses a biodegradable polyester and its preparation method. The inventive biodegradable polyester has the following repeated unit structure, wherein n=1-1,000, M=1-1,000, o=0-11, P=2-13, q=0-11, and r=0-10. The prepared product has excellent processing performance and mechanical performance and outstanding biodegradability, and can be used to substitute for the widely used PE plastic film.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

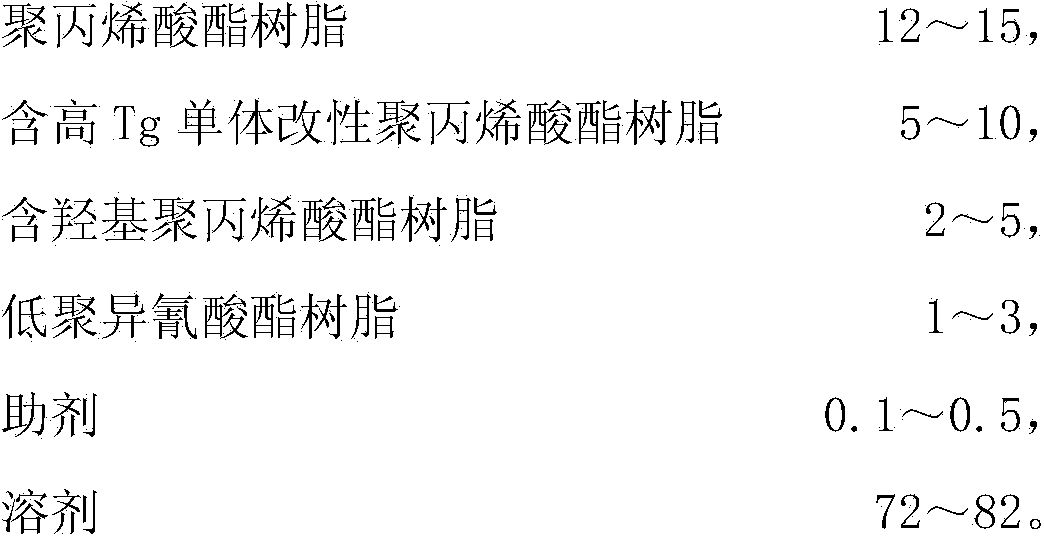

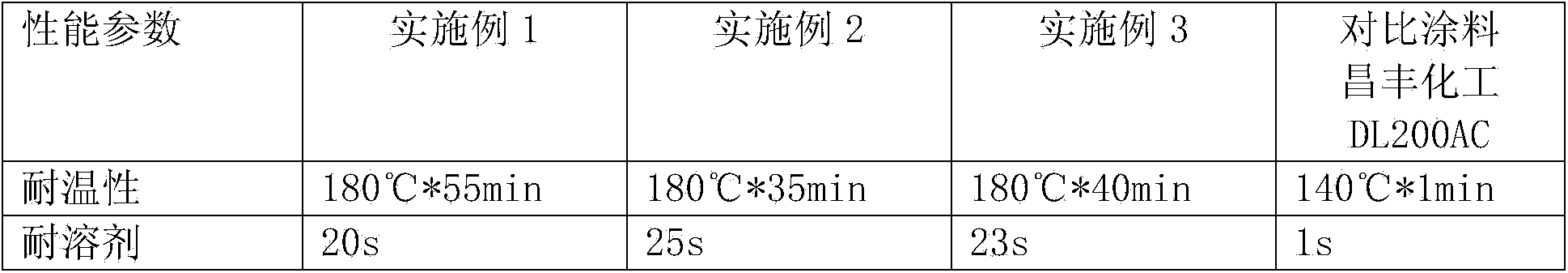

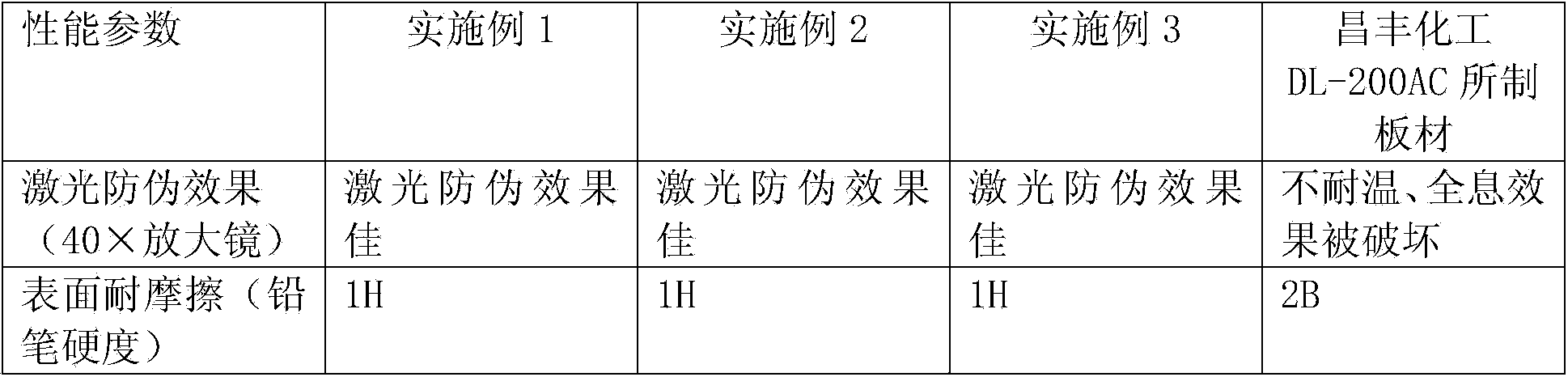

Coating composition for transferable laser anti-counterfeiting plate and method for preparing transferable laser anti-counterfeiting plate

ActiveCN103555113AHigh hardnessMeet high temperature resistance requirementsAnti-corrosive paintsPolyurea/polyurethane coatingsAdhesivePolyethylene glycol

The invention discloses a coating composition for a transferable laser anti-counterfeiting plate and a method for preparing the transferable laser anti-counterfeiting plate. The coating composition comprises the following components in parts by weight: 2-15 parts of polyacrylate resin, 5-10 parts of high-Tg-monomer-containing modified polyacrylate resin, 2-5 parts of hydroxyl-containing polyacrylate resin, 1-3 parts of low polyisocyanate resin, 0.1-0.5 part of aid and 72-82 parts of solvent. The method for preparing the transferable laser anti-counterfeiting plate comprises the following steps: coating the coating composition on a polyethylene glycol terephthalate (PET)-based film, performing die pressing, plating aluminum, coating and transferring a heat-seal adhesive, and preparing a transferable film; stripping the PET-based film on the transferable film, compounding the coating composition to a coil base material, and preparing the transferable laser anti-counterfeiting plate. The coating composition can meet high solvent-resistant and temperature-resistant temperatures in the production process of laser anti-counterfeiting plates. Moreover, the PET-based film used by transferable color steel can be repeatedly used, environment friendliness is promoted, and the production cost is reduced.

Owner:SHANGHAI WEIKAI CHEM +1

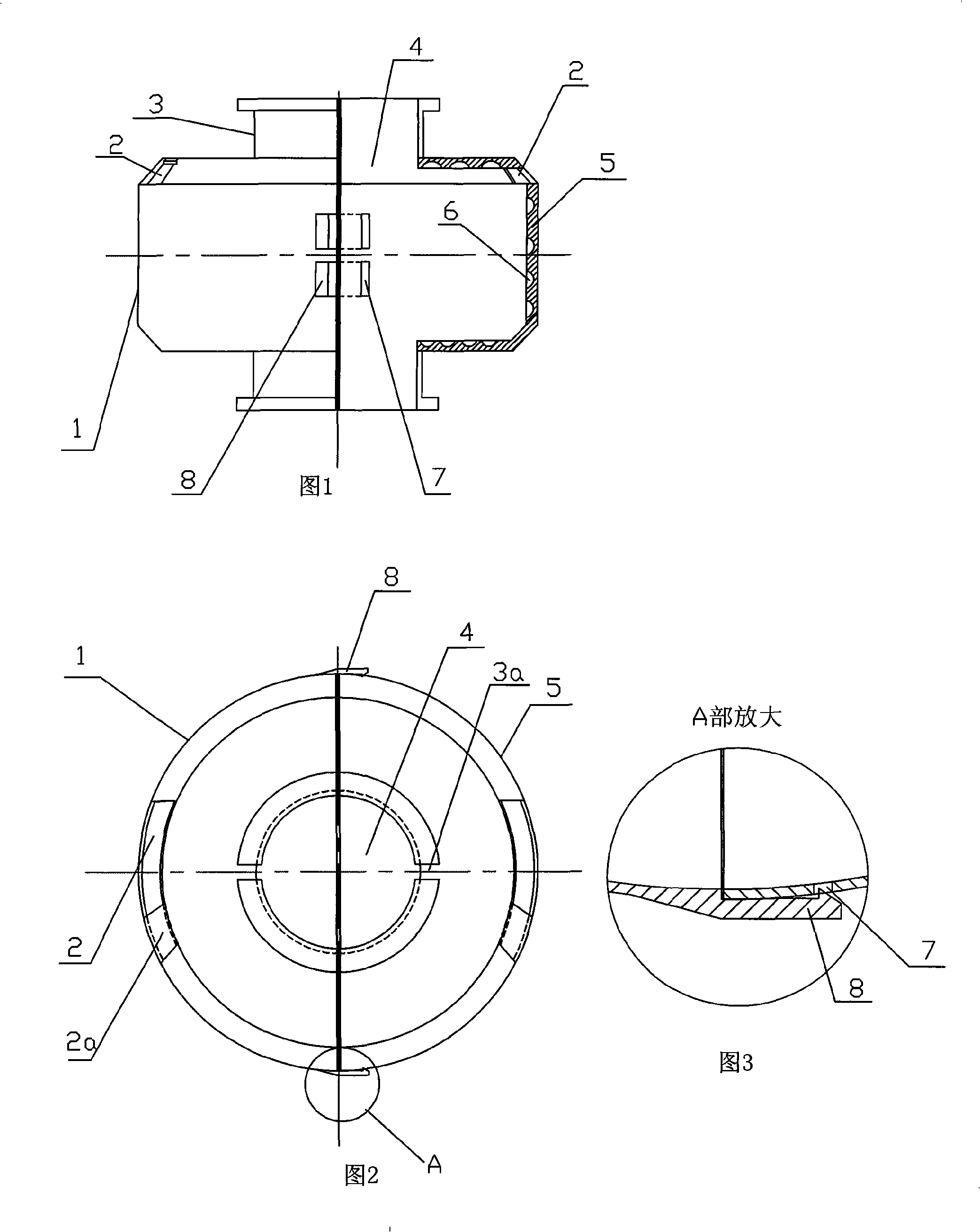

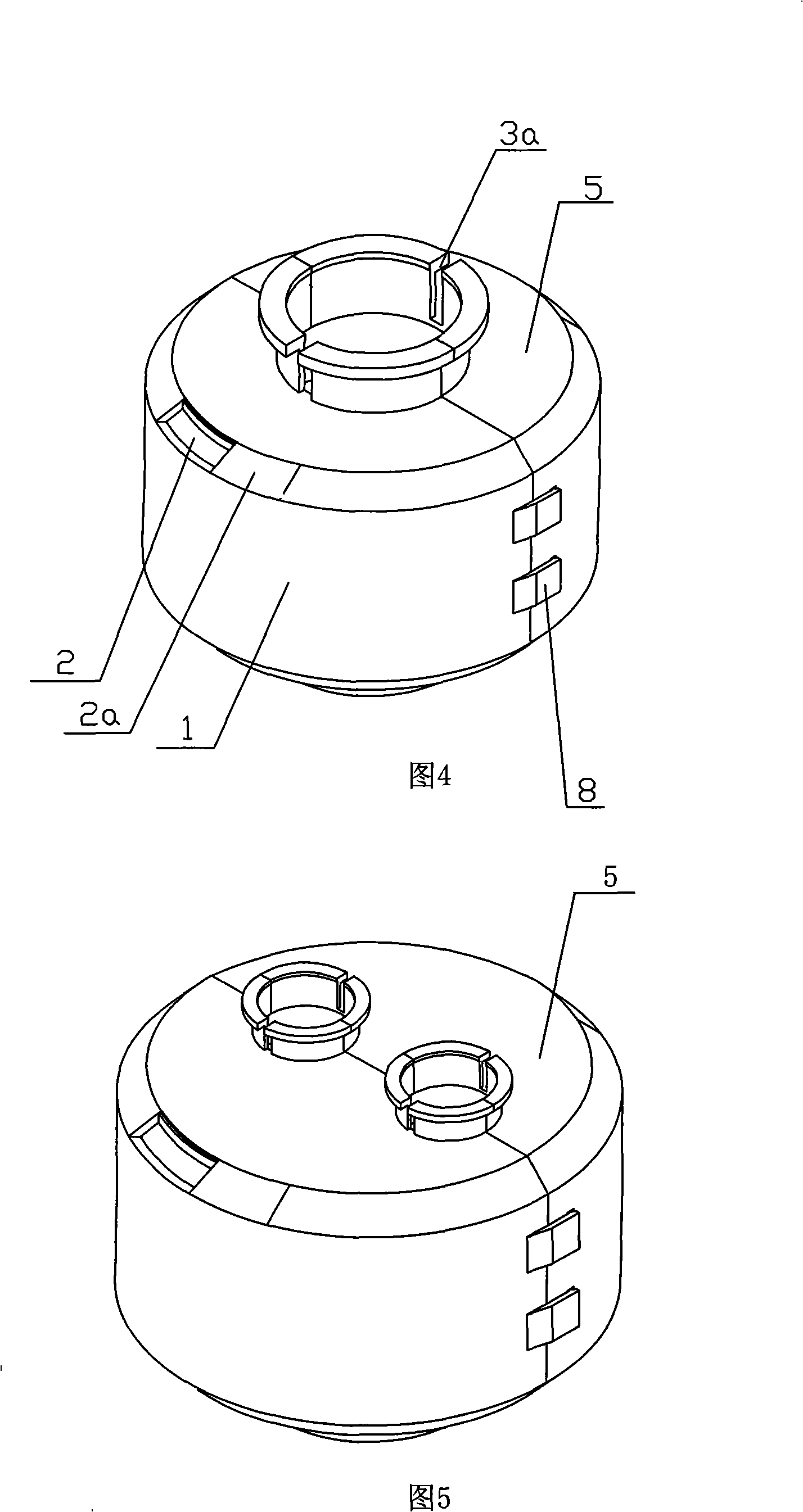

Plant press strip device

InactiveCN101401529ANo white pollutionEasy to operateCultivating equipmentsHorticultureNeck partsRoot system

The invention provides a layering machine for layering propagation of plants. The layering machine comprises two half shells (1 and 5), wherein one to two elastic claws (8) and corresponding clamping grooves (7) are arranged on the half shells, so that the two half shells form a hollow shell; two ends of each half shell are provided with a half neck part (3) respectively to form a neck part for enclosing and fixing branches of the plants; the half shells are provided with a feed inlet (2) respectively; and the inner walls of the half shells are provided with a group of drop pits (6) respectively. The layering machine has the advantages that the layering machine can be used repeatedly; management such as water replenishing, fertilizer applying and so on is convenient; the layering machine has good ventilation and drainage performances and accelerates the root growing speed; pocking marks make root systems run through a substrate to and fro, and make root balls compact; and the layering machine is convenient to transport due to small root systems and light weight.

Owner:杨成林

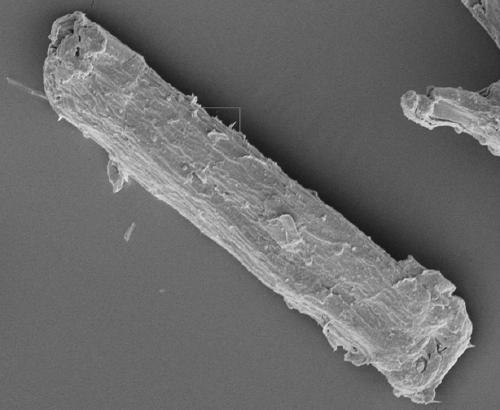

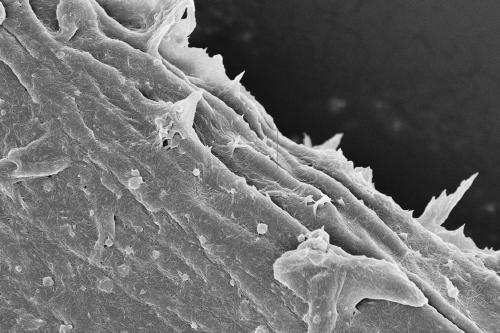

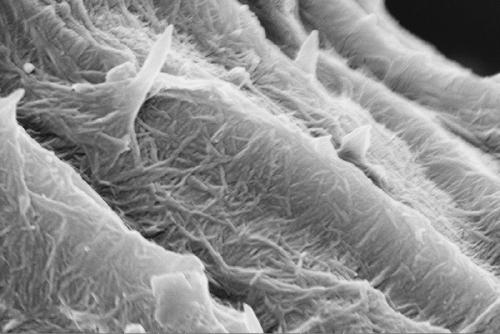

Environment-friendly degradable-type halloysite nano-tubes/polyethylene film material and preparation method of same

The invention discloses an environment-friendly degradable-type halloysite nano-tubes / polyethylene film material which is composed of, by weight, 60-70 parts of linear low-density polyethylene, 8-15 parts of waxy corn starch, 8-15 parts of plant fiber powder, 3-6 parts of a silane coupling agent, 25-35 parts of a degradable calcium carbonate master batch, 10-18 parts of vinyl-terminated silicon oil, 0.3-0.8 parts of hydrogen-containing silicon oil, a proper amount of a sulfuric acid solution, a proper amount of a platinum catalyst, 10-15 parts of halloysite nano-tubes, 8-12 parts of white carbon black, and a proper amount of anhydrous ethanol. The polyethylene film material, after use, can be naturally decomposed into water and CO2 within 6-18 months, is high in biodegradation speed without generation of white pollution, and satisfies environment protection demand. The white carbon black and the modified halloysite have cooperative effects to form a special dual-filler net structure, so that the film material is significantly improved in tensile strength, stiffness and the like.

Owner:合肥市智源包装科技有限公司

Organic polymer coating material as well as method of coating fertilizer by using coating material

The invention relates to an organic polymer coating material as well as a method of coating a fertilizer by using the coating material. The organic polymer coating material is characterized by comprising the following components in percent by weight: 10%-32% of a polyamide curing agent, 8%-20% of paraffin and the balance being cycloaliphatic epoxy resin. The invention provides an organic polymer coating material which is cheap, free from white pollution and capable of precisely controlling degradation rate and time, and has dewatering and water-blocking functions. The invention further provides a method of uniformly spraying an organic polymer, the curing agent and a sealing material on various granulated fertilizer surfaces to form an organic-polymer-coated granulated fertilizer which has a controlled release function. The coated fertilizer prepared by using the method disclosed by the invention has a nutrient release period of 2-3 months, can promote the degradation of putamina in soil and does not damage a soil structure and a plant root. Besides, the coating speed is high, the yield is high and the cost is low.

Owner:NINGXIA VIKO GREEN TECH CO LTD

Fertilizer special for eucalyptus

The invention discloses a fertilizer special for eucalyptus, and relates to the composite fertilizer technical field. The fertilizer special for eucalyptus comprises a coating layer and the fertilizer particles in the coating layer, the fertilizer particles comprise nitrogen, phosphor, potassium, calcium, zinc and a molasses alcohol broth, the coating layer is a slow release carrier, the slow release carrier comprises eleaostearic acid, an adhesive and mineral powder. The fertilizer can provides the trace element such nitrogen element, phosphor element, potassium element, calcium element and zinc element which are required by growth of eucalyptus, the fertilizer particle contains the molasses alcohol broth, abundant amino acid, humic acid and organic matter in the molasses alcohol broth are used for improving and supplementing nutrition for the soil, the match is reasonable, rapid growth of the eucalyptus can be promoted, the fertilizer additive particle is coated in a coating layer, the fertilizer is slowly released, so that loss rate of the fertilizer is effectively reduced, the use ratio of the fertilizer is increased, the slow release carrier is prepared by stearic acid, an adhesive and mineral powder which can be degraded, so that no white pollution can be generated.

Owner:GUANGXI SOURCE OF THE FERTILIZER IND

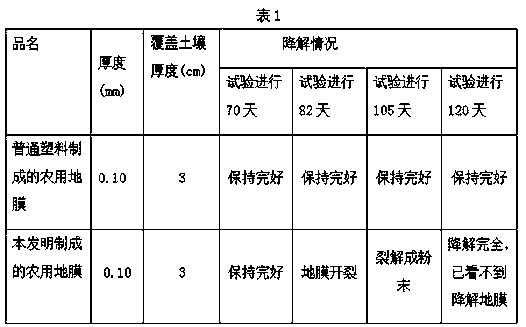

Corn field special-purpose degradable environmental protection mulch film, and preparation method thereof

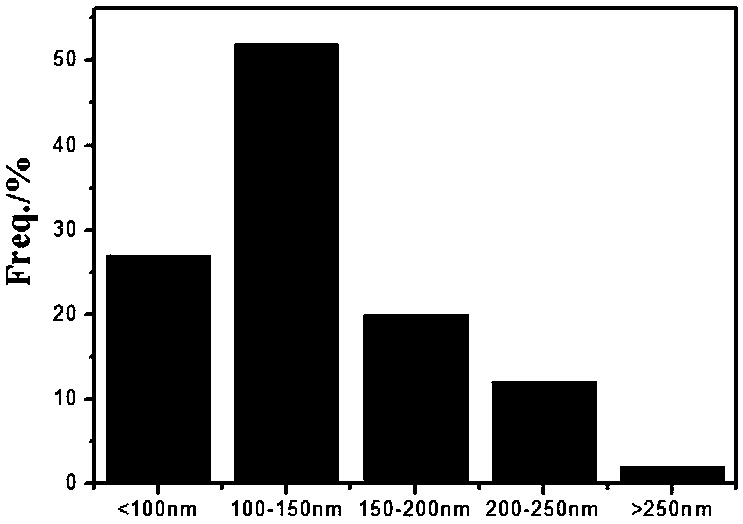

InactiveCN109181090ASmall particle sizeLarge specific surface areaPlant protective coveringsChemistryPlasticizer

The invention belongs to the technical field of agricultural plastic mulching film, and more specifically relates to a corn field special-purpose degradable environmental protection mulch film, and apreparation method thereof. The corn field special-purpose degradable environmental protection mulch film comprises, by weight, 90 to 100 parts of linear low density polyethylene, 10 to 15 parts of low density polyethylene, 40 to 50 parts of modified cassava starch, 7 to 12 parts of modified nanometer calcium carbonate, 5 to 10 parts of bagasse powder, 2 to 3 parts of polyvinyl alcohol, 0.08 to 0.2 part of photosensitizer iron stearate, 0.05 to 0.1 part of a phosphite ester type anti-oxidant, 0.3 to 0.5 part of a thermal degradation promoter, 1 to 3 parts of a compatibilizer, and 2 to 5 partsof a plasticizer. The corn field special-purpose degradable environmental protection mulch film is invented based on corn growth rules and light illumination and temperature climate factors; photosensitizer iron stearate, the phosphite ester type anti-oxidant, and the thermal degradation promoter are introduced, so that problems in the prior art that degradation of mulch film in soil is difficultto realize, and degradation induction period is difficult to control are solved; the obtained corn field special-purpose degradable environmental protection mulch film is easily degradable, is green,is friendly to the environment; no white pollution is caused; and field pollution is reduced.

Owner:袁志平

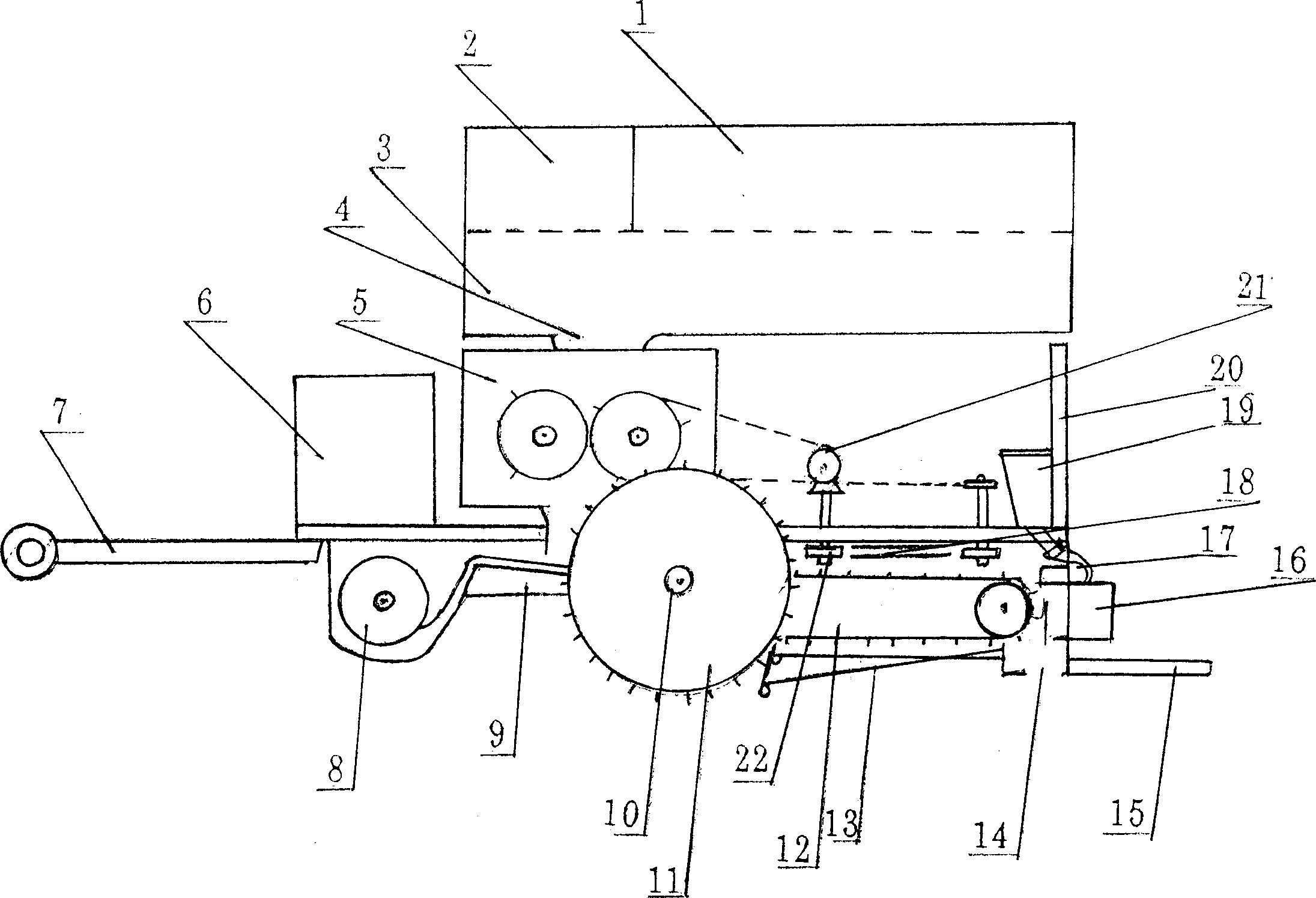

Soil, fertilizer, water and seed hermetic sealing planter

InactiveCN1736143ANo white pollutionUnsolvable problemsClimate change adaptationSowingHermetic sealPlastic mulch

The invention belongs to the field of agricultural planting, which in detail is a planting machine with soil, fertilizer, water and seeds sealed in it. The machine is concluded with soil box, fertilizer box, water box, agitator with spiral tooth, power velocity variation, film former, apron belt, connecting lever cam, seed-covering equipment, film sealer, transverse heat-sealing zone, change-speed carrier wheel zone and film joining-up wheel; sealing the soil, fertilizer, water and seeds with degradable film and implanting it in field, sand, deserted hillside and hillside; the sealed seed germinating and growing by using the nutrition inside the film without watering for 40-60 days and growing into strong sprout; planting the tree seeds two months earlier and the growing period being prolonged; the possibility of being frozen to death naturally is little and the survival rate is high.

Owner:陶金元

Litchi planting method

InactiveCN106900447AIncrease the absorption areaIncrease the areaBiocideCalcareous fertilisersGrowth controlObserved Survival

The invention belongs to the technical field of planting, and particularly relates to a litchi planting method. The litchi planting method comprises the following steps that 1, cultivated land is selected and a garden is built; 2, grafting is conducted; 3, soil preparation and field planting are conducted; 4, shoot growth controlling and clipping are conducted. According to the litchi planting method, the survival rate and the yield of planted litchis are increased obviously, the litchis are bright in color, the size is large and uniform, the skin is thin, the sarcocarp is thick, the litchis are tender, juicy and sweet, and the litchis are rich in fragrance.

Owner:陆川县钰荣种养专业合作社

Fertilizer special for tea tree

InactiveCN104016791APromote rapid growthImprove fertilizer efficiencyFertilizer mixturesChemistryHumic acid

The invention discloses a fertilizer special for tea tree, which relates to the composite fertilizer technical field. The fertilizer special for tea tree comprises a coating layer and fertilizer particles in the coating layer, the fertilizer particle comprises 2-3 parts of nitrogenous fertilizer, 2-3 parts of phosphate fertilizer, 10-15 parts of decomposed fermentation silkworm excrement and 10-15 parts of molasses alcohol broth; the coating layer is a slow release carrier, the slow release carrier comprises stearic acid, an adhesive and mineral powder. The fertilizer special for tea tree can provides the trace element such as nitrogen element, phosphor element and potassium element which are required by growth of tea tree, abundant amino acid, humic acid and organic matter in the molasses alcohol broth are used for improving and supplementing nutrition for the soil, can promote the rapid growth of new leaf of the tea tree; the fertilizer particle is coated in the coating layer, the fertilizer is slowly released, so that loss rate of the fertilizer is effectively reduced, the use ratio of the fertilizer is increased, the slow release carrier is composed of stearic acid, the adhesive and mineral powder which are graded, so that white pollution is not generated.

Owner:GUANGXI SOURCE OF THE FERTILIZER IND

Efficient-printing polyethylene film material for toothpaste sheet and preparation method of polyethylene film material

The invention discloses an efficient-printing polyethylene film material for a toothpaste sheet, wherein the polyethylene film material comprises the following materials in parts by weight: 60-70 parts of linear low density polyethylene, 8-15 parts of waxy corn starch, 8-15 parts of plant fiber powder, 3-6 parts of silane coupling agent, 25-35 parts of degradation type calcium carbonate masterbatch, 10-18 parts of vinyl-terminated silicone oil, 0.3-0.8 part of silicone oil containing hydrogen, a proper amount of sulfuric acid solution, a proper amount of platinum catalyst, 2-5 parts of maleic anhydride, and 0.5-1 part of sorbic acid. The polyethylene film material, after being used, is degraded into water and carbon dioxide under the natural conditions within 6-18 months, the biodegradation is fast, no white pollution is caused, and the requirement of environmental protection is met; in addition, due to the addition of the maleic anhydride and the sorbic acid, the compatibility of the polyethylene and a calcium carbonate particle is strengthened, the roughness is improved, the binding power between the surface of a polyethylene film and printing ink is improved, and efficient printing is achieved.

Owner:合肥市智源包装科技有限公司

Enhanced and toughened plant fiber-polyethylene composite membrane material and preparation method thereof

The invention discloses an enhanced and toughened plant fiber-polyethylene composite membrane material. The material is prepared from, by weight, 50-60 parts of linear low-density polyethylene, 8-15 parts of waxy corn starch, 8-15 parts of plant fiber powder, 3-6 parts of stearic acid triethanolamine ester quaternary, 25-35 parts of degradable calcium carbonate master batch, 10-18 parts of vinyl-terminated silicone oil, 0.3-0.8 part of hydrogen containing silicone oil, a proper amount of sulfuric acid solution, a proper amount of platinum catalyst, 10-16 parts of straw extract fiber and 15-20 parts of towel gourd fiber. After being used, the composite membrane material can be decomposed into water and carbon dioxide under the natural conditions within 6-18 months, is high in biodegradation speed and free of white pollution, and meets the environment protection requirement; the prepared plant fiber-polyethylene composite membrane material has good stretching resistance and tear resistance.

Owner:合肥市智源包装科技有限公司

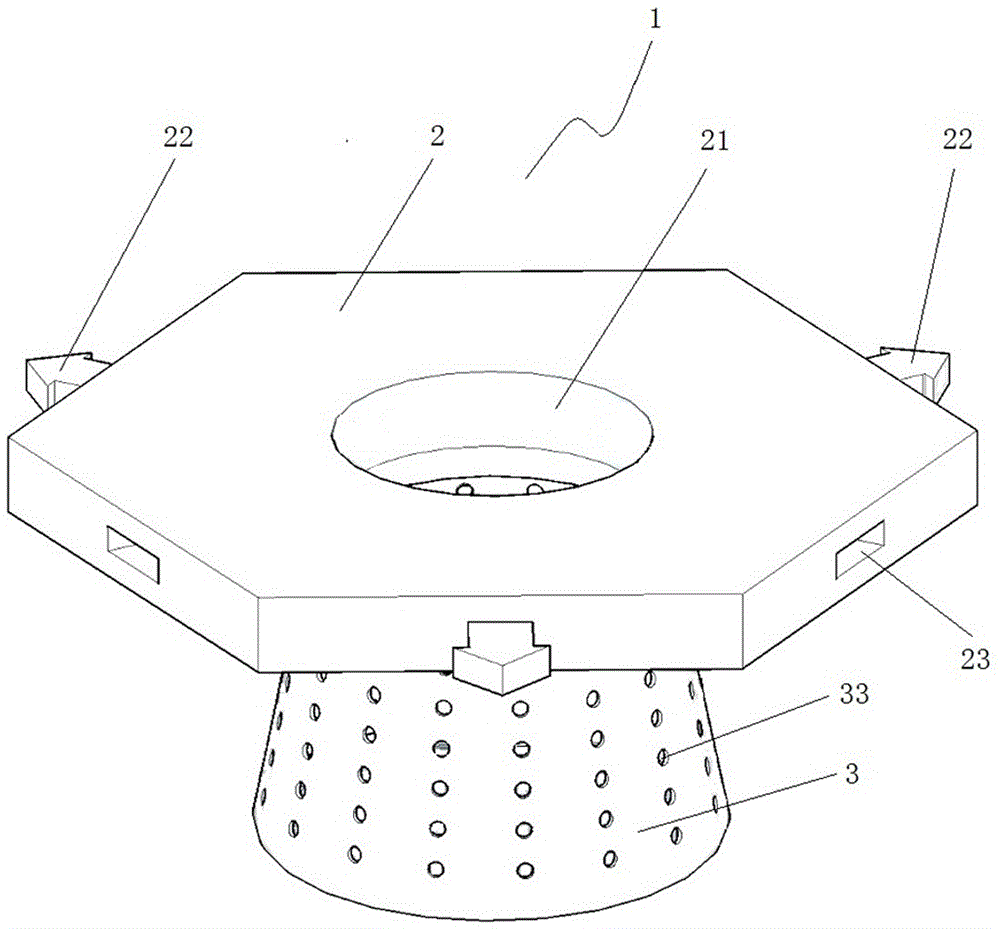

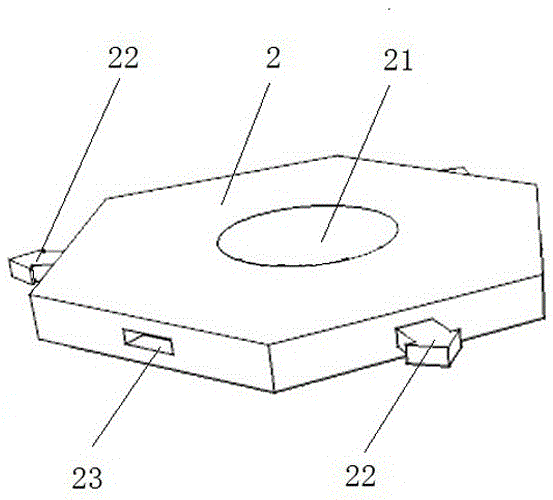

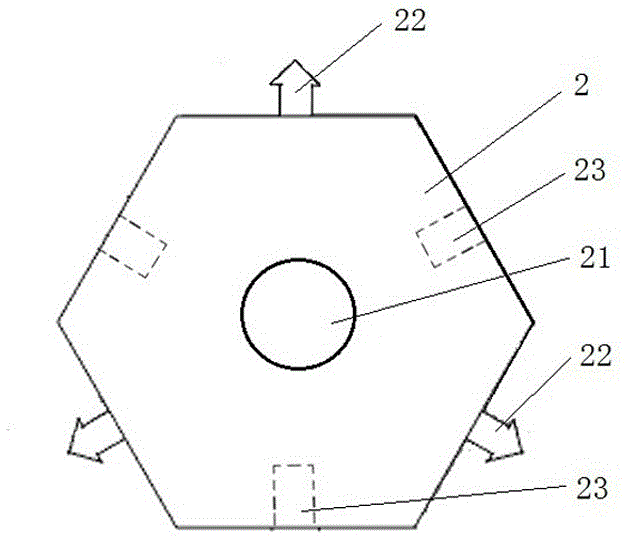

Floating planting device for preventing fish biting

InactiveCN106305195AAffect productivityAffects handlingSustainable biological treatmentCultivating equipmentsPlant rootsModular design

The invention provides a floating planting device for preventing fish biting. The device comprises at least one planting plate consisting of a planting base plate and a planting base, wherein the planting base plate is in a regular hexagonal shape, and a through hole allowing a planting basket to be clamped is formed in the center of the planting base plate; outer clamping heads and inner clamping grooves are arranged on the hexagonal side edges at intervals, so that different planting plates are convenient to splice; the planting base is arranged at the bottom of the planting base plate and is provided with an accommodating tank with a plurality of air holes. The planting base plate and the planting base are made of anti-oxidation plastic through one-time compression molding, the service life of a bed body is greatly prolonged, the bed body is convenient to carry, and white pollution can be avoided; the planting plate is nonlinearly spliced, and the integrity and the wind and wave resistance are greatly improved; the planting basket is protected by the planting base, and influences on the production capacity and the sewage treatment capacity due to poor growth of plants caused by the fact that plant roots are bit excessively by fish can be prevented; by means of the modular design of the planting plate, the planting plates can be spliced and shaped randomly, are convenient to construct and replace and meet requirements of various water landscapes.

Owner:HUNAN AGRICULTURAL UNIV

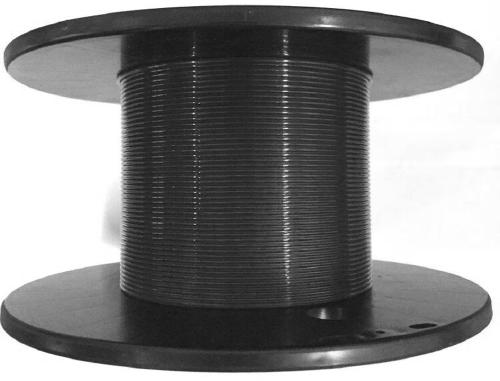

Nanometer cellulose/cellulose compound, enhanced polylactic acid 3D printing material and preparation method of enhanced polylactic acid 3D printing material

The invention belongs to the field of macromolecular composite materials and 3D printing materials, and specifically relates to a nanometer cellulose / cellulose compound capable of being applied to a polylactic acid 3D printing material and the relevant enhanced 3D printing material. According to the invention, the natural cellulose, acid, a silane coupling agent and polylactic acid are used as rawmaterials to obtain the nanometer cellulose / cellulose compound and the enhanced polylactic acid 3D printing material through a constant temperature water bath reaction and blending extrusion. In a preparation process, the steps of raw material pretreatment, mixing, heating in water bath, drying, blending extrusion, wire drawing and the like are performed; a whole preparation technology is simple;the repeatability is high; compared with pure polylactic acid, the prepared 3D printing material has the advantages that the mechanical property is remarkably improved, and the processing performanceis high; compared with an ordinary natural cellulose enhanced polylactic acid 3D printing material, the enhanced polylactic acid 3D printing material has the advantages that the transparency is high;during printing, end blockage and edge tilting are not prone to occur; and relatively-high application value is realized in the fields of home, decoration, lamps, art, model design and the like.

Owner:广州冠杰环保新材料科技有限公司

Production method of environment-friendly tableware

The invention discloses a production method of environment-friendly tableware. The environment-friendly tableware comprises the following components in percentage by weight: 6-17% of carbon dust powder, 4-16% of corn straws, and 78-85% of mung bean starch. The preparation method comprises the following steps of: mixing carbon dust powder, corn straws, and mung bean starch; adding proper amount of water to the components for uniformly mixing the components; feeding the uniform mixture to a mould to carry out high-temperature steam forming by a pipeline; feeding the formed tableware to a disinfection processor by a conveying belt to carry out sterilization processing; and transmitting the disinfected tableware to a filming machine by a conveying belt to carry out film covering. The production method has the characteristics that the environment-friendly tableware is not easy to break, the normal use is ensured, an effect of preventing oil and water can be reached without an inner coating, and a full degradation of the environment-friendly tableware can be really realized. Moreover, the environment-friendly tableware has a short degradation period, water resistance and oil resistance and is easy to clean, and in particular the environment-friendly tableware has the advantages of high degradation rate, no white pollution and the like.

Owner:CHANGZHOU UNIV

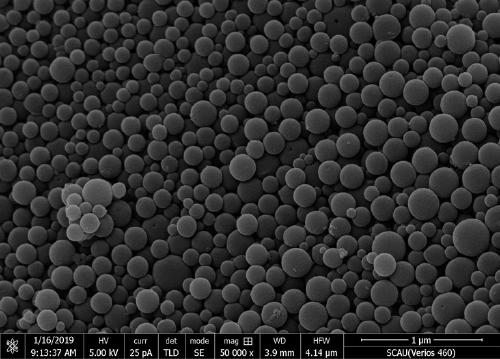

Lignin micro/nanospheres, enhanced polylactic acid 3D printing material and preparation method thereof

ActiveCN110237784ATake full advantage of thermoplasticityGive full play to anti-aging propertiesMicroballoon preparationMicrocapsule preparationWater bathsPolyvinyl alcohol

The invention belongs to the field of macromolecule composite materials and 3D printing materials, and in particular relates to lignin micro / nanosphesres and a related enhanced polylactic acid 3D printing material for an FDM (fused deposition modeling) type 3D printing technique. The lignin micro / nanosphesres and the enhanced polylactic acid 3D printing material thereof are prepared from natural lignin, an organic solvent, polyvinyl alcohol and polylactic acid as raw materials through a constant-temperature water bath reaction and blending extrusion. The preparation process comprises mixing, water bath heating, drying, blending extrusion, wire drawing, and the like, the whole preparation process is simple and high in repeatability, the prepared 3D printing material has remarkably improved mechanical properties and good processing performance when being compared with pure polylactic acid, and compared with a common lignin enhanced polylactic acid 3D printing material, the 3D printing material is high in glossiness, not liable to cause end blocking or edge warping in printing, and has high application values in fields such as household articles, decoration, lamps and art and model designing.

Owner:SOUTH CHINA AGRI UNIV

Controlled release combination of coating film for fertilizer and preparation method thereof

InactiveCN1686968ANo white pollutionAccurate control of degradation rateFertiliser formsFertilizer mixturesControlled releaseOrganic solvent

The present invention discloses a fertilizer controllable released covering film composition and its preparation method. Said covering film composition contains waste and old-polystyrene, additive and organic solvent. Its preparation method includes the following steps: pulverizing waste and old polystyrene, preparing organic solvent, uniformly mixing polystyrene plastic granules and additive, then mixing then with organic solvent and stirring them at 90-130 deg.C, feeding fertilizer granules into fluid-bed, heating to 40 deg.C and making them be flowed out from fluid-bed, at the same time using nozzle to spray covering film solution on the surface of fertilizer granule so as to obtain the fertilizer with covering film.

Owner:陕西美世朗生态科技有限公司

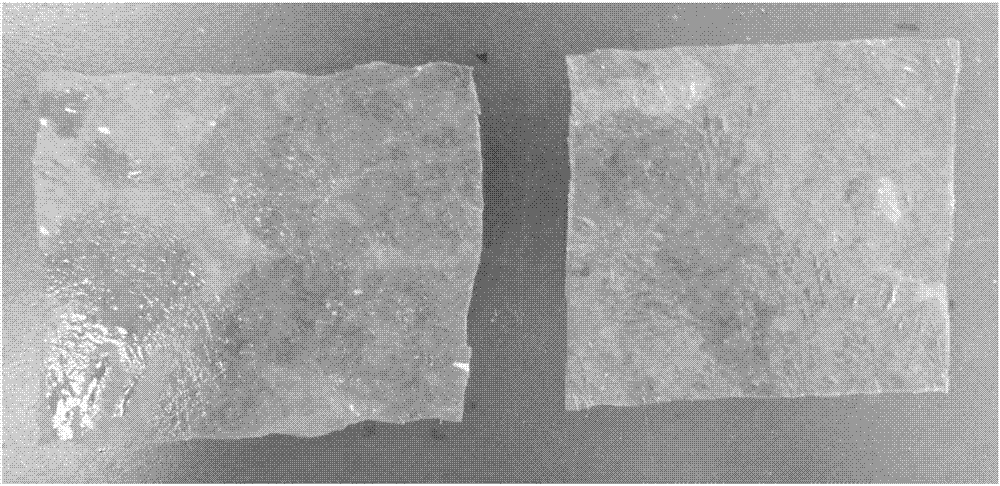

Preparation method of edible collagen membrane

The invention discloses a preparation method of an edible collagen membrane. The method comprises the following steps: first, performing a reaction on animal collagen dissolved by an acetic acid solution and hydroxycarboxylic acid-N-hydroxysuccinimide ester, removing bubbles, performing film forming and drying to obtain a transparent collagen membrane, soaking the obtained transparent collagen membrane in a solution containing oxidase for a reaction, after the reaction is finished, performing washing by water and performing drying to obtain the edible collagen membrane. In the method provided by the invention, with the adoption of step-by-step crosslinking modification on a collagen membrane, the system is uniform in crosslinking, the membrane is more uniform and compact, and the crosslinking degree is higher, so that the tensile strength of the membrane can be greatly improved, and meanwhile, the membrane is transparent in color, and is more suitable for being used as a packaging material for highlighting the color of packaged objects. The method provided by the invention is simple in method and easy in operation and is easy for popularization and application.

Owner:SICHUAN UNIV

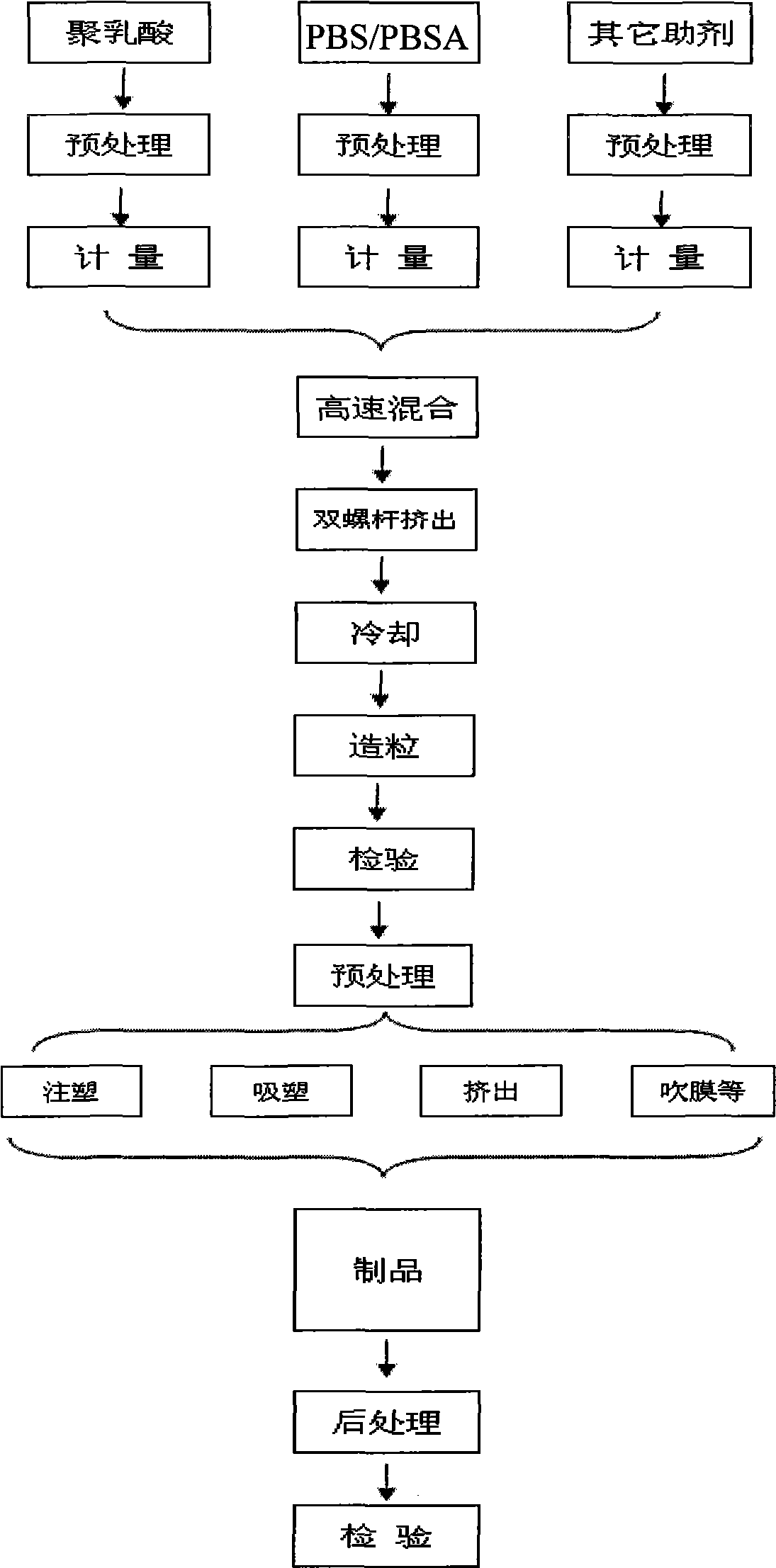

Polylactic acid/PET (polyethylene terephthalate) alloy containing biodegradable material and preparation method thereof

The invention relates to a PET (polyethylene terephthalate) and polylactic acid blend alloy containing biodegradable material and a preparation method thereof. Blend alloy is formed by mixing 30%-60% of polyethylene terephthalate, 30%-50% of polylactic acid and 5%-10% of compatilizers in weight proportion. The preparation method includes the steps: firstly, drying the polylactic acid and the polyethylene terephthalate for 1-2 hours; secondly, mixing the polyethylene terephthalate, the polylactic acid and the compatilizers at a high speed, and extruding, granulating and drying the mixture by a double-screw extruder; thirdly, extruding, granulating and drying the mixture again. The extruding and granulating temperature is controlled to range from 190 DEG C to 220 DEG C. Dried materials are subjected to injection molding to form a sheet product. The prepared polylactic acid / polyethylene terephthalate blend alloy sheet product has good biodegradability, and environmental pollution caused by the polyethylene terephthalate serving as a non-degradable plastic component is avoided.

Owner:李博琪

Method for cultivating eucalyptus tissue culture seedling by adopting light media container

InactiveCN103477989AIncreased yield and quality of bottle seedlingsGood air permeabilityClimate change adaptationAfforestationRoot systemPesticide

A method for cultivating a eucalyptus tissue culture seedling by adopting a light media container is characterized by adopting plant tissue culture and rapid propagation, optimizing ratio and treating processes of light media raw materials, improving a rooting bottle seedling hardening method and selecting a small atomized insecticide spraying machine to replace a method for manually spraying insecticide. The light media container has good water permeability and air permeability and is light, so that the labor intensity is reduced; root systems are developed, nursery stocks are strong, and the seedling recovering period is short after afforestation, thus, costs for seedling culture and afforestation are reduced; and moreover, rooting bottle seedling yield is higher than 98%, transplanting survival rate of bottle seedlings is higher than 95%, seedling morbidity is lower than 2%, the seedling culture period is relatively shortened to 45-60 days, then, the outplanting can be performed, the outplanting rate of large seedlings is higher than 90%, and the survival rate of afforestation is increased by 15%.

Owner:沈云

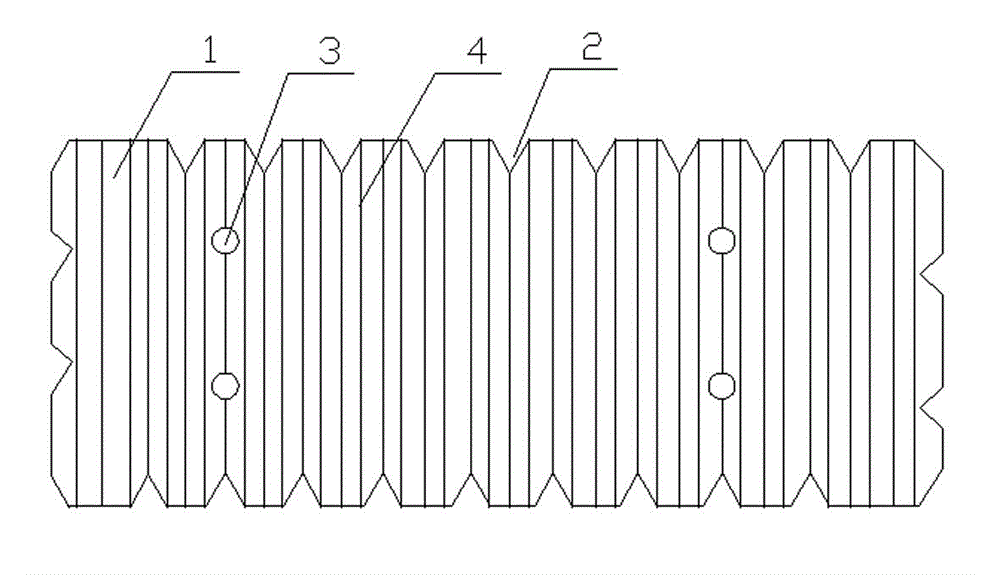

Sand-stabilizing, tree-planting, rain-collecting and moisture-holding desertification control plate

InactiveCN102720175AIsolated contactPrevent movementClimate change adaptationWatering devicesVegetationSoil science

The invention relates to a sand-stabilizing, tree-planting, rain-collecting and moisture-holding desertification control plate. The plate is characterized in that dentation notches are formed at the periphery of the desertification control plate at a certain interval; and pile insertion holes are formed on the surface of the plate. By the sand-stabilizing, tree-planting, rain-collecting and moisture-holding desertification control plate, desert wind can be prevented from contacting loose sandy soil, so that a sand body can be prevented from moving; sunshine is reflected, heat and light are isolated, moisture is prevented from being evaporated, the temperature stability and humidity stability of soil are kept, and the survival of plants is facilitated; and most of limited rain is converged and collected to the periphery of roots of the plants on the lower side of the plate to form a plate surface rain-collecting drip irrigation effect, so that effective rain can be effectively utilized to the maximum extent. The plate is easy to manufacture, low in material consumption and cost, convenient to construct, quickly implemented, low in construction cost and high in plant survival rate, materials are easy to collect, a desertification control effect is improved, and the desertification control investment is saved.

Owner:余绳鑫

Degradable corrosion-resistant paint

ActiveCN104293071AGood compatibilityPromote decompositionFireproof paintsCarboxyl rubber coatingsSolventSodium sulfate

The invention discloses degradable corrosion-resistant paint. The degradable corrosion-resistant paint is prepared from the following raw materials in parts by weight: 74-77 parts of modified mixed resin, 40-43 parts of phenolic resin, 6-9 parts of carboxyl nitrile rubber, 1.4-1.7 parts of hydroxyethyl cellulose, 2.5-2.8 parts of calcium stearate, 1.7-2 parts of lauryl sodium sulfate, 5-8 parts of talcum powder, 9-12 parts of mica powder, 11-14 parts of attapulgite, 1.2-1.5 parts of an aluminum-zirconium coupling agent TL-4, 5-8 parts of ammonium polyphosphate, 23-26 parts of zinc borate, 8-11 parts of microencapsulated red phosphorus, 3.3-3.6 parts of a flexibilizer, 0.6-0.9 part of a curing agent, 1-1.3 parts of a defoaming agent, 1.1-1.4 parts of a leveling agent, 0.6-0.9 part of a mildew preventive, 1.7-2 parts of pigments and 58-61 parts of a solvent. The degradable corrosion-resistant paint disclosed by the invention has excellent corrosion resistance and flame resistance, and excellent adhesion and impact resistance.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Polylactic acid/PC (polycarbonate) alloy containing biodegradable material and preparation method thereof

The invention relates to a PC (polycarbonate) and polylactic acid blend alloy containing biodegradable material and a preparation method thereof. Blend alloy is formed by mixing 30%-50% of polycarbonate, 30%-50% of polylactic acid and 5%-10% of compatilizers in weight proportion. The preparation method includes the steps: firstly, drying the polylactic acid and the polycarbonate for 1-2 hours; secondly, mixing the polycarbonate, the polylactic acid and the compatilizers at a high speed, and extruding, granulating and drying the mixture by a double-screw extruder; thirdly, extruding, granulating and drying the mixture again. The extruding and granulating temperature is controlled to range from 190 DEG C to 220 DEG C. Dried materials are subjected to injection molding to form a sheet product. The prepared polylactic acid / polycarbonate blend alloy sheet product has good biodegradability, and environmental pollution caused by the polycarbonate serving as a non-degradable plastic component is avoided.

Owner:李博琪

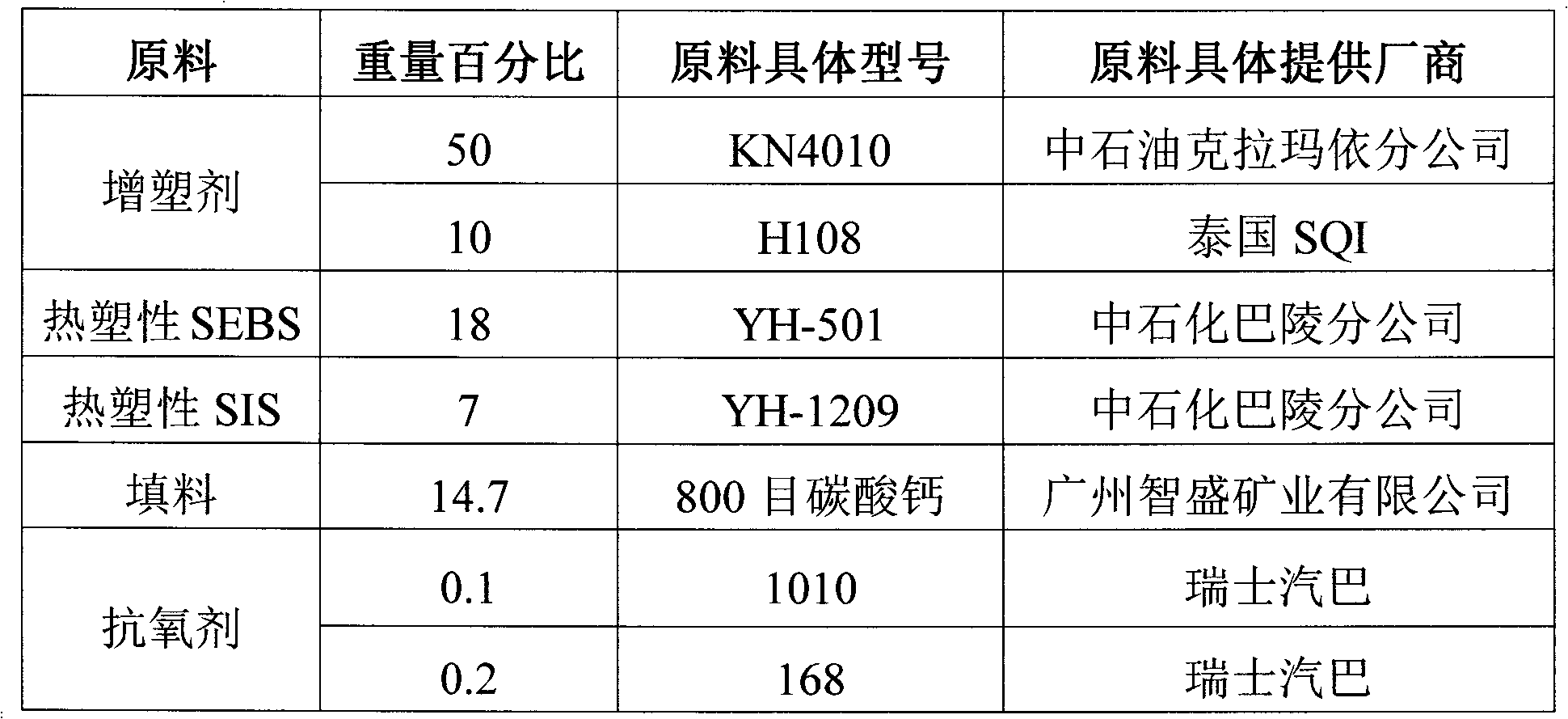

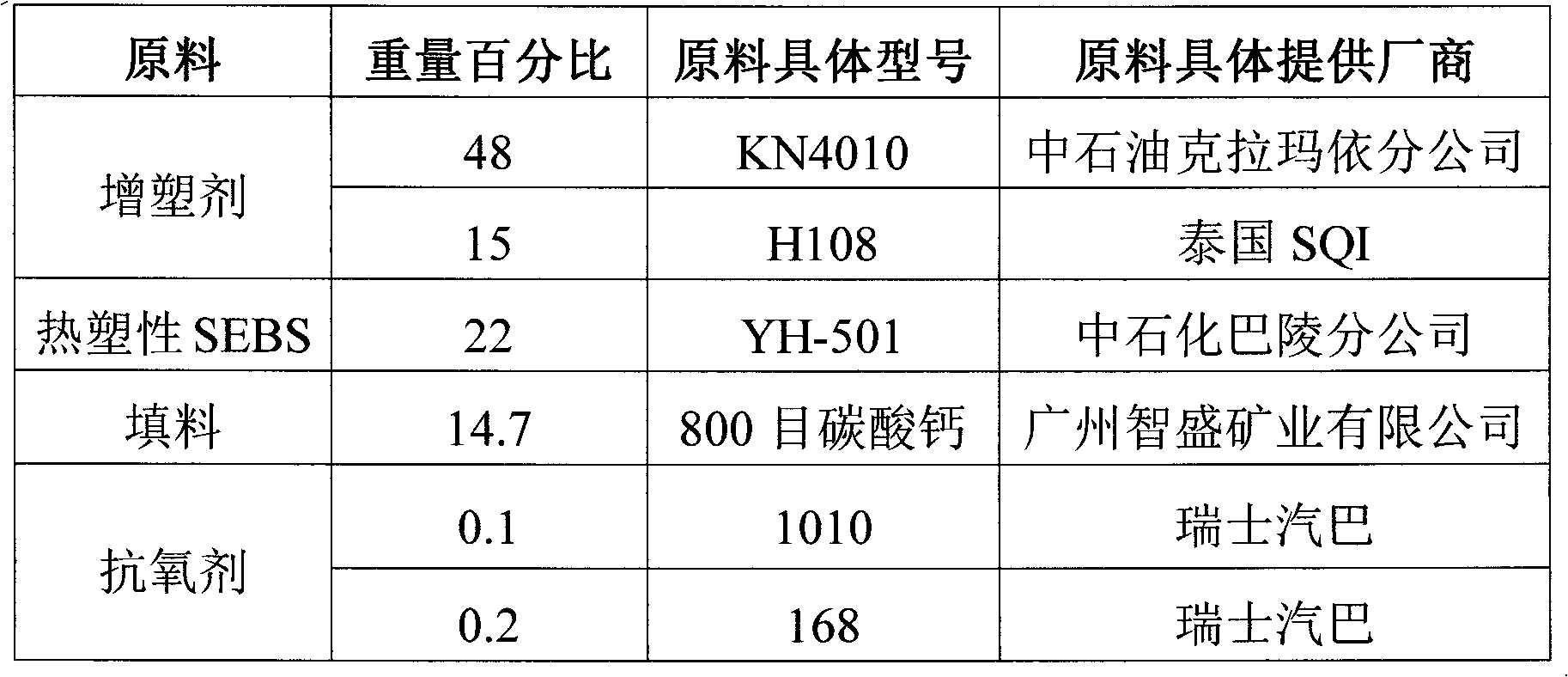

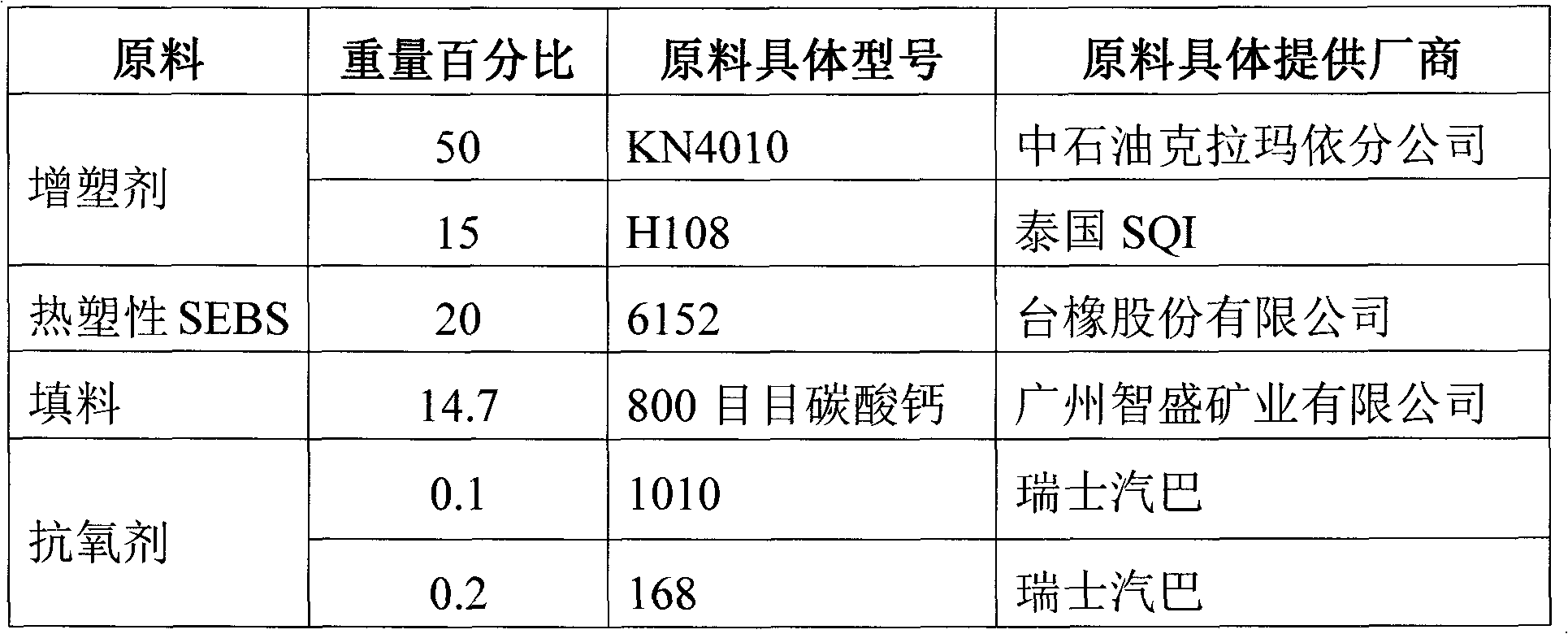

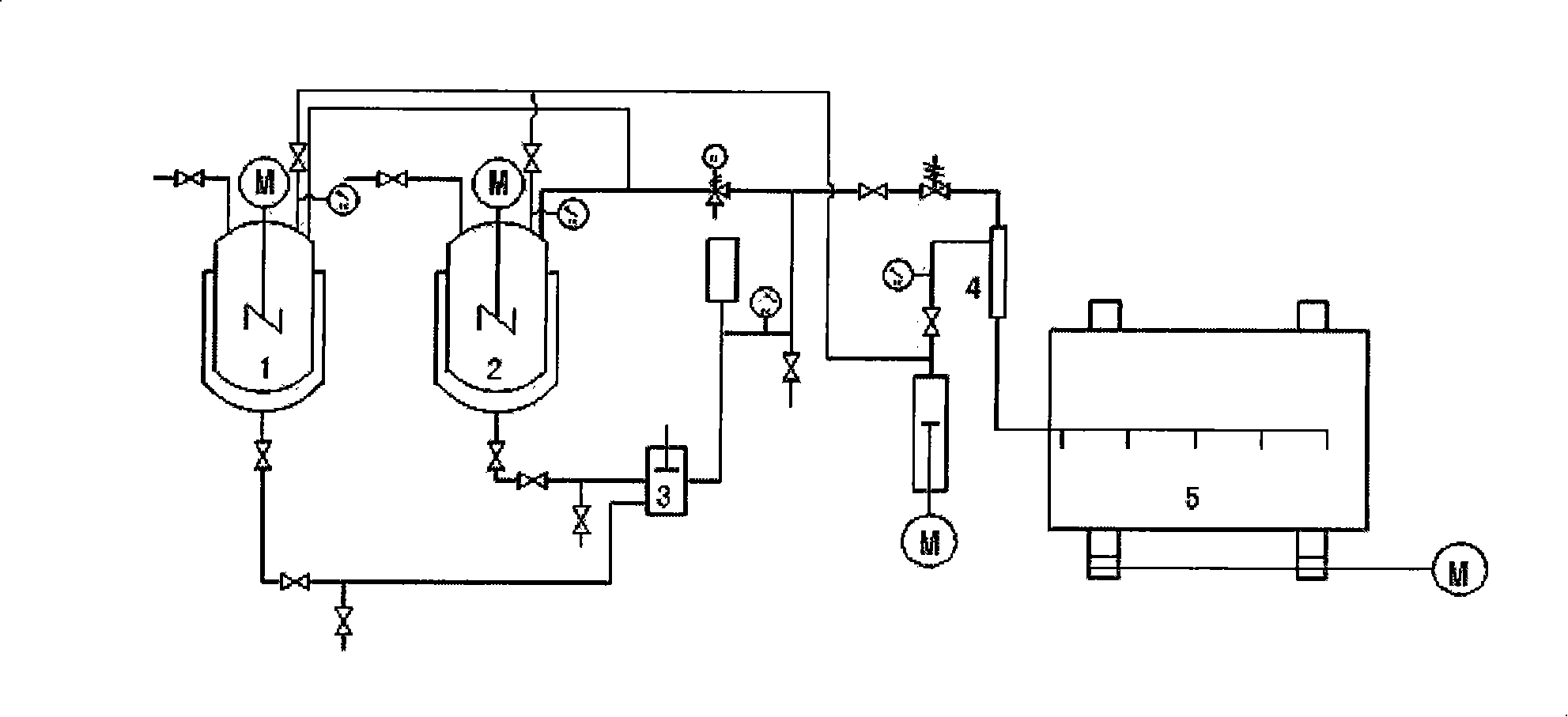

Method for preparing hot melt adhesive for damping interval of ceramic tile

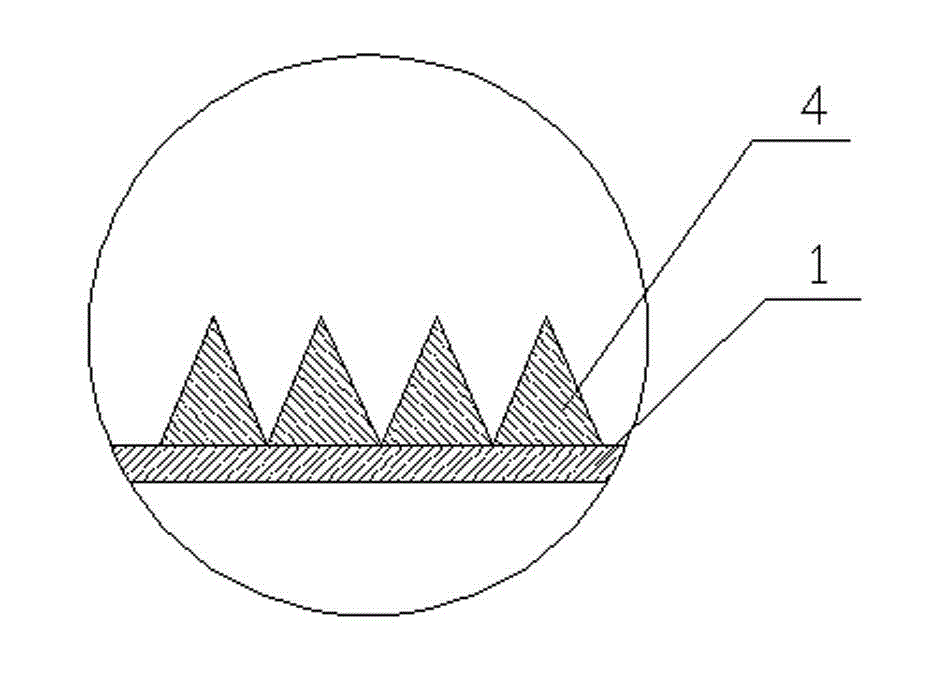

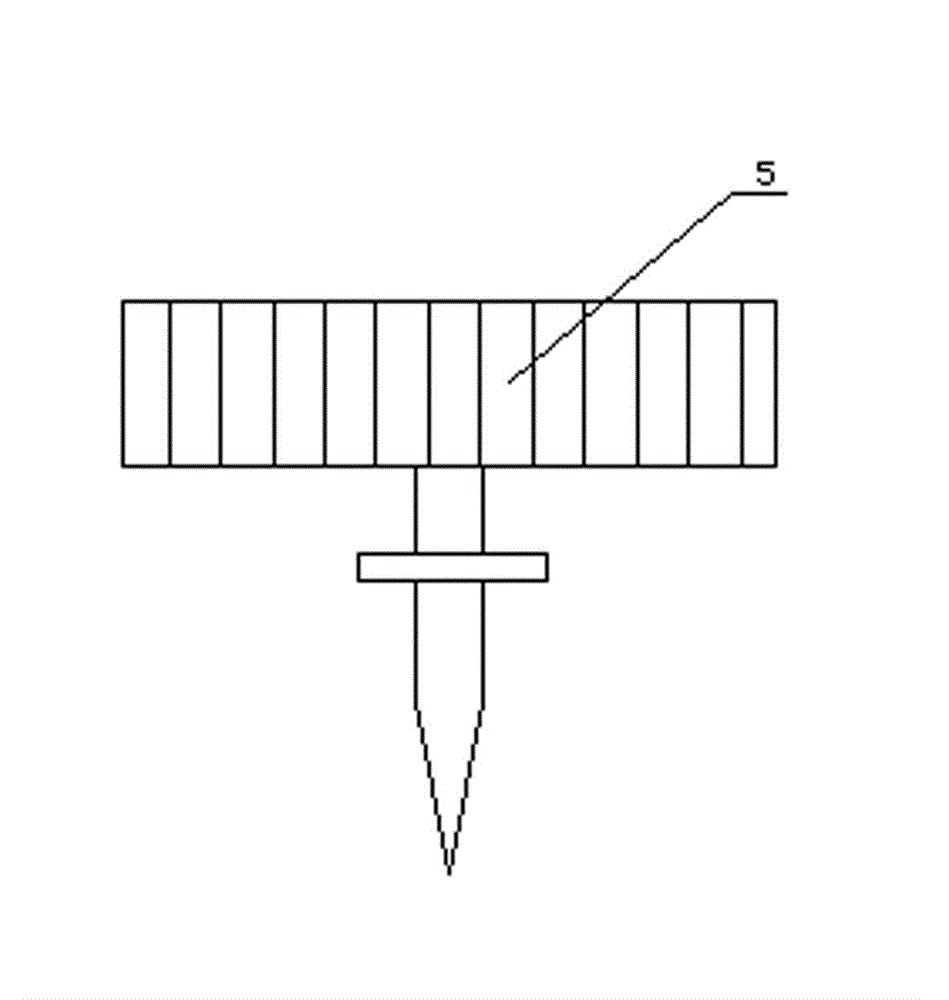

InactiveCN102660207AImprove protectionNo white pollutionNon-macromolecular adhesive additivesThermoplastic elastomerHot-melt adhesive

The invention relates to a method for preparing a hot melt adhesive for a damping interval of a ceramic tile. The hot melt adhesive is characterized by comprising the following components in percentage by weight: 60-70 percent of a plasticizing agent, 15-25 percent of a thermoplastic elastomer, 10-20 percent of a filler and 0.2-0.4 percent of an antioxidant. The method comprises the following steps of: during preparation, weighing each component according to weight percentage, putting the plasticizing agent into a reactor kettle, stirring at the temperature of 120-135 DEG C for 20-35 minutes; putting the filler into the reaction kettle, and stirring at the temperature of 130-145 DEG C for 10-20 minutes; putting the thermoplastic elastomer into the reaction kettle, stirring at the temperature of 145-165 DEG C for 40-70 minutes, and eliminating air bubbles in vacuum simultaneously; and performing screw extrusion under the normal pressure, and packaging. The hot melt adhesive produced with the method can be taken as an interval buffering material for a ceramic tile instead of the conventional foam material, does not cause white pollution, and contributes to protecting the environment; and the hot melt adhesive has the advantages of moderate elasticity, high oil resistance transfer, easiness for peeling after interval, prevention of marks, easiness for spraying, quick curing and the like.

Owner:郑昭

Preparation process of double-degradation agricultural film

The invention discloses a preparation process of a double-degradation agricultural film, which is used for solving the problems that the agricultural film is not easy to degrade and serious in white pollution. The adopted technical scheme is as follows: the double-degradation agricultural film is prepared by coating nanometer titania and adding modified starch. The double-degradation agricultural film is easy to degrade, high in degradation speed and free of white pollution; and the preparation process is simple, low in cost and easy for batch production.

Owner:HEBEI MILSON TITANIUM DIOXIDE

Degradable polymer filmcoated controlled release fertilizer, preparation thereof and special filmcoated material

ActiveCN101323545BHas the ability to degradeAchieve friendlyFertilizer mixturesPolyolControl release

The invention discloses a polymer coated released fertilizer and a preparation method thereof and a special coating material thereof. The coating material comprises isocyanate, polyol, degradable functional monomer, an aid agent of coating and a chain extender, wherein, the mol ratio between the isocyano group in the isocyanate and the hydroxyl group in the polyol is 1:2 to 2:1 and the mass of the degradable functional monomer is 1 percent to 20 percent of the mass of the coating material. The coated released fertilizer provided by the invention consists of a core and a karyotheca, wherein, the core is granule fertilizer and the karyotheca is prepared from the coating material, and the mass of the karyotheca is 2 percent to 10 percent of the mass of the core. The coating material has goodfilm forming and water resisting performance and can be degraded in nature. The hardness and the elasticity of the material can be adjusted by changing the mixure ratio of the coating material so as to prepare released fertilizers with different releasing periods.

Owner:CNSG ANHUI HONG SIFANG FERTILIZER IND CO LTD

Polylactic acid/random copolymerization polypropylene alloy biodegradable material and preparation method thereof

InactiveCN106519607ADecrease intermolecular binding forceSolve the biodegradation problemAlloyPolypropylene

The invention relates to a random copolymerization PP (Polypropylene) / polylactic acid blend alloy biodegradable material and a preparation method of the biodegradable material. A blend is prepared from the following components by weight: 10 percent to 30 percent of random copolymerization PP, 50 percent to 90 percent of polylactic acid and 5 percent to 15 percent of a compatilizer. The preparation method of the biodegradable material comprises the following steps: carrying out drying treatment on the polylactic acid for 1 hour to 2 hours; uniformly blending the random copolymerization PP and the compatilizer into a high-speed mixer at a rotary speed of 800rpm to 1500rpm; melting, blending and granulating the mixed blend through adopting a double-screw extruder and controlling the temperature to be 190 DEG C to 210 DEG C; after drying grains, mixing the grains with the polylactic acid again at a high speed; extruding and granulating; then carrying out injection molding to process the grains into sheet-shaped products. A polylactic acid / random copolymerization PP blend alloy sheet material product prepared by the method has relatively good biodegradability, and pollution to environments, caused by a non-degradable plastic component, namely the random copolymerization PP, is avoided.

Owner:李博琪

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com