Nanometer cellulose/cellulose compound, enhanced polylactic acid 3D printing material and preparation method of enhanced polylactic acid 3D printing material

A nanocellulose, 3D printing technology, applied in the direction of additive processing, etc., can solve the problems of cumbersome preparation process of nanocellulose, difficult to fully utilize, poor compatibility, etc., to improve compatibility, improve poor compatibility, compatibility good capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

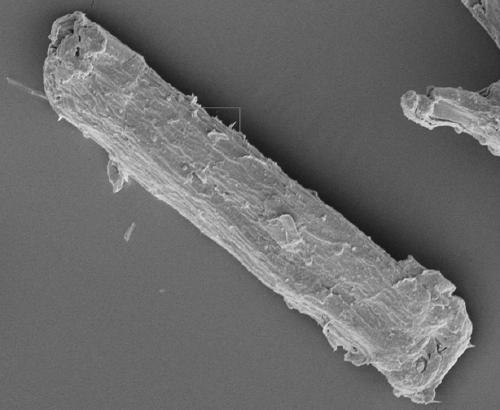

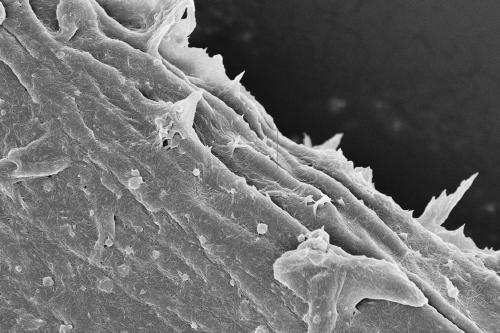

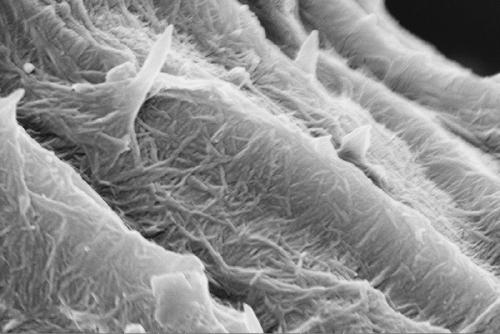

Image

Examples

Embodiment 1

[0037] A reinforced polylactic acid 3D printing material prepared by the following steps:

[0038] (1) After crushing 2g of cotton cellulose, treat it with 25 ml of 64% sulfuric acid + 25 ml of oleic acid in a constant temperature water bath at 50°C for 2 hours until the solution turns yellow, and dilute with 500 ml of water after stopping the reaction; Finally, take off the mixed solution containing flocculent cellulose for subsequent use;

[0039] (2) Centrifuge the mixed liquid containing flocculent cellulose at a high speed of 8000 r / m for 15 minutes, collect the upper turbid liquid, add water to the flocculent cellulose at the bottom and mix until it becomes turbid, and then centrifuge again, and so many cycles until separation Finally, add water to the flocculent cellulose at the bottom and mix until the turbidity remains unchanged, and combine the obtained turbid liquid to form a stable nano-cellulose sol;

[0040] (3) Pulverize 2g of cotton cellulose and pass through ...

Embodiment 2

[0050] A reinforced polylactic acid 3D printing material prepared by the following steps:

[0051] (1) After crushing 2g of flax cellulose, treat it with 35ml of 64% sulfuric acid in a constant temperature water bath at 45°C for 1 hour until the solution turns slightly yellow, and dilute with 700ml of water after stopping the reaction; Mixed liquid for use;

[0052] (2) Centrifuge the mixed liquid containing flocculent cellulose at a high speed of 8000 r / m for 20 minutes, collect the upper turbid liquid, add water to the flocculent cellulose at the bottom and mix until it becomes turbid, and then centrifuge again, repeating this many times until separation Finally, add water to the flocculent cellulose at the bottom and mix until the turbidity remains unchanged, and combine the obtained turbid liquid to form a stable nano-cellulose sol;

[0053] (3) Grinding 2g of flax cellulose and passing through a 150-mesh sieve to obtain 150-mesh cellulose powder;

[0054] (4) Take 200ml...

Embodiment 3

[0060] A reinforced polylactic acid 3D printing material prepared by the following steps:

[0061] (1) After pulverizing 2g of jute cellulose, treat it with 40ml of 30% hydrochloric acid in a constant temperature water bath at 60°C for 1 hour until the solution turns slightly yellow, and dilute with 600ml of water after stopping the reaction; Mixed liquid for use;

[0062] (2) Centrifuge the mixed liquid containing flocculent cellulose at a high speed of 12000 r / m for 10 minutes, collect the upper layer of turbid liquid, add water to the flocculent cellulose at the bottom and mix until it becomes turbid, and then centrifuge again, repeating this cycle for many times until separation Finally, add water to the flocculent cellulose at the bottom and mix until the turbidity remains unchanged, and combine the obtained turbid liquid to form a stable nano-cellulose sol;

[0063] (3) Pulverize 2g of jute cellulose and pass through a 150-mesh sieve to obtain 150-mesh cellulose powder....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com