Patents

Literature

37results about How to "Be transparent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing transparent heat-resistance polylactic acid modification material

ActiveCN102206406AChange in biodegradabilityHigh biodegradation rateThermal deformationPolymethyl methacrylate

The invention discloses a method for preparing a transparent heat-resistance polylactic acid modification material, in which three methods for improving the heat resistance of polylactic acid, namely a method for changing a polylactic acid crystal state by using a nucleating agent, a method for changing a polylactic acid molecular structure by the crosslinking of a chain extender and a method formixing the polylactic acid and high glass transition temperature (Tg) polymer materials, are adopted. The method comprises the following steps of: drying all raw material mixed complexes at 80 DEG C for 5 hours; and granulating or directly processing to form a transparent heat-resistance polylactic acid product. The polylactic acid modification material comprises the following raw materials in parts by weight: 100 parts of polylactic acid, 5-10 parts of chitin whisker polymethyl methacrylate coating, 0.5-2.0 parts of chain extender, 3-5 parts of oligomer polylactic acid, and 0.1-0.5 part of 3-(nonyl-phenyl) phosphite ester. By using the method, the thermal deformation temperature of the polylactic acid composite material is over 100 DEG C, and the biodegradability and the high transparency of the composite material are effectively maintained.

Owner:JIANGSU GUANGHUI PACKAGE +2

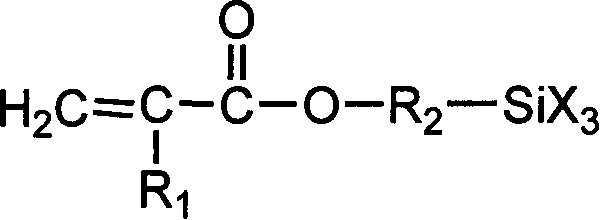

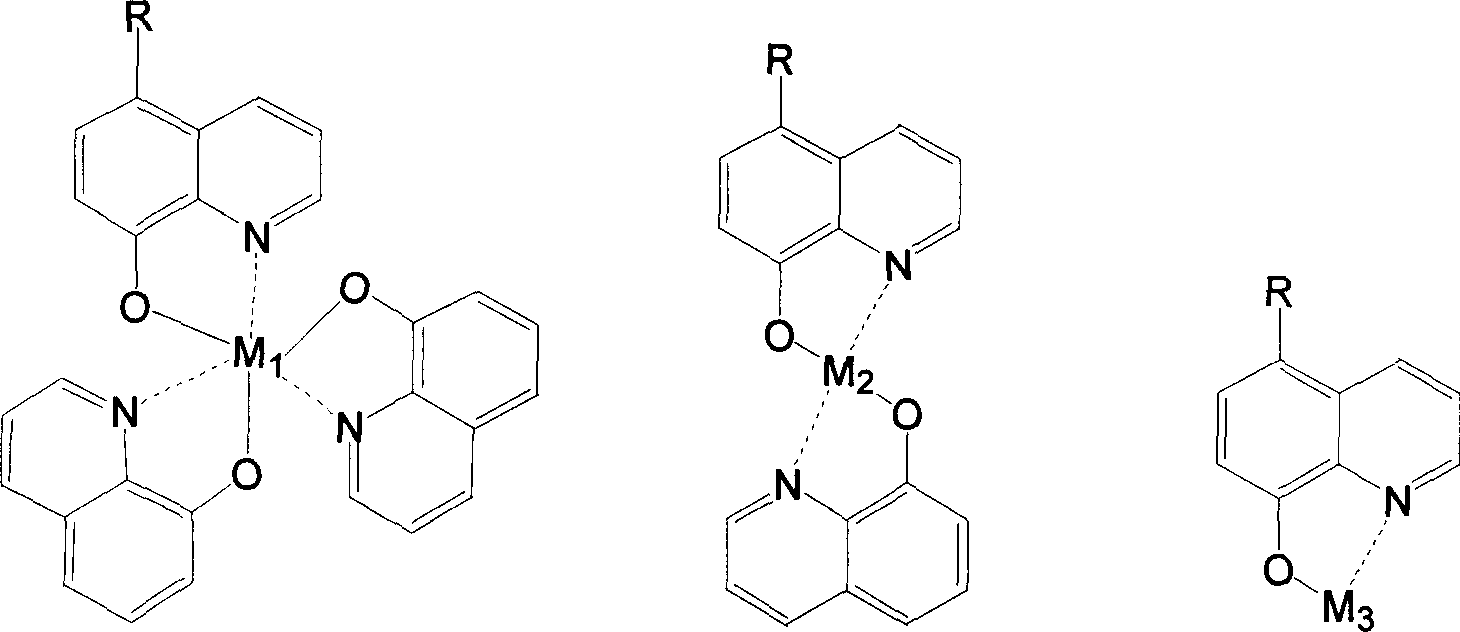

Olefin monomer containing 8-hydroxyquinoline metal complex and its production method and use

InactiveCN1569837AGood solubilityImprove stabilityGroup 1/11 element organic compoundsGroup 3/13 element organic compoundsIonChemistry

The invention relates to a series of olefin monomer of a polymerisable functional group 8-hydroxyquinoline metal complex, its preparation process and use thereof, wherein the preparation process consists of synthesizing alkene monomers containing 8-hydroxyquinoline through reaction between vinyl compound containing reacting function group with modified 8-hydroxyquinoline, then compounding with metallic ions and 8-hydroxyquinoline.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Nano hydrogel material and preparation method and use thereof

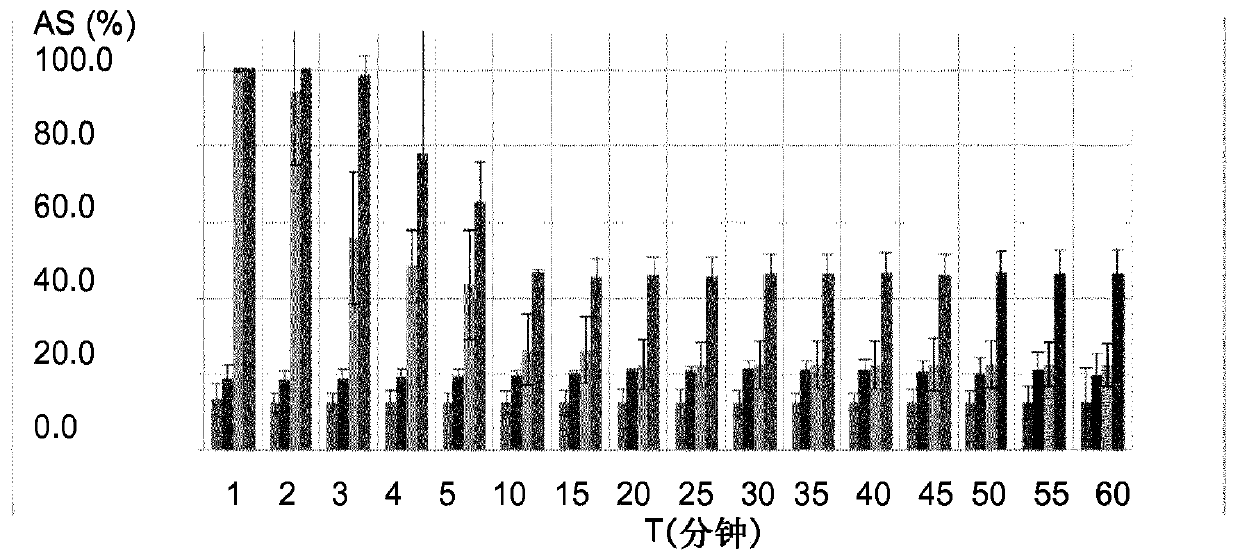

This invention relates to nanometer hydrogel stuff and its preparation method. This nanometer hydrogel stuff adopt method of intercalation and reversible addition - rupture chain transfer free radical polymerization, add monomer, initiator, cross-linking agent, chain transfer agent and montmorillonite all to organic solvent system, at presence of initiator, obtain nanometer structure hydrogel stuff. This hydrogel can reach swelling balance in 2 hours; can reach de- swelling balance in 20 minutes. The swelling rate of this invention is 400 to 700 percent.

Owner:海南中科翔新材料科技有限公司

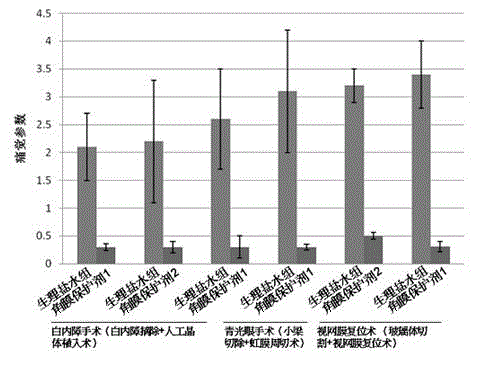

Corneal surface protectant as well as preparation method and application thereof

ActiveCN104083396AKeep moistBe transparentOrganic active ingredientsSenses disorderCorneal surfaceOphthalmology

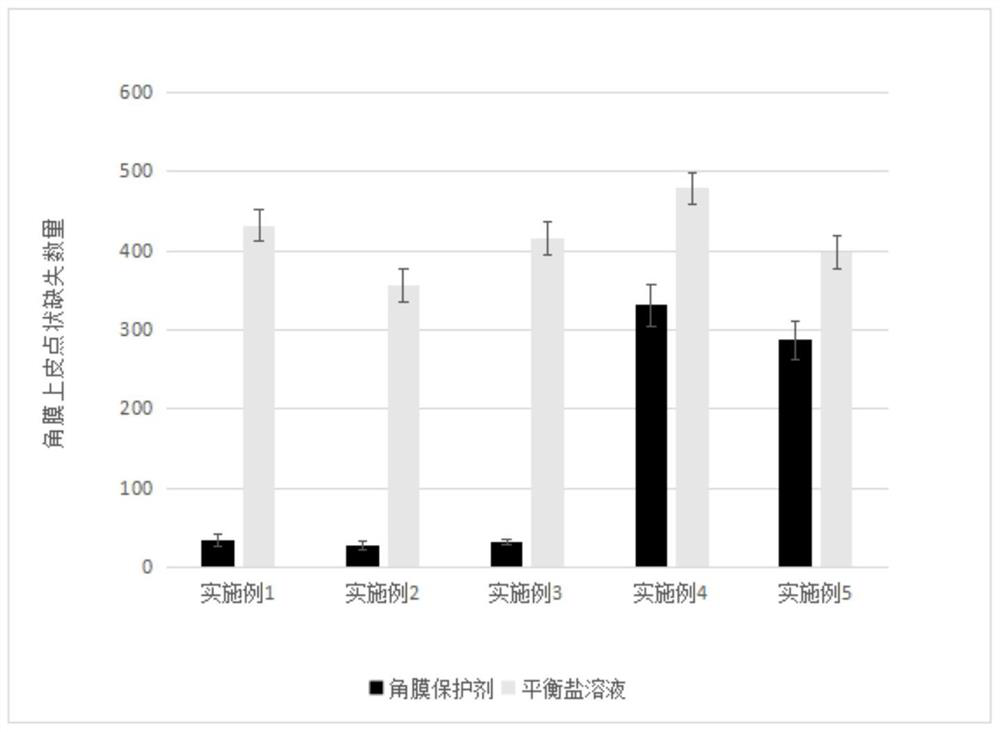

The invention belongs to the technical field of medical supplies, particularly relates to a corneal surface protectant, and also relates to a preparation method of the corneal surface protectant and an application range of the product. The corneal surface protectant disclosed by the invention comprises the following components: sodium hyaluronate, chondroitin sulfate or chitosan, wherein the molecular weight of the sodium hyaluronate is 100,000-2,000,000D and the concentration range is 5-200mg / ml; the molecular weight of the chondroitin sulfate is 5,000-100,000D and the concentration range is 5-200mg / ml; the molecular weight of the chitosan is 5,000-2,000,000D and the concentration range is 5-200mg / ml. Compared with the traditional preserving fluid, which is just applied to storing in vitro cornea tissue, the corneal surface protectant prepared by the method disclosed by the invention can be applied to a clinical operation, can coat the corneal surface in the operation process, and can keep the wettability and the transmittance of the cornea within a period of time, the dapping frequency in the operation is greatly reduced, the operation schedule is accelerated, and the comfort level of a sufferer is improved.

Owner:JINAN SANWEI MEDICAL INSTR CO LTD

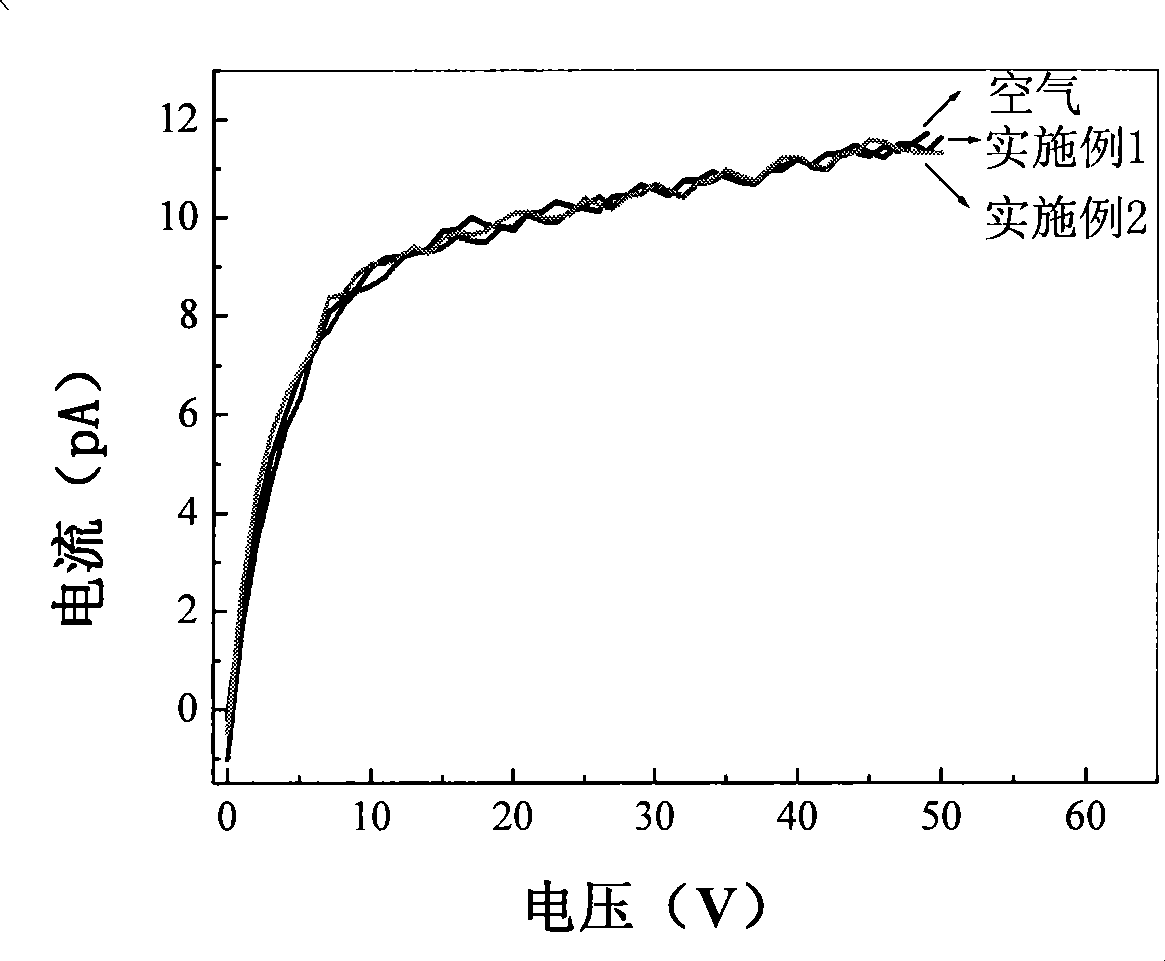

Modified silicone resin and preparation method thereof

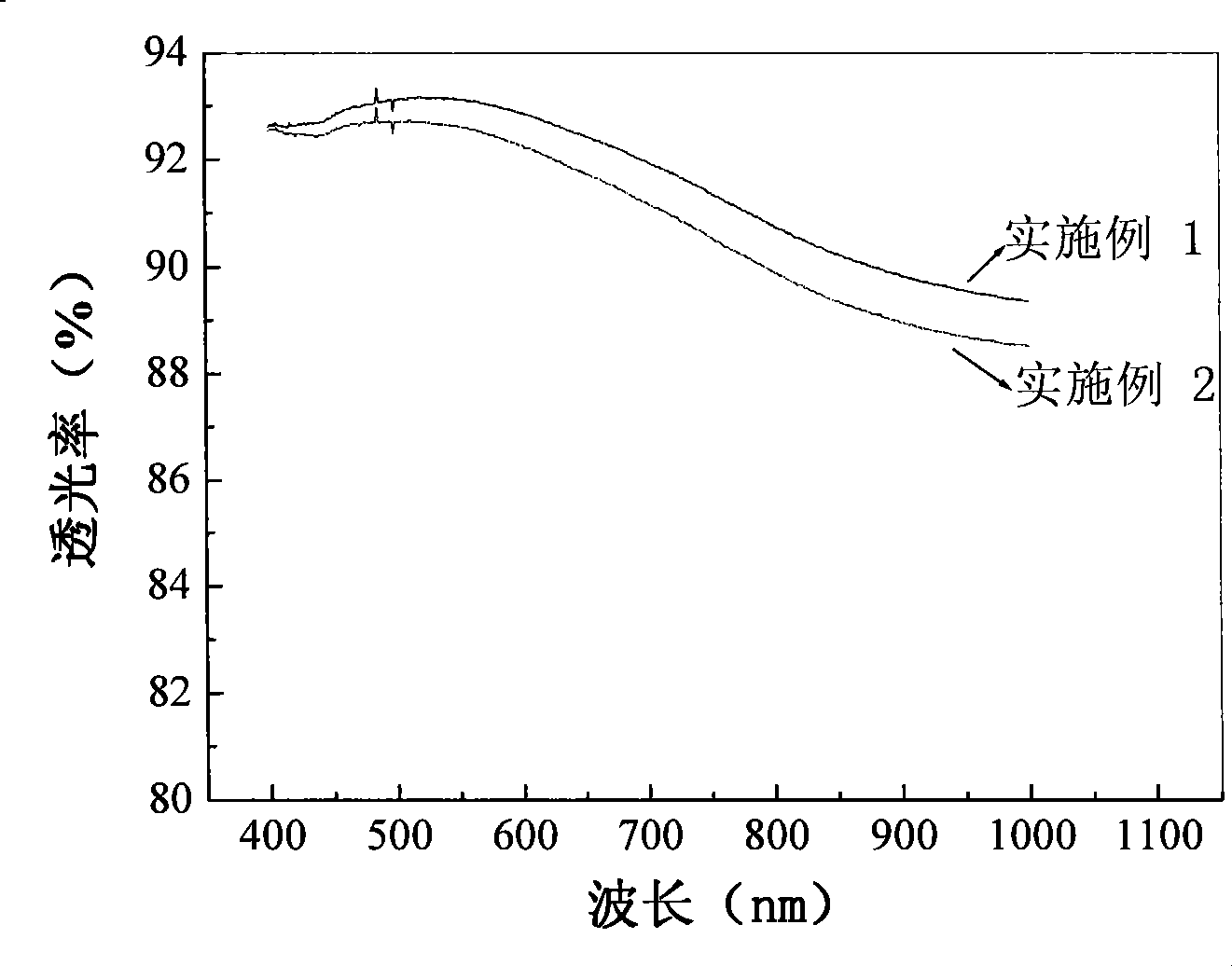

The invention discloses a modified silicone resin and a preparation method thereof. The modified silicone resin provided by the invention is a compound consisting of silicon oil and polysilsesquioxane, the flexural modulus of the modified silicon resin is 160 to 280 MPa, the transmittance in visible light (400 to 800 nm) range is 88 to 93 percent, and the insulativity of the modified silicon resin is the same as that of air. The preparation method for the modified silicone resin comprises the following steps: 1) dissolving the silicon oil and the polysilsesquioxane into a solvent to obtain a mixed solution; 2) placing the mixed solution in the environment of the temperature of between 0 and 40 DEG C and the relative humidity of 10 to 40 percent, and volatilizing the solvent to make that the percentage composition of gross mass of the polysilsesquioxane and the silicon oil in the mixed solution is 50 to 80 percent; and 3) placing the solution obtained in the step 2) in the acid environment with the relative humidity of more than 80 percent and pH of 0 to 3 to obtain the modified silicone resin.

Owner:INST OF CHEM CHINESE ACAD OF SCI

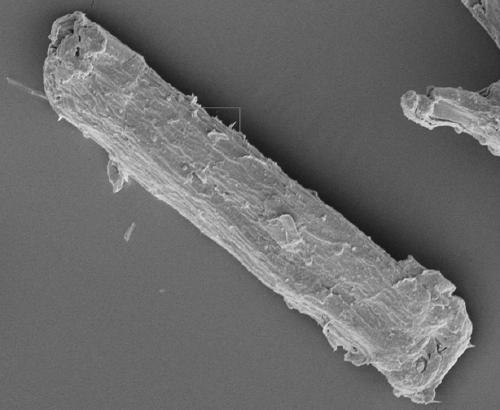

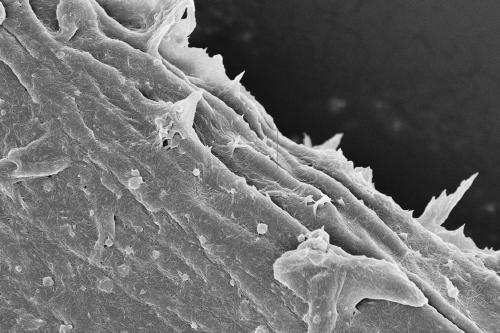

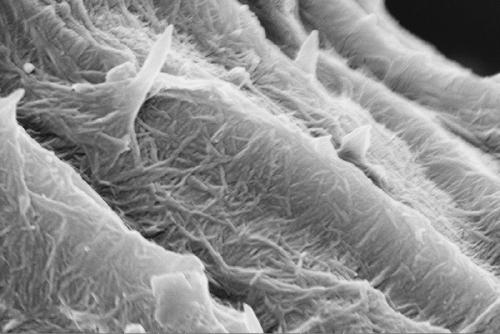

Nanometer cellulose/cellulose compound, enhanced polylactic acid 3D printing material and preparation method of enhanced polylactic acid 3D printing material

The invention belongs to the field of macromolecular composite materials and 3D printing materials, and specifically relates to a nanometer cellulose / cellulose compound capable of being applied to a polylactic acid 3D printing material and the relevant enhanced 3D printing material. According to the invention, the natural cellulose, acid, a silane coupling agent and polylactic acid are used as rawmaterials to obtain the nanometer cellulose / cellulose compound and the enhanced polylactic acid 3D printing material through a constant temperature water bath reaction and blending extrusion. In a preparation process, the steps of raw material pretreatment, mixing, heating in water bath, drying, blending extrusion, wire drawing and the like are performed; a whole preparation technology is simple;the repeatability is high; compared with pure polylactic acid, the prepared 3D printing material has the advantages that the mechanical property is remarkably improved, and the processing performanceis high; compared with an ordinary natural cellulose enhanced polylactic acid 3D printing material, the enhanced polylactic acid 3D printing material has the advantages that the transparency is high;during printing, end blockage and edge tilting are not prone to occur; and relatively-high application value is realized in the fields of home, decoration, lamps, art, model design and the like.

Owner:广州冠杰环保新材料科技有限公司

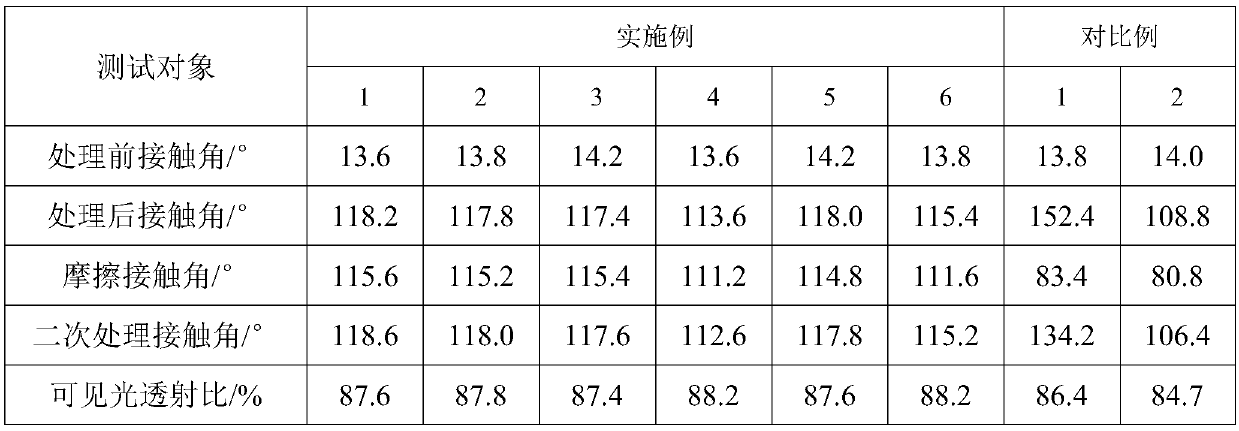

High-transparency glass hydrophobic agent and preparation method thereof

The invention belongs to the technical field of hydrophobic treatment on surface of glass, and particularly relates to a high-transparency glass hydrophobic agent and a preparation method thereof. Thehigh-transparency glass hydrophobic agent is prepared from the following raw materials in parts by weight: 100 parts of dimethylcyclosiloxane, 20-50 parts of phenylsiloxane, 5-10 parts of a silane coupling agent, 0.1-1 part of an alkaline catalyst, 5-100 parts of a nonionic surfactant and 10-90 parts of a solvent. A transparent hydrophobic film can be formed on the surface of glass, when water issprayed on the surface of the glass, water drops are formed, a contact angle reaches up to 110 degrees, the dropping speed of the water drops is greatly increased, and the water drops can automatically roll off without marks, so that the problem of unclear line of sight is solved.

Owner:湖北隆胜四海新材料有限公司

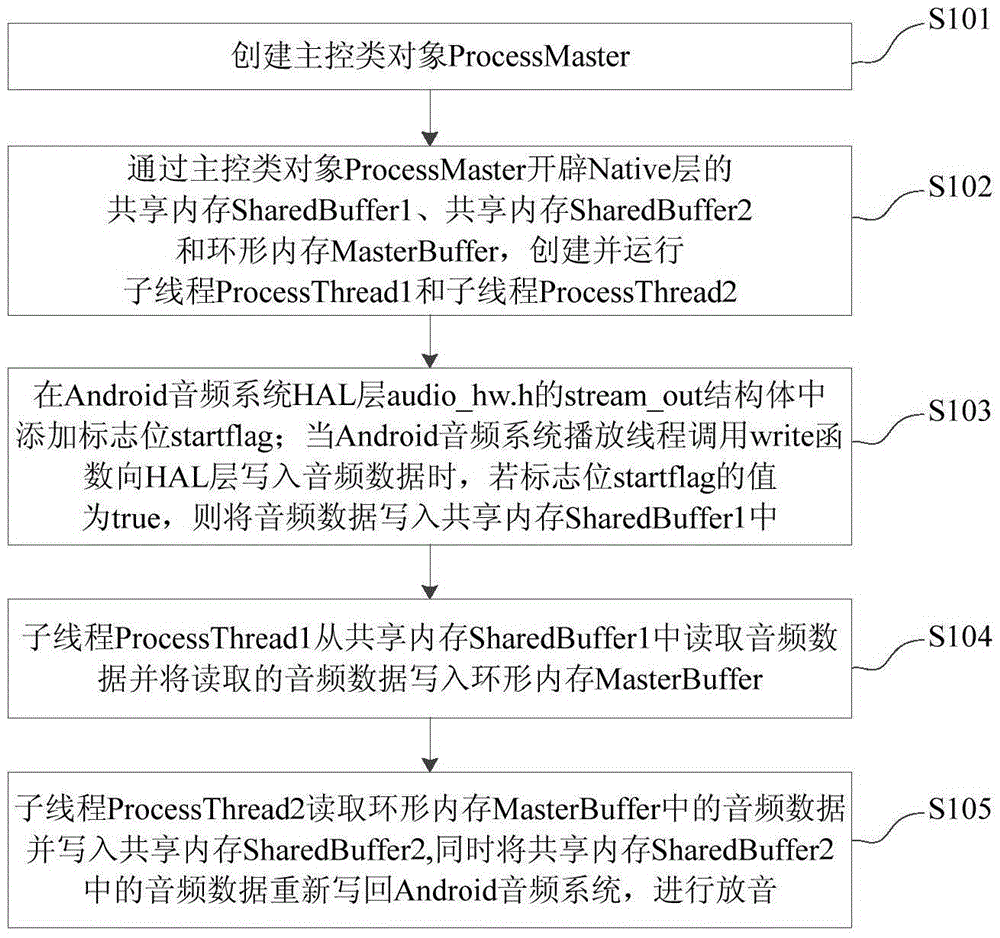

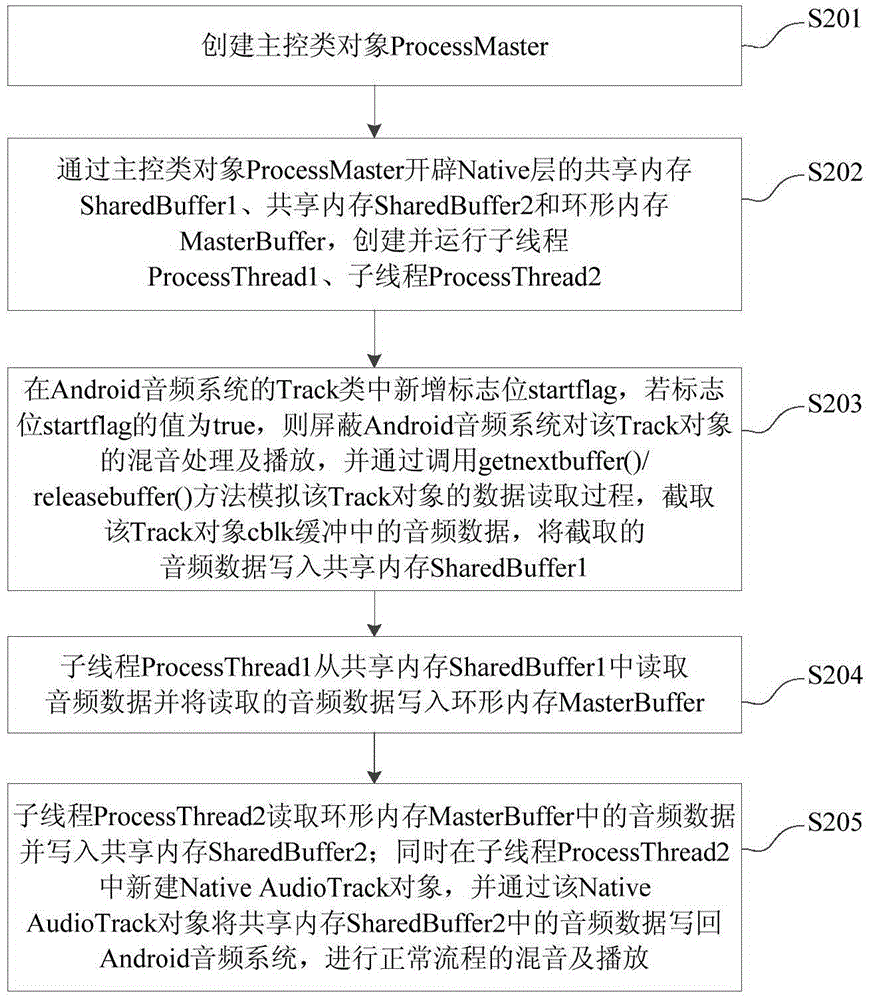

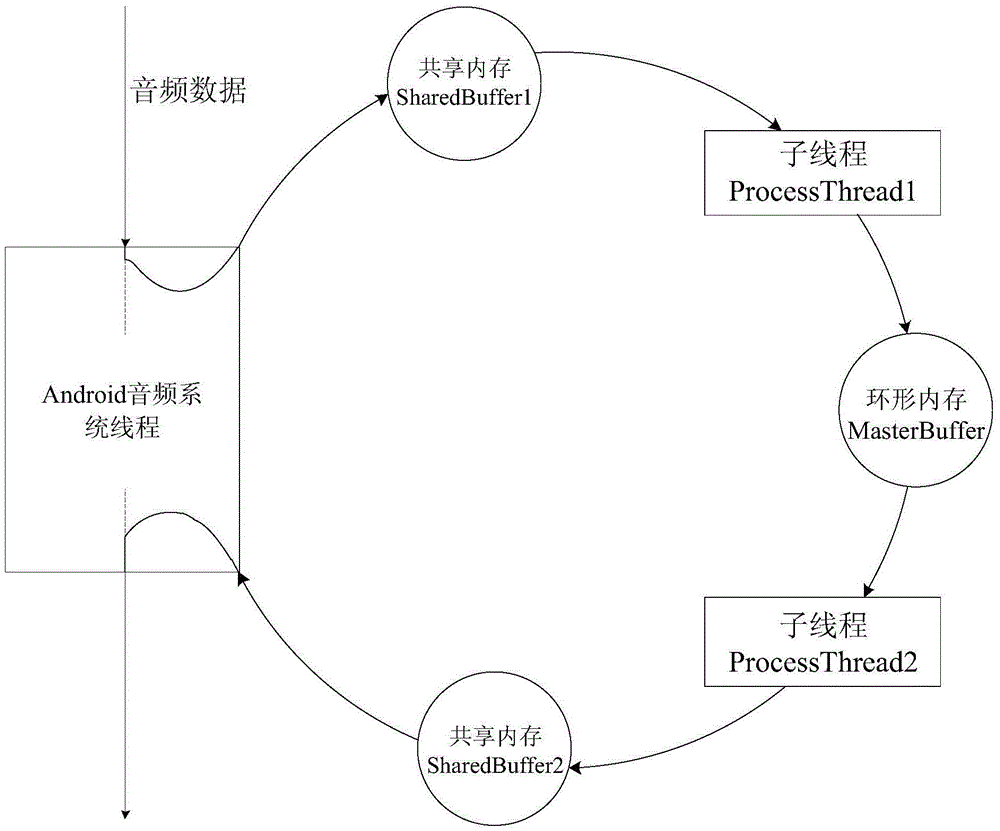

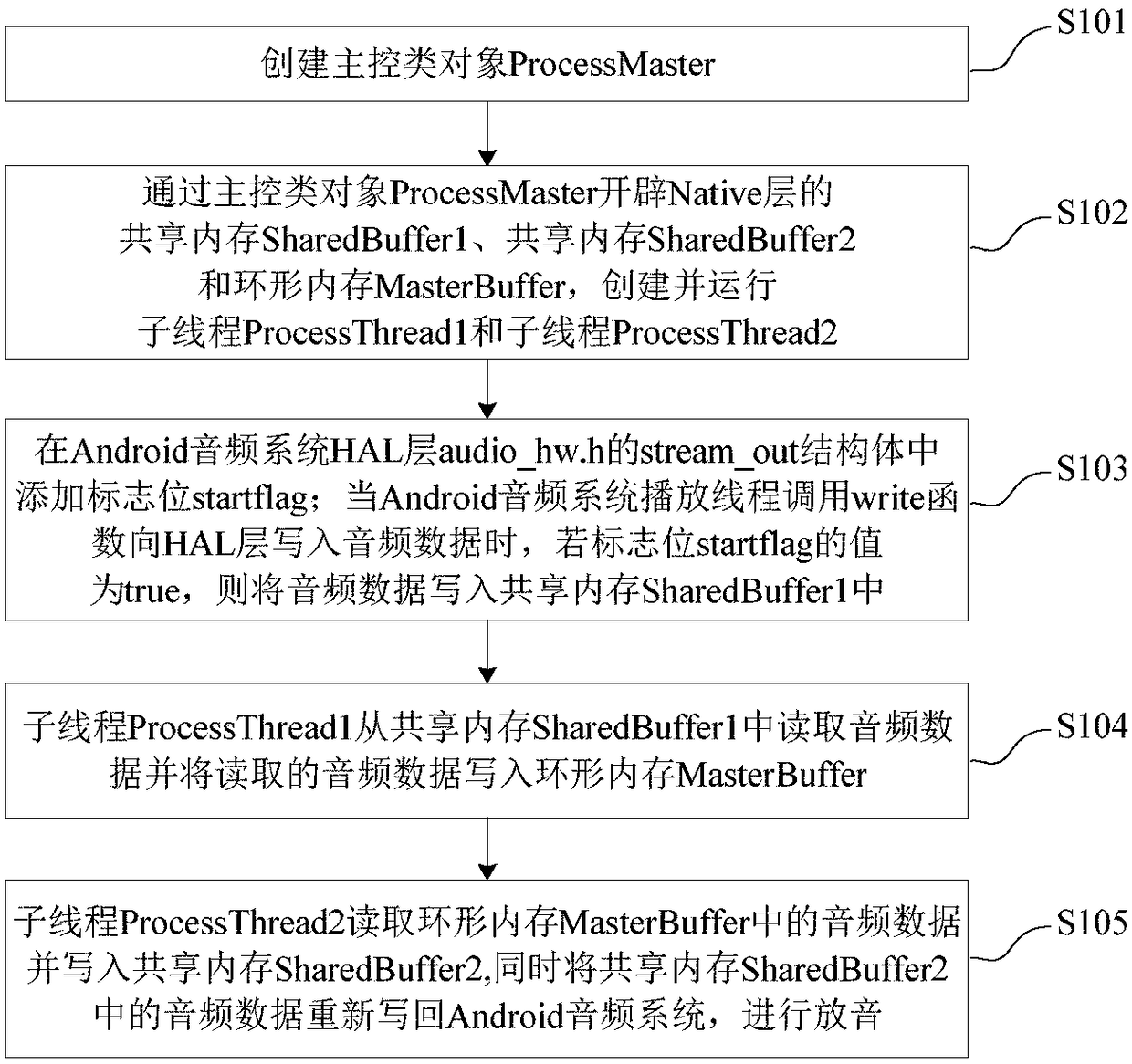

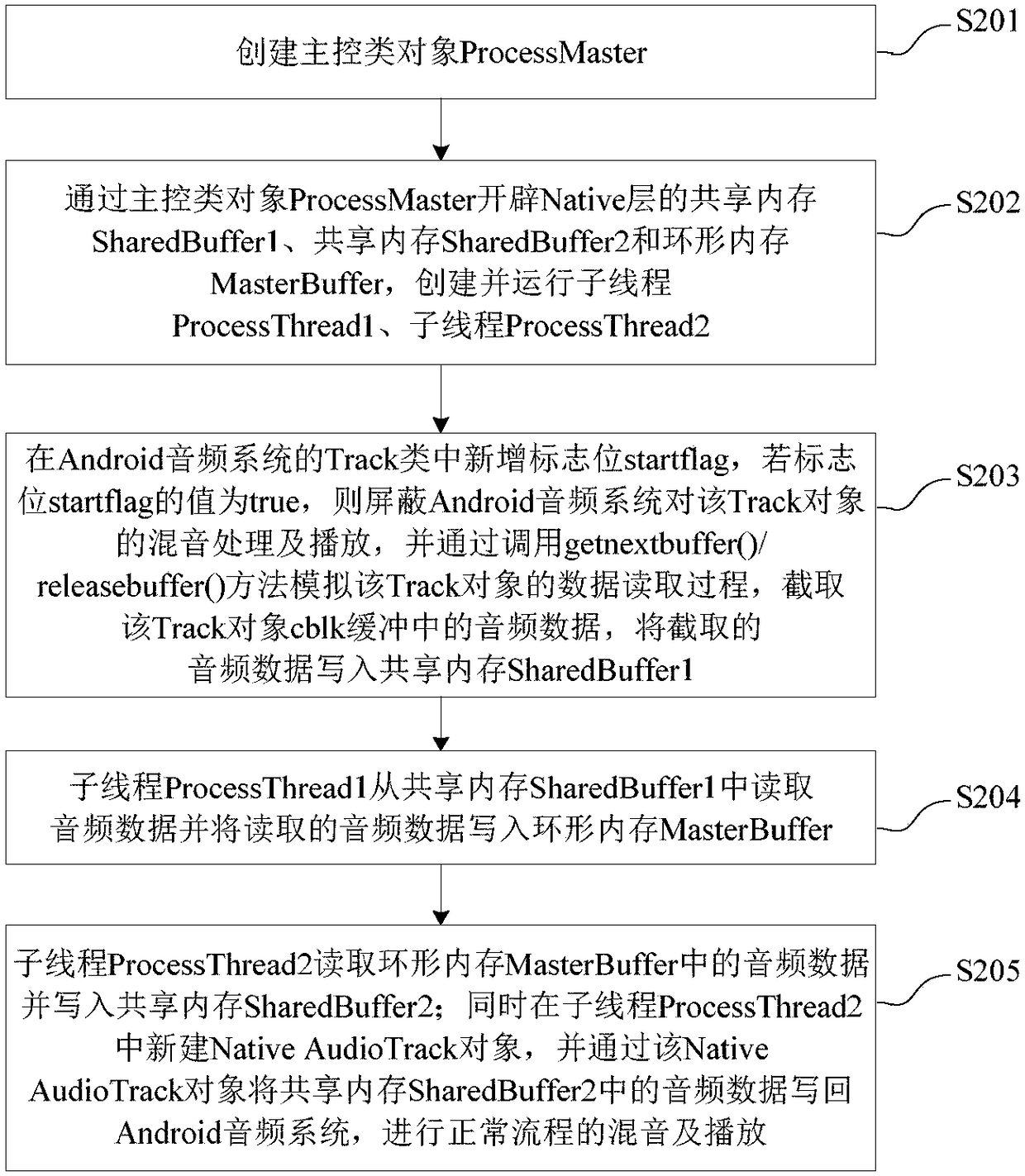

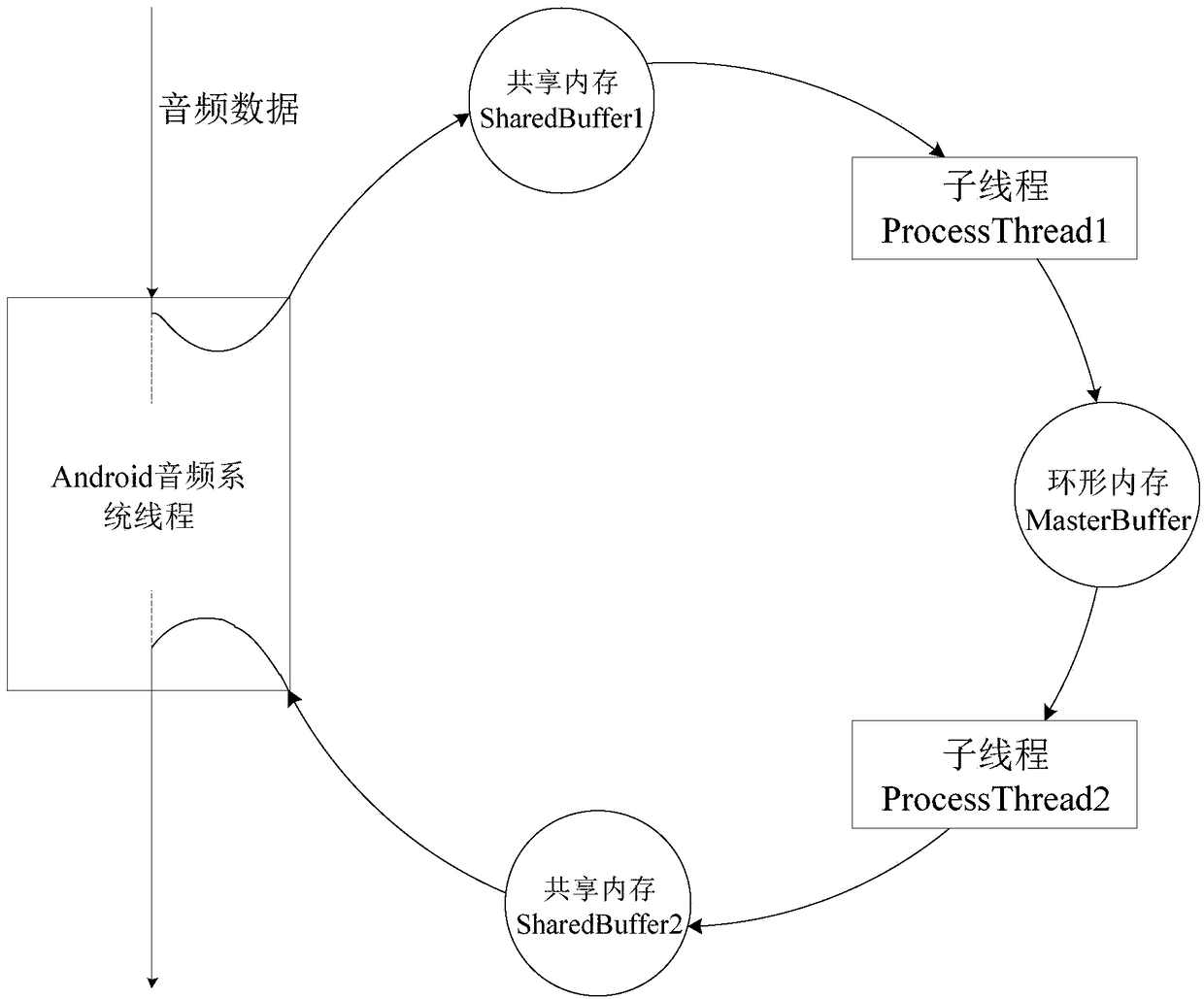

Third-party audio player oriented data interception method

The invention proposes a third-party audio player oriented data interception method. Starting from an audio core AudioFlinger of a Native layer of an Android system, a complete data interception closed loop is formed through interactive cooperation of a newly created cooperative working sub-thread and a standard Android audio system thread, so that the transparency to a third-party audio player can be kept while audio data of any third-party audio player are accurately intercepted. The third-party audio player oriented data interception method proposed by the invention is implemented with a software method and has good portability and backward compatibility.

Owner:NANJING UNIV OF POSTS & TELECOMM

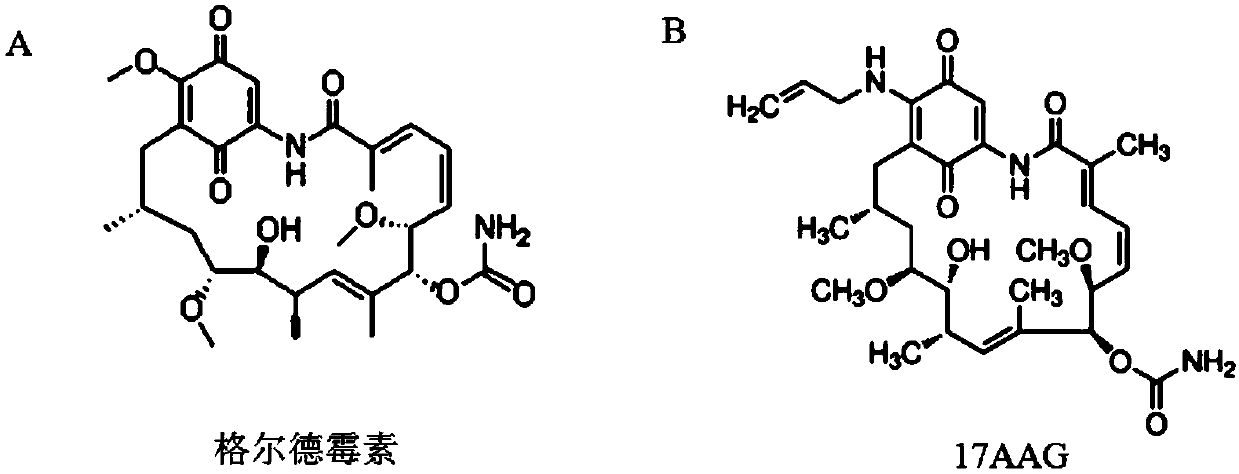

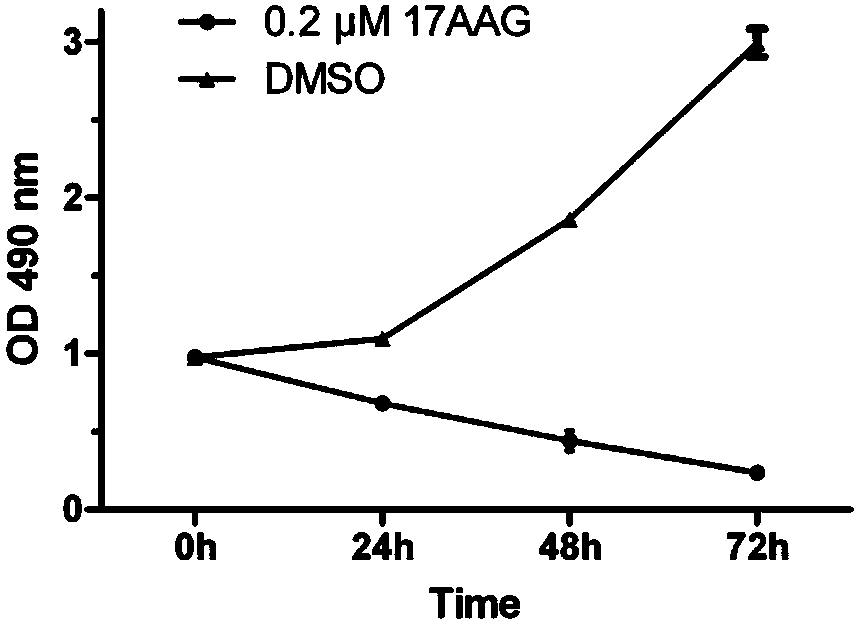

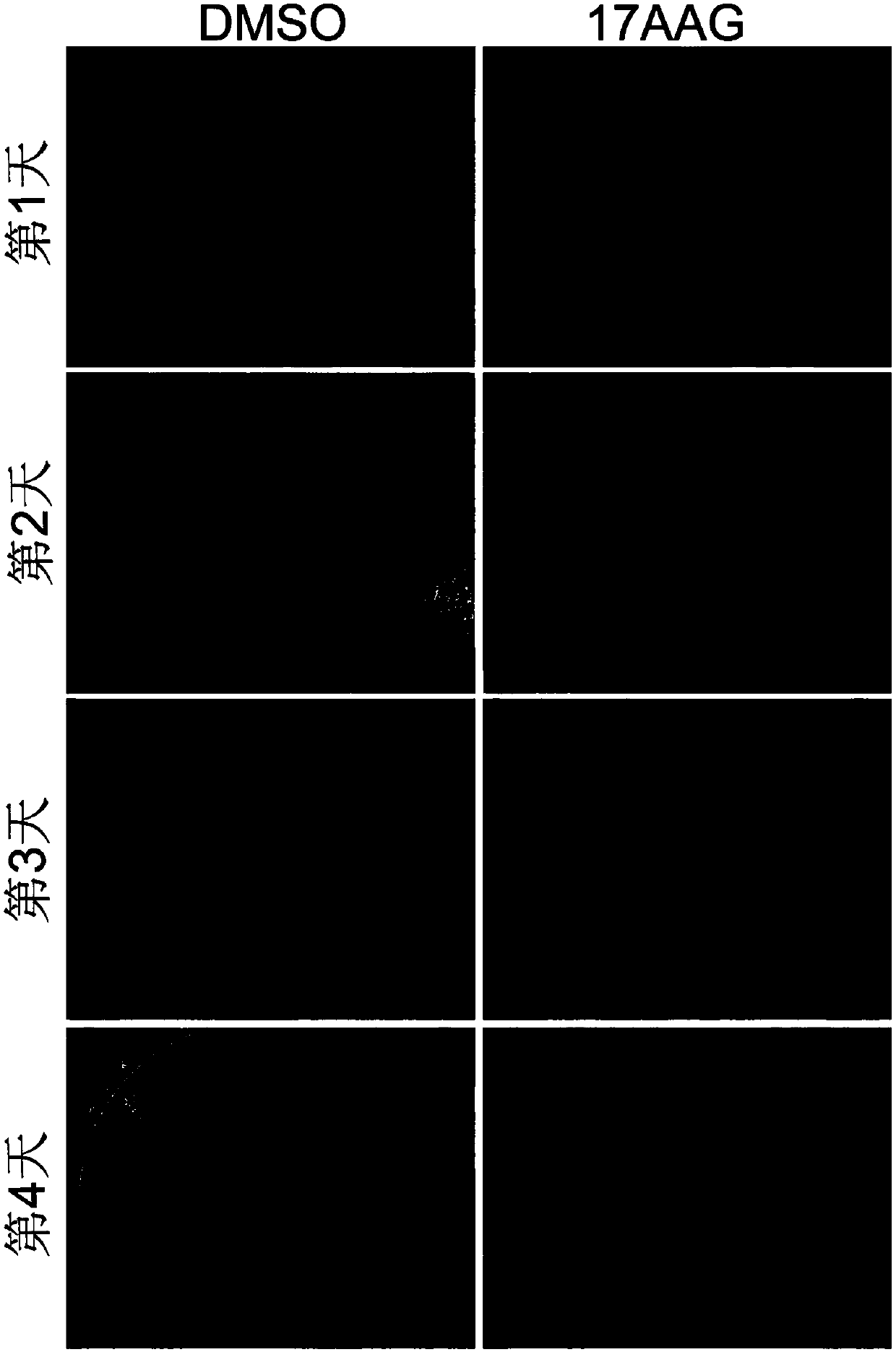

New application of geldanamycin and derivative thereof in treating and inhibiting posterior capsular opacification

InactiveCN107737122APrevent proliferationReduce proliferationOrganic active ingredientsSenses disorderGeldanamycinFibrosis

The invention relates to new application of geldanamycin and a derivative thereof in treating and inhibiting posterior capsular opacification, belonging to the technical field of medicines. Experiments prove that a geldanamycin derivative 17AAG inhibits human lens epithelial cells from proliferating and induces lens epithelial cells to die; in an in vitro rat lens capsular bag cultivation model, 17AAG inhibits residual lens epithelial cells from proliferating, migrating and fiberizing in a lens posterior capsule greatly, induces cells with posterior capsule overgrown to die, and promotes turbid lens posterior capsule to recover transparency; in a rabbit intraocular lens replacement model, 17AAG can inhibit posterior capsular opacification. The geldanamycin and the derivative thereof inhibit posterior capsular opacification by inhibiting HSP90 molecular chaperone activity of lens cells, and have a therapeutical effect on the formed posterior capsular opacification at the same time. 17AAG has new application in treating posterior capsular opacification, and is a candidate medicine that 17AAG has development potential and can prevent and treat posterior capsular opacification.

Owner:HENAN UNIVERSITY

Rose flavor beverage

The invention discloses a rose flavor beverage. The rose flavor beverage is prepared according to the steps of mixing the following raw materials by weight percent, and then adopting dry ice for cooperatively homogenizing, filtering, sterilizing and filling. The raw materials include 1-1.5% of rose hydrosol, 1.5-2% of rose honey and the balance of water. The edible rose is used as the raw material of the rose flavor beverage disclosed by the invention, a rose hydrosol by-product which is generated after a steam distillation method is adopted for preparing essential oil is mixed with water at a ratio, no external pigment, essence, sweetening agent or preservative is added, the components are natural and pure, and the fragrance is light and pleasant. The rose flavor beverage has unique flavor and healthcare functions, such as, oxidation resistance, and is suitable for all people.

Owner:庐江县璟泰玫瑰花种植有限责任公司

Preparation method of medicine-carrying soft corneal contact lens

The invention discloses a preparation method of a medicine-carrying soft corneal contact lens. The preparation method comprises the following steps: sequentially adding a methylacrylic acid-beta-hydroxy ethyl acrylate prepolymer, ethylene glycol dimethyl acrylate (EGDMA), azodiisobutyronitrile (AIBN) and medicines into a solvent, uniformly stirring, coating the obtained slurry to a plate with a round hole, then transferring and printing the slurry to the surface of a male die, and then putting the plate into an oven, and heating and curing; repeating the operation to obtain a medicine film with different layers; and after uniformly mixing methylacrylic acid-beta-hydroxy ethyl acrylate (HEMA), methylacrylic acid, N-vinyl pyrrolidone (NVP), EGDMA and AIBN, weighing the mixed solution in a female die, then further embedding the male die printed with the medicine film into the female die, then putting the female die in the oven, curing, and turning to form a sheet to obtain the medicine-carrying soft corneal contact lens. The medicine-carrying soft corneal contact lens prepared by the preparation method disclosed by the invention is strong in transmission of light, long in drug sustained release period, stable to release and high in bioavailability.

Owner:JINAN UNIVERSITY

Method for manufacturing antibacterial watering bucket

The present invention discloses a method for making antibacterial drinking water urn. Said method includes the following steps: firstly, making high-concentrated antibacterial PET mother granules: uniformly mixing PET, nano-grade inorganic antibacterial agent and adjuvant in high-speed mixing machine; then placing the above-mentioned mixture into twin screw extruder machine, in the temperature range of 250-280deg.C melting and making high-concentrated antibacterial PET mother granules; then mixing the obtained high-concentrated antibacterial PET mother granules and PET raw material according to a certain ratio, drying for 4hr. at 150deg.C in air blast drying machine, adding the above-mentioned material into injection-moulding machine and forming to obtain drinking water urn bottle blank, then placing said drinking water urn bottle blank into bottle-blowing machine to make blowing so as to obtain the invented antibacterial drinking water urn.

Owner:MEILIN ZHENGGUANGHE GROUP SHANGHAI

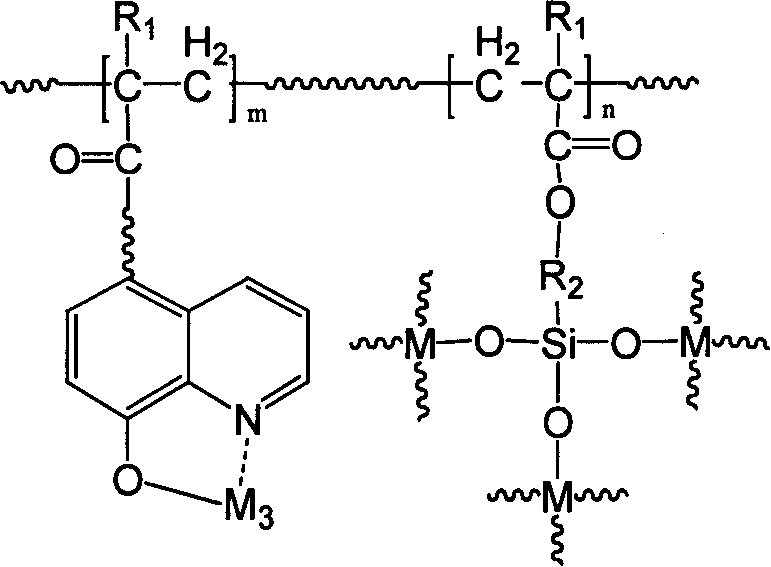

High-polymer molecular hybrid luminescent materials containing 8-hydroxyquinoline metal complex and production thereof

InactiveCN1818011ABe transparentMaintain mechanical propertiesLuminescent compositionsDisplay deviceQuinoline

A high-polymer molecular hybrid luminescent material containing 8-hydroxy quinoline metal complex and its production are disclosed. In the general formula, R1 represents hydrogen atom or alkyl radical containing 1-10 carbon atom, R2 represents alkyl radical containing 1-10 carbon atom, m and n are unit number of two atactic copolymerization structural units (m:n=1:1-100), M expresses B, P, Si, Ti or Al. In formula (1), M1 is trivalent metal component, in formula (2), M2 is bivalent metal component, and in formula (3), M3 is univalent metal component. The process is carried out by adding vinyl monomer of 8-hydroxy quinoline metal complex, organic silicon vinyl monomer, catalyst and initiating agent into sol system, or inorganic phase hydrolytic condensation reacting while organic copolymerization reacting under the existence of coupling agent to obtain the final product. It is simple, has better stability, film forming performance and higher luminescent efficiency. It can be used for electro-luminescent planar display device.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

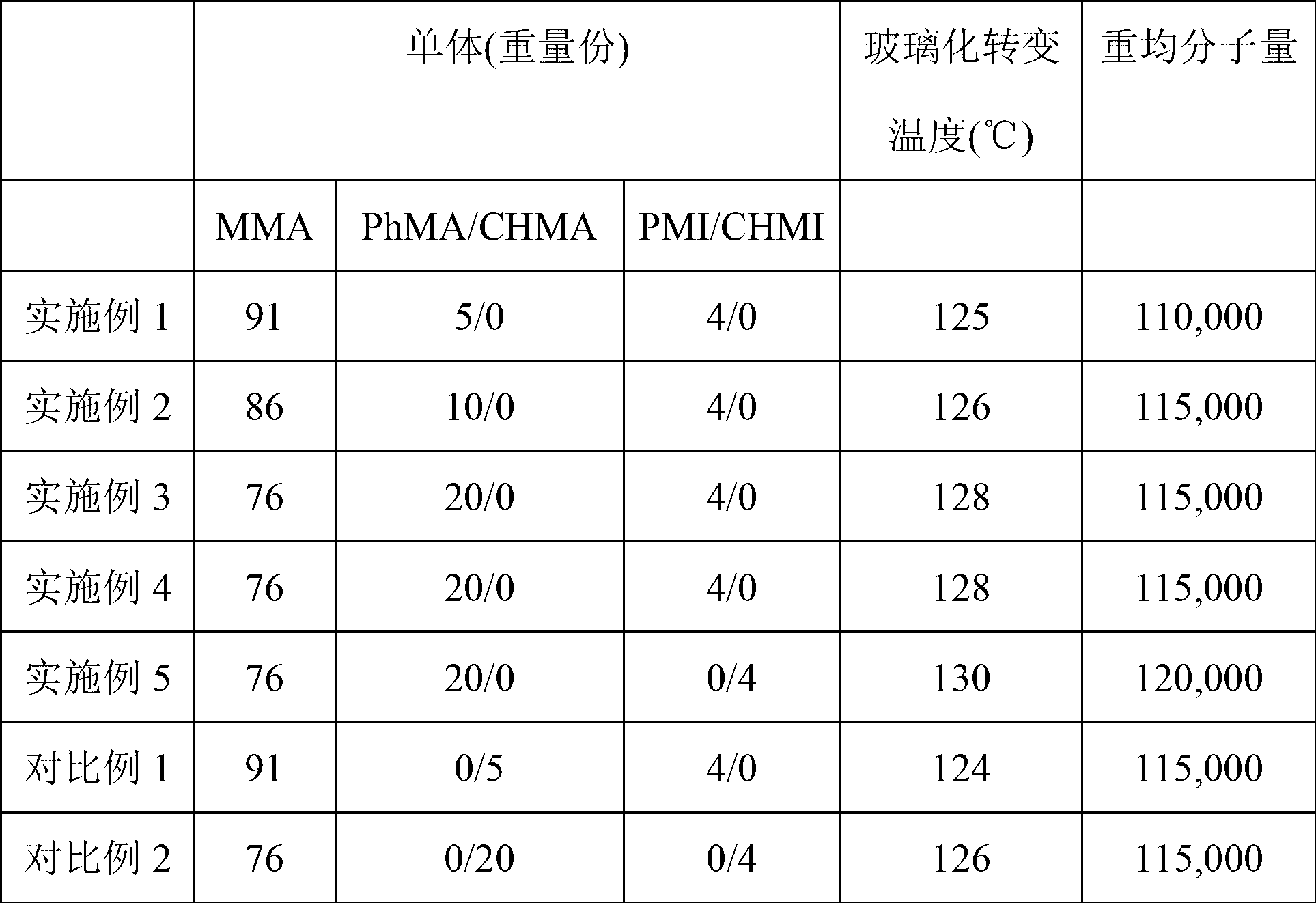

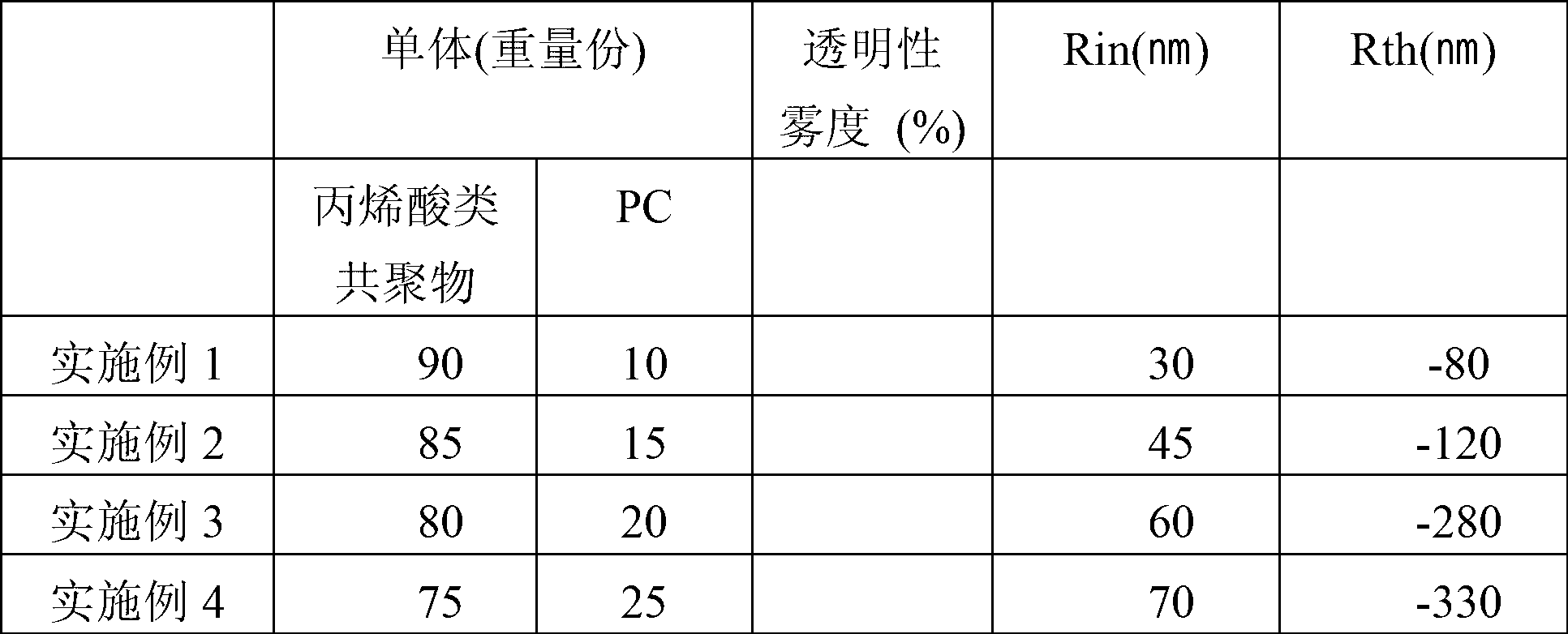

Acryl-based copolymers and optical film including the same

ActiveCN102985454AGood heat resistanceBe transparentDiffusing elementsNon-linear opticsAcrylateOptical film

Owner:LG CHEM LTD

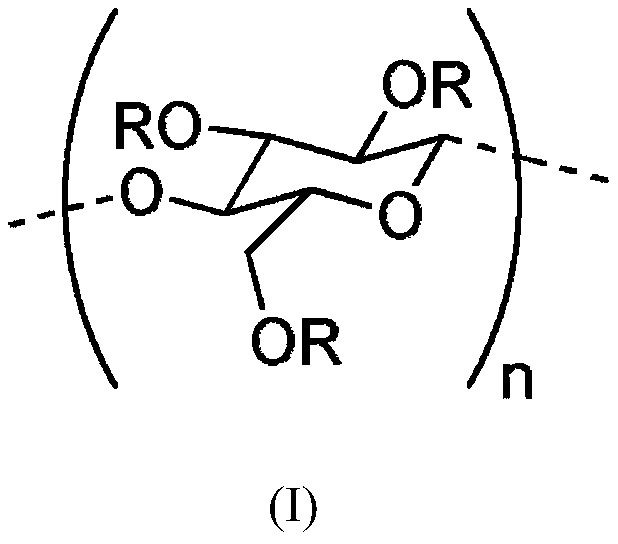

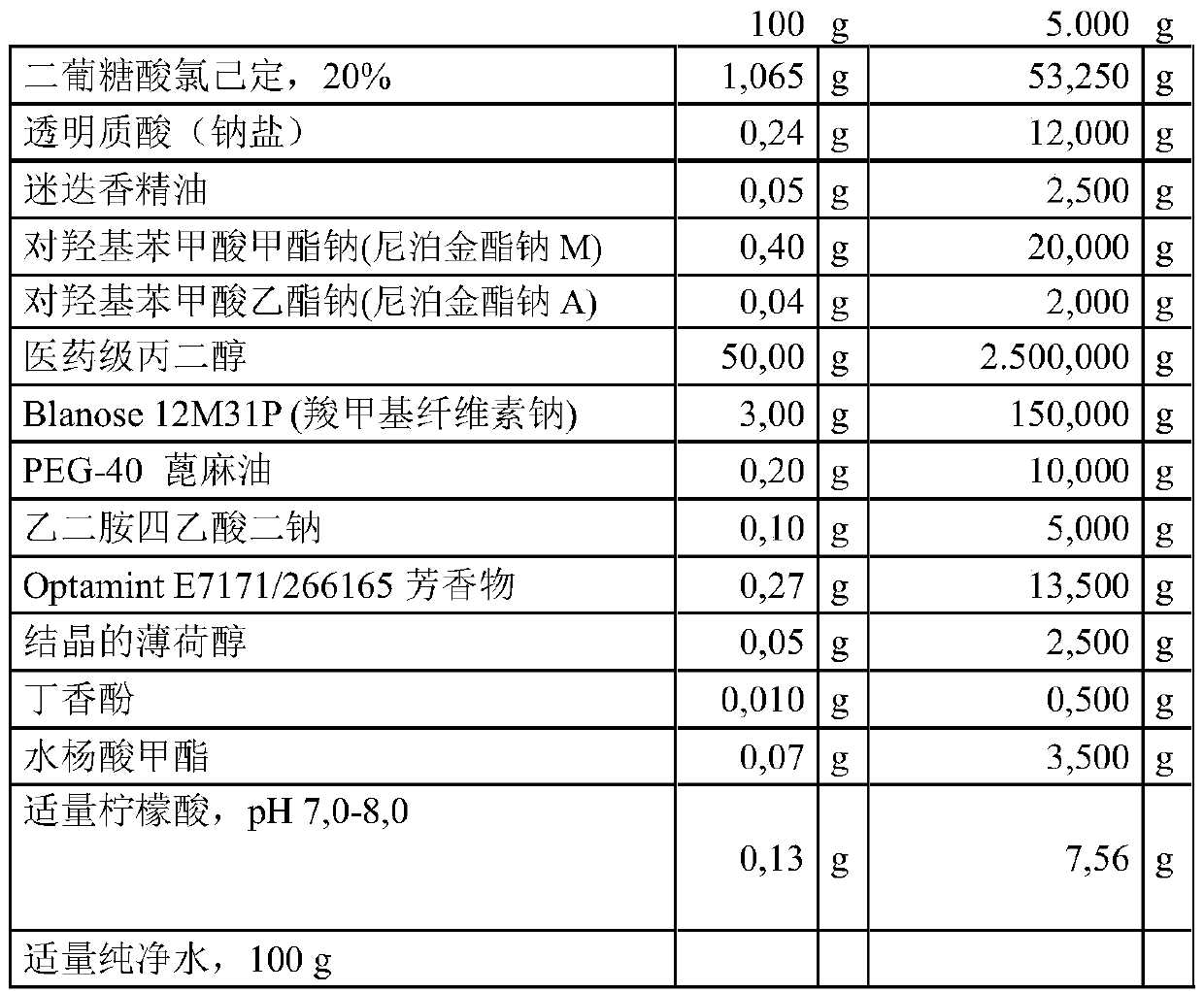

Gel comprising chlorhexidine

ActiveCN110996891AMaintain consistencyBe transparentCosmetic preparationsToilet preparationsOral diseaseChlorhexidine

The invention relates to a gel composition comprising chlorhexidine and / or a pharmaceutically acceptable salt thereof; hyaluronic acid and / or a pharmaceutically acceptable salt thereof; and a gellingmatrix, wherein the gelling matrix comprises water, and cellulose derivatives. The invention also relates to a method for preparing the gels and to particular uses of the gels in the field of oral cavity cosmetics, hygiene, prevention of oral cavity diseases and treatment of said diseases.

Owner:实验室金公司

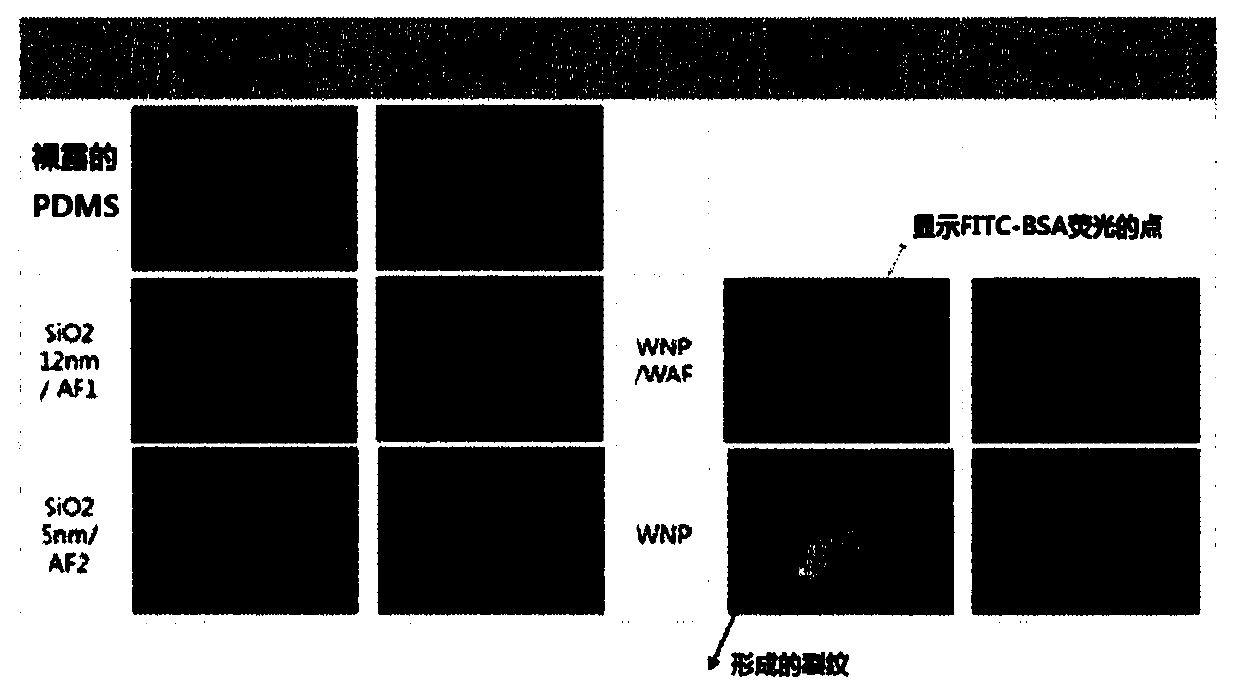

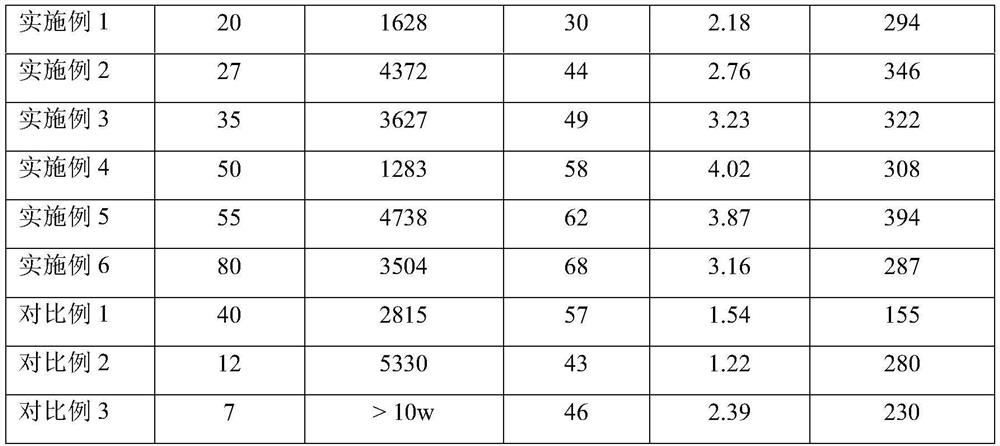

Method for modifying surface of polymer substrate and polymer substrate having surface modified thereby

ActiveCN110582529AWithout compromising transparencyDoes not compromise flexibilityPretreated surfacesMaterial granulationPolymer sciencePolymer substrate

Owner:汉阳大学校产学协力团埃丽卡校区 +1

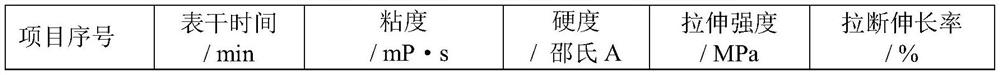

Low-viscosity and high-strength transparent dealcoholized organosilicon sealant and production method thereof

PendingCN114196372AHigh mechanical strengthMaintain viscosityMacromolecular adhesive additivesEndcappingPolymer science

The invention discloses a transparent dealcoholized organosilicon sealant with low viscosity and high strength, which is characterized by comprising the following components in parts by weight: 100 parts of alkoxy-terminated polydimethylsiloxane; 5 to 50 parts of methoxy modified silicon resin; 5-50 parts of methyl MQ silicone resin; 3-10 parts of a cross-linking agent; 0.5-3 parts of a coupling agent; 0.5-3 parts of a compound catalyst; the invention also discloses a production method of the transparent dealcoholized organosilicon sealant with low viscosity and high strength. The low-viscosity and high-strength transparent dealcoholized organosilicon sealant has the advantages of high mechanical strength and low viscosity, and can be widely applied to the fields of electronic appliances, high-end medical equipment, automobile industry and the like; the production method disclosed by the invention is simple to operate, good in reproducibility and small in dust.

Owner:GUANGZHOU BAIYUN CHEM IND +1

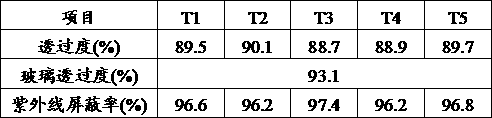

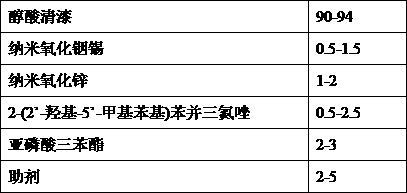

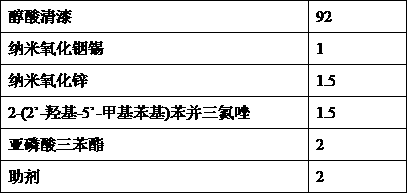

Protective coating, and preparation method and application thereof

The invention relates to a transparent or semitransparent composite functional coating, and a preparation method and an application thereof. The coating comprises alkyd resin varnish, nano indium tin oxide (ITO), 2-(2'-hydroxyl-5'-methyl phenyl) benzotriazole, triphenyl phosphite and an accessory according to certain mass proportions. The coating is good in performance, and is capable of effectively preventing and stopping yellowing, cracking and oxidizing phenomena of a protected substrate, thereby being a new protective coating with an anti-aging function.

Owner:肇庆易涂宝涂料有限公司

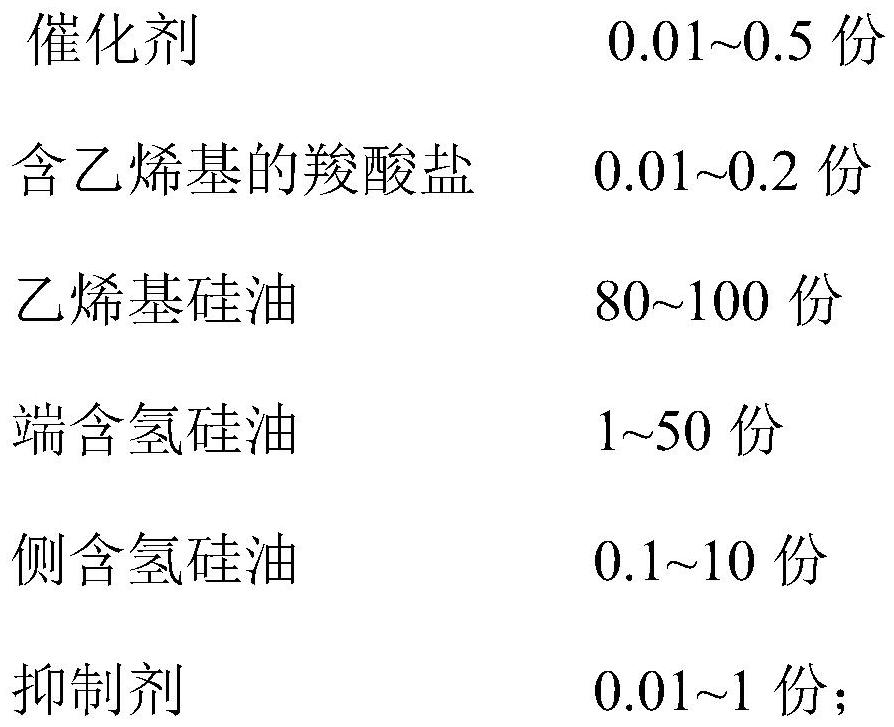

High-heat-resistance silica gel and preparation method thereof

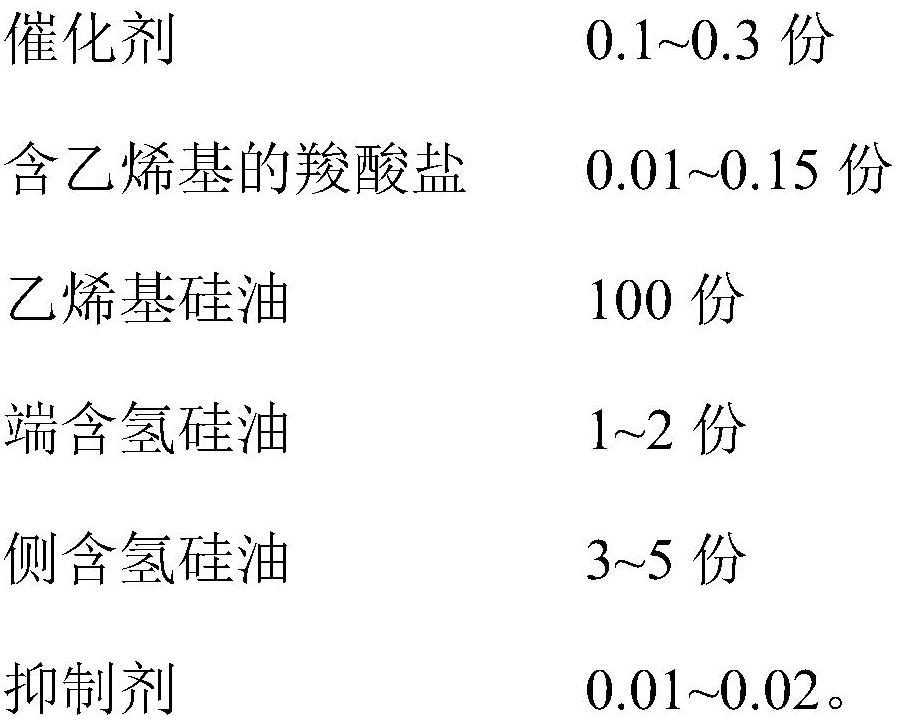

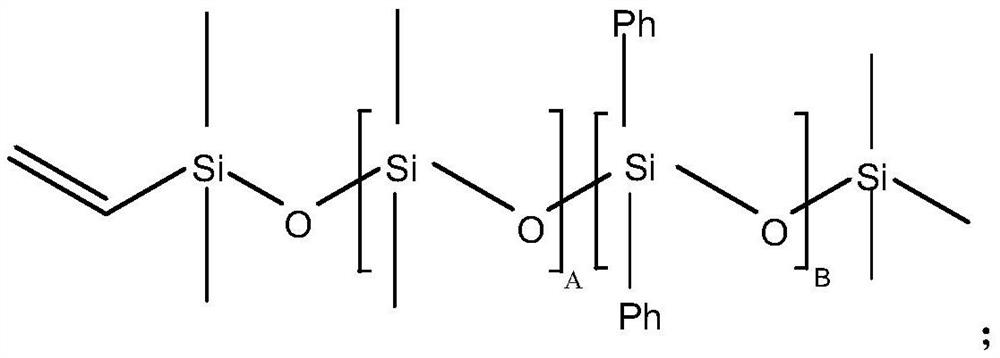

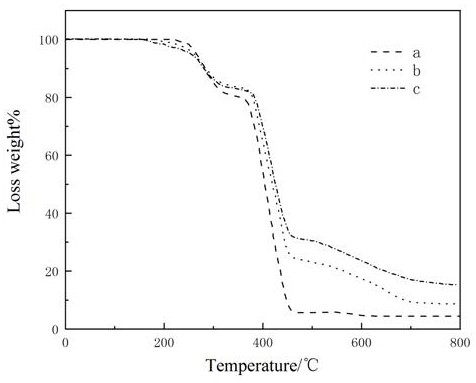

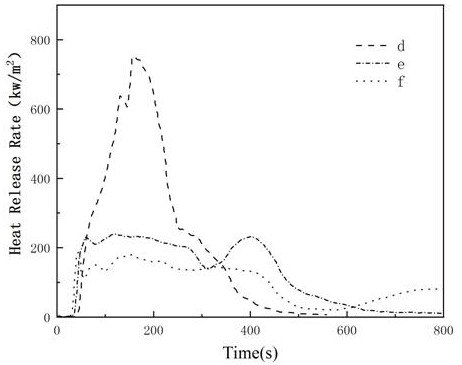

The invention relates to high-heat-resistance silica gel and a preparation method thereof. The high-heat-resistance silica gel is prepared from the following raw materials in parts by weight: 0.01-0.5part of a catalyst, 0.01-0.2 part of carboxylate containing vinyl, 80-100 parts of vinyl silicone oil, 1-50 parts of terminal hydrogen-containing silicone oil, 0.1-10 parts of side hydrogen-containing silicone oil and 0.01-1 part of an inhibitor, wherein carboxylate containing vinyl is nickel carboxylate containing vinyl and / or niobium carboxylate containing vinyl. The silica gel can still keep the needle penetration degree not to be reduced, and is not hardened and free of cracks and transparent after being baked at the temperature of 250 DEG C for 1000 hours, has excellent electrical insulating property, and can be stably applied to the field of high-power IGBTs.

Owner:GUANGZHOU BAIYUN CHEM IND

Production process of EVA (Ethylene Vinyl Acetate) film for flame-retardant laminated glass

ActiveCN113771326AGuaranteed stabilityGuaranteed service lifeNon-macromolecular adhesive additivesMacromolecular adhesive additivesFlat glassThermal dilatation

The invention discloses a production process of an EVA (Ethylene Vinyl Acetate) film for flame-retardant laminated glass, and belongs to the technical field of glass interlayer glue. The EVA film in the laminated glass has the advantages of high hardness, high strength, high collision resistance and high damage resistance, the high-altitude safety of the laminated glass is improved, the curability and weather resistance are good, the creep deformation caused by thermal expansion and cold contraction of the laminated glass is prevented, the stability and the service life of an interlayer are guaranteed, and flat glass is transparent and flame-retardant and still has good light transmission. The fireproof glass is still transparent in the initial stage of a fire, flames can be seen through the glass, and the fire site and the fire danger degree can be judged. Along with fire spreading and expanding, indoor temperature is increased, the interlayer is heated to expand and foam, a transparent substance is gradually expanded and converted into a non-transparent porous substance to form a very thick fireproof heat-insulating layer, and the fireproof heat-insulating protection effect is achieved. The excellent fireproof heat-insulating performance is achieved, and the application environment and temperature range is wide.

Owner:安徽省阳明达新材料科技有限公司

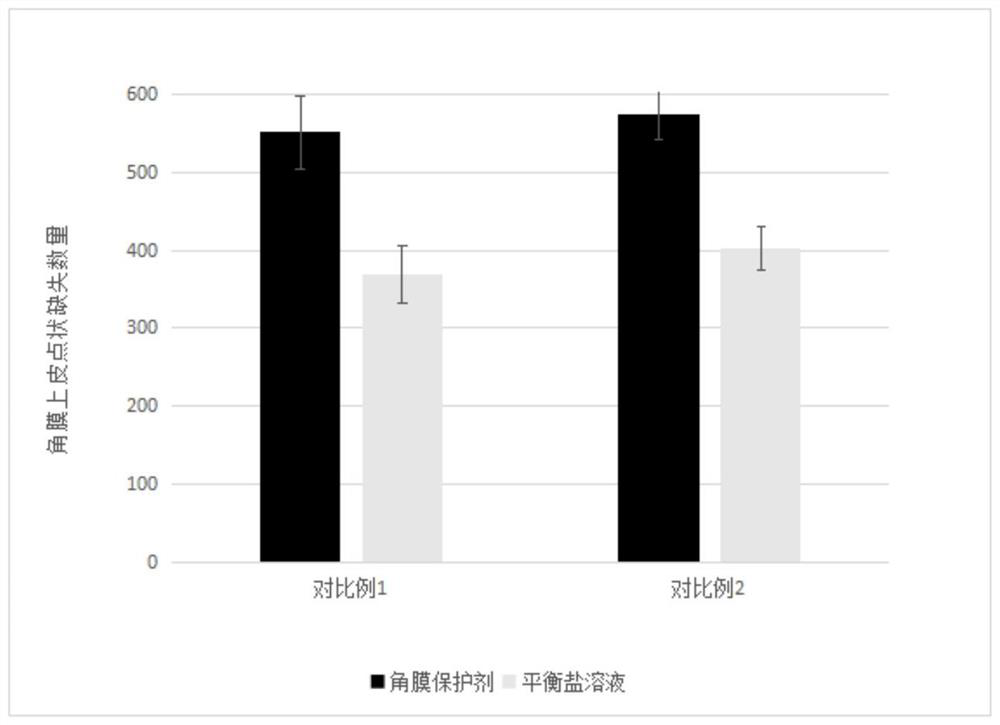

Cornea protective agent as well as preparation method and application thereof

PendingCN113876800AHigh transparencyReduced risk of epithelial dysfunctionOrganic active ingredientsSenses disorderSurgeryMethyl palmoxirate

The invention provides a cornea protective agent. The cornea protective agent comprises hydroxypropyl methyl cellulose with the viscosity of 5mPa.S to 200,000 mPa.S and / or chondroitin sulfate with the molecular weight of 20,000 to 500,000, an anti-inflammatory substance and a buffer solution. The cornea protective agent disclosed by the invention can protect the cornea surface in an operation, can keep the cornea surface moist within a certain time and keep good transparency of the cornea, and provides a good operation visual field. Meanwhile, the risk of postoperative corneal epithelium dysfunction can be reduced, and postoperative complications are reduced.

Owner:TIANJIN JINGMING NEW TECH DEV CO LTD

Method for improving moist feeling of decorative wood material

InactiveCN1429694AGuaranteed textureEnsure normal breathingCork treatment detailsPulp and paper industryBathing

A process for improving the moist feeling of decorative wood features that the said decorative wood is immersed in a treating liquid containing non-silicon non-ionic softening agent (with wt. 1-8% relative to wood wt. and bathing ratio of 1:10 at 40-100 deg.C for 10-60 min for increasing the grade of decorative wood.

Owner:NANTONG TEXTILE VOCATIONAL TECH COLLEGE

A data interception method for third-party audio players

ActiveCN105468360BBe transparentImprove portabilityExecution paradigmsComputer hardwareComplete data

The invention proposes a third-party audio player oriented data interception method. Starting from an audio core AudioFlinger of a Native layer of an Android system, a complete data interception closed loop is formed through interactive cooperation of a newly created cooperative working sub-thread and a standard Android audio system thread, so that the transparency to a third-party audio player can be kept while audio data of any third-party audio player are accurately intercepted. The third-party audio player oriented data interception method proposed by the invention is implemented with a software method and has good portability and backward compatibility.

Owner:NANJING UNIV OF POSTS & TELECOMM

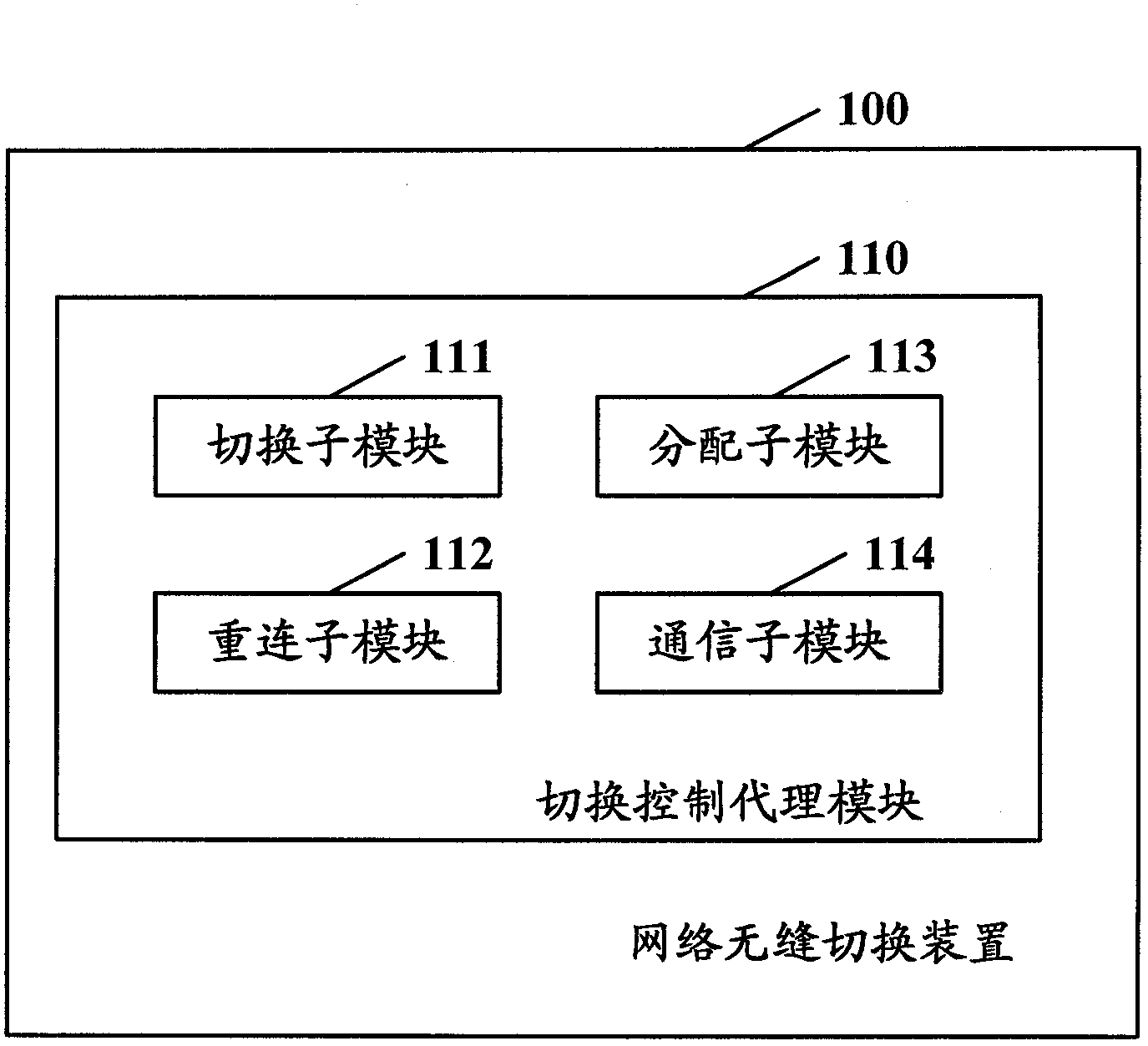

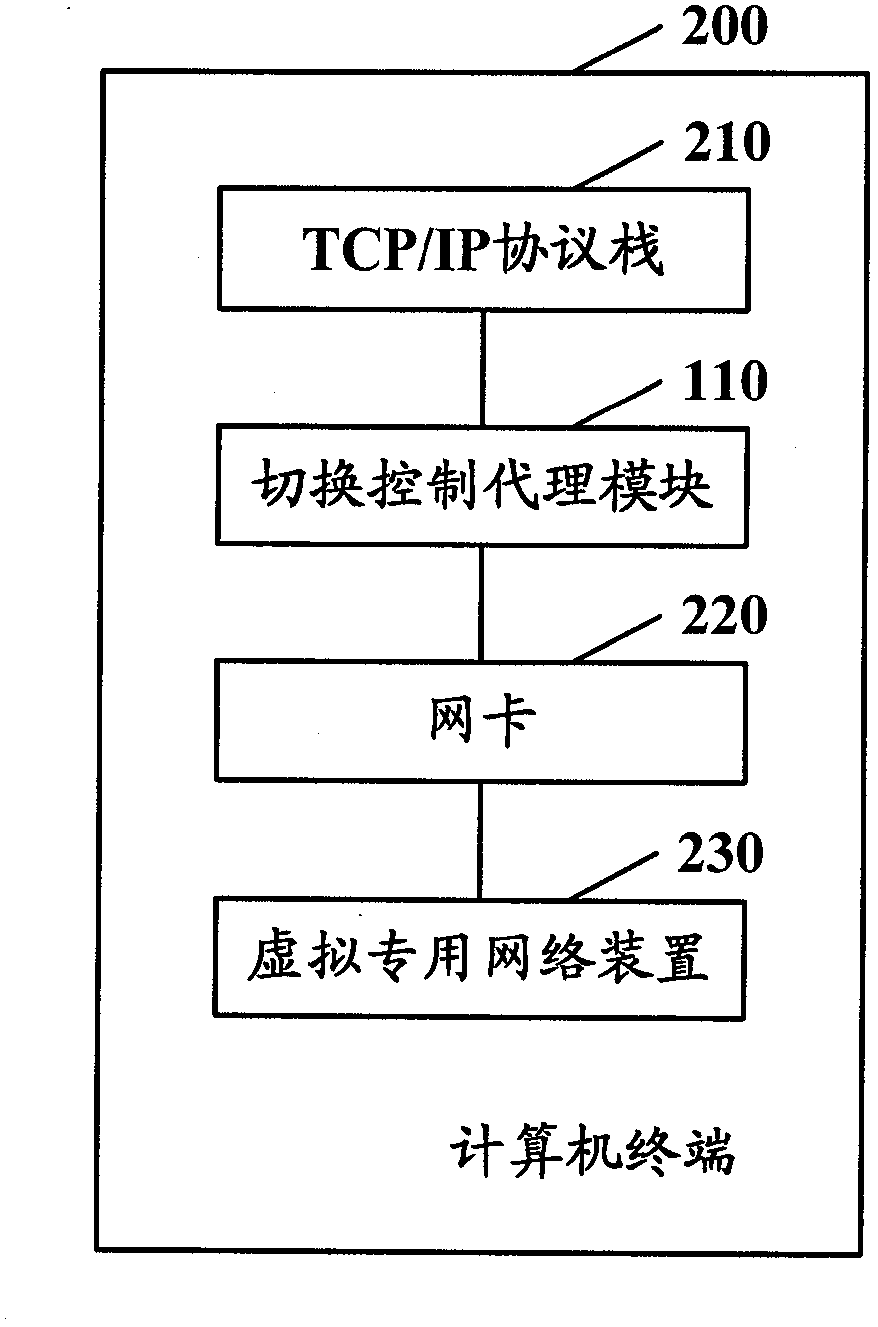

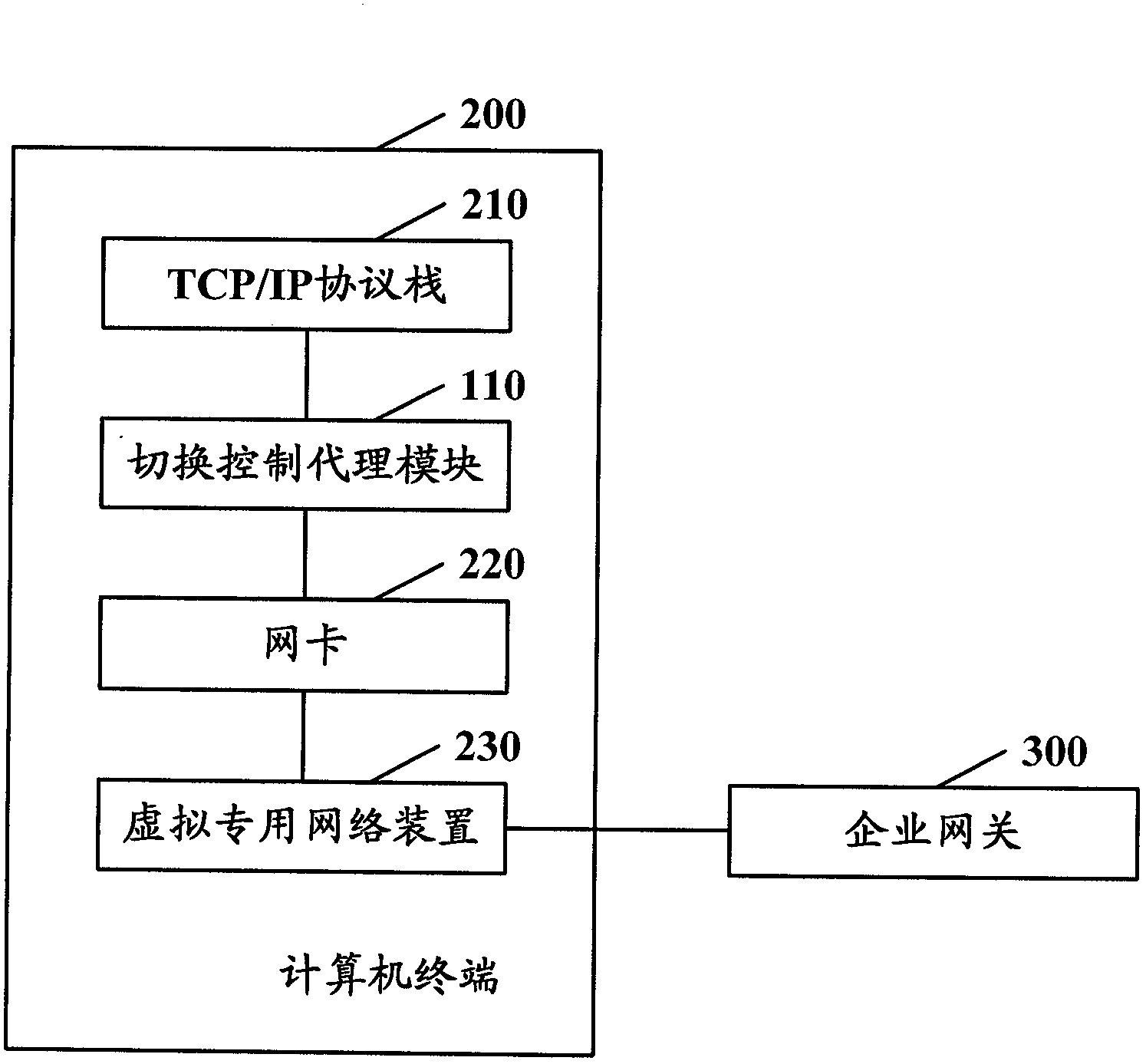

Network seamless handover device and system and computer terminal

ActiveCN102055638BRealize seamless switchingWon't dropNetworks interconnectionPrivate networkNetwork on

The embedment of the invention discloses a network seamless handover device, a network seamless handover system and a computer terminal. The device is used in a terminal which is connected to an enterprise gateway through a virtual private network, and comprises a handover control proxy module which is positioned between a transmission control protocol (TCP) / internet protocol (IP) stack and a network card and is used for shielding the plug and play (PNP) event of the network card for the TCP / IP stack and reconnecting to the enterprise gateway through the virtual private network after the network handover is accomplished successfully. The technical scheme provided by the invention can realize the seamless handover of the network on the basis of not changing the conventional network architecture.

Owner:LENOVO (BEIJING) LTD

Method for improving moist feeling of decorative wood material

InactiveCN1201908CGuaranteed textureEnsure normal breathingCork treatment detailsEngineeringSilicone

Owner:NANTONG TEXTILE VOCATIONAL TECH COLLEGE

Wood decorative material biological enzyme pretreatment method

InactiveCN1201909CGuaranteed textureEnsure normal breathingWood treatment detailsCork treatment detailsElectricityWax

Disclosed is a pretreatment method of biological enzymes for wood decoration materials, which is characterized by: first planing the wood; then scouring the wood planing, and adding 1 to 4% of biological enzymes relative to the weight of the wood planing into the scouring liquid; Scouring conditions: bath ratio 1:10-15, temperature 85-100°C, time 45-90 minutes, and finally washing with water. Effect: It solves the huge demand for interior wood decoration materials, and can plant cheap fast-growing trees in desertification areas or some barren mountains, wild lands, roadsides, etc. to increase farmers' income and reduce the felling of ancient and famous trees. It can effectively remove pectin, wax, ash, natural pigments, etc. in wood, so that the water absorption of wood and the color yield and uniformity of dyeing can be significantly improved, saving water, electricity, steam and chemical agents, reducing sewage discharge, and shortening production process, improve product quality, reduce production costs, reduce environmental pollution, and have very beneficial social and economic benefits.

Owner:NANTONG TEXTILE VOCATIONAL TECH COLLEGE

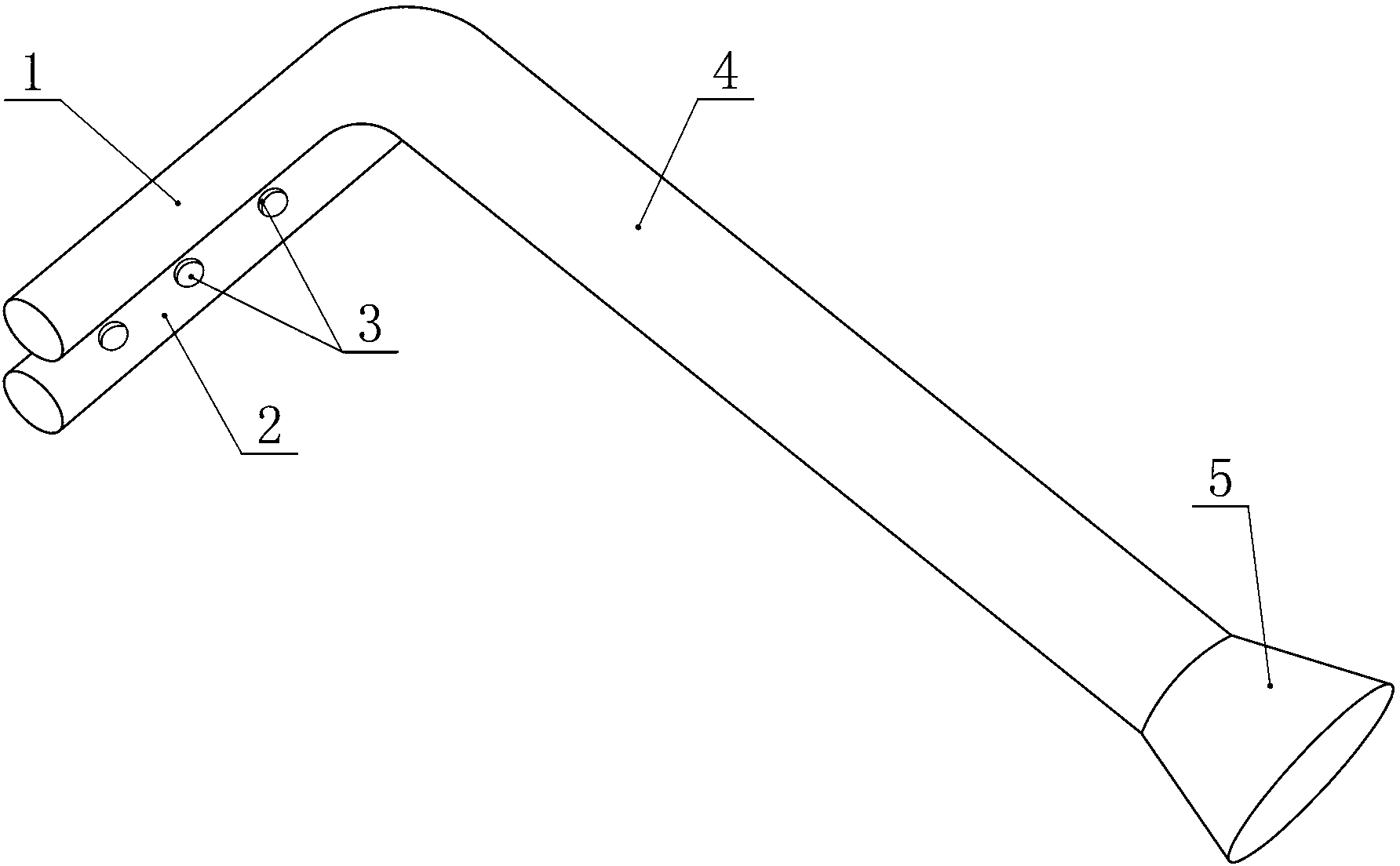

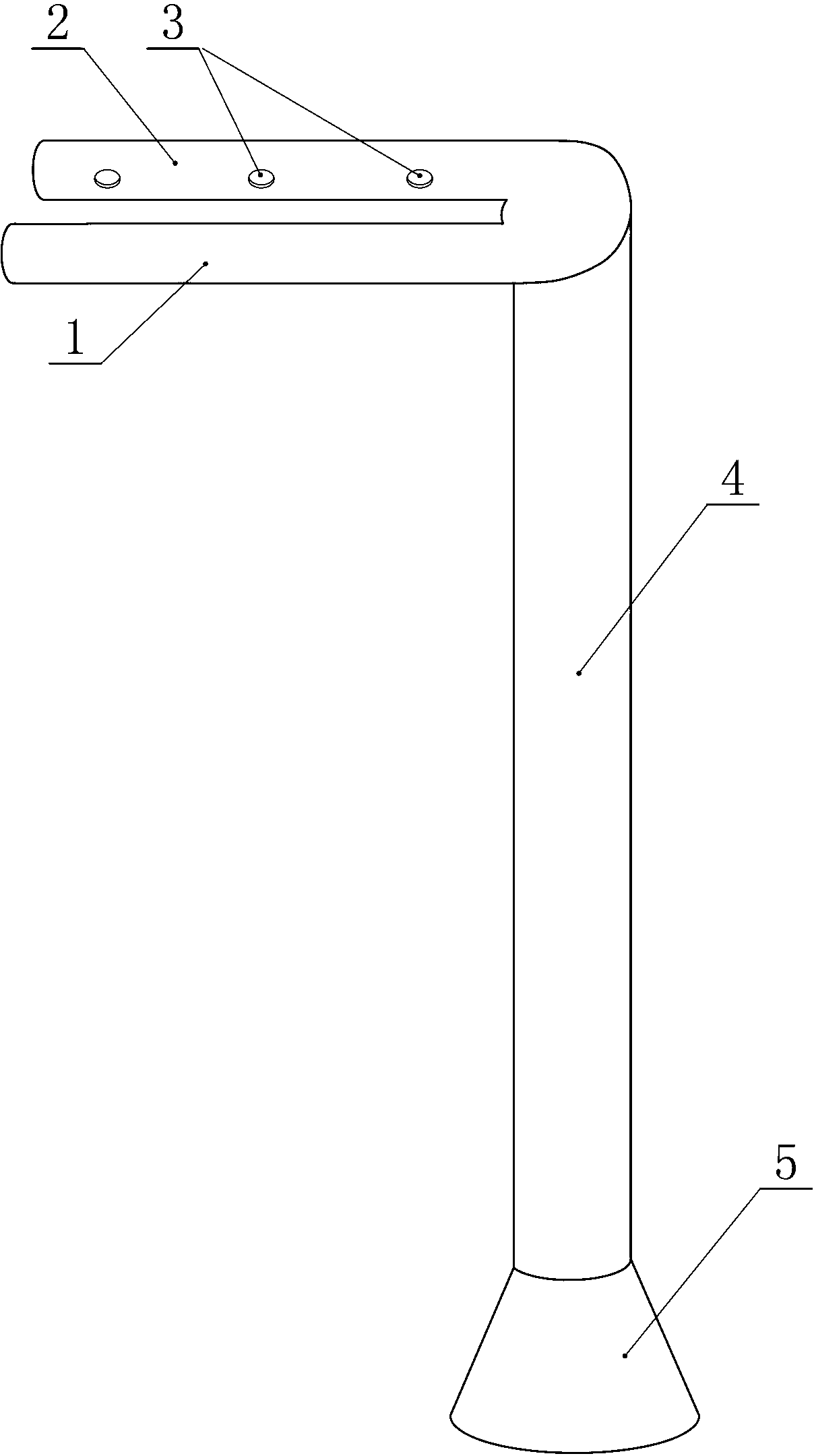

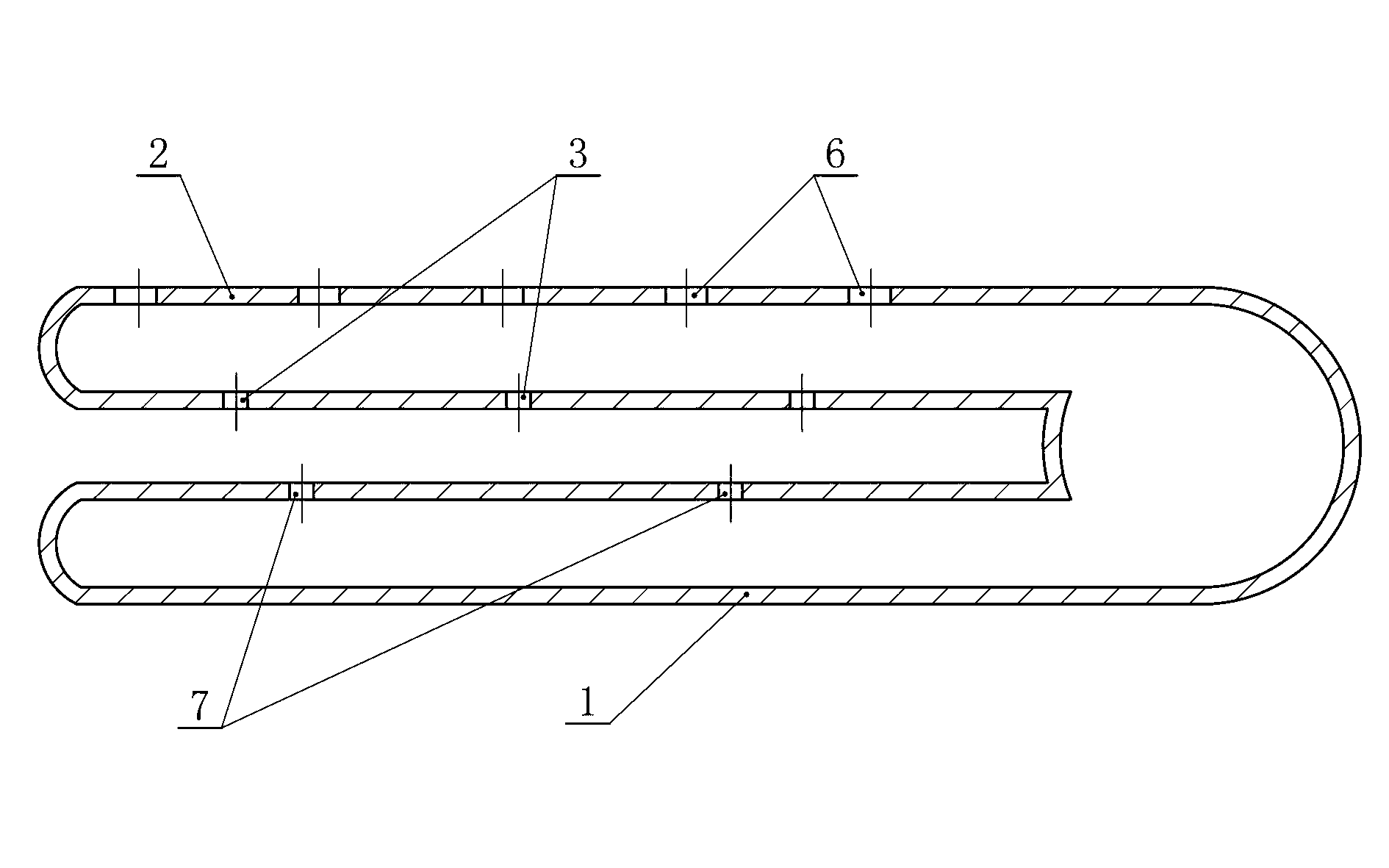

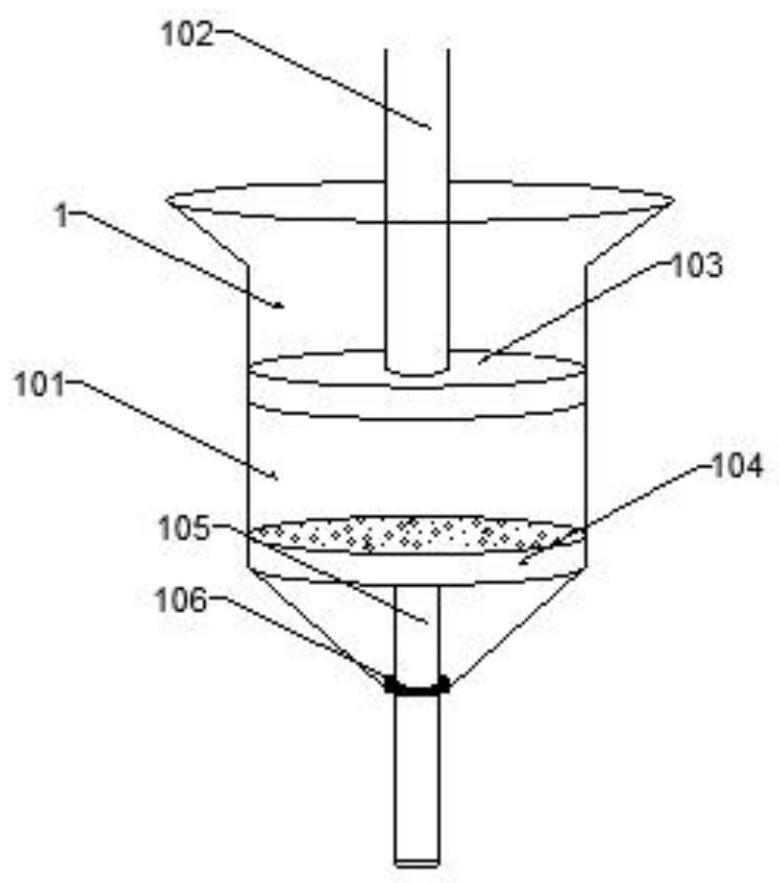

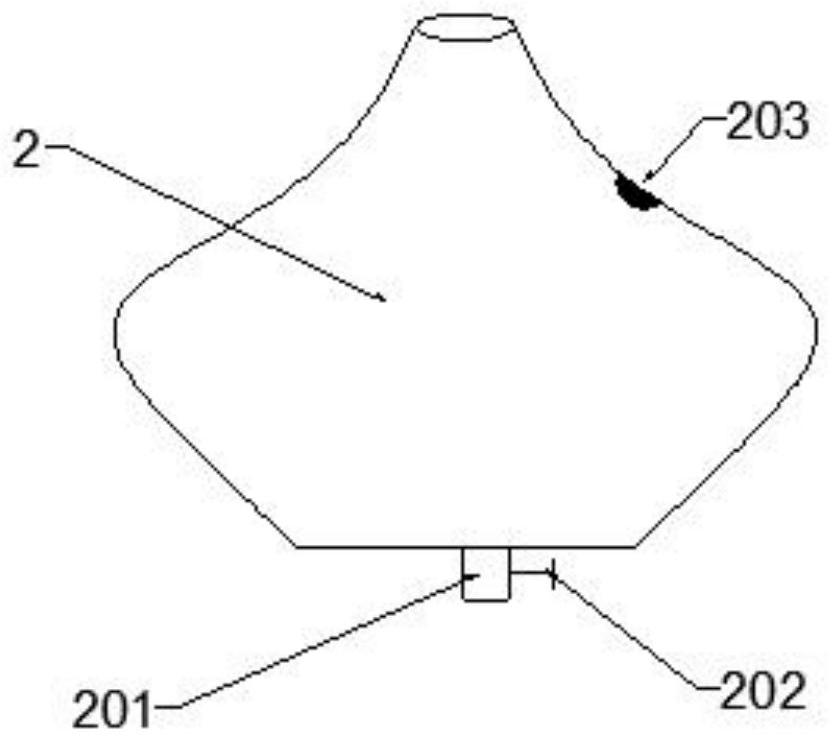

Rinsing needle for operation of excimer laser photorefractive in-situ keratomileusis

InactiveCN102836060AReduce damageShorten operation timeBathing devicesEye treatmentCorneal layerBiomedical engineering

A rinsing needle for operation of excimer laser photorefractive in-situ keratomileusis comprises a needle handle, wherein the tail end of the needle handle is provided with a syringe connecting base; an upper needle and a lower needle are arranged at one side of the head end of the needle handle in a direction which has an included angle of 120 DEG with the needle handle; the needle handle is communicated with the upper needle and the lower needle; the front ends of the upper needle and the lower needle are sealed; the lower side of the upper needle is provided with two water outlets; the upper side of the lower needle is provided with three water outlets with diameter of 0.2 mm; the lower side of the lower needle is provided with five water outlets with diameter of 0.4 mm; and the distance between the upper needle and the lower needle is 0.3 mm. The front end of the rinsing needle is closed; the top end of the needle does to need to be moved between corneal layers, and the cellular damage to corneal stroma is reduced. When the needle slides forward and backward, the rinsing for the upper part and the lower part between the corneal layers and the moistening for the surfaces of the corneal layers can be finished; a plurality of operating procedures can be finished at one time and the operative time is saved; and the cellular damage to corneal stroma is reduced while the moistening protection to corneas is finished, so that the operation is safer and faster.

Owner:董媛 +1

Contact lens care solution containing antioxidant substances and preparation method thereof

PendingCN114410391ABe transparentOxygen free radical scavengingInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsVitamin COphthalmology

The invention discloses a contact lens care solution containing antioxidant substances and a preparation method of the contact lens care solution, and belongs to the field of eye health care. The aqueous solution is prepared from the following components: 0.01 to 0.2 weight percent of VC (Vitamin C), 0.01 to 0.2 weight percent of ergothioneine, 0.1 to 2 weight percent of humectant, 0.01 to 0.5 weight percent of antibacterial agent, 0.05 to 0.95 weight percent of buffering agent, 0.01 to 0.1 weight percent of surfactant, 0.35 to 1.0 weight percent of osmotic pressure regulator and 93 to 98 weight percent of water for injection; the pH value of the contact lens care solution is 6-8. According to the contact lens care solution provided by the invention, the VC and the ergothioneine which are obtained by adopting a fermentation process and have no toxic or side effects are used as antioxidants, and the contact lens care solution can be used for improving the oxidation resistance of worn contact lenses and protecting eyes from free radical damage, has an anti-inflammatory repair effect and improves the wearing comfort.

Owner:深圳中科欣扬生物科技有限公司

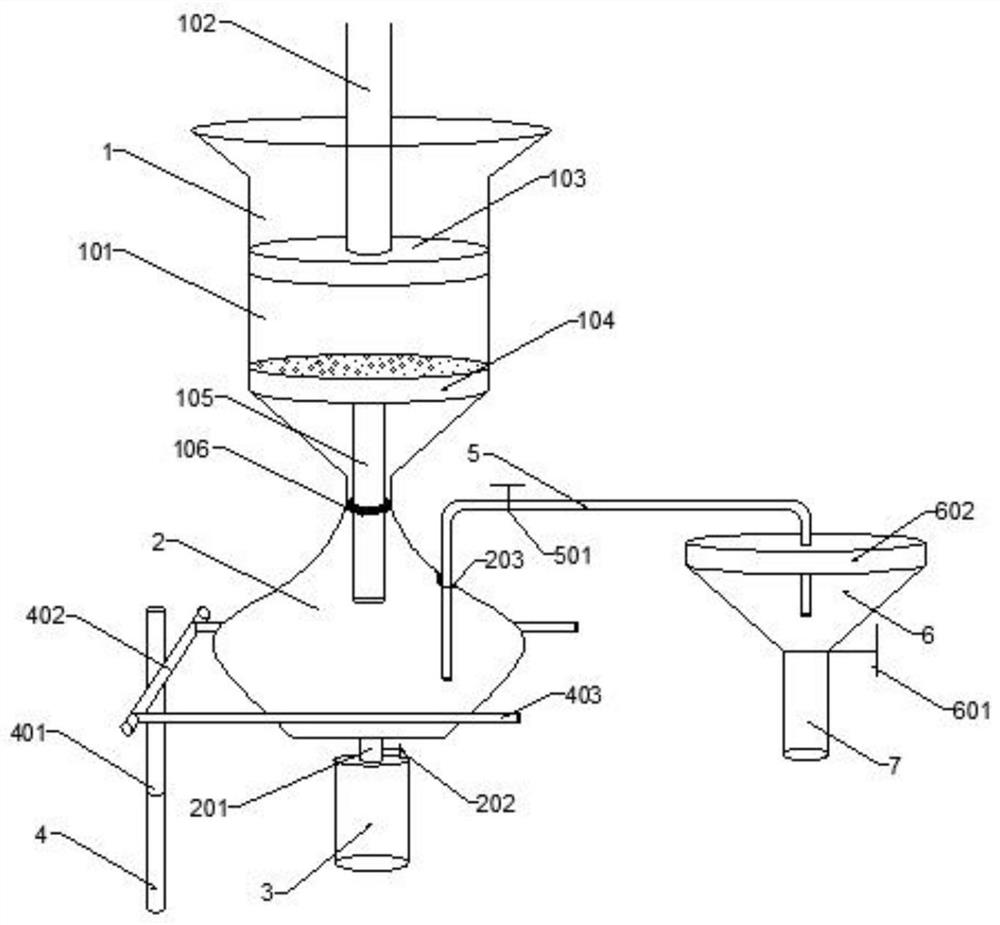

Filtering device for apple beverage production

PendingCN113712142AFully compressedBe transparentMulti-step food processesFiltration circuitsFruit juiceProcess engineering

The invention discloses a filtering device for apple beverage production and relates to the technical field of filtering devices. Pretreated apples are compressed through a hydraulic jack, the apples are compressed into fruit puree and fruit juice, the fruit puree and the fruit juice are put into a precipitation bag after multiple times of filtering, after precipitation is conducted in the precipitation bag for a period of time, a water pump is used to suck juice liquid at an upper layer in the precipitation bag into a sterilization kettle, the juice is sterilized and clarified by the sterilization kettle, and placed in a juice collecting device, a clamping device is used to clamp a surface of the precipitation bag and move downwards, and puree or pulp located at a lower layer in the precipitation bag is scraped into a pulp collecting device. In the filtering device for apple beverage production, before apple juice is clarified through an enzyme preparation method, apples are fully compressed, impurities such as peels and kernels are filtered out, fruit pulp and fruit juice are collected separately, and the apple juice with impurities removed is clarified and kept transparent.

Owner:SHAANXI NORMAL UNIV

Modified polylactic acid material for disposable syringe

ActiveCN102311622BOvercoming brittlenessMeet the mechanical performance requirementsFilling materialsPlasticizer

The invention discloses a modified polylactic acid material for a disposable syringe, prepared by using the following ingredients: 100 weight portions of polylactic acid, 5-30 weight portions of flexibilizer, 0.05-1 weight portions of responsive solubiliser, 2-5 weight portions of plasticizer, and 3-15 weight portions of filling material. The invention has the advantages of reasonable formula, simple preparation technology, and the material can be completely degraded. The prepared modified polylactic acid material overcomes the problems of hard texture and large brittleness of polylactic acid, and keeps the characteristic of transparency, completely satisfying the mechanical property requirement of material quality of the syringe in GB15810-2001 disposable sterile syringe.

Owner:CHENGDU XINJIN SHIFENG MEDICAL APP ANDINSTR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com