High-heat-resistance silica gel and preparation method thereof

A silicone gel, high heat-resistant technology, applied in the field of silicone gel, can solve the problems of affecting transparency, limited improvement of heat resistance, and cracks, etc., to achieve stable application, excellent heat resistance, and excellent electrical insulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

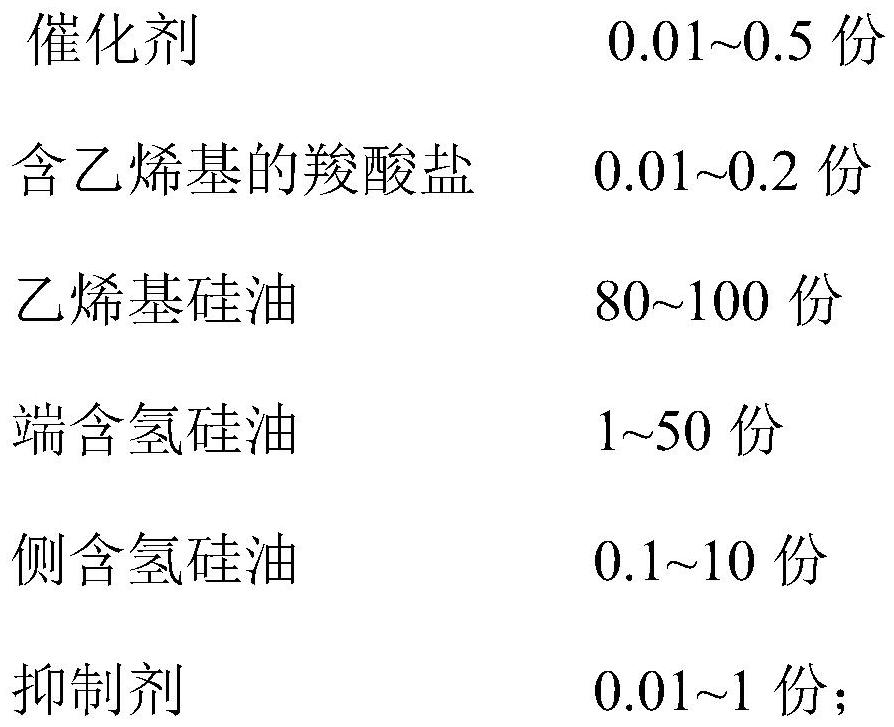

[0053] A kind of high heat-resistant silicone gel, its formula is made up of the raw material of following parts by weight:

[0054]

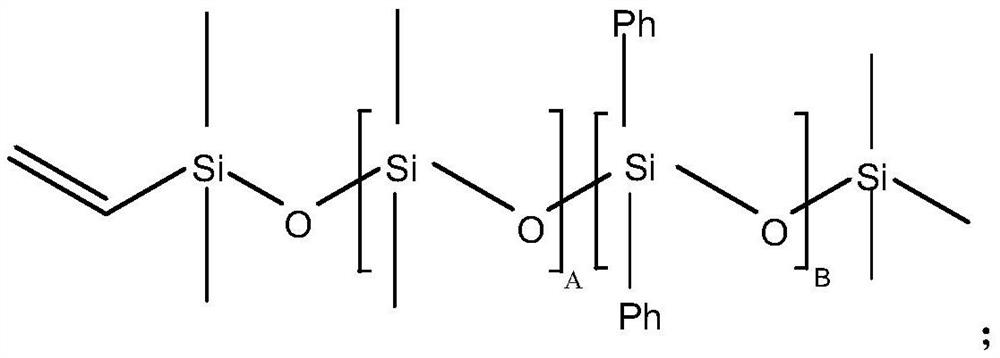

[0055] Among them, the viscosity of the single-ended vinyl silicone oil is 2000cSt, the phenyl content is 3mol%, and the vinyl content is 0.08mmols / g. The structural formula is as follows:

[0056]

[0057] Among them, the double-ended vinyl silicone oil has a viscosity of 1000cSt, a phenyl content of 3mol%, and a vinyl content of 0.16mmols / g. The structural formula is as follows:

[0058]

[0059] Among them, the viscosity of the terminal hydrogen-containing silicone oil is 800cSt, the phenyl content is 7mol%, and the hydrogen content is 0.16mmols / g. The structural formula is as follows:

[0060]

[0061] Among them, the side hydrogen-containing silicone oil has a viscosity of 400cSt, a phenyl content of 5mol%, and a hydrogen content of 3mmols / g. The structural formula is as follows:

[0062]

[0063] Wherein, the inhibitor is ...

Embodiment 2

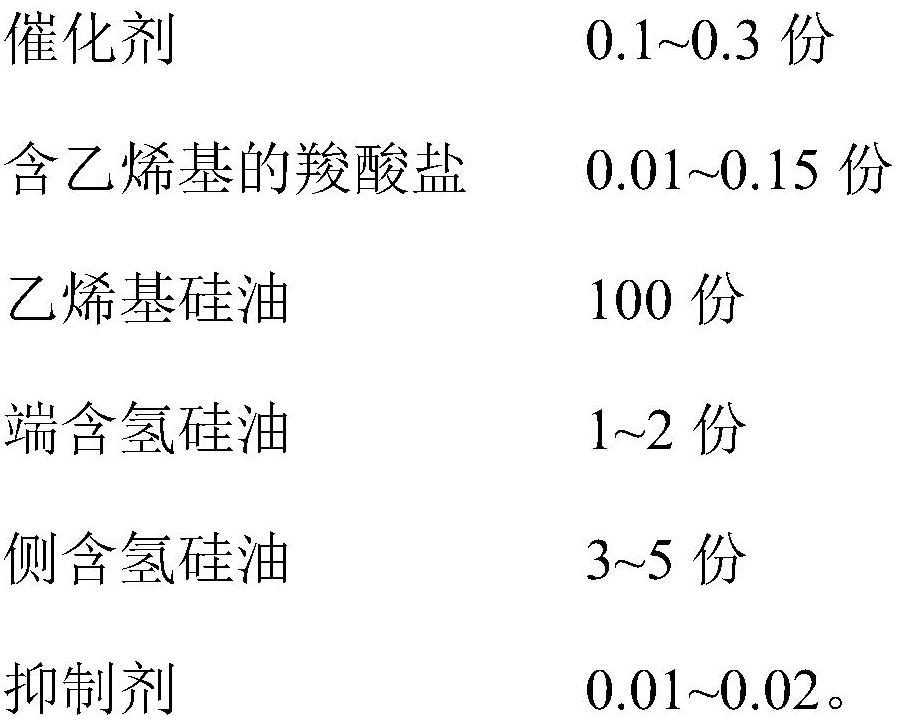

[0071] A kind of high heat-resistant silicone gel, its formula is made up of the raw material of following parts by weight:

[0072]

[0073] Among them, the viscosity of the single-ended vinyl silicone oil is 2000cSt, the phenyl content is 3mol%, and the vinyl content is 0.08mmols / g. The structural formula is as follows:

[0074]

[0075] Among them, the double-ended vinyl silicone oil has a viscosity of 1000cSt, a phenyl content of 3mol%, and a vinyl content of 0.16mmols / g. The structural formula is as follows:

[0076]

[0077] Among them, the viscosity of the terminal hydrogen-containing silicone oil is 800cSt, the phenyl content is 7mol%, and the hydrogen content is 0.16mmols / g. The structural formula is as follows:

[0078]

[0079] Among them, the side hydrogen-containing silicone oil has a viscosity of 400cSt, a phenyl content of 5mol%, and a hydrogen content of 3mmols / g. The structural formula is as follows:

[0080]

[0081] Wherein, the inhibitor is ...

Embodiment 3

[0089] A kind of high heat-resistant silicone gel, its formula is made up of the raw material of following parts by weight:

[0090]

[0091]

[0092] Among them, the viscosity of the single-ended vinyl silicone oil is 2000cSt, the phenyl content is 3mol%, and the vinyl content is 0.08mmols / g. The structural formula is as follows:

[0093]

[0094] Among them, the double-ended vinyl silicone oil has a viscosity of 1000cSt, a phenyl content of 3mol%, and a vinyl content of 0.16mmols / g. The structural formula is as follows:

[0095]

[0096] Among them, the viscosity of the terminal hydrogen-containing silicone oil is 800cSt, the phenyl content is 7mol%, and the hydrogen content is 0.16mmols / g. The structural formula is as follows:

[0097]

[0098] Among them, the side hydrogen-containing silicone oil has a viscosity of 400cSt, a phenyl content of 5mol%, and a hydrogen content of 3mmols / g. The structural formula is as follows:

[0099]

[0100] Wherein, the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com