Protective coating, and preparation method and application thereof

A functional coating and coating technology, applied in the direction of polyester coatings, coatings, etc., to achieve excellent synergistic effects, enhanced oxidation resistance and aging resistance, and good preservation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

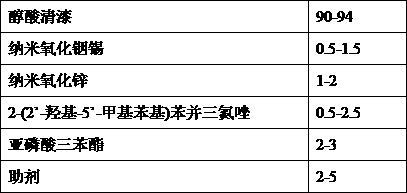

Method used

Image

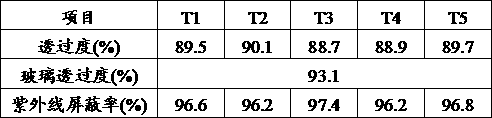

Examples

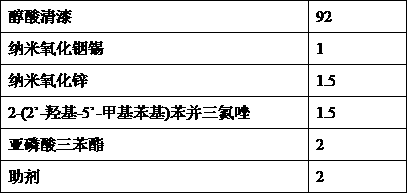

Embodiment 1

[0035] Called 92 weighing alcoholic paint, add a loose oil -saving with a weight of 10%, close it and stir for 4 minutes, then stir down and add 1 weight nanoxide tin, 1.5 nano -oxide of 1.5 weights, 0.5 weight 2 2 weights 2-(2'-hydroxyl-5'-methampitor) benzene-pyrodinol, 2-weights with 2 weights and 2 weights, and 2 weights of 2 weights, continue to stir for 5 minutes, static, volatilize, and add the place to joinThe pine oil -saving, that is, the composite functional coating T1 of the present invention.

[0036] Among them, the particle size of nano oxide tin and nano oxide is 100 nm.

[0037] Among them, the aid consists of a film formner, adhesion, tidam, and anti -junction agent at 1: 1: 1: 1.The membrane agent is a mixture obtained by the mass mixing of acrylic resin membrane, polyurethane membrane, and nitrate fiber membrane.The fluoridicine is fluorine -modified acrylic fluid;

Embodiment 2

[0039] Called 91 weighing alcoholic paint, add a loose oil at 20%of its weight, be closed and stirred for 6 minutes, then stir down and add 0.5 nano oxide tin tin, nano -nanoxide of 1 weight, 1.5 weights of 1.5 weights 2-(2'-hydroxyl-5'-methampitor) benzene-pyropide, 3 weights of triathletes and 3 weights of 3 weights, and 3 weights, continue to stir for 7 minutes, static, volatilize, add and join the additional additional joiningThe pine oil -saving, that is, the composite functional coating T2 of the present invention.

[0040] Among them, the particle size of nano oxide tin and nano oxide is 200 nm.

[0041] Among them, the aid consists of a film formner, adhesion, piing agent, and anti -jacking agent at a weight ratio of 1: 2: 2: 2.The membrane agent is a mixture obtained by the mass mixing of acrylic resin membrane, polyurethane membrane, and nitrate fiber membrane.Ethyl tritenols, alpine; the fluid is a phosphate modified acrylic fluid;

Embodiment 3

[0043] Called 90 weighing alcoholic paint, add a loose oil -saving with a weight of 30%, close it and stir for 8 minutes, then stir down and add 1.5 nano oxide tin, 2 nano oxide of 2 weights, 2.5 weights of 2.5 weights 2.-(2'-hydroxyl-5'-methampitor) benzene-pyrodinol, 2-weights with 2 weights and 2 weights, and 2 weights of 2 weights.The pine oil -saving, that is, the composite functional coating T3 of the present invention.

[0044] Among them, the particle size of nano -oxide tin and nano oxide is 300 nm.

[0045] Among them, the aid consists of a film formner, adhesion, tidam, and anti -junction agent at 1: 1: 1: 1.The membrane agent is a mixture obtained by the mass mixing of acrylic resin membrane, polyurethane membrane, and nitrate fiber membrane.The flowing agent is the methamphetamine of the acrylic butyl anecodate;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com