Modified silicone resin and preparation method thereof

A technology for modifying silicon and resin, which is applied in the field of modified silicone resin and its preparation, which can solve the problems of reduced electrical insulation, influence on dielectric properties, and decreased transparency of silicone resin, and achieve improved toughness and strength, and excellent insulation performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

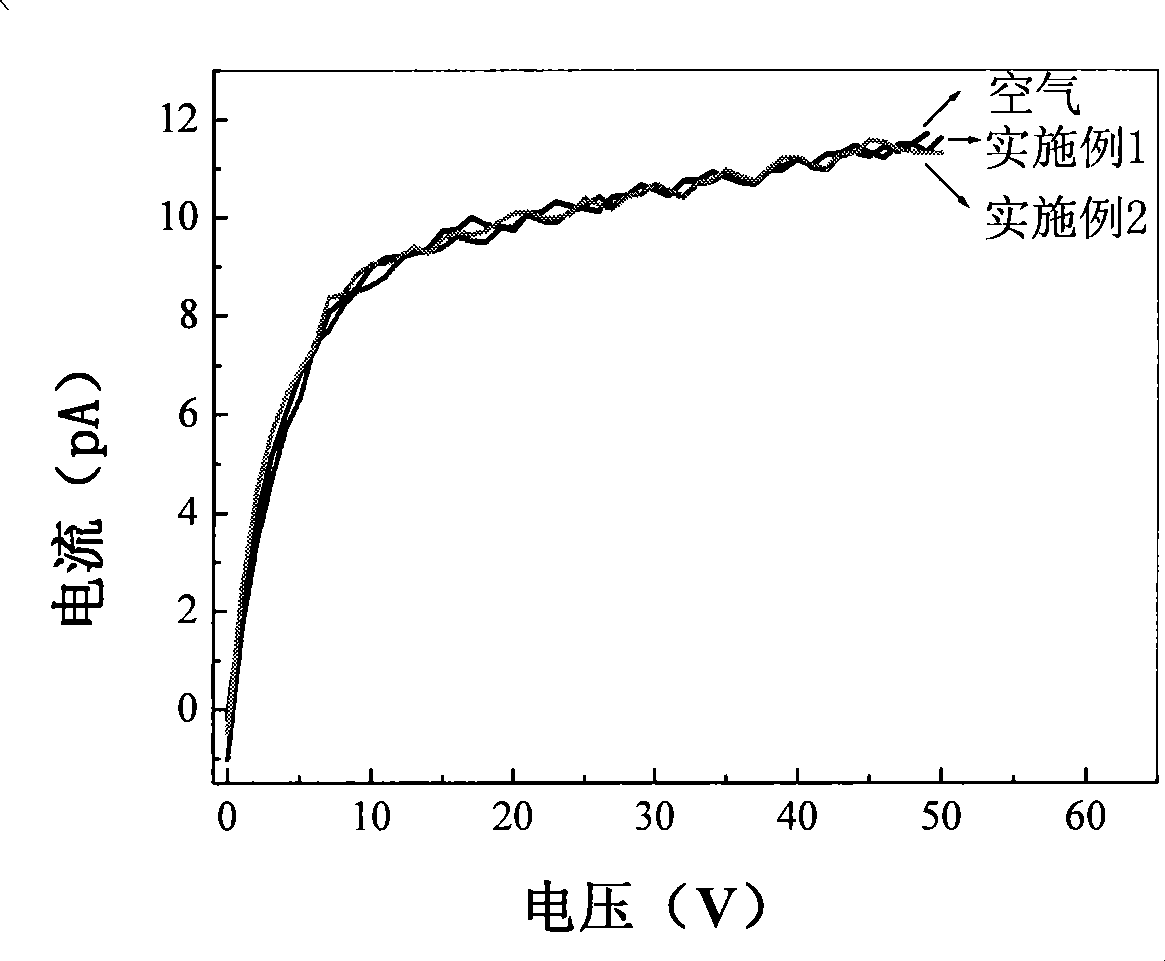

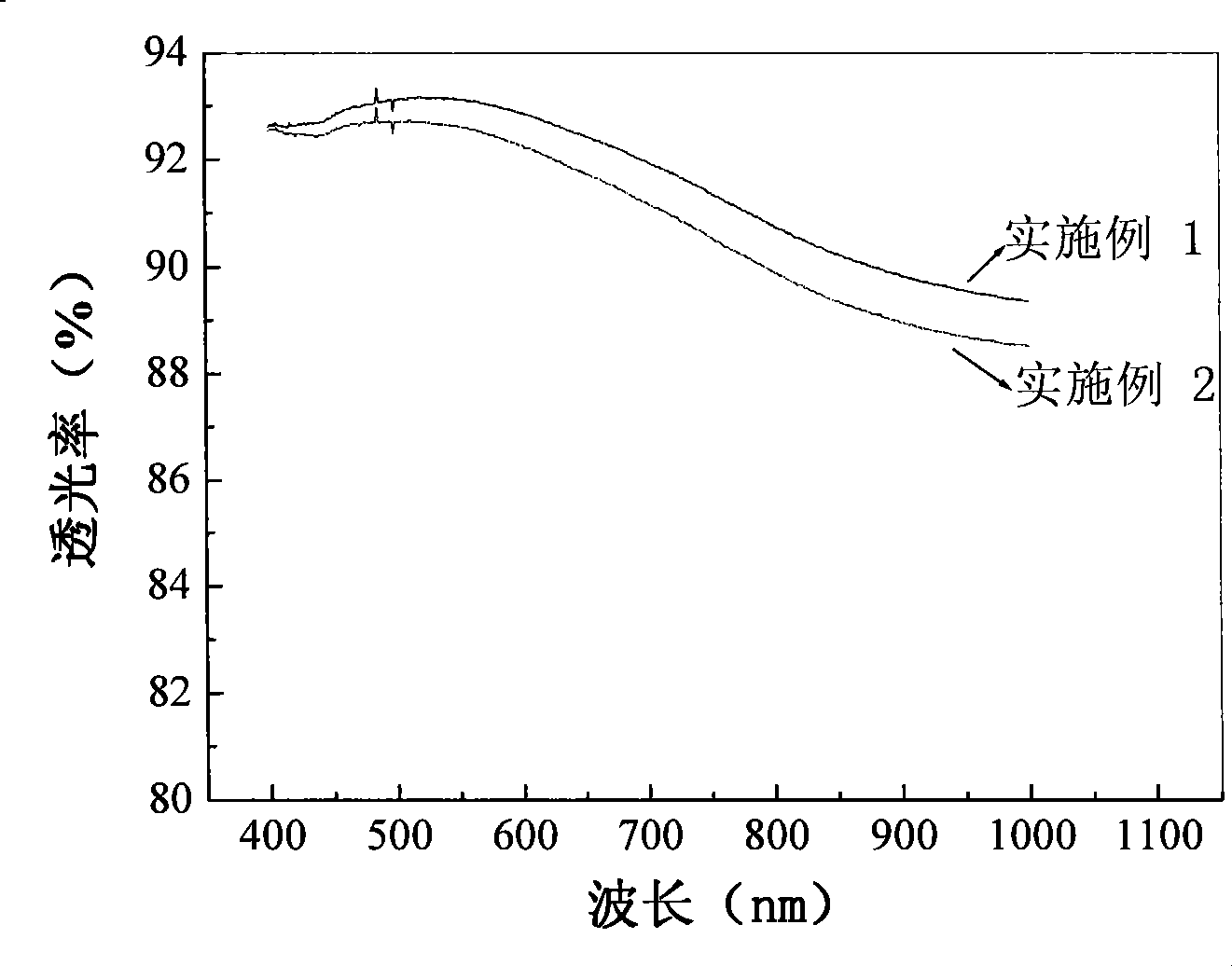

Embodiment 1

[0026] Add 20g of methyltriethoxysilane into a reaction bottle with a stirrer, add 6g of dilute hydrochloric acid containing 153uL / L of HCl, reflux at 80°C for 12h, and age at room temperature for 12h to settle the resin at the bottom of the bottle. Wash off the HCl with distilled water until pH=7 is neutral, pour off the upper layer of water, add 12g of ethanol after drying, and prepare a 20g concentration of 30% (mass fraction) polymethylorganosilsesquioxane solution, and analyze it by mass spectrometry The number average molecular weight was measured to be 900.

[0027] Hydroxymethyl silicone oil (viscosity at 20°C is 15-50mm 2 the s -1 ) is a product of Beijing Dingye Industry and Trade Co., Ltd., and the brand number is 203. Add 4 g of hydroxymethyl silicone oil into the 20 g of polymethylorganosilsesquioxane solution prepared above, and mix evenly to obtain a clear and uniform mixed solution. Among them, the weight ratio of hydroxymethyl silicone oil to polymethylorga...

Embodiment 2

[0033] Add 24g of phenyltrimethoxysilane into a reaction bottle with a stirrer, add 10g of dilute hydrochloric acid containing 153uL / L of HCl, reflux at 80°C for 24h, and age at room temperature for 48h to settle the resin at the bottom of the bottle. Wash off HCl with distilled water until the pH=7 is neutral, pour off the upper layer of water, add 12g of acetone after drying, and prepare a 20g concentration of 30% (mass fraction) polyphenylorganosilsesquioxane solution, and use mass spectrometry Its number average molecular weight was measured to be 1500. Hydroxymethyl silicone oil (viscosity at 20°C is 15-50mm 2 the s -1) is a product of Beijing Dingye Industry and Trade Co., Ltd., the brand name is 203, 2g of hydroxymethyl silicone oil is added to the 20g of polyphenylorganosilsesquioxane solution prepared above, and mixed evenly to obtain a clear and uniform mixed solution. Among them, the weight ratio of hydroxymethyl silicone oil to polyphenylorganosilsesquioxane is 0...

Embodiment 3

[0039] Add 26g of vinyltriethoxysilane into a reaction bottle with a stirrer, add 12g of dilute hydrochloric acid containing 153uL / L of HCl, reflux at 80°C for 24h, and age at room temperature for 48h to settle the resin at the bottom of the bottle. Wash off the HCl with distilled water until the pH=7 is neutral, pour off the upper layer of water, add 12g of tetrahydrofuran after drying, and prepare a 20g concentration of 30% (mass fraction) polyvinylorganosilsesquioxane solution, and analyze it by mass spectrometry The number average molecular weight was measured to be 2000. Hydroxymethyl silicone oil (viscosity at 20°C is 15-50mm 2 the s -1 ) is a product of Beijing Dingye Industry and Trade Co., Ltd., and the brand name is 203. Add 5 g of hydroxymethyl silicone oil to the 20 g of polyvinylorganosilsesquioxane solution prepared above, and mix well to obtain a clear and uniform mixed solution. Among them, the weight ratio of hydroxymethyl silicone oil to polyvinylorganosils...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com