Rinsing needle for operation of excimer laser photorefractive in-situ keratomileusis

An excimer laser and needle technology, which is applied in the field of medical devices, can solve the problems of difficult corneal debris washing, corneal stromal cell damage, and inability to wet the corneal surface, and achieves the effect of saving operation time, reducing damage and saving irrigation fluid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

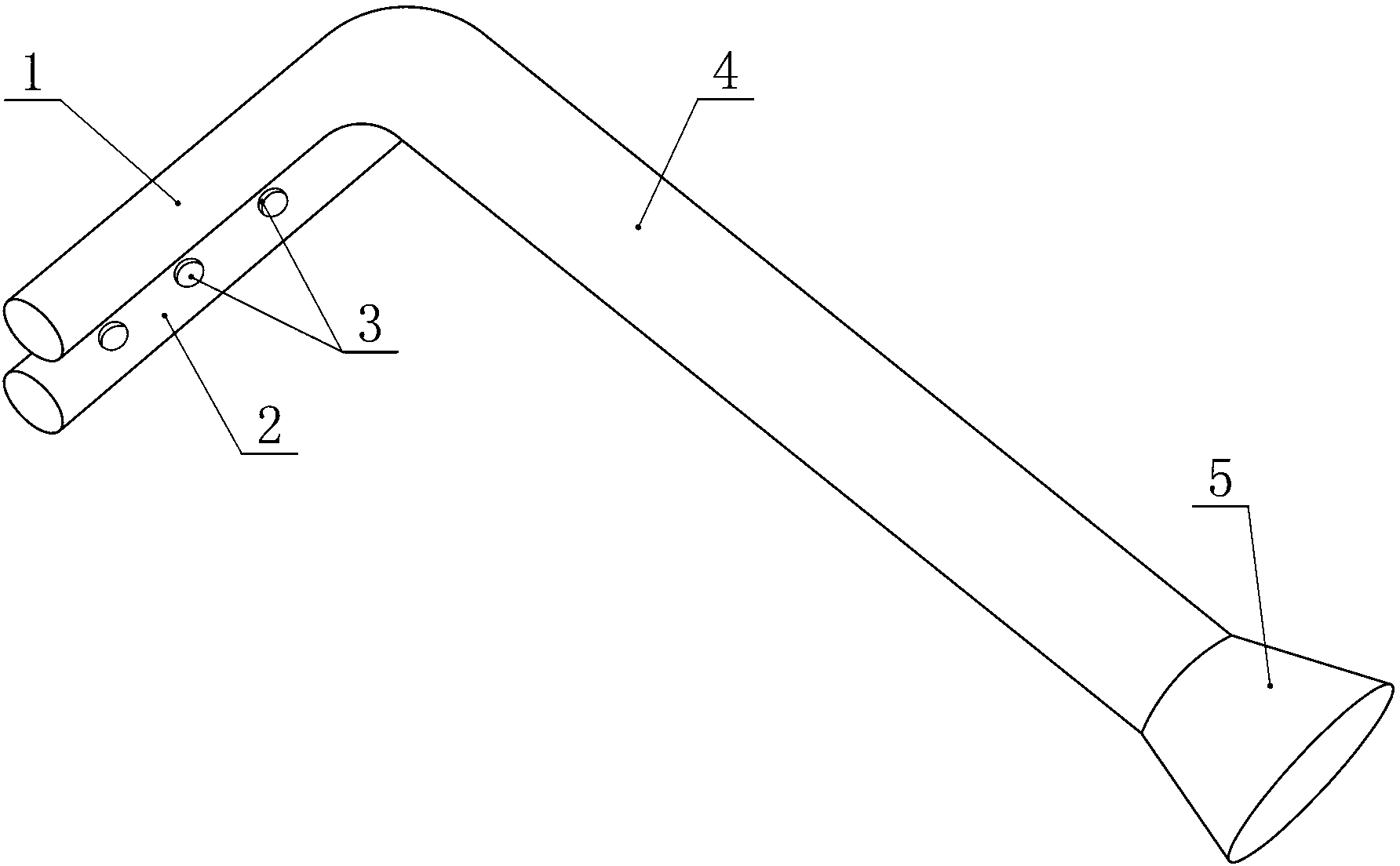

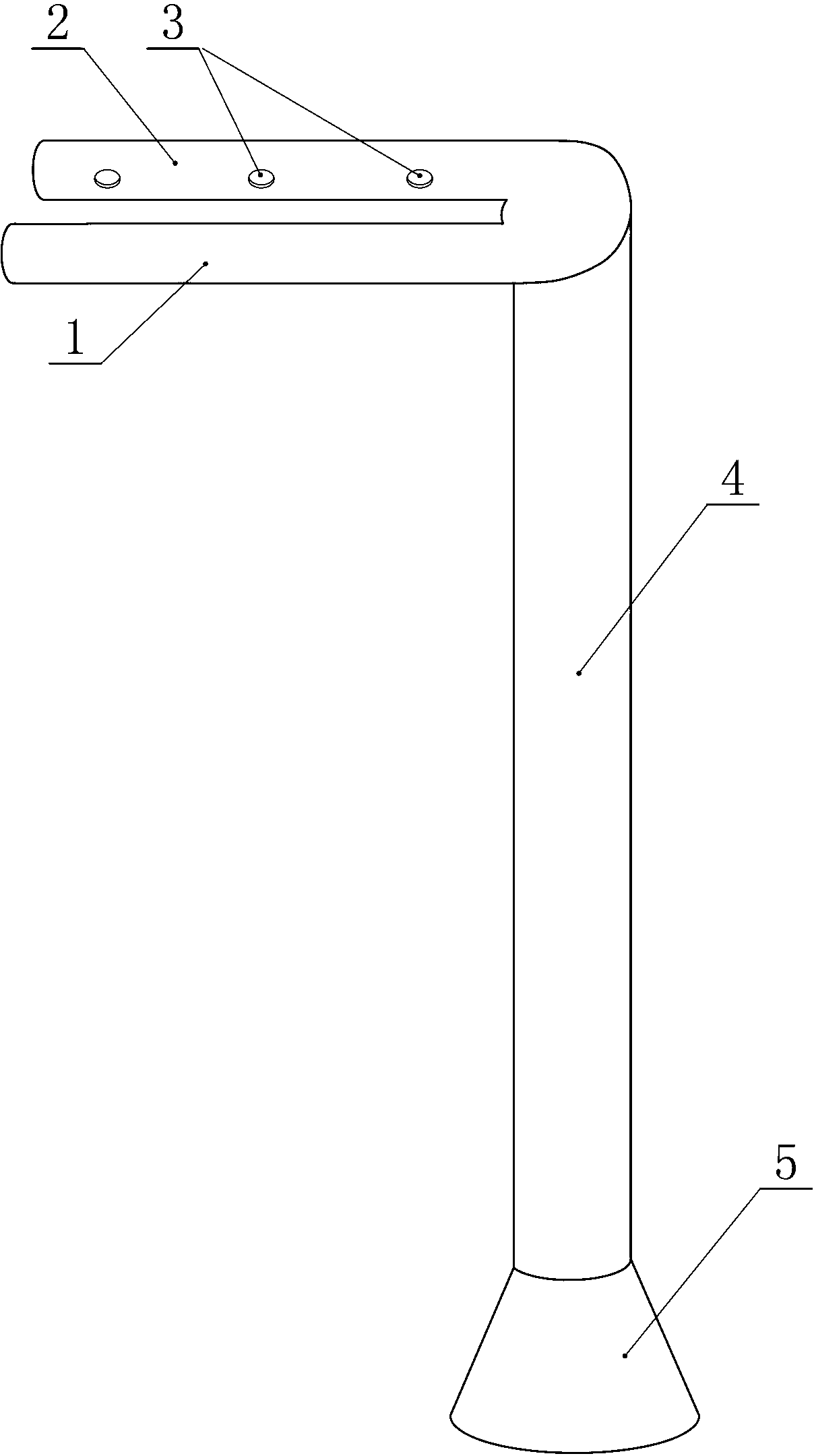

[0020] A flushing needle for excimer laser refractive in situ keratomileusis, whose parameters are:

[0021] Needle handle: thicker than ordinary flushing needles, with a diameter of 1.2mm.

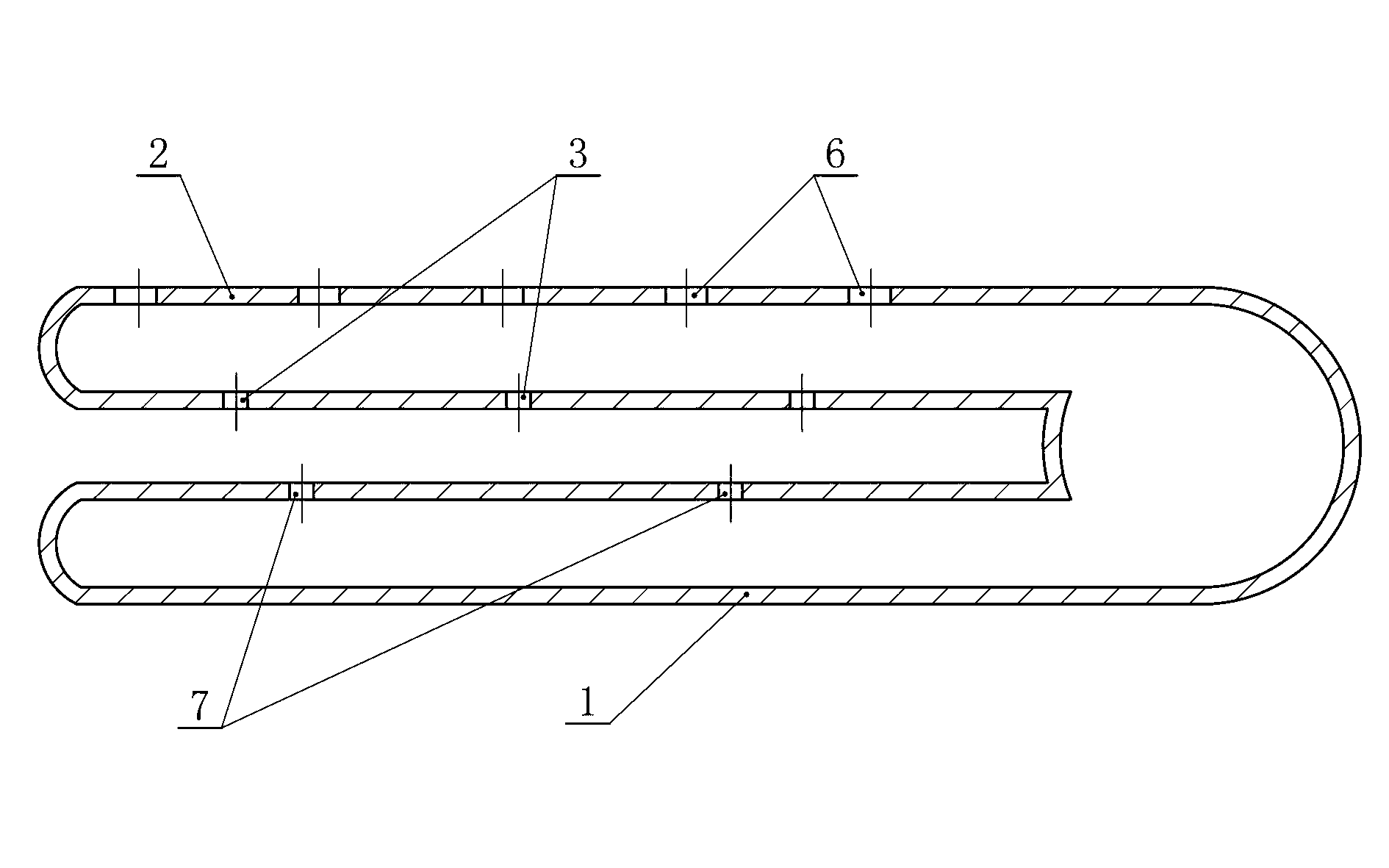

[0022] Needle: It is divided into upper needle 1 and lower needle 2, both of which are 10mm long and 0.6mm in diameter. The ends of needle 1 and lower needle 2 are closed. The distance between the upper needle 1 and the lower needle 2 is 0.3mm.

[0023] Water outlet holes: There are 5 water outlet holes below the lower needle 2 with a diameter of 0.4 mm.

[0024] The lower needle 2 is provided with 3 outlet holes with a diameter of 0.2 mm.

[0025] There are 2 water outlet holes under the upper needle head 1, with a diameter of 0.2 mm.

[0026] The above-mentioned water outlet holes can be evenly distributed on the needle head.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com