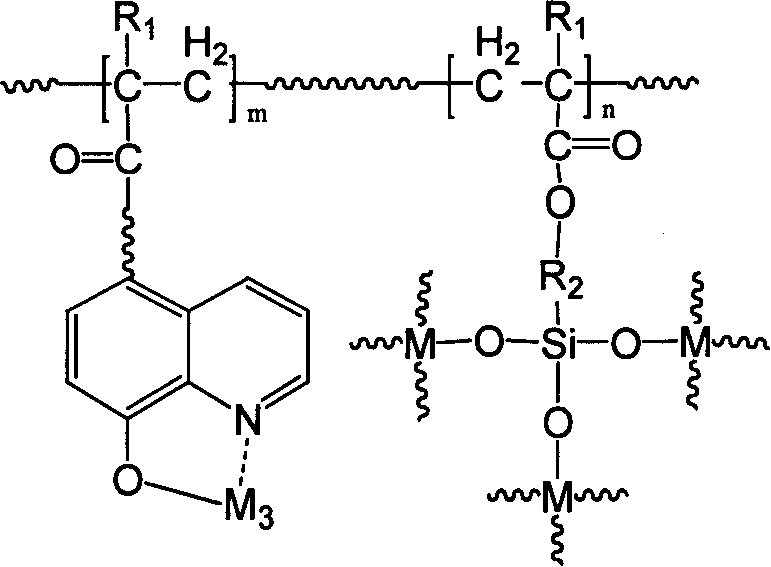

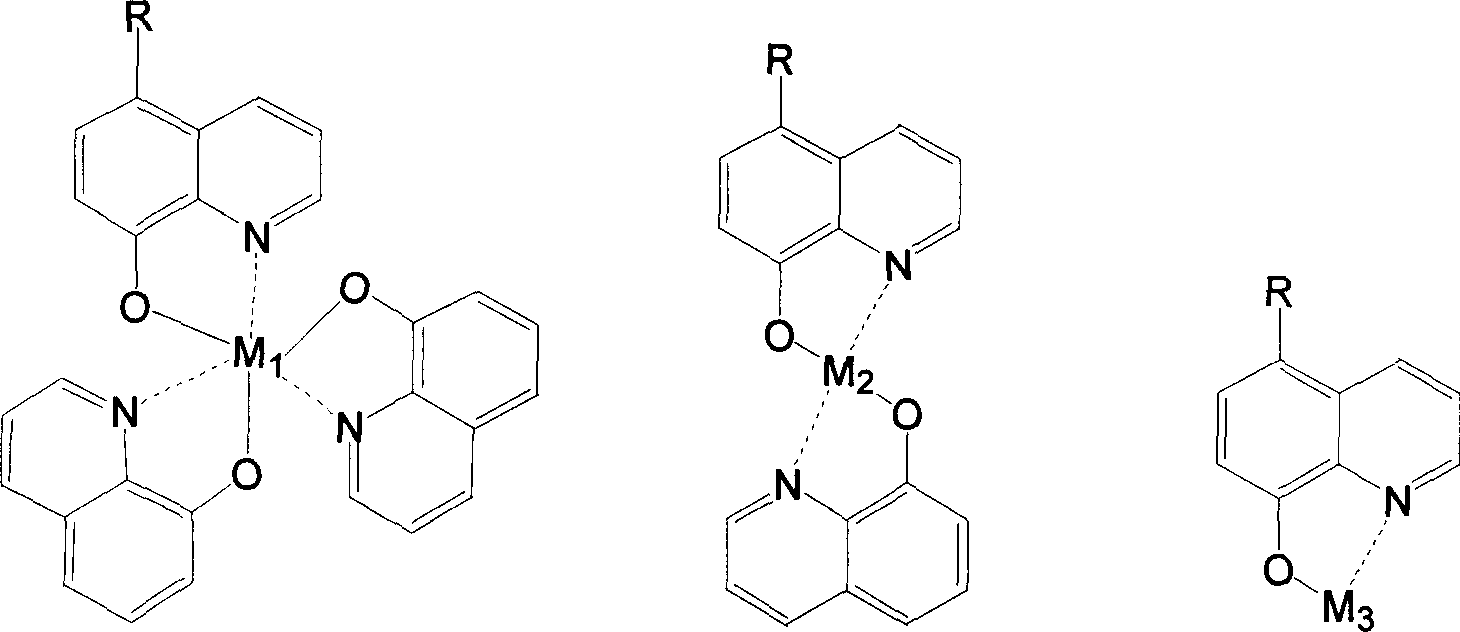

High-polymer molecular hybrid luminescent materials containing 8-hydroxyquinoline metal complex and production thereof

A technology of metal complexes and hydroxyquinoline, which is applied in the direction of luminescent materials, chemical instruments and methods, can solve the problems of reduced lifetime, uneven dispersion, and reduced fluorescence lifetime of electroluminescent devices, and achieve excellent thermodynamic properties and uniform distribution , enhance the effect of efficiency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

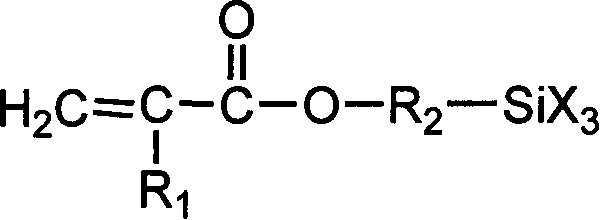

Method used

Image

Examples

Embodiment 1

[0025] Take 6.01g (0.01mol) ethylenic monomer containing 8-hydroxyquinoline aluminum complex, 24.8g (0.1mol) γ-(methacryloxy)propyltrimethoxysilane, without any silane coupling Reagent, 5% dilute hydrochloric acid 4mL (0.005mol), 1.0g (0.007mol) hexamethylenetetramine, azobisisobutyronitrile (AIBN) 0.2g (0.0012mol), respectively added to 150mL (1.86mol) In tetrahydrofuran, the solution was stirred at 80°C for 6 hours, and then dried at room temperature for 10 days to obtain a yellow-green molecular hybrid luminescent material.

Embodiment 2

[0027]Take 0.495g (0.001mol) of ethylenic monomer containing 8-hydroxyquinoline zinc complex, 12.4g (0.05mol) γ-(methacryloxy)propyltrimethoxysilane, without any silane coupling Reagent, 3.0mL 0.3mol / L dilute acetic acid solution, 0.8g (0.0058mol) hexamethylenetetramine, azobisisobutyronitrile (AIBN) 0.1g (0.0006mol), respectively add to 100mL (1.24mol) In tetrahydrofuran, the solution was stirred at 100°C for 2 hours, and then dried at room temperature for 42 days to obtain a yellow molecular hybrid luminescent material.

Embodiment 3

[0029] Take 0.601g (0.001mol) of ethylenic monomer containing 8-hydroxyquinoline aluminum complex, 9.5g (0.001mol) γ-(methacryloxy)propyl tris(β-methoxyethoxy) Silane, add 7.55g (0.05mol) tetramethoxysilane, 2.0g (0.11mol) water, 0.2g (0.00032mol) dibutyltin dilaurate, 0.0036g (0.00002mol) benzyl ketal, and add them to In 60 mL (0.74 mol) of tetrahydrofuran, the solution was stirred at 30°C for 6 hours, irradiated with an ultraviolet lamp for 30 seconds, and then dried at room temperature for 10 days to obtain a yellow-green molecular hybrid luminescent material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com