Method for preparing hot melt adhesive for damping interval of ceramic tile

A hot-melt adhesive and ceramic tile technology, applied in adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of low automation, white pollution, and difficult degradation, and achieve easy peeling and curing Fast, easy glue application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

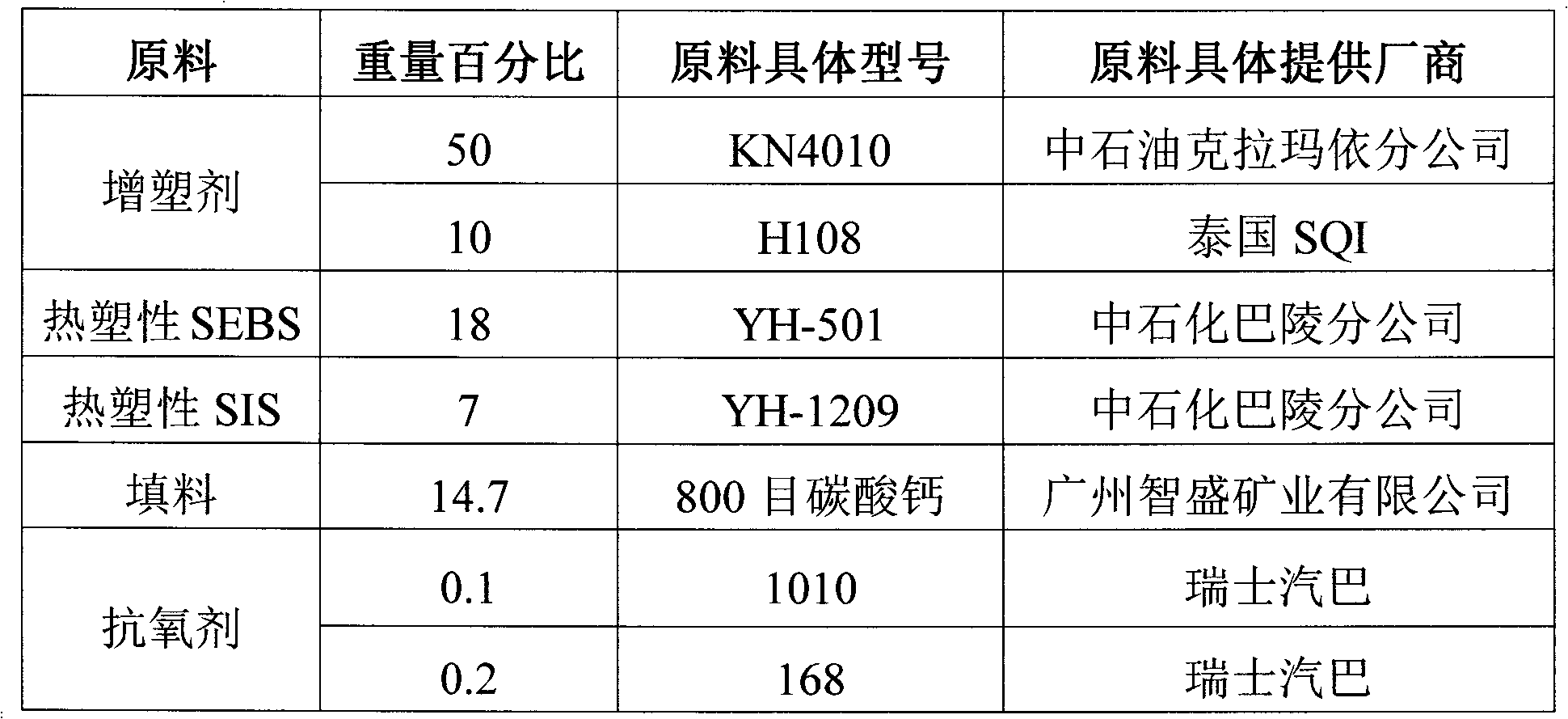

[0024] Prepare following hot melt adhesive according to the method of the present invention:

[0025]

[0026] The characteristics of the hot melt adhesive obtained in this example: the melt viscosity is 3800cp at 160°C, and the Shore hardness is 82 when the colloid is 25°C; the spacer tiles are peeled off after 72 hours of heavy pressure, and the peeling force is 13.3N, which is relatively laborious. Watch There are a few traces on the surface of the tiles, but no oil marks.

example 2

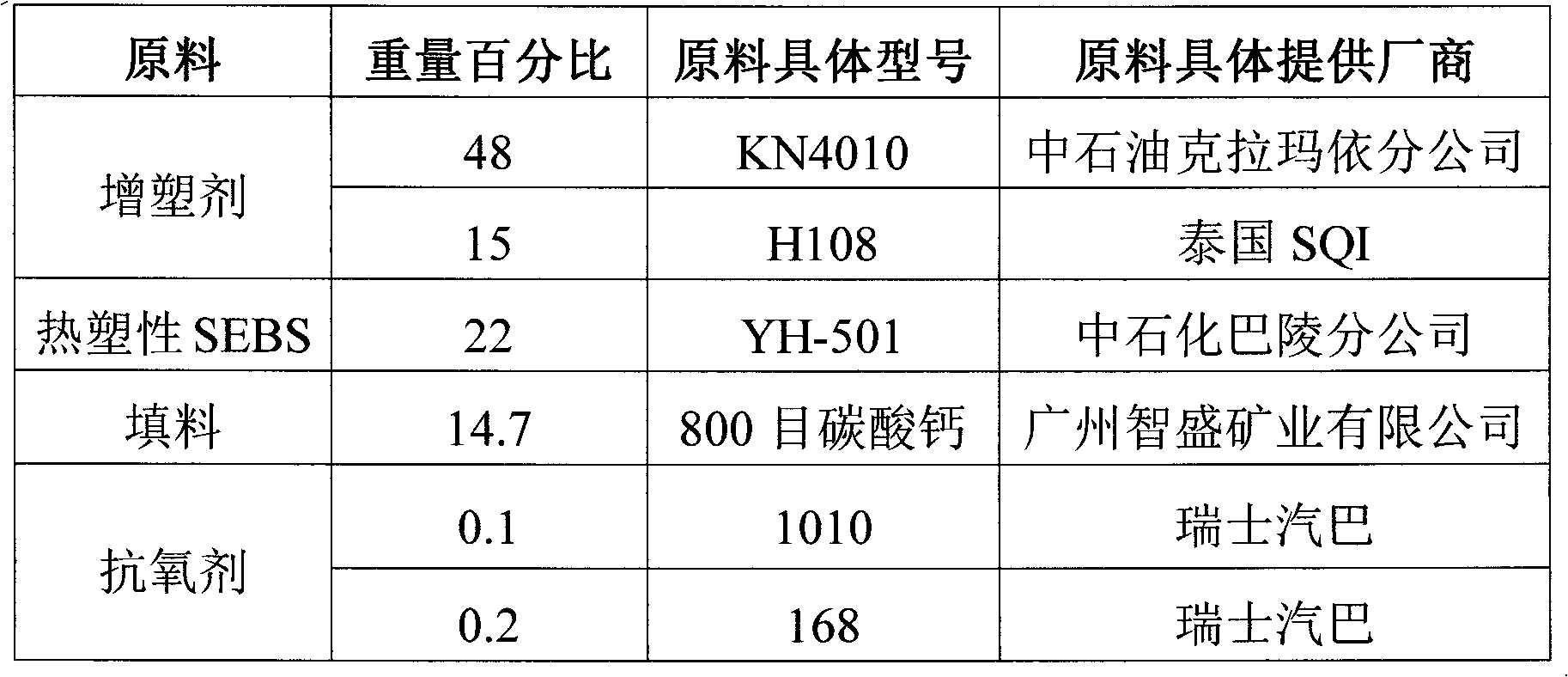

[0028] Prepare following hot melt adhesive according to the method of the present invention:

[0029]

[0030] The characteristics of the hot melt adhesive obtained in this example: the melt viscosity is 2700cp at 160°C, and the Shore hardness is 89 when the colloid is 25°C; the spacer tiles are peeled off after 72 hours of heavy pressure, and the peeling force is 9.5N, which still requires a lot of force , watch the surface of the tiles, no traces, no oil marks.

example 3

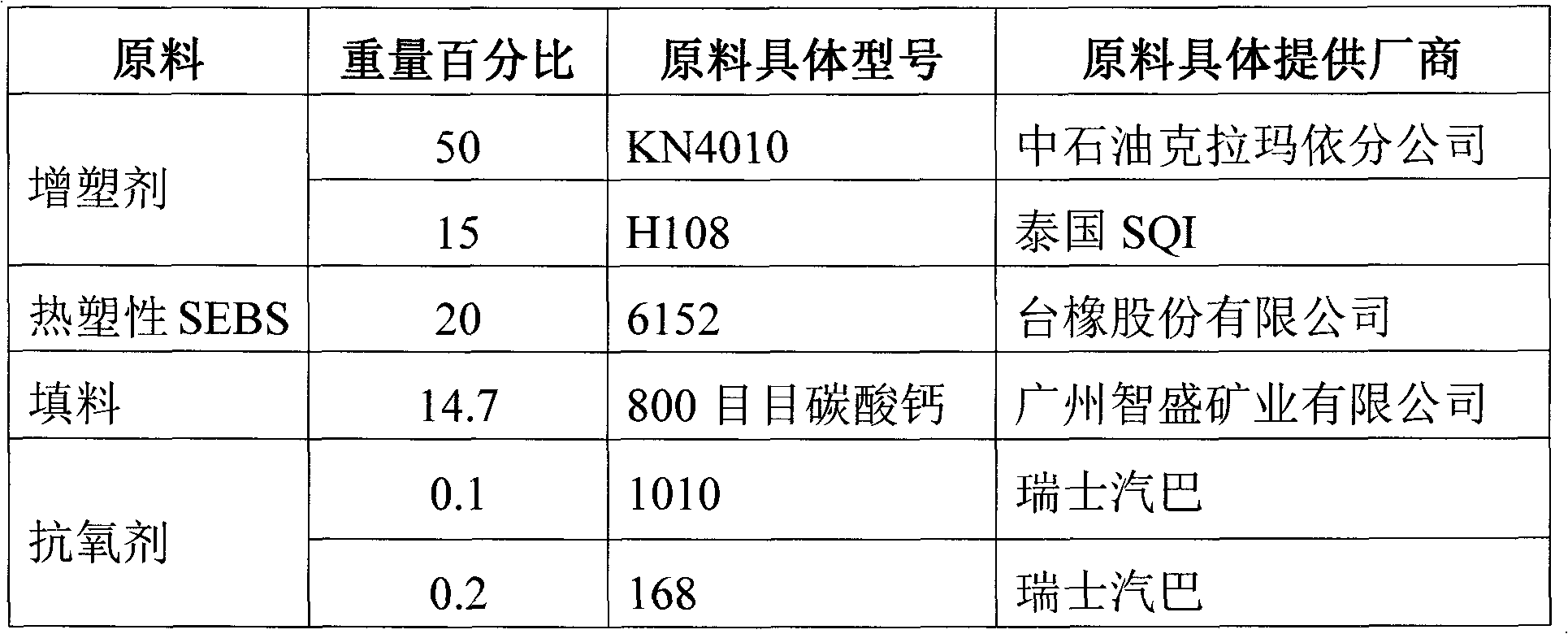

[0032] Prepare following hot melt adhesive according to the method of the present invention:

[0033]

[0034] The characteristics of the hot melt adhesive obtained in this example: the melt viscosity is 2850cp at 160°C, and the Shore hardness is 86 when the colloid is at 25°C; the spacer tiles are peeled off after 72 hours of heavy pressure, and the peeling force is 8.4N, which still requires a lot of force , watch the surface of the tiles, no traces, no oil marks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com