Material capable of completely biodegrading and preparation method thereof

A technology of biodegradable materials and copolymers, applied in the field of fully biodegradable materials and their preparation, can solve the problems of white pollution, poor water resistance, etc., and achieve the effects of cost reduction, heat resistance improvement and strength increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

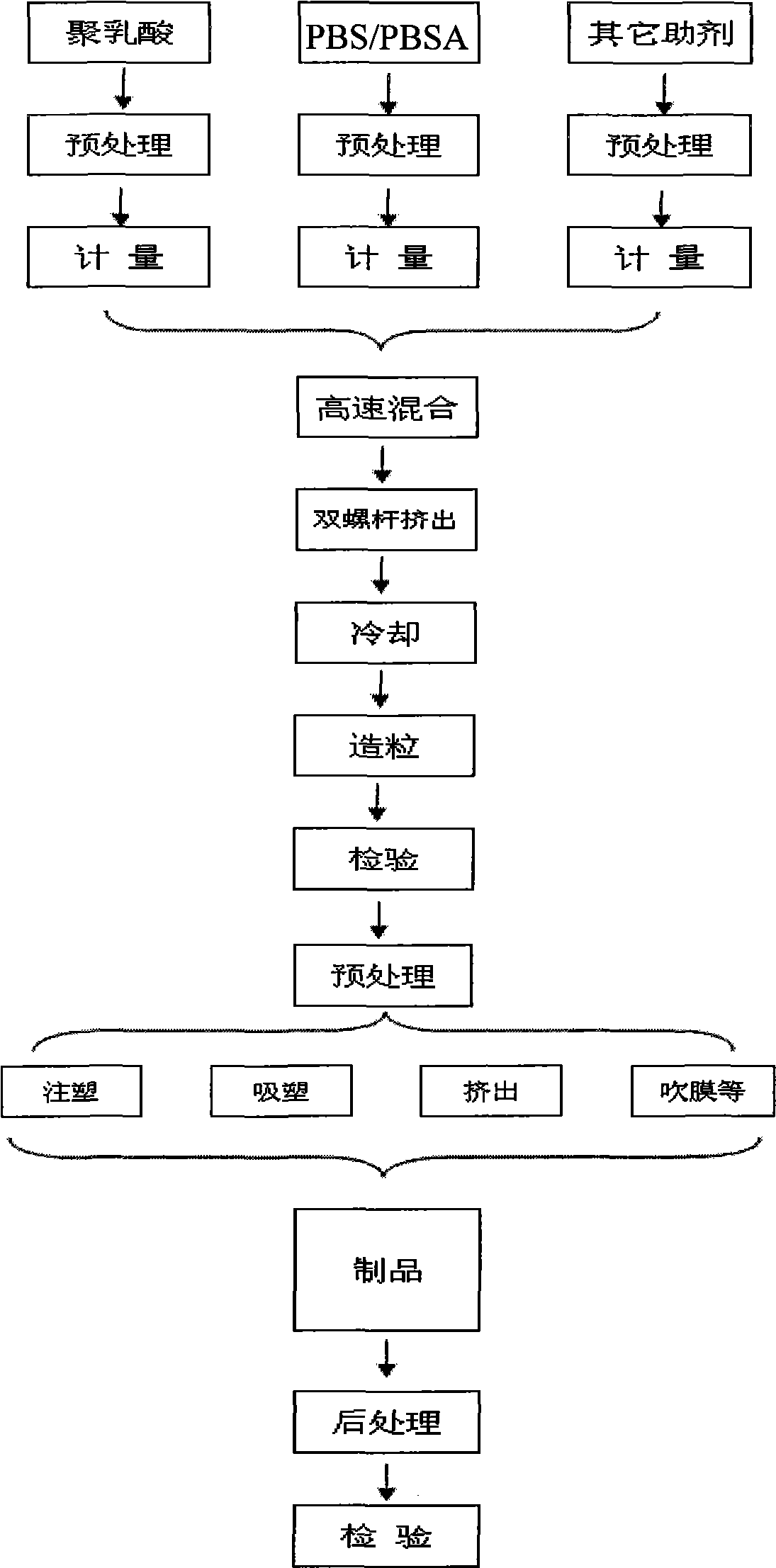

Method used

Image

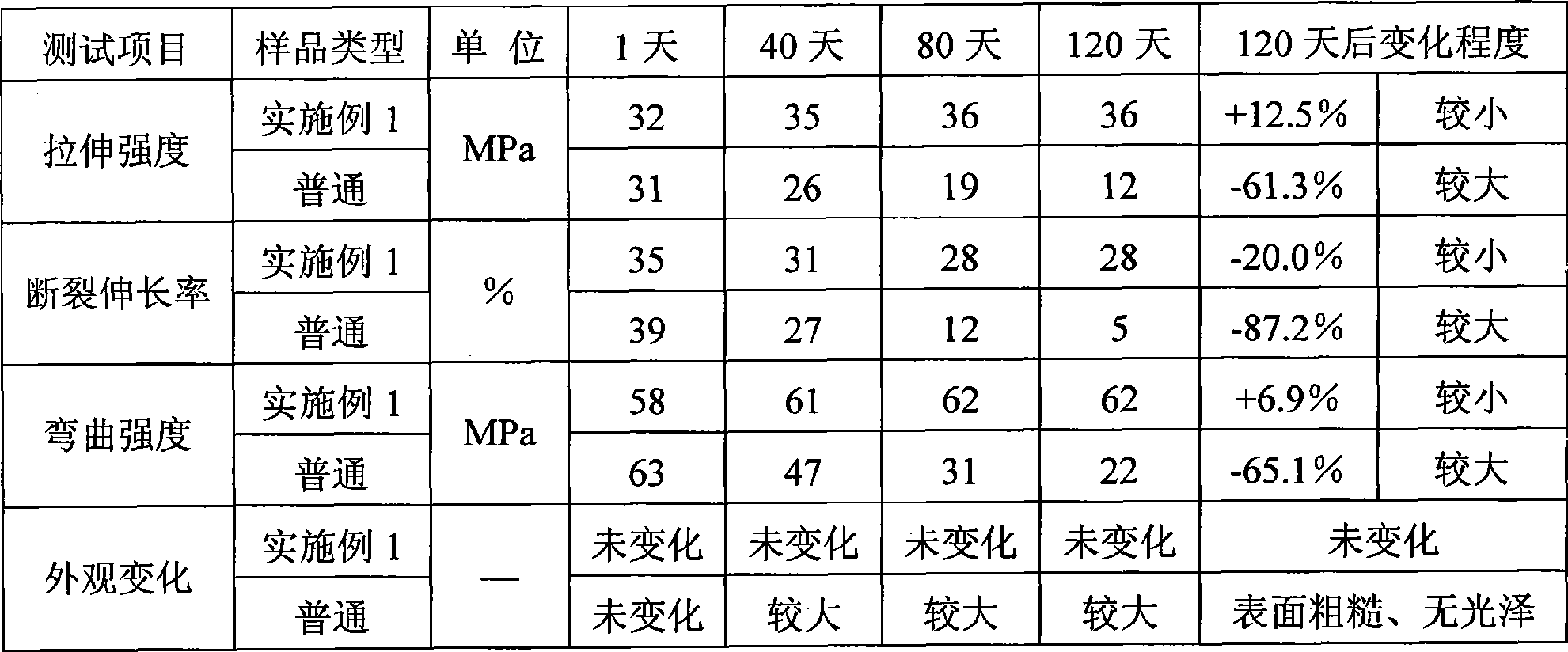

Examples

Embodiment 1

[0053] Embodiment 1 (injection molded product):

[0054] (1) Composition and content composition: 100 parts of PBS (produced by Anqing Hexing Chemical Industry, injection molding grade), 40 parts of PLA (produced by NatureWork, brand 3051D), compound modified tapioca starch (100 mesh, hydroxypropyl substitution degree 0.06-0.07%) ) 40 parts, 30 parts of inorganic filler (talc powder, 5000 mesh), 0.5 part of coupling agent (silane coupling agent KH560), 1.0 part of functional additive vinyl bis stearamide (EBS). The amounts of the above materials are by weight.

[0055] (2) Pretreatment of raw materials:

[0056] ① Drying: In drying equipment such as a hot air oven, the drying temperature of PBS and PLA is 80°C for 4 hours; the drying temperature for starch and inorganic fillers is 105°C for 4 hours;

[0057] ②Mixing: Stir each prepared raw material in a mixing mixer for 2 minutes at high speed, 3 minutes at low speed, and keep the temperature at room temperature (20-30°C) ...

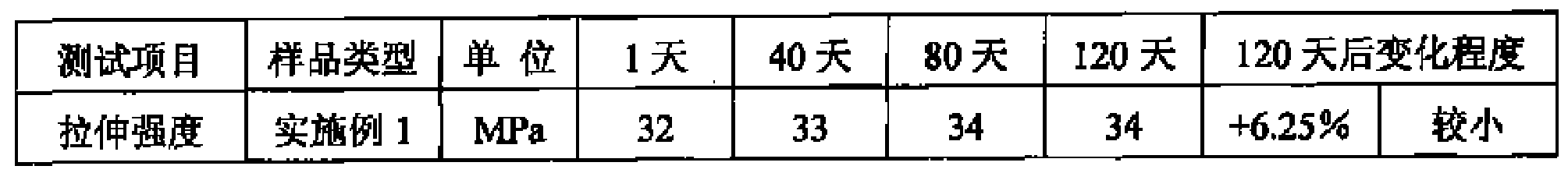

Embodiment 2

[0067] Embodiment 2 (blister product):

[0068] (1) Composition and content: 100 parts of PBSA (produced by Mitsubishi Chemical, trade mark AD92W), 5 parts of PLA (produced by NatureWork, trade mark 3051D), compound modified tapioca starch (100 mesh, hydroxypropyl substitution degree 0.06-0.07%) 10 10 parts, 10 parts of inorganic filler (talc powder, 5000 mesh), 0.1 part of coupling agent (silane coupling agent KH560), 0.1 part of functional additive vinyl bis stearamide (EBS). The amounts of the above materials are by weight.

[0069] (2) Pretreatment of raw materials:

[0070] ①Drying: In drying equipment such as a hot air oven, the drying temperature of PBSA and PLA is 80°C, and the drying time is 3 hours; the drying temperature of starch and inorganic filler is 105°C, and the drying time is 3 hours;

[0071] ②Mixing: Stir each prepared raw material in a mixing mixer for 1 minute at high speed, 2 minutes at low speed, and keep the temperature at room temperature (20-30°...

Embodiment 3

[0079] Embodiment 3 (blown product):

[0080] (1) Composition and content composition: 100 parts of PBSA (produced by Mitsubishi Chemical, brand AD92W), 20 parts of PLA (produced by NatureWork, brand 3051D), compound modified tapioca starch (100 mesh, hydroxypropyl substitution degree 0.06-0.07%) 15 20 parts, 20 parts of inorganic filler (talc powder, 5000 mesh), 0.2 part of coupling agent (silane coupling agent KH560), 0.5 part of functional additive vinyl bis stearamide (EBS). The amounts of the above materials are by weight.

[0081] (2) Pretreatment of raw materials:

[0082] ①Drying: In drying equipment such as a hot air oven, the drying temperature of PBSA and PLA is 80°C, and the drying time is 3 hours; the drying temperature of starch and inorganic filler is 105°C, and the drying time is 3 hours;

[0083] ②Mixing: Stir each prepared raw material in the mixing mixer for 2 minutes at high speed, 2 minutes at low speed, and keep the temperature at room temperature (20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com