Patents

Literature

35results about How to "Does not affect biodegradability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

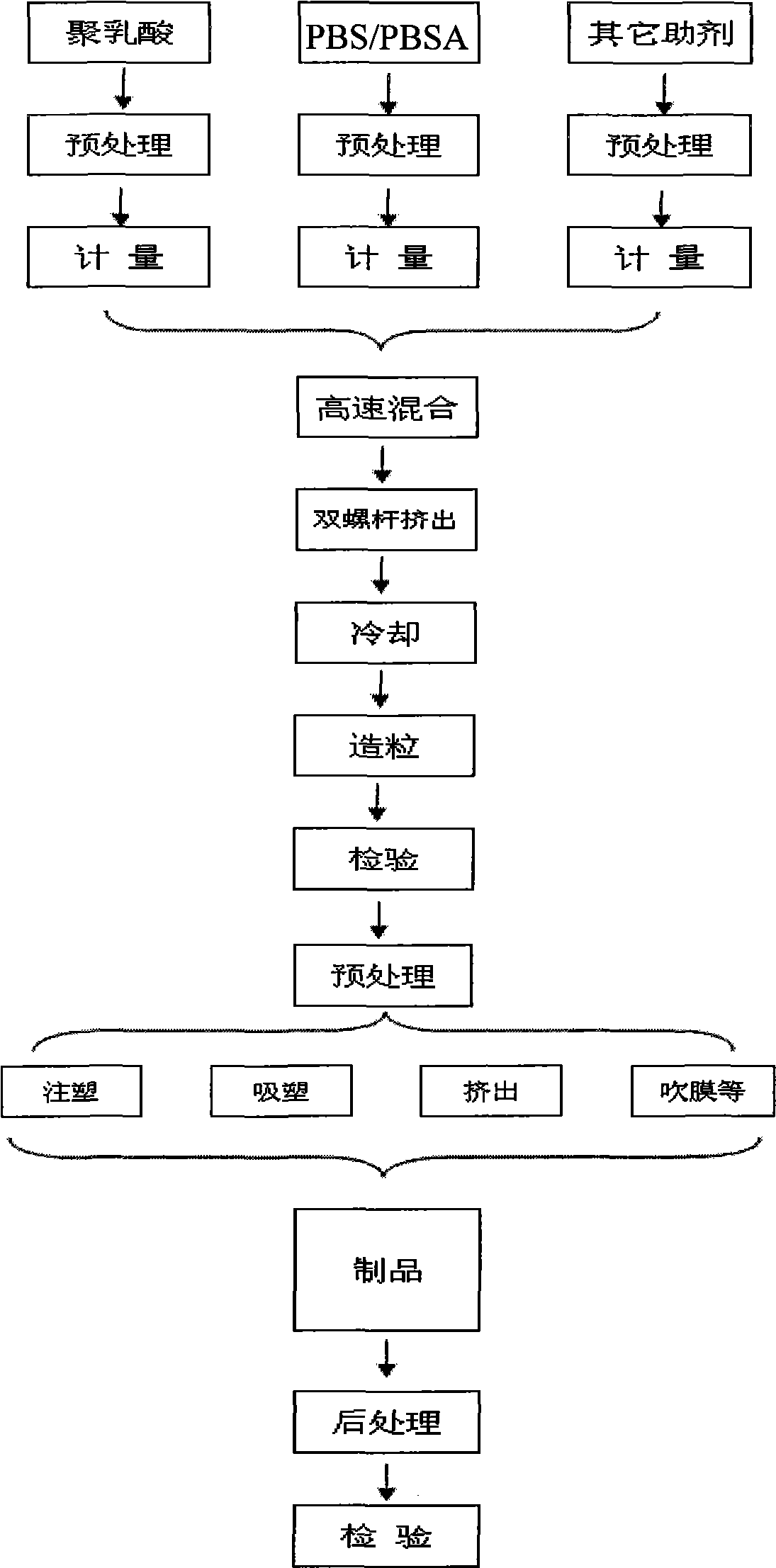

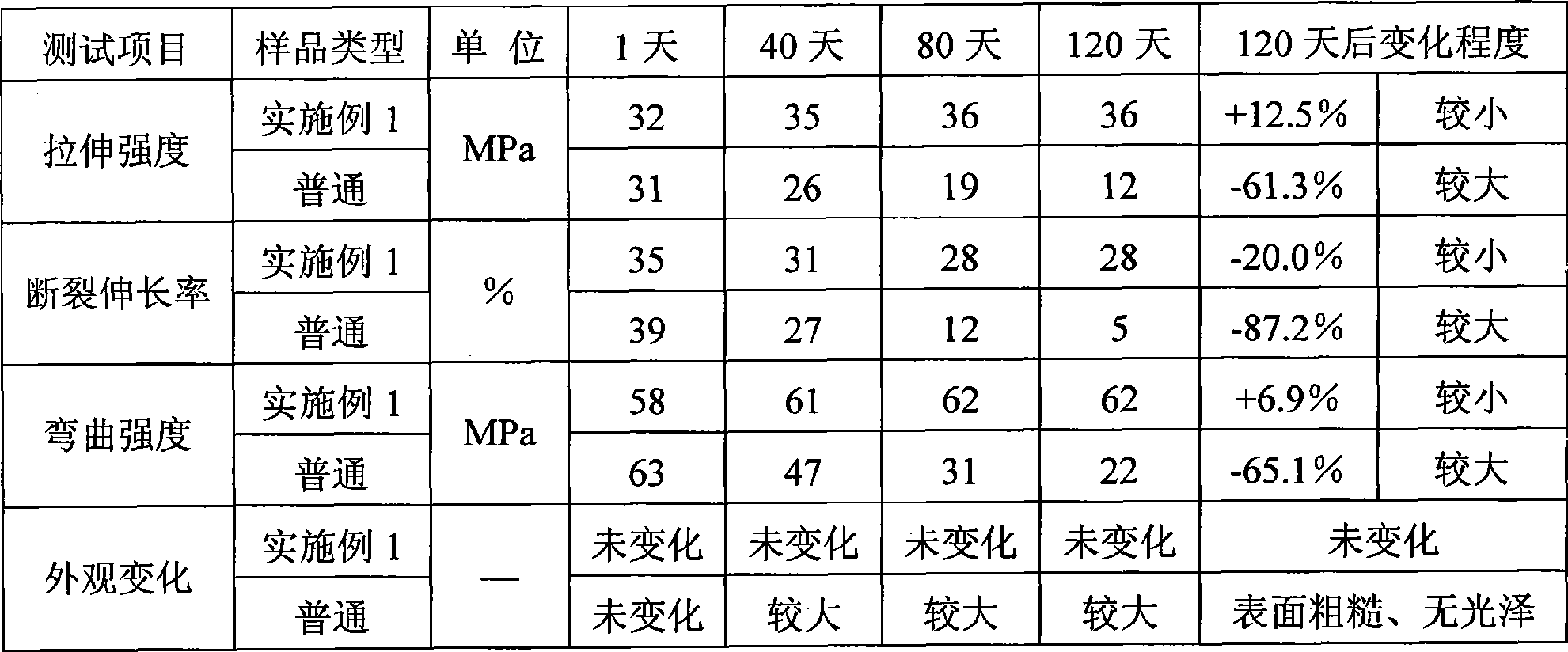

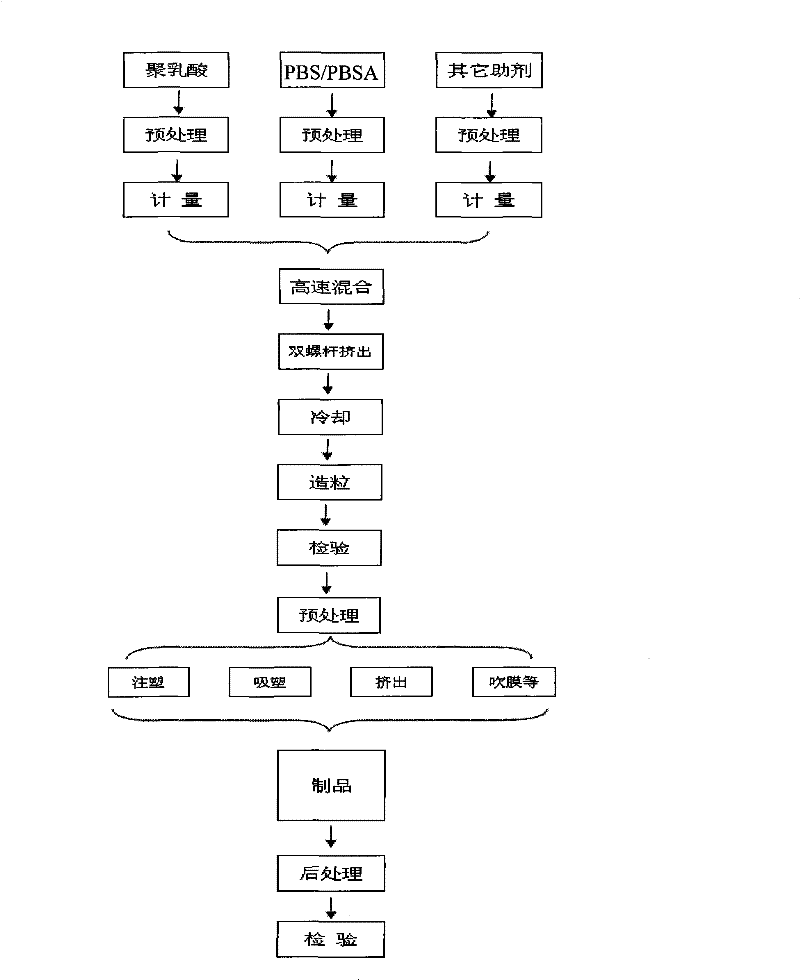

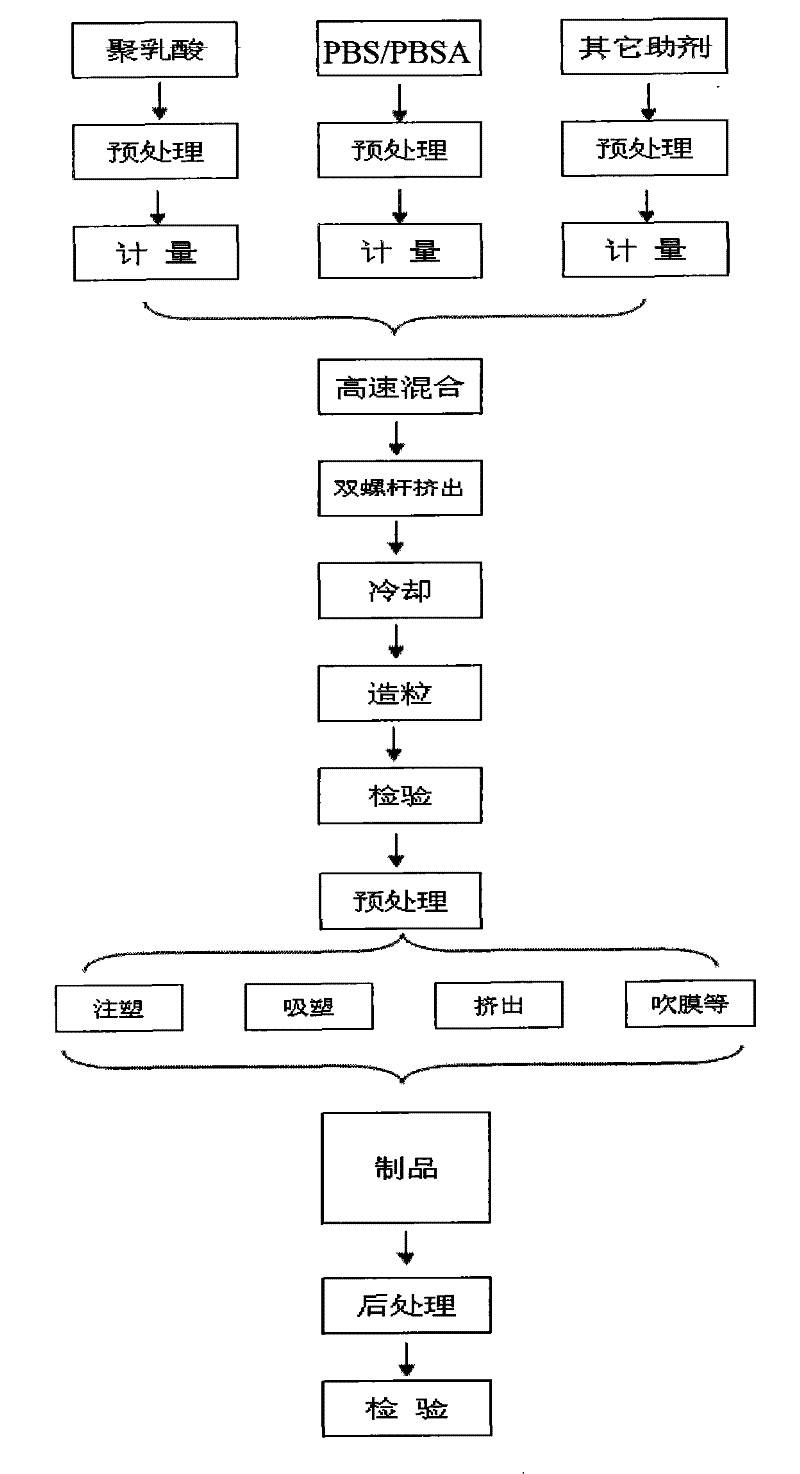

Material capable of completely biodegrading and preparation method thereof

The invention relates to a material capable of completely biodegrading, containing the following parts by weight:100 of polyester resin, 5-100 of polylactic resin and the multipolymer thereof, 10-80 of compounding converted starch, 10-60 of inorganic fillers and 0.1-0.9 of resin acceptor, wherein the polyester resin is at least one of polybutylene succinate resin, polybutylene adipate resin and the multipolymer thereof. The invention also provides a preparation method of the material. The material capable of completely biodegrading can combine the advantages of each component and has high intensity, modules, elongation at break and toughness, good heat resistance, and the like, thereby meeting the property requirements of a plurality of plastic products in the market and in particular products, such as non-returnable containers, mess kits, agricultural films, and the like, which cause serious white pollution, retaining the complete biodegradability of the material and reducing the production cost under the precondition of no influence on the property requirement.

Owner:深圳市未名北科环境材料有限公司 +1

Method for manufacturing biologically degradable polyester composite material with capacity increasing function

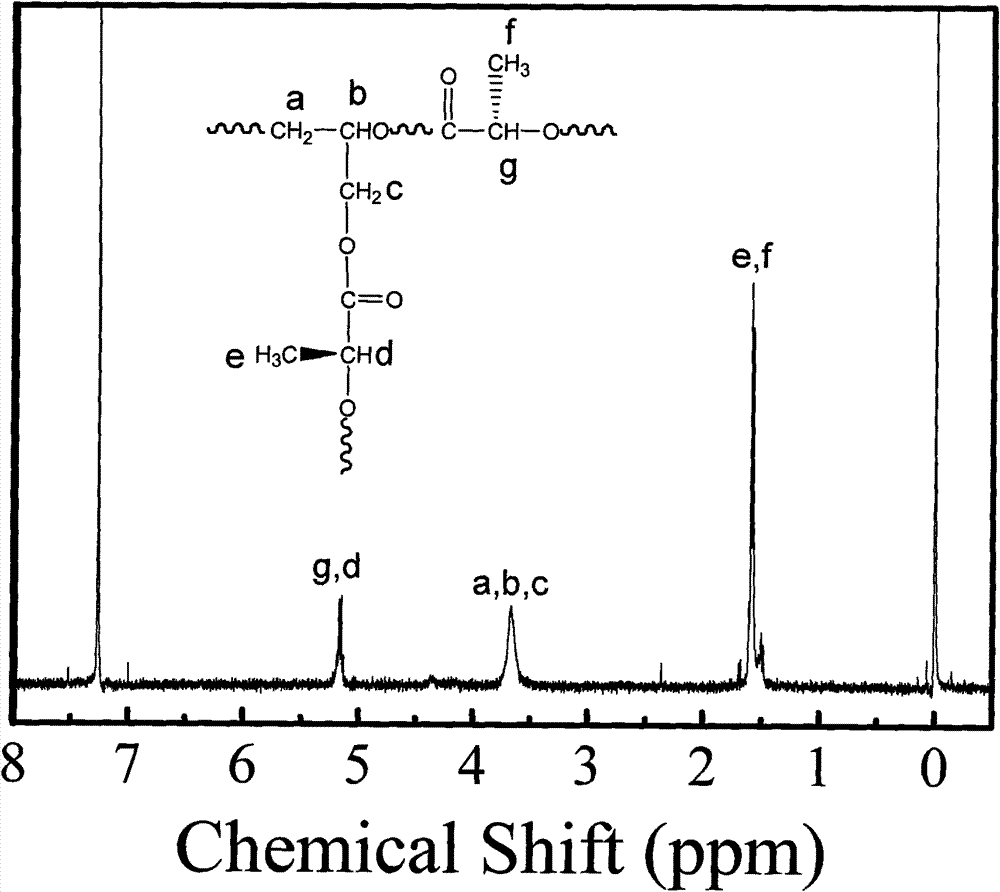

The invention belongs to the technical field of polymer materials, which more particularly relates to a preparation method of a biological decomposable polyester composite material with compatibilization function. The specific steps are that: a method of small molecular diol hydroxyl end capping is adopted for preparing polylactic acid and biological decomposable polyester diol, a diisocyanate series chain extender is used for preparing the block copolymer of the polylactic acid and the decomposable polyester by a method of fusion chain extension, and the block copolymer is used in a blend system of the polylactic acid and the corresponding polyester to play the role of compatibilization function. The preparation method of the biological decomposable polyester composite material is simple in method and technique, easy in industrial production and the prepared block copolymer can increase the compatibility of the polylactic acid and the biological decomposable polyester blend system effectively and play the role of a compatibilizer.

Owner:TONGJI UNIV

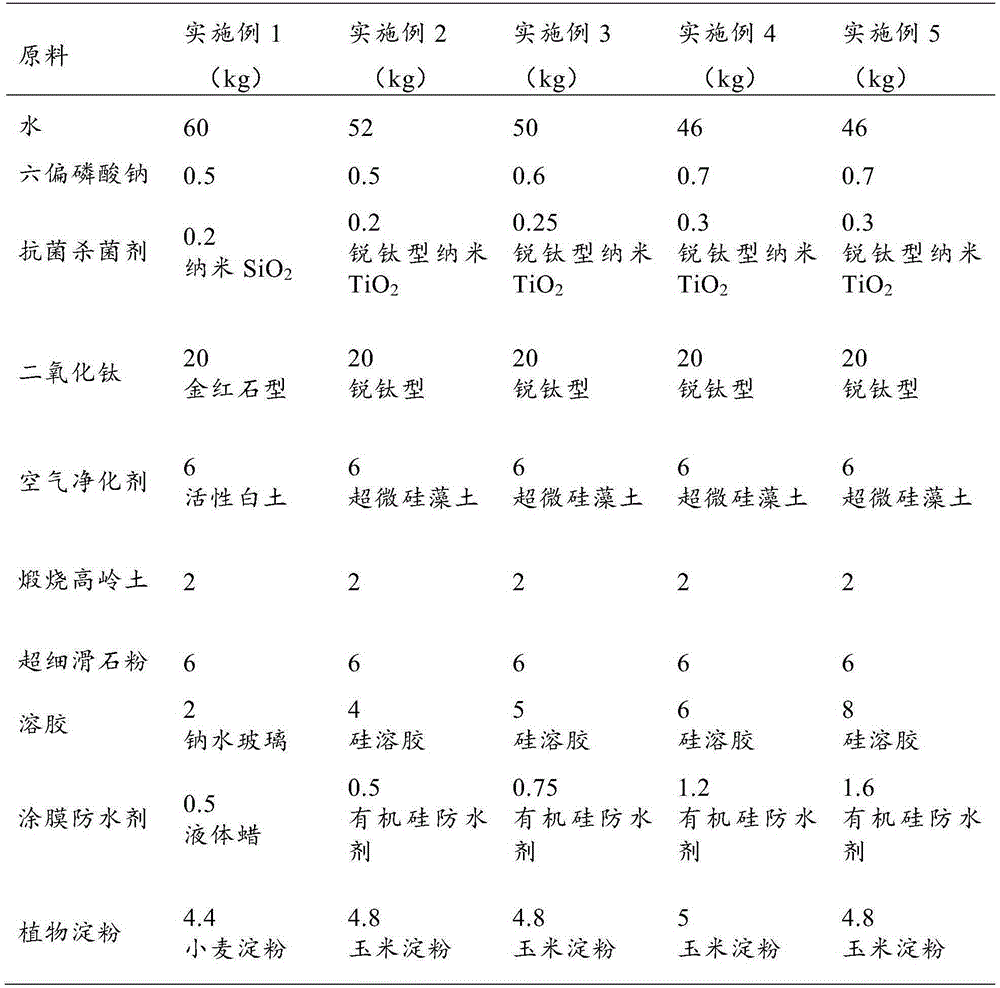

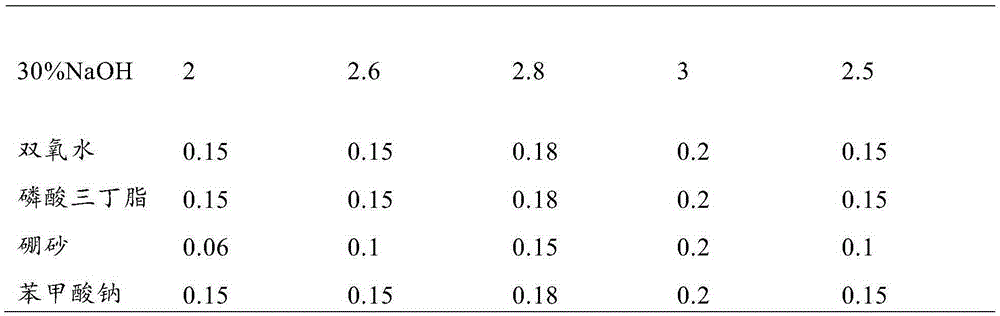

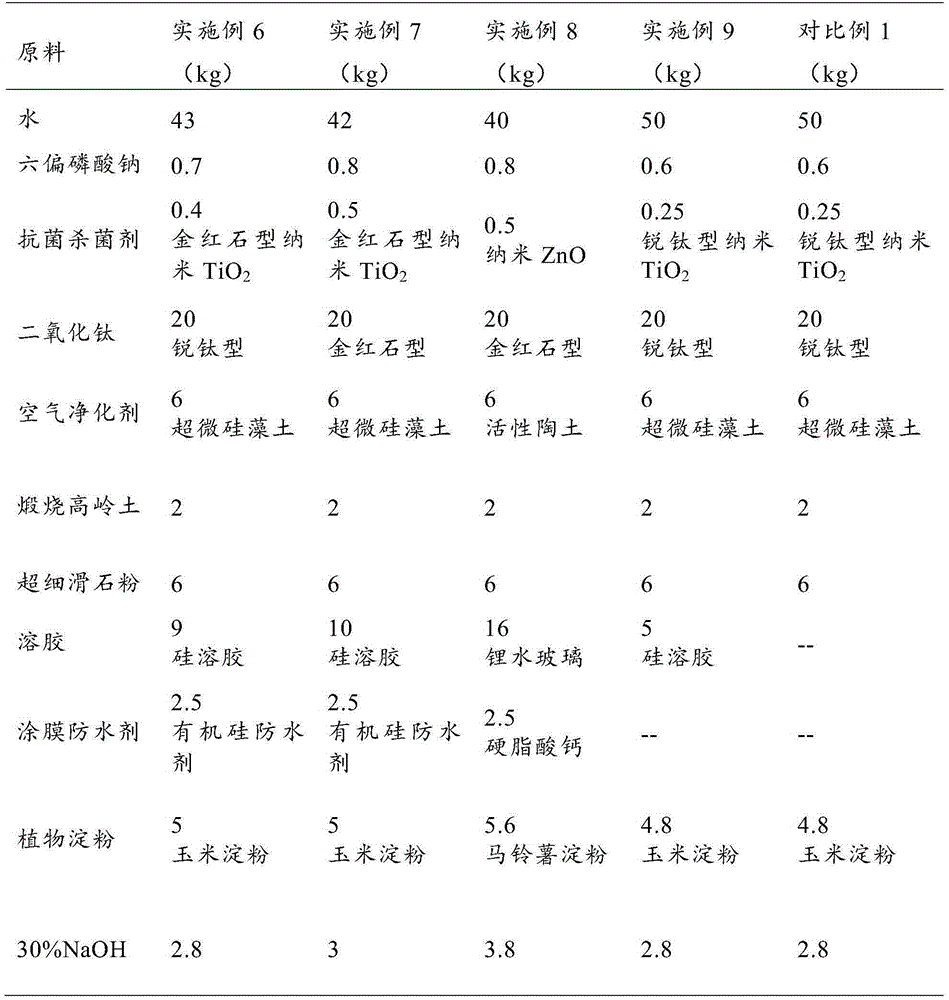

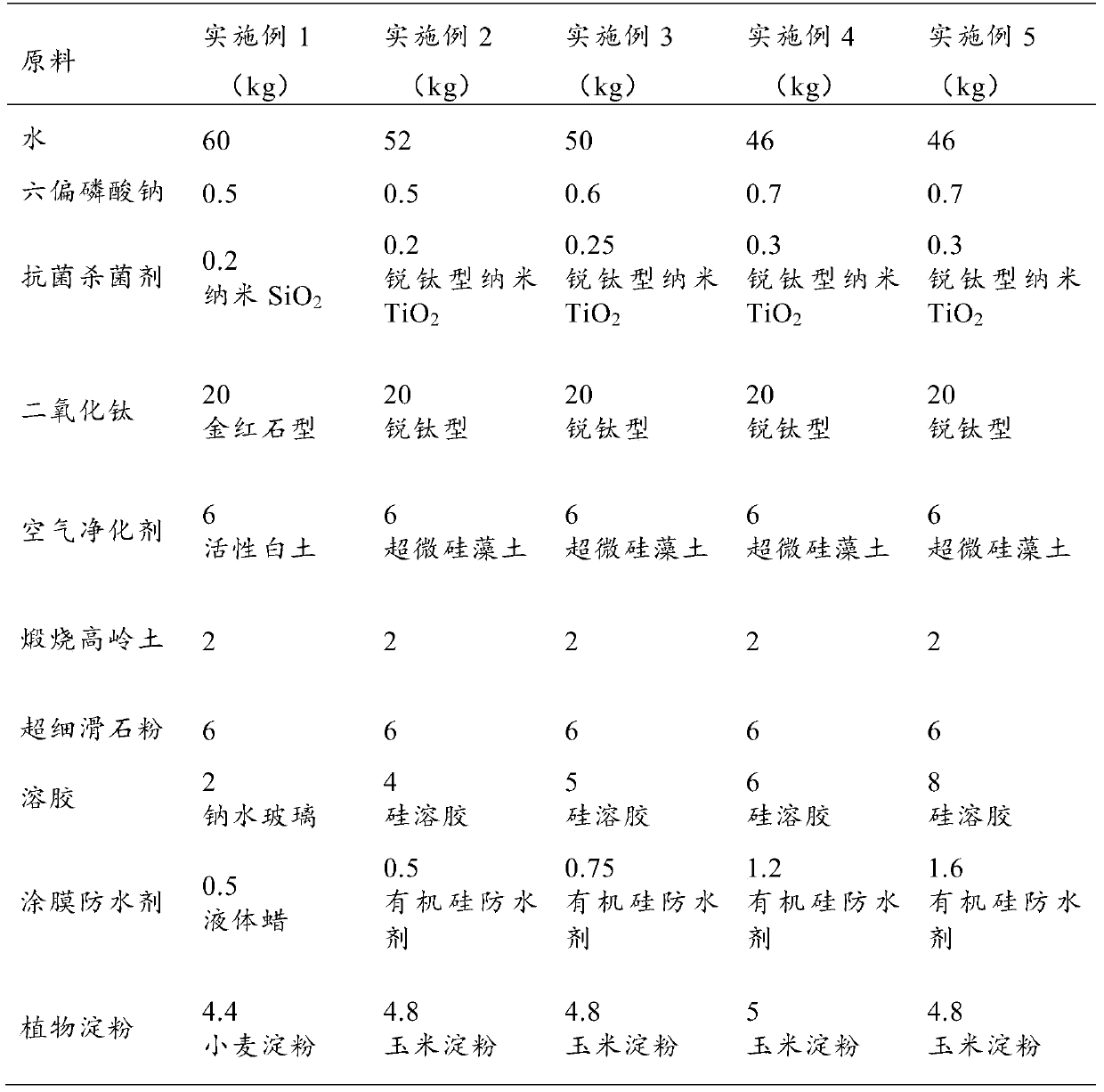

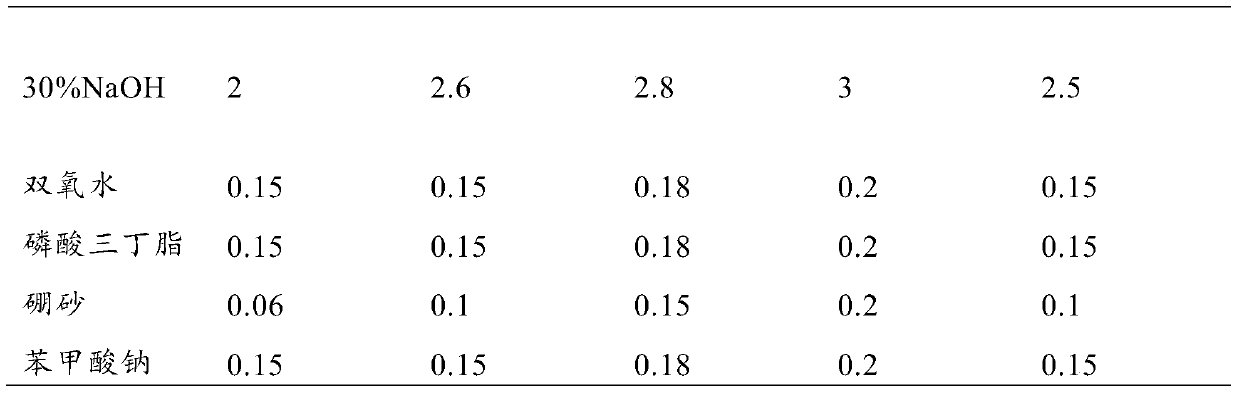

Plant ecological interior wall coating and preparation method thereof

ActiveCN105368164ALow NaOH contentImprove water resistanceStarch coatingsEcological environmentBinding force

The invention discloses a plant ecological interior wall coating and a preparation method thereof. The plant ecological interior wall coating is characterized by being prepared from a titanium dioxide filler, a borax crosslinking agent, an oxidizing agent, water, plant starch serving as a binding agent and sol serving as a binding agent modifier. According to the plant ecological interior wall coating, the plant starch is utilized as the binding agent, no synthetic resin emulsion is contained, complete biodegradation can be achieved, and the coating is an ecological environment-friendly interior wall coating in the true sense; the sol is added to serve as the binding agent modifier, the higher film coating binding force and film coating strength are achieved, and the technical property can reach the GB / T9756-2009 standard of a qualified synthetic resin emulsion interior wall coating product and is obviously suprior to the JC / T423-91 technical requirements for a water-soluble interior wall coating.

Owner:烟台阳光新材料技术有限公司

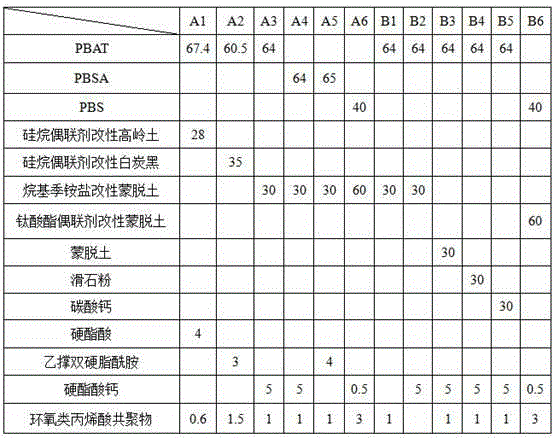

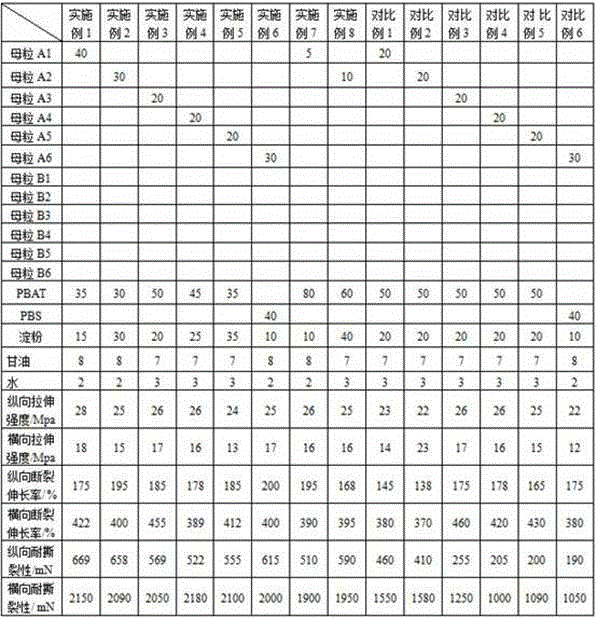

Full-biodegradable composite as well as preparation method and application of full-biodegradable composite

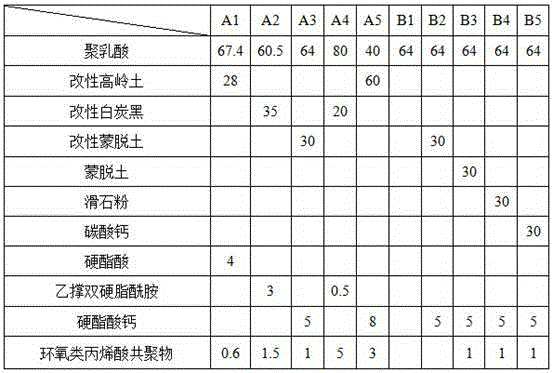

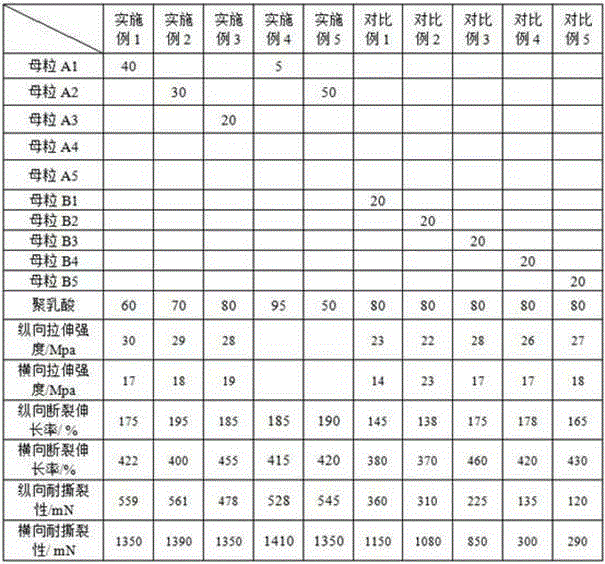

The invention discloses a full-biodegradable composite as well as a preparation method and application of the full-biodegradable composite. The full-biodegradable composite comprises the following components: 5-40 parts of inorganic filler full-biodegradable masterbatches, 40-80 parts of biodegradable copolyester, 10-40 parts of starch and 5-20 parts of a plasticizer, wherein the inorganic filler full-biodegradable masterbatches comprise the following components: 20-80 parts of biodegradable copolyester, 20-80 parts of inorganic filler, 0.1-10 parts of a lubricating agent and 0.1-5 parts of a compatilizer; and the inorganic filler is one or a combination of modified kaolin, modified white carbon black and modified montmorillonite. According to the full-biodegradable composite, the modified montmorillonite, the modified kaolin or the modified white carbon black is added as an enhancer, and an epoxy acrylic copolymer is introduced as the compatilizer, so that the compatibility of inorganic filler and matrix resin is enhanced, and the uniform dispersion is achieved; and the masterbatches are added into the matrix resin, so that the problem of relatively low tearing strength of a blend film and a sheet can be effectively improved.

Owner:KINGFA SCI & TECH CO LTD +1

Totally degradable foam buffer packaging material and its manufacturing method

The invention provides a complete biodegradable foam cushioning packing material and method for preparation, characterized in that starch over 80% content is used as base-material, ultra-fine polyvinyl alcohol is used as film forming intensifier, water is used as foaming agent, and core forming agent and flow modifier are added, wherein the mixture is amalgamated through blending homogeneous machine and fed into reverse-flighted screw extrusion machine for one-shot extrusion forming. The product can be used to substitute polystyrene foam for filling with no requirement on shapes.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Inorganic filler full-biodegradable composite as well as preparation method and application of inorganic filler full-biodegradable composite

InactiveCN104479315AGood compatibilityImproved tear strength lowerFlat articlesPolymer scienceKaolin clay

The invention discloses an inorganic filler full-biodegradable composite as well as a preparation method and application of the inorganic filler full-biodegradable composite. The inorganic filler full-biodegradable composite comprises the following components: 5-50 parts of inorganic filler full-biodegradable masterbatches and 50-95 parts of polylactic acid, wherein the inorganic filler full-biodegradable masterbatches comprise the following components: 20-80 parts of polylactic acid, 20-80 parts of inorganic filler, 0.1-10 parts of a lubricating agent and 0.1-5 parts of a compatilizer; and the inorganic filler is one or a combination of modified kaolin, modified white carbon black and modified montmorillonite. According to the inorganic filler full-biodegradable composite, the modified montmorillonite, the modified kaolin or the modified white carbon black is added as an enhancer, and an epoxy acrylic copolymer is introduced as the compatilizer, so that the compatibility of the inorganic filler and matrix resin is enhanced, and the uniform dispersion is achieved; and the masterbatches are added into the polylactic acid, so that the problem of relatively low tearing strength of a polylactic acid film and a sheet can be effectively improved.

Owner:KINGFA SCI & TECH CO LTD +1

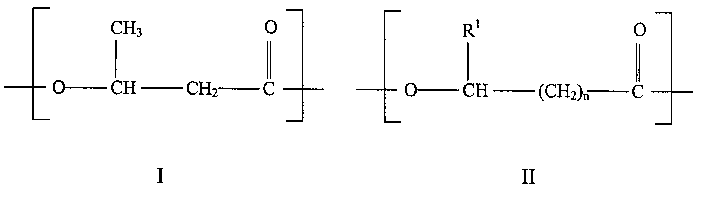

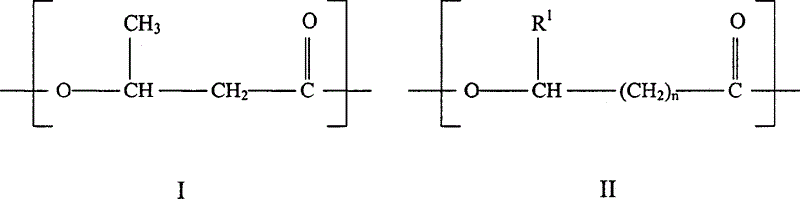

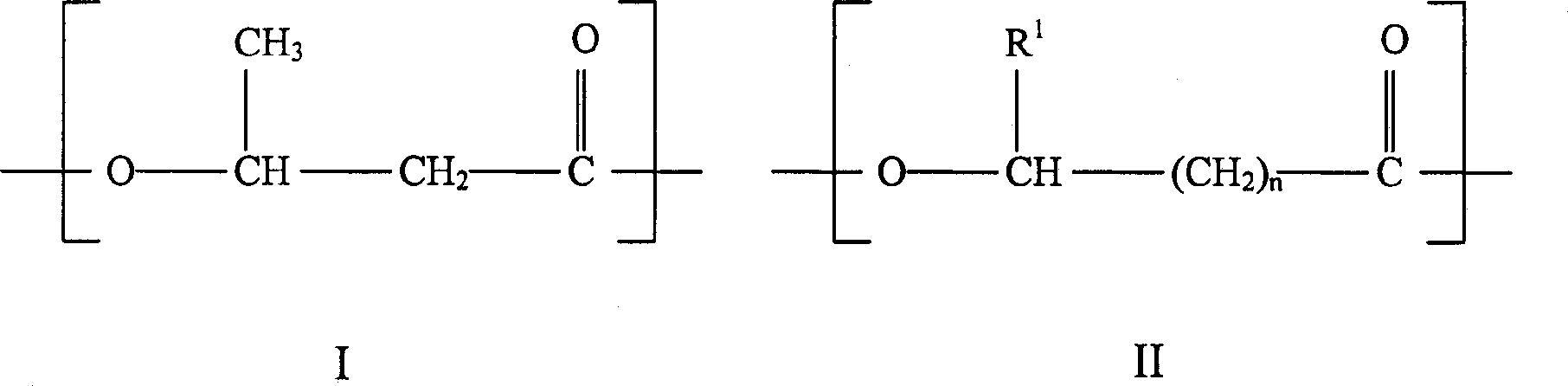

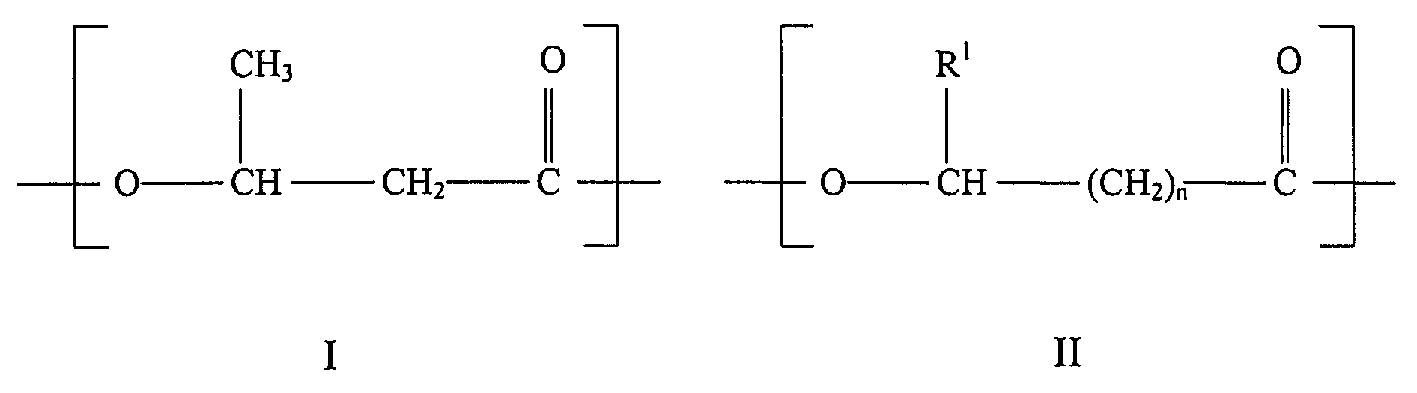

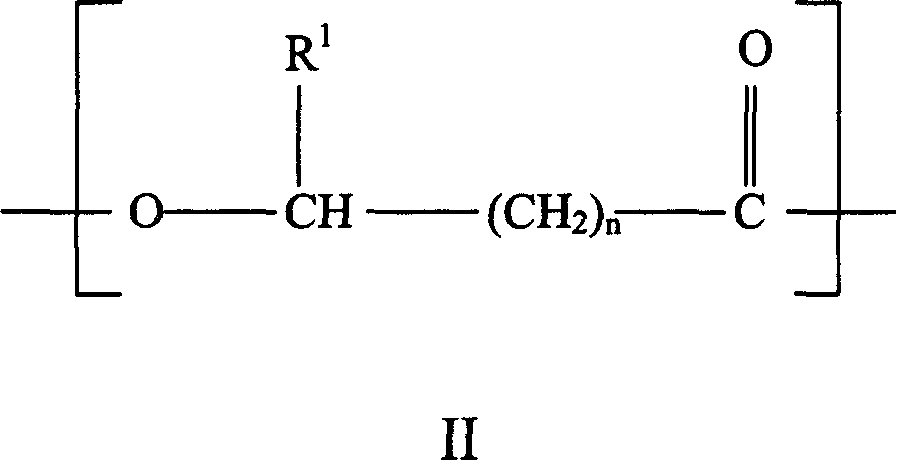

Biodegradable material comprising polyhydroxy fotty acid ester blending polymer

One new kind of biodegradable material with low cost and high machining performance is mixture containing including 3-hydroxy butyrate homopolymer and copolymer of 3-hydroxy butyric acid and non-HB structure hydroxy fatty acid in the weight ratio of 1 / 9 to 9. The copolymer contains at least two random structural units I and II, with the structural unit I accounting for the molar ratio of 10-95 %. The plastic products made of the biodegradable material are also provided.

Owner:SHANTOU F T Z FREE TRADE ZONE LIANYI BIOTECH

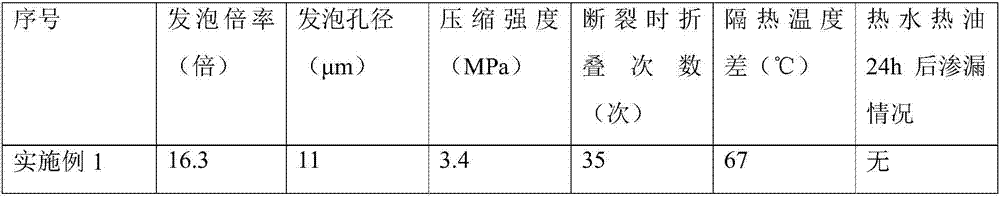

Full biodegradable fiber-reinforced starch foaming tableware and preparation method thereof

ActiveCN106947117AImprove toughnessHigh foaming ratioTable equipmentsCoatingsInternal layerHot press

The invention relates to biodegradable material, specifically relates to a full biodegradable fiber-reinforced starch foaming tableware and a preparation method thereof. The foaming tableware is divided into two layers of an outer layer and an internal layer, the outer layer is prepared from the following components in mass percent: 50 to 82 percent of cassava starch, 5 to 20 percent of biodegradable short fiber, 5 to 10 percent of biodegradable flexibilizer, 1 to 3 percent of compatilizer, 5 to 10 percent of foaming agent, 1 to 5 percent of heat insulation agent and 1 to 2 percent of releasing agent. All the components are mixed and stirred uniformly, then biodegradable thin film is sprayed and coated on a mixture subjected to hot press molding so that the full biodegradable fiber-reinforced starch foaming tableware is prepared. The tableware has the advantages that the strength is high, the rigidity is large, the toughness is good, the foaming ratio is high, the foaming aperture is small, the heat insulation is good, the water-resistance and oil-resistance is good, and all the material can be fully biodegraded so as to be the best choice to substitute a foaming polystyrene tableware.

Owner:庞买只

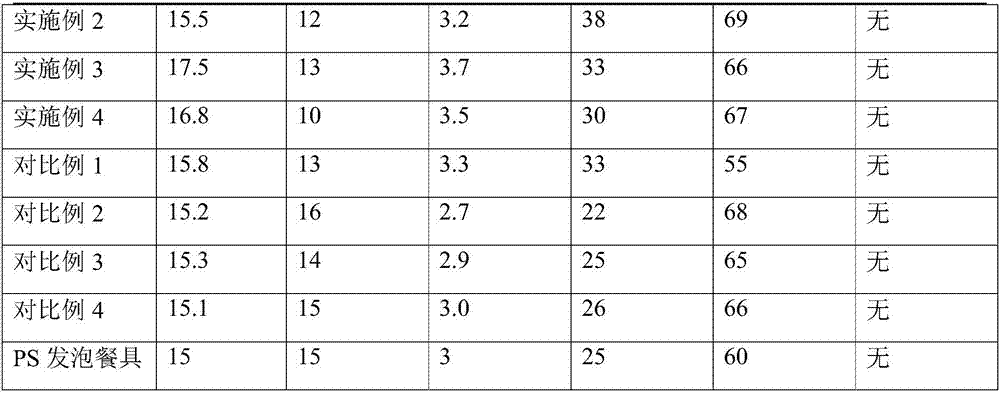

Method for extracting bioflocculant from excess activated sludge

InactiveCN102153182AReduce manufacturing costAvoid trainingSludge treatment by de-watering/drying/thickeningWater/sewage treatment by flocculation/precipitationFlocculationAlkalinity

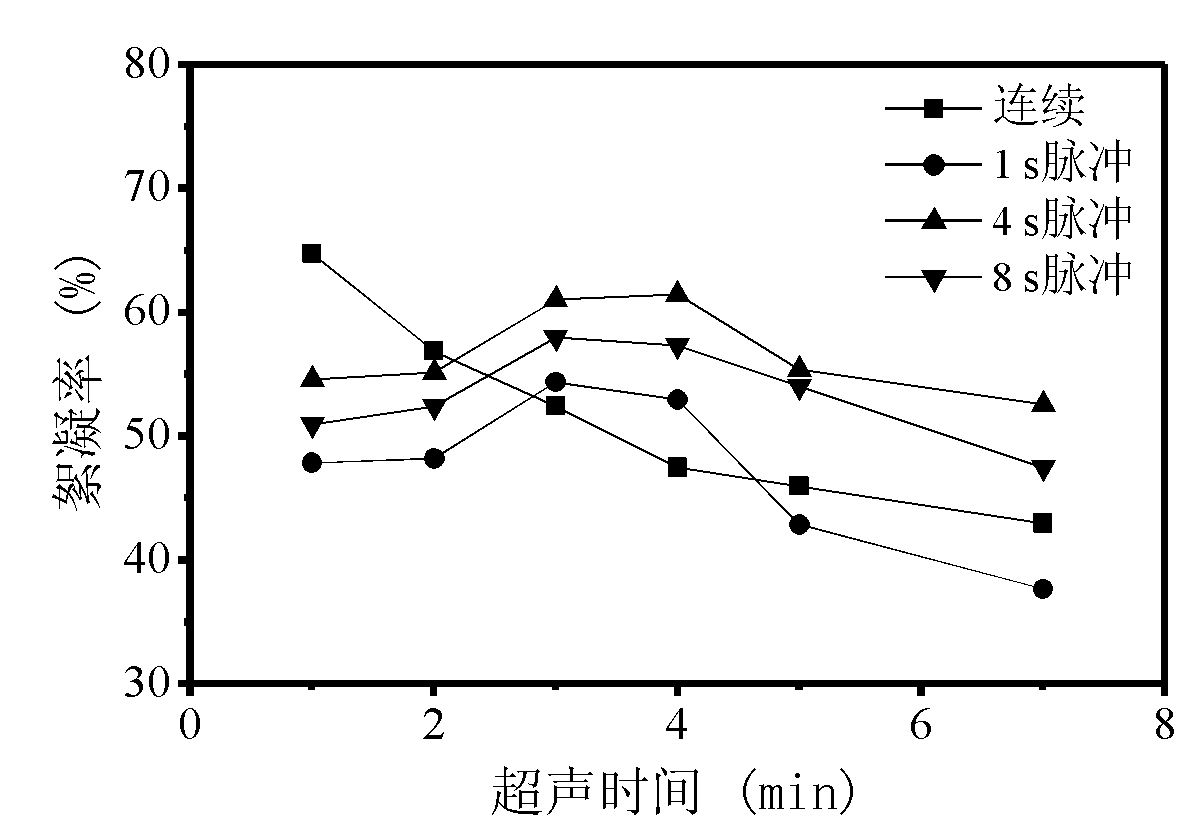

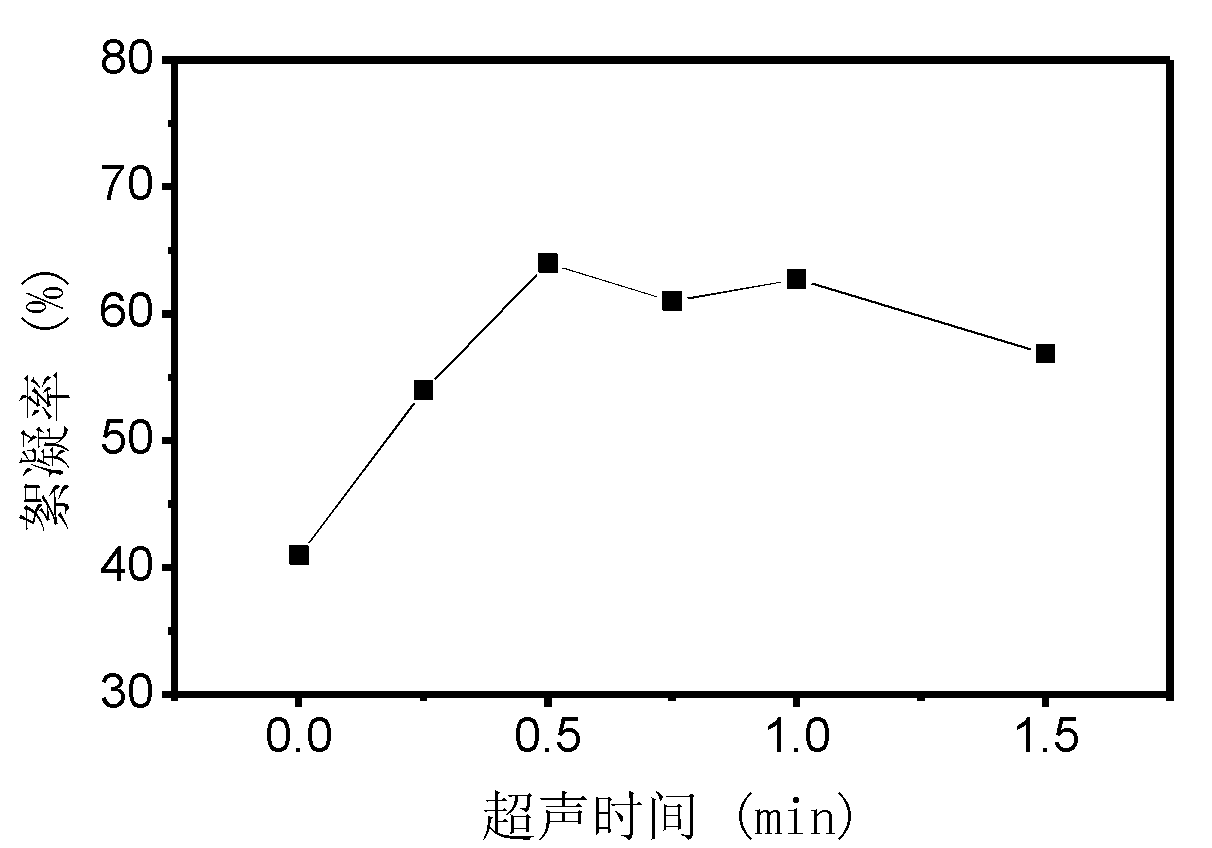

The invention relates to a method for extracting bioflocculant from excess activated sludge, in particular to a method for preparing the bioflocculant by adopting an ultrasonic method. The method comprises the following steps of: A, getting back the excess activated sludge from a sewage treatment plant adopting a biological treatment process, standing for 8-24h at a temperature of 4-5 DEG C, and dumping supernate to obtain gravity concentrated sludge; B, carrying out ultrasonic treatment on the gravity concentrated sludge for 30-120s under the conditions that the frequency is 20-53kHz and the power is 120-240W to obtain a sludge sample; and C, centrifuging the sludge sample for 10-30min at a speed of 6,000-12,000rpm to obtain supernate, namely the bioflocculant. Determination on the bioflocculant provided by the invention shows that flocculation can be about 70% when pH value is equal to 9.0, and the flocculation effect is rapidly promoted while the alkalinity is increased; the bioflocculant is biodegradable, and no secondary pollution is produced after the bioflocculant is used; the price is low, the process controllability is high, the requirement of industrial production can be easily met, good environmental, economic and social benefits are realized, and the bioflocculant can be widely applicable to recycling of the excess activated sludge produced by a sewage biological treatment plant.

Owner:TONGJI UNIV

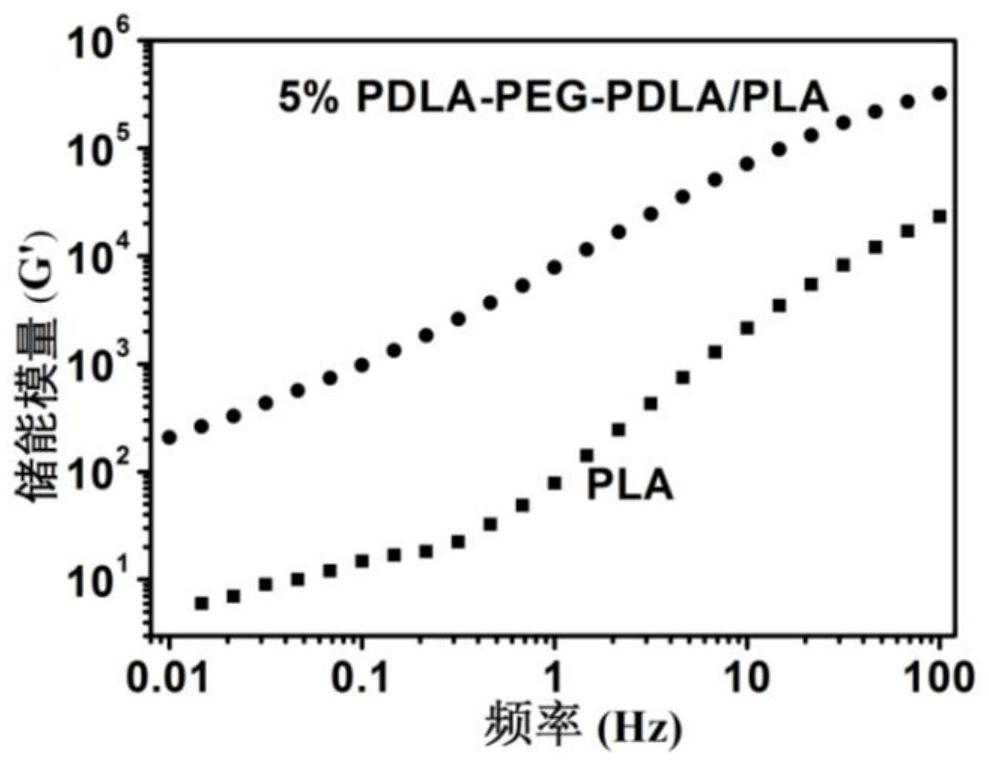

Polylactic acid melt reinforcing agent and preparation method thereof

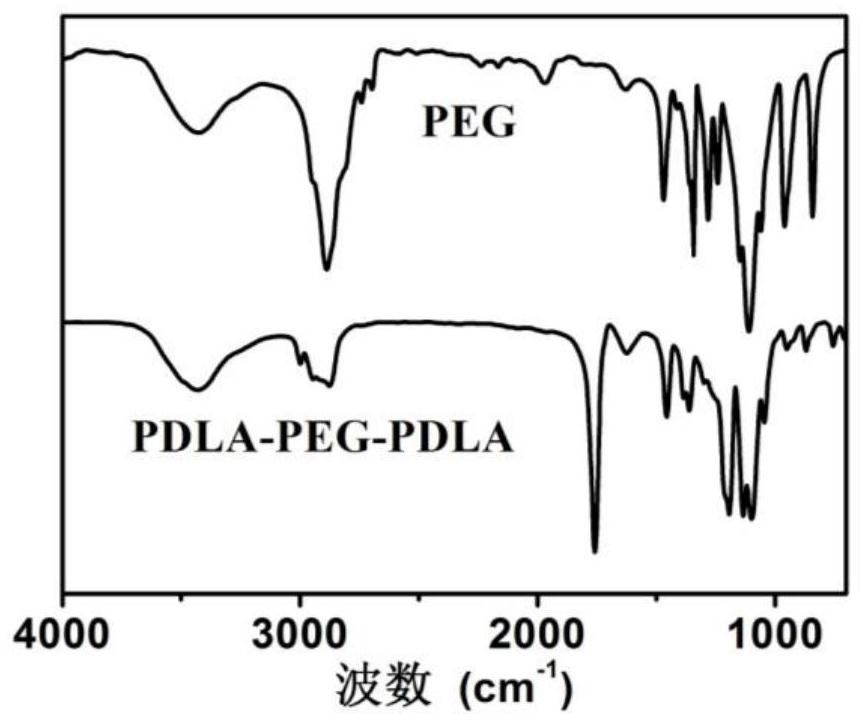

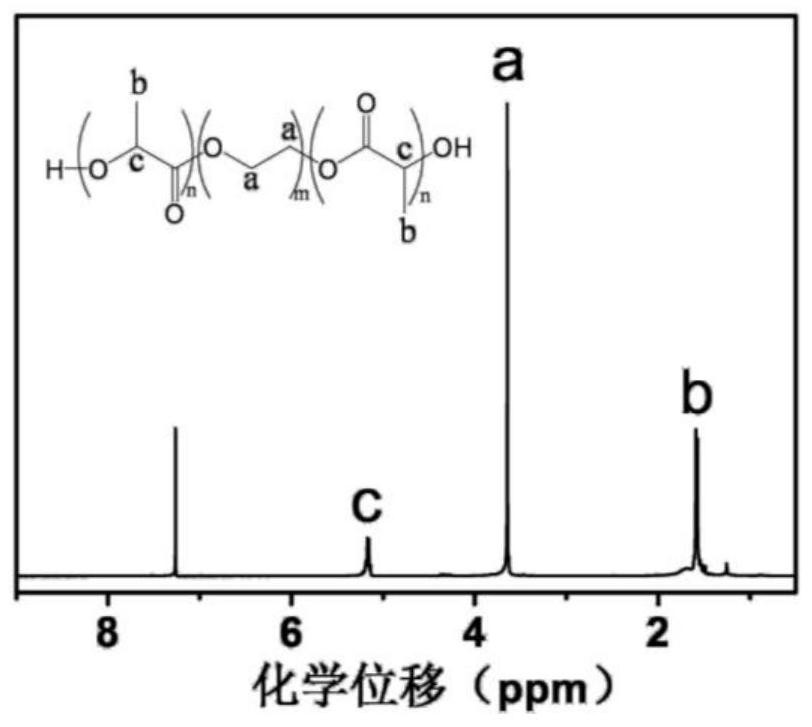

The invention discloses a polylactic acid melt reinforcing agent and a preparation method thereof. The copolymer involved in the invention forms a stereocomplex crystal network with a higher melting point mainly through a dextral polylactic acid PDLA chain segment in PDLA-PEG-PDLA and a matrix levorotatory polylactic acid PLLA molecular chain, the melt strength is increased, the PEG segment not only has the effect of improving molecular motion and promoting the formation of stereocomplex crystals, and but also has the effect of toughening the whole blend. The reinforcing agentdisclosed by the invention has the advantages of small addition amount, simple formula and the like, and has a good industrial production prospect.

Owner:EAST CHINA UNIV OF TECH

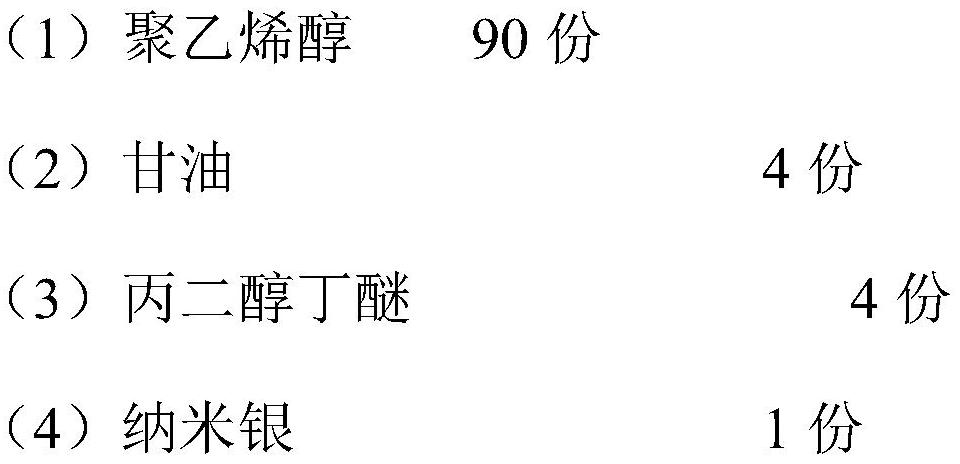

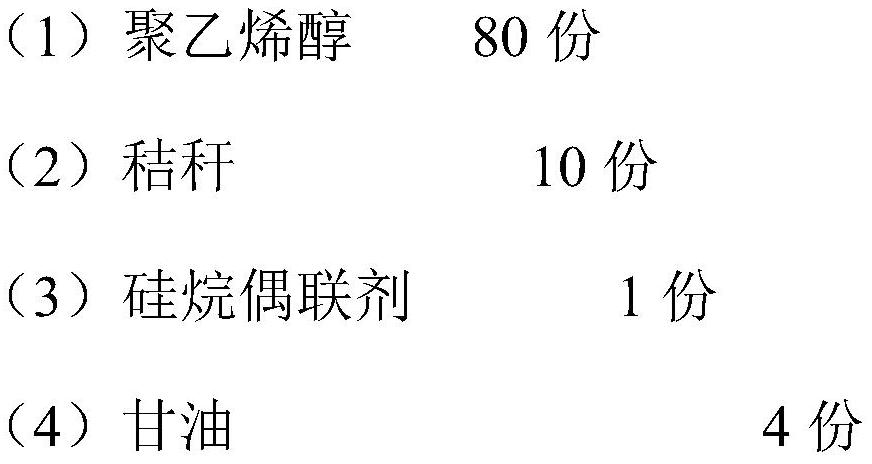

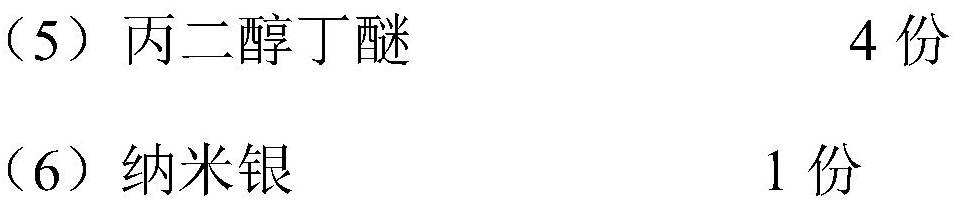

Completely biodegradable plastic film prepared from straws and preparation method thereof

The invention discloses a completely biodegradable plastic film prepared from straws and a preparation method of the completely biodegradable plastic film, relates to the technical field of resource utilization of straws in agricultural wastes, and solves the problem of relatively high technical cost of preparing a completely biodegradable material by utilizing a biodegradable polymer in the priorart. The biodegradable plastic is prepared from the following raw materials in parts by weight: 50-90 parts of a biodegradable polymer, 10-40 parts of straws, 0.5-2 part of a surface modifier, 5-10 parts of a plasticizing modifier, 5-10 parts of a film-forming agent and 0.2-1 part of nano-silver. According to the method for preparing the completely biodegradable material by replacing part of thebiodegradable polymer with the straw, the technical raw material cost is effectively reduced, and the effects of resource saving, environmental protection, wide raw material source, simple process, easiness in industrialization and the like are achieved.

Owner:CHINA TIANYING +1

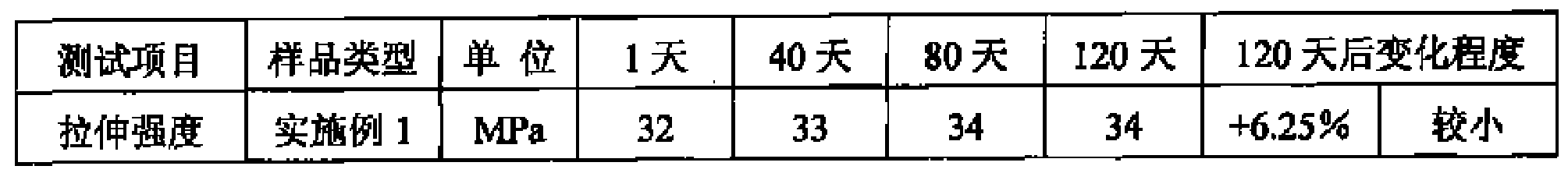

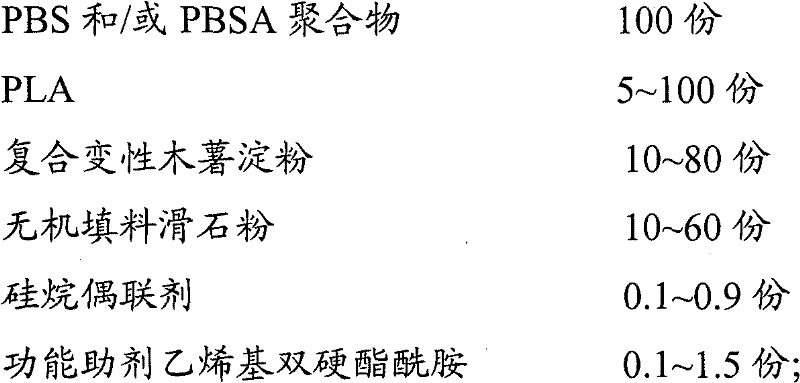

Material capable of completely biodegrading and preparation method thereof

The invention relates to a material capable of completely biodegrading, containing the following parts by weight:100 of polyester resin, 5-100 of polylactic resin and the multipolymer thereof, 10-80 of compounding converted starch, 10-60 of inorganic fillers, 0.1-0.9 of resin acceptor and 0.1-1.5 of functional agent wherein the polyester resin is at least one of polybutylene succinate resin, polybutylene adipate resin and the multipolymer thereof. The invention also provides a preparation method of the material. The material capable of completely biodegrading can combine the advantages of each component and has high intensity, modules, elongation at break and toughness, good heat resistance, and the like, thereby meeting the property requirements of a plurality of plastic products in the market and in particular products, such as non-returnable containers, mess kits, agricultural films, and the like, which cause serious white pollution, retaining the complete biodegradability of the material and reducing the production cost under the precondition of no influence on the property requirement.

Owner:深圳市未名北科环境材料有限公司 +1

PBAT fiber and preparation method thereof

ActiveCN113122952AFast crystallizationAvoid stickingMonocomponent copolyesters artificial filamentMelt spinningIsophthalic acid

The invention relates to a PBAT fiber and a preparation method. Molecular chain segments of the PBAT fiber comprise a butylene terephthalate chain segment, a butylene adipate chain segment and an isophthalic acid-5-sodium sulfoisophthalic acid butanediol ester chain segment, the molar content of the butylene adipate chain segment is 50%-150% relative to the molar content of the butylene terephthalate chain segment, and the molar content of the isophthalic acid-5-sodium sulfoisophthalic acid butanediol ester chain segment is 0.5%-4% relative to the molar content of the terephthalic acid butanediol ester chain segment; and the breaking strength of the PBAT fiber is 2.0-5.5 cN / dtex, the elongation at break is 15%-60%, and the AA rate is greater than or equal to 98%. The preparation method comprises the following steps that terephthalic acid and adipic acid are correspondingly esterified and then subjected to pre-polycondensation, then two prepolymers are mixed, an isophthalic acid-5-sodium sulfonate ester is added, then final polycondensation is carried out, and finally the PBAT fiber is prepared by a melt spinning method. According to the PBAT fiber, the balance relation between the crystallization capacity and the performance of PBAT is regulated and controlled through the length of the chain segment, and the performance of the fiber is improved by introducing SSIPA into the chain segment.

Owner:XINJIANG BLUE RIDGE TUNHE CHEM IND JOINTSTOCK +1

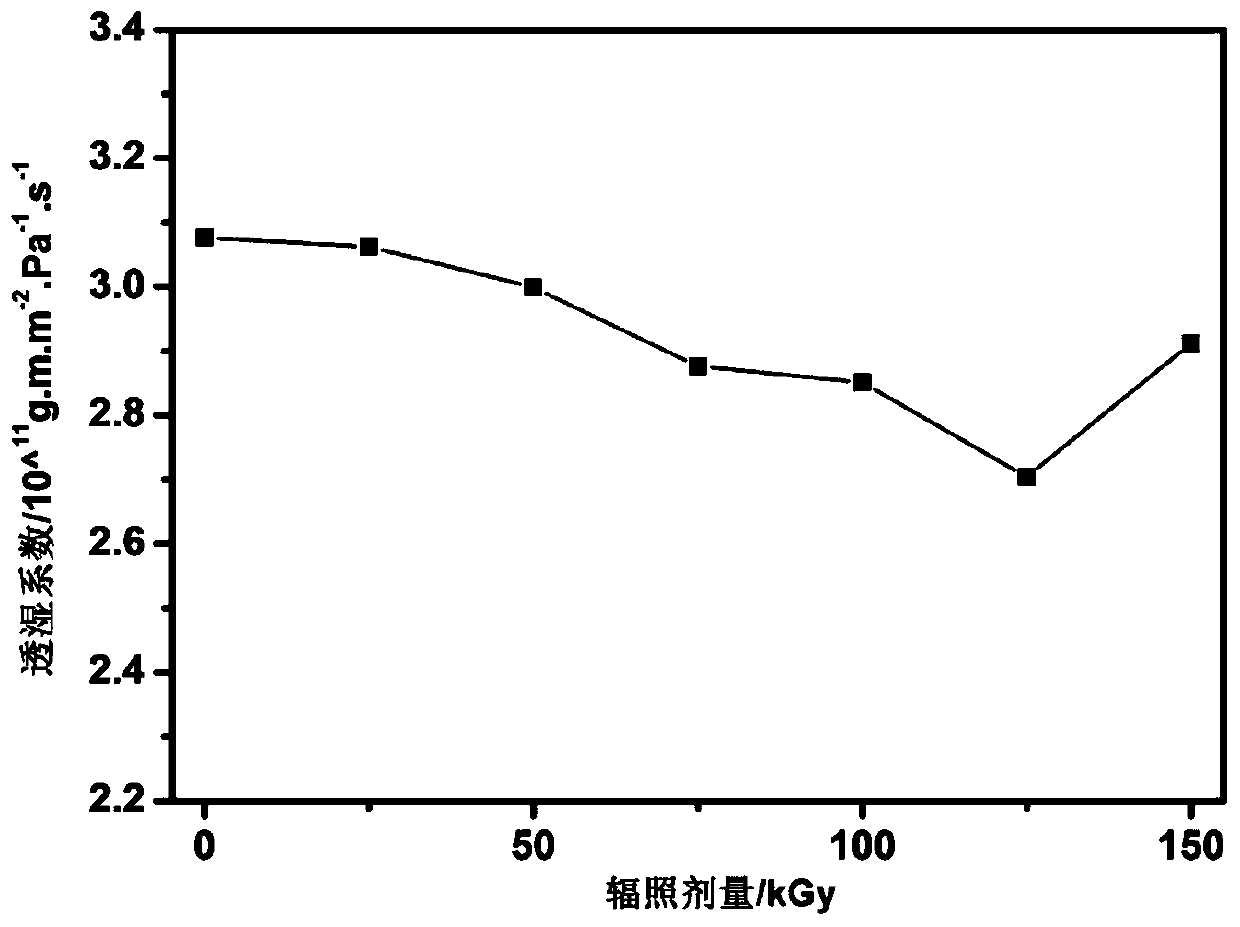

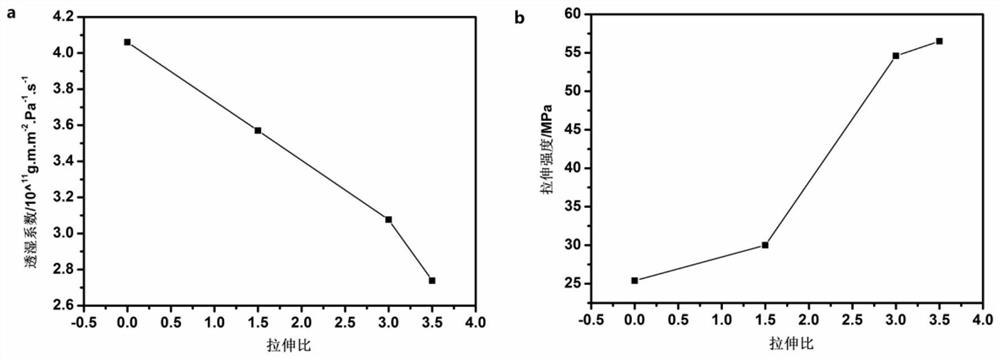

Water vapor barrier biodegradable polymer film as well as preparation and application thereof

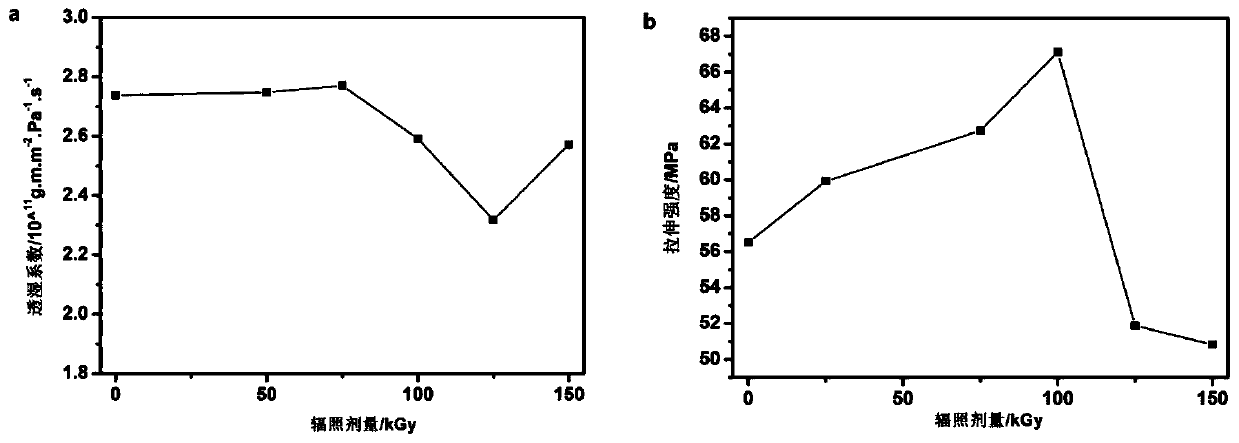

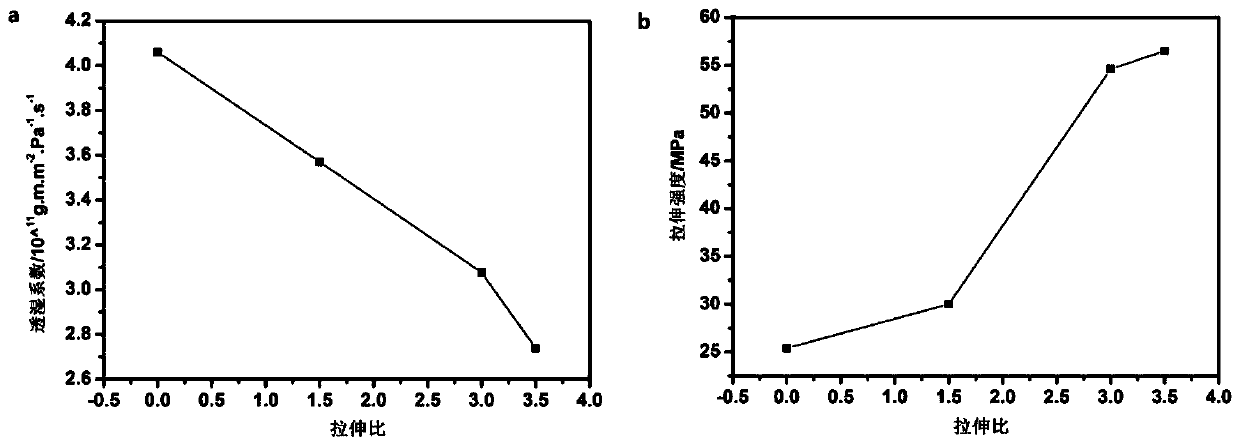

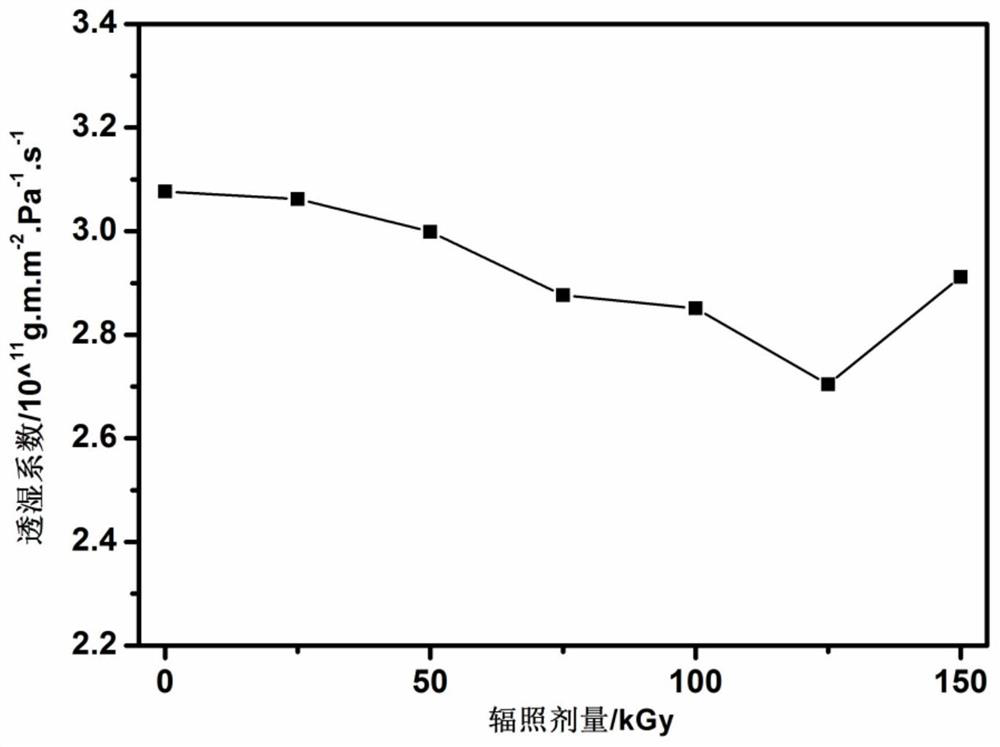

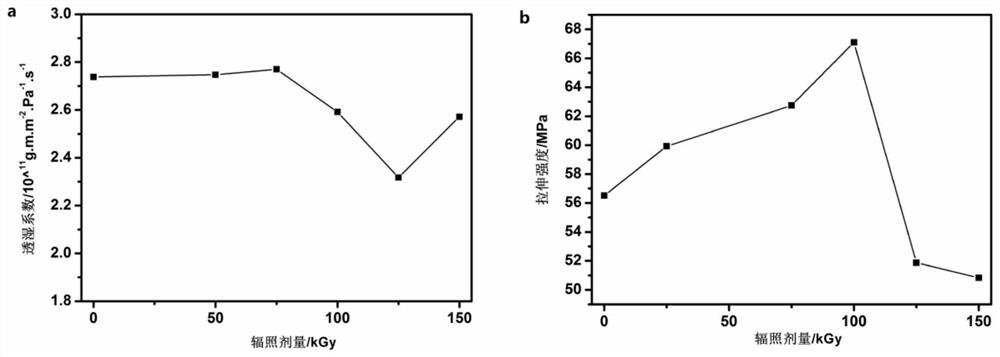

ActiveCN111234279AImprove mechanical propertiesImprove barrier propertiesFlexible coversWrappersPolymer sciencePlastic mulch

The invention belongs to the field of biodegradable materials. The invention discloses a water vapor barrier biodegradable polymer film as well as preparation and application thereof. The preparationmethod comprises the following steps: blending the biodegradable polymer and the cross-linking agent to obtain a special material, molding the special material to form a thick film, carrying out bidirectional stretching on the thick film, and carrying out electron beam irradiation to obtain the water vapor barrier biodegradable polymer film, thereby improving the water vapor barrier property of the biodegradable polymer film. According to the invention, the overall flow process design of the preparation method is improved, wherein the biodegradable polymer film is modified by using a two-way stretching process and an electron beam irradiation technology, so that the problem of poor water vapor barrier property of the biodegradable polymer film can be effectively solved, and the biodegradable polymer film can be widely applied to the fields of agricultural mulching films, food and daily necessity packaging, electronic product packaging and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

A kind of water vapor barrier biodegradable polymer film and its preparation and application

ActiveCN111234279BImprove barrier propertiesImprove mechanical propertiesFlexible coversWrappersPolymer scienceWater vapor

The invention belongs to the field of biodegradable materials, and discloses a water vapor barrier biodegradable polymer film and its preparation and application. The preparation method is to firstly blend a biodegradable polymer and a crosslinking agent to obtain a special The material is formed into a thick film, and then the thick film is biaxially stretched, and finally electron beam irradiation is performed to obtain a water vapor barrier biodegradable polymer film, which improves the water vapor barrier properties of the biodegradable polymer film. The present invention improves the overall flow process design of the preparation method and modifies the biodegradable polymer film by using the biaxial stretching process and electron beam irradiation technology, which can effectively solve the problem of poor water vapor barrier properties of the biodegradable polymer film. It can be widely used in many fields such as agricultural mulching film, food and daily necessities packaging, and electronic product packaging.

Owner:HUAZHONG UNIV OF SCI & TECH

Degradable appliance dental cast resin for SLA 3D printing and preparation method of same

PendingCN111171241AProne to photopolymerizationImprove formation efficiencyAdditive manufacturing apparatusCellulosePolymer science

The invention discloses degradable appliance dental cast resin for SLA 3D printing. The degradable appliance dental cast resin is prepared by mixing hydroxyl acrylate, urethane acrylate, cellulose modified polylactic acid ester, an acrylate monomer, a photoinitiator, an inorganic filler and a defoaming agent; wherein the acrylate monomer and the photoinitiator enable the mixture to be subjected toa photopolymerization reaction very easily, so that the photocuring efficiency is improved; the cellulose modified polylactic acid ester enables the dental cast resin to have the advantage of high degradation speed; the added defoaming agent can effectively eliminate bubbles in the resin liquid, so that the quality and the success rate of printed products are improved; the added inorganic fillerdoes not influence the biodegradability, enhances the hardness, compressive strength and notch impact strength of the material, and satisfies the use requirements in the field of oral appliances. Thematerial cost is equivalent to that of a traditional material, and the material has the advantages of being high in degradation speed, high in hardness, high in compressive strength, small in shrinkage rate, convenient to manufacture and low in manufacturing cost.

Owner:SHANDONG HUGE DENTAL MATERIAL CO LTD

Degradable UV gravure embossed sand-feeling ink for gold and silver cardboard

The invention relates to the technical field of ink, and in particular, relates to a degradable UV gravure embossed sand-feeling ink for a gold and silver cardboard material. The ink comprises the following components by the weight percentage: 15%-25% of epoxidized soybean oil acrylate, 10%-15% of acrylate, 15%-25% of 1,6-hexanediol diacrylate, 10%-20% of isobornyl acrylate, 2%-4% of a 184 photoinitiator, 3%-6% of a TPO photoinitiator, 8%-12% of an amine initiator, 3%-5% of sand finish powder, 5%-8% of wax powder, and 1%-3% of an auxiliary agent. The degradable UV gravure embossed sand-feeling ink for a gold and silver cardboard has no solvent and no toxic gas emissions when in use, is environmentally friendly, and has no pollution; the ink after curing has the advantages of strong pattern three-dimensional sense, good adhesion force and good fluidity, can meet the requirements of decorative inks, can be biodegraded after being discarded, meets new concepts of environmental protection, reduces environment pollution, and achieves the purpose of sustainable development.

Owner:HUIZHOU PERFECT CHEM IND CO LTD

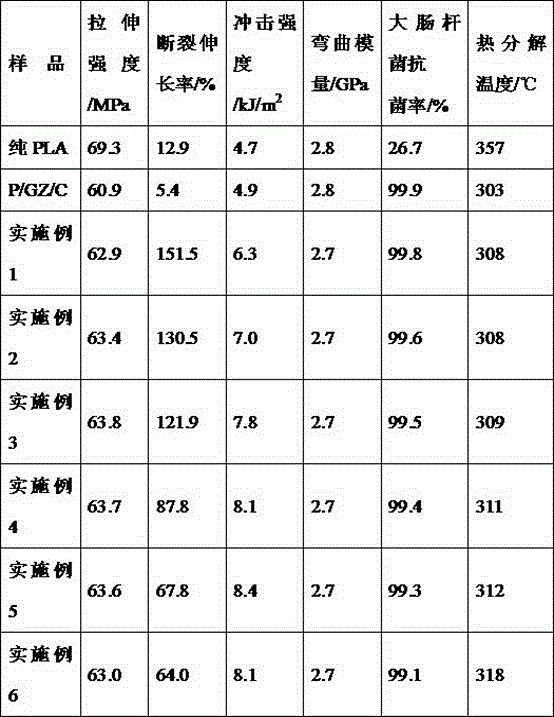

A kind of environment-friendly and toughened strong antibacterial degradable polylactic acid composite material and preparation method thereof

InactiveCN105001605BHigh molecular weightImprove mechanical propertiesEnvironmental resistanceCopper

The invention discloses a green and environment-friendly toughened strong-antibacterial degradable polylactic acid composite and a preparation method thereof. The composite is prepared from, by weight, 1000 parts of polylactic acid, 3-18 parts of chain extender, 7-20 parts of nanometer zinc oxide, 0.20-0.55 part of coupling agent and 1-8 parts of chlorophyll copper acid. According to the visible light absorption and transmission principle of the chlorophyll copper acid, with the nanometer zinc oxide processed by the chlorophyll copper acid and the coupling agent as a composite antibacterial agent, the visible light utilization rate of the nanometer zinc oxide is increased; through the environment-friendly small-molecule chain extender, the molecular weight of the polylactic acid is improved, the composite has the strong antibacterial performance, and the mechanical property and thermal property are improved; meanwhile, the greenness, environmentally friendliness and complete degradability characteristics of the polylactic acid are kept. Through the simple preparation process, the green and environment-friendly completely-degradable polylactic acid composite with strong antibacterial performance, the improved mechanical property and the improved thermal property is obtained.

Owner:ZHENGZHOU UNIV

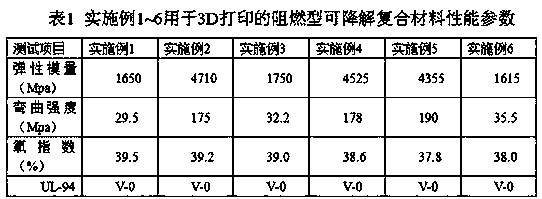

A kind of flame-retardant degradable composite material for 3D printing and preparation method thereof

ActiveCN106519606BIncreased dispersionImprove flame retardant performanceFiberUltimate tensile strength

The invention discloses an inflaming retarding type degradable composite material for hot melting type 3D (Three-Dimensional) printing and a preparation method thereof. Set raw materials are added into a high-speed mixer according to a formula ratio to be mixed; the raw materials comprise the following components in percentages by mass: 40 to 95 percent of degradable matrix material, 2 to 40 percent of expanding inflaming-retarding system and 1 to 40 percent of modified reinforcing fiber; a mixture is added into a screw extruder and is drawn to be a filament strip, the diameter of which is 1.75mm or 3mm, for later use after being subjected to fusion and mixing. The composite material has the characteristics of good degradation performance, high inflaming retarding performance, high toughness and high strength, and is applicable to the fused-deposition quick modeling of 3D printing.

Owner:SHAANXI UNIV OF SCI & TECH

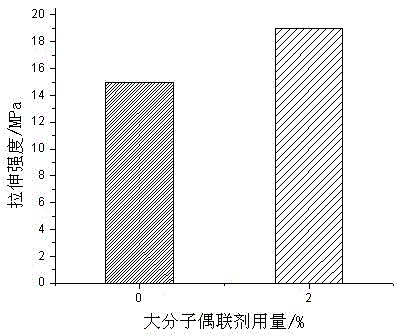

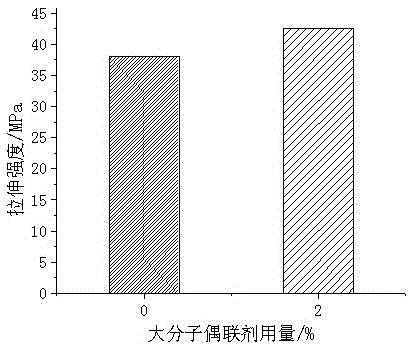

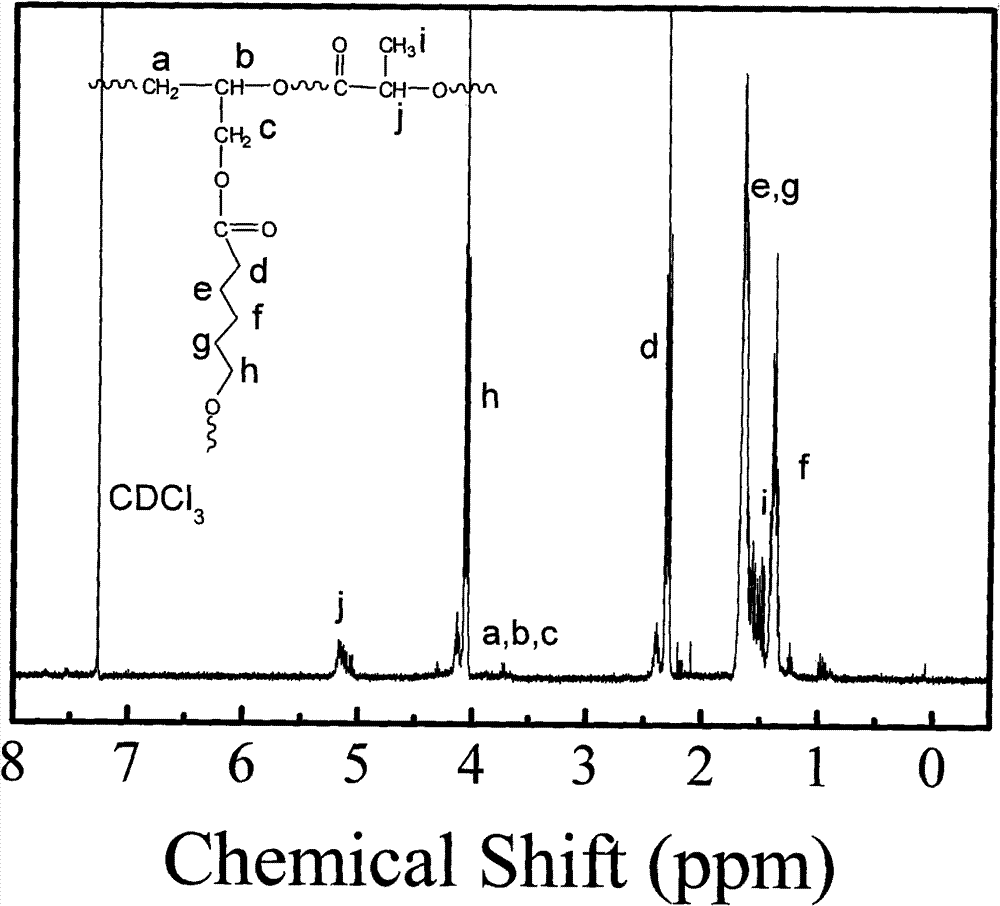

A kind of preparation method of biomass fiber-aliphatic polyester composite material

Owner:SHAANXI HUAHAOXUAN NEW ENERGY TECH DEV CO LTD

Biodegradable high-polymer additive, preparation method and application thereof

The invention discloses a biodegradable high-polymer additive with a branching structure, a preparation method and application thereof. A branched polymer provided by the invention is formed by combining sequential ring opening polymerization and coordination ring opening polymerization of negative ions, polycaprolactone (PCL) and poly l-lactic acid (PLLA) or poly d-lactic acid (PDLA) and propanol polyepoxide are prepared into a graft polymer with a controllable structure. The length of each inlay section of a main chain of the branched polymer and the length of a grafted chain can be regulated and controlled by changing a monomer feeding rate. The branched polymer not only has good volume increasing effect for a polylactic acid / polycaprolactone blend system, but also can reduce the melt viscosity and improve the processability of blends.

Owner:INST OF CHEM CHINESE ACAD OF SCI

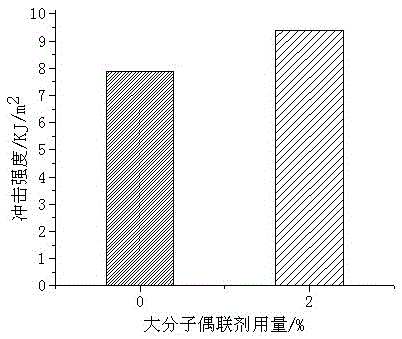

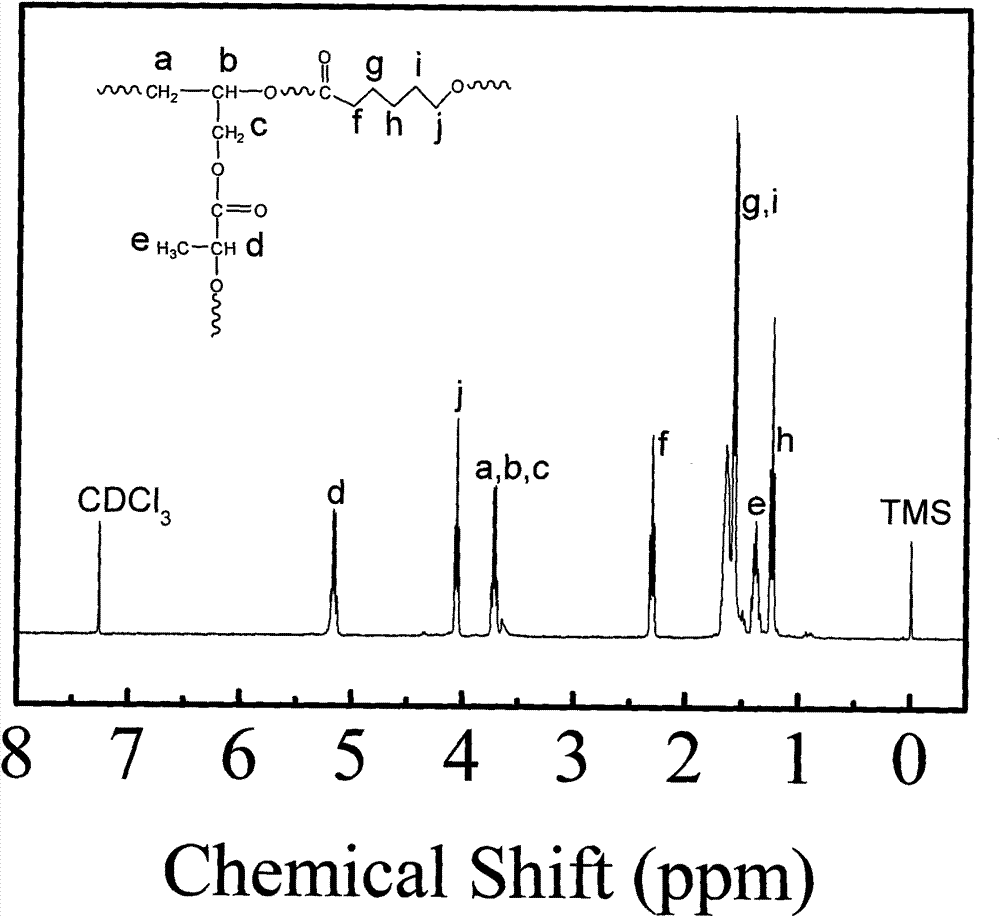

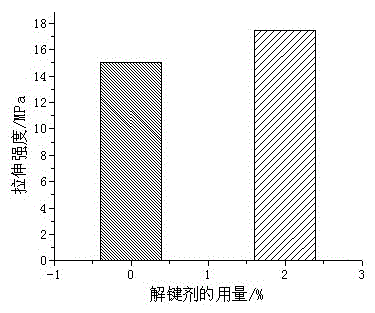

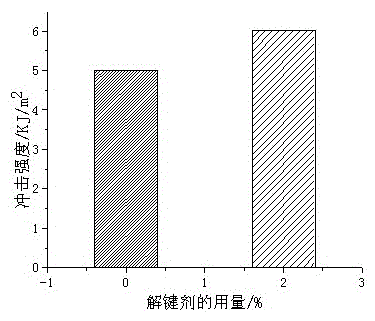

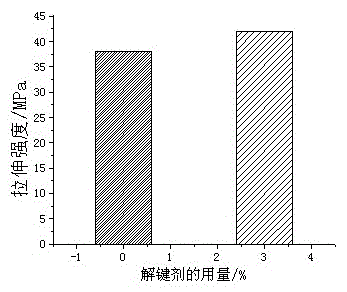

A method for preparing aliphatic polyester composites from surface-modified ctmp fibers

ActiveCN103865242BPlay a reinforcing roleImprove performanceVegetal fibresPolymer scienceResin matrix

The invention discloses a method for preparing an aliphatic polyester composite material through surface modified chemithermomechanical pulp (CTMP) fibers. The method comprises the following steps: (1) performing surface hydrophobic pretreatment on the CTMP fibers by using an unbonding agent; (2) preparing CTMP fiber pulp sheets and performing dry dissociation on the CTMP fibers subjected to hydrophobic treatment; and (3) compounding the CTMP fibers subjected to hydrophobic modification and a thermoplastic resin matrix. According to the fibers subjected to surface hydrophobic treatment, the hydrogen bonding action between the fibers is weakened, the aggregation effect in a polymer matrix is reduced, and the interfacial strength of the composite material is improved, so that the composite material has excellent comprehensive performance, particularly mechanical property. The method can be used for multiple aliphatic polyester matrixes, the raw material limitation is low, and the composite material is wide in application and can be used for the fields of household appliances, automobile industry, packaging and articles of everyday use. The method is low in production cost, contributes to popularization and application and has high significance for improving the utilization level of biomass raw materials, relieving oil resource crisis and protecting the environment.

Owner:SHAANXI HUAHAOXUAN NEW ENERGY TECH DEV CO LTD

Totally degradable foam buffer packaging material and its manufacturing method

The invention provides a complete biodegradable foam cushioning packing material and method for preparation, characterized in that starch over 80% content is used as base-material, ultra-fine polyvinyl alcohol is used as film forming intensifier, water is used as foaming agent, and core forming agent and flow modifier are added, wherein the mixture is amalgamated through blending homogeneous machine and fed into reverse-flighted screw extrusion machine for one-shot extrusion forming. The product can be used to substitute polystyrene foam for filling with no requirement on shapes.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Plant ecological interior wall coating and preparation method thereof

ActiveCN105368164BLow NaOH contentImprove water resistanceAntifouling/underwater paintsAlkali metal silicate coatingsEcological environmentCross linker

The invention discloses a plant ecological interior wall coating and a preparation method thereof. The plant ecological interior wall coating is characterized by being prepared from a titanium dioxide filler, a borax crosslinking agent, an oxidizing agent, water, plant starch serving as a binding agent and sol serving as a binding agent modifier. According to the plant ecological interior wall coating, the plant starch is utilized as the binding agent, no synthetic resin emulsion is contained, complete biodegradation can be achieved, and the coating is an ecological environment-friendly interior wall coating in the true sense; the sol is added to serve as the binding agent modifier, the higher film coating binding force and film coating strength are achieved, and the technical property can reach the GB / T9756-2009 standard of a qualified synthetic resin emulsion interior wall coating product and is obviously suprior to the JC / T423-91 technical requirements for a water-soluble interior wall coating.

Owner:烟台阳光新材料技术有限公司

ZnO-chitosan grafted polylactic acid mulching film

InactiveCN113789059AFacilitate graftingGood dispersionPlant protective coveringsPolymer sciencePlasticizer

The invention provides a ZnO-chitosan grafted polylactic acid mulching film, and relates to the technical field of mulching films. The mulching film comprises the following raw materials by weight: 40-50 parts of polylactic acid, 80-100 parts of ZnO-chitosan, 0.15-1.5 parts of a lubricant, 2-3 parts of a plasticizer, 0.15-1.5 parts of an ultraviolet absorbent, and 2-4 parts of a pH regulator. According to the invention, chitosan is grafted on the surface of ZnO to increase the dispersibility of ZnO in a polymer, then ZnO-chitosan is grafted with polylactose, and ZnO-chitosan-polylactic acid is used as a base material to be mixed with other auxiliaries to prepare the mulching film, so the tensile property, elongation at break and impact strength of the mulching film are increased, and the biodegradability of polylactic acid is not affected.

Owner:甘德彬

A kind of preparation method of pbat fiber

ActiveCN113201805BHigh crystallinityDoes not affect biodegradabilityFilament/thread formingMonocomponent copolyesters artificial filamentThermodynamicsEngineering

The invention relates to a preparation method of PBAT fiber. When the PBAT fiber is spun, the processes of cooling, bundling, oiling, drafting and winding are carried out in sequence. The cooling adopts a combination of slow cooling and strong cooling. The cooling section includes a slow cooling section. and strong cooling section; the slow cooling section refers to that when the wire strands are cooled to 110-130°C, the strands are cooled to 50-70°C under a cooling tunnel of 10-15 meters; After the slow cooling section is over, the strands are cooled to room temperature, and the cooling air temperature is 5-10°C. The invention optimizes the cooling process of PBAT spinning, that is, when the filaments are cooled to near the crystallization temperature, the method of slow cooling is adopted, and the temperature is set near the crystallization temperature of PBAT for heat preservation, and sufficient crystallization time is given to the PBAT to make the PBAT crystallize. Perfect, improve the crystallinity of PBAT, the improvement of crystallinity can avoid the phenomenon of thread sticking in the process of bundling and winding of PBAT fiber, and improve the quality of PBAT fiber.

Owner:XINJIANG BLUE RIDGE TUNHE CHEM IND JOINTSTOCK +1

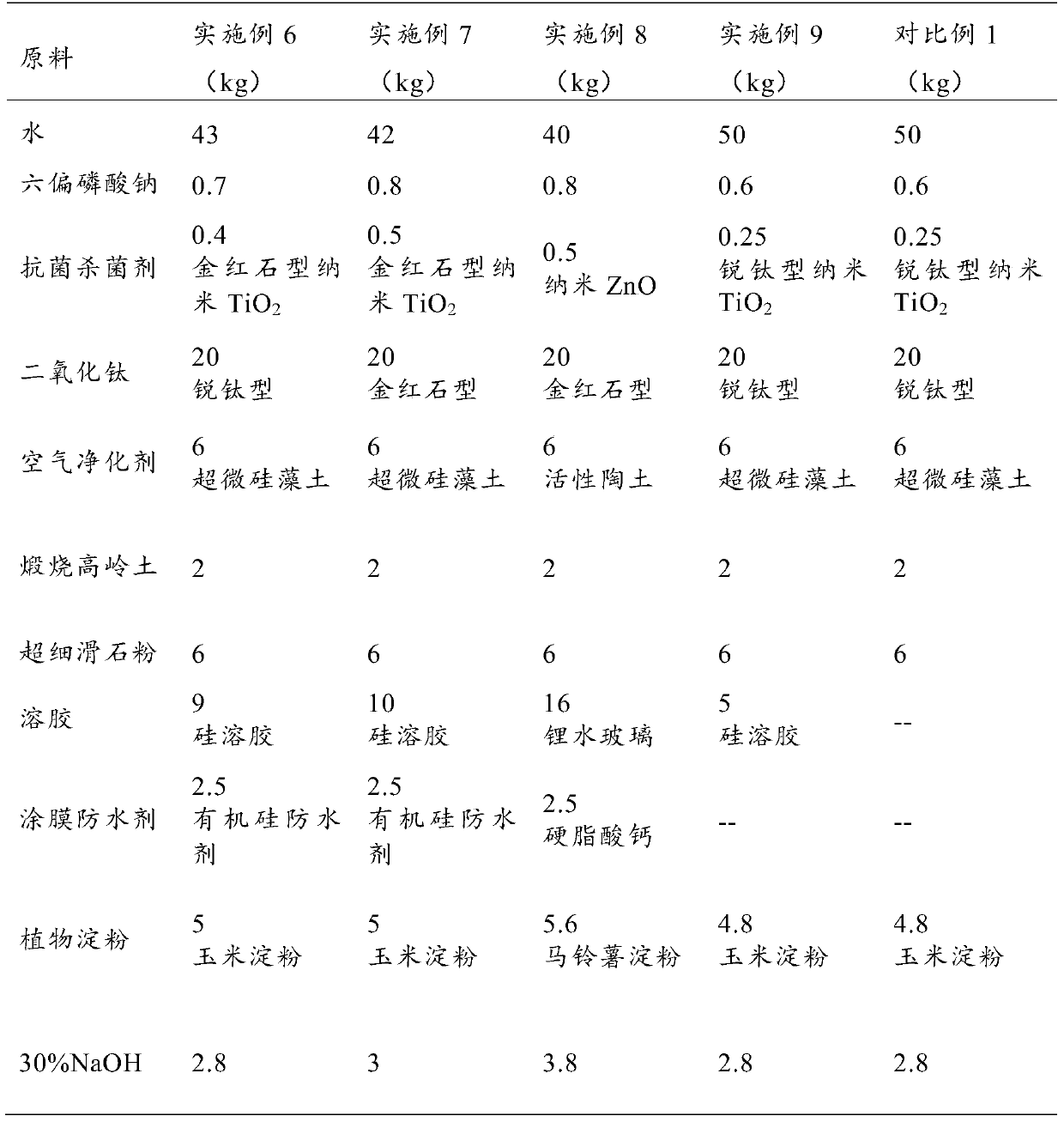

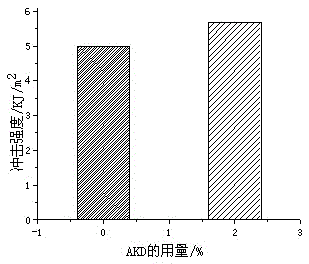

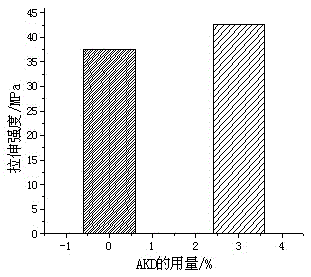

A method for preparing aliphatic polyester composite materials by surface-modifying biomass fibers with alkyl ketene dimers

The invention discloses a method for preparing aliphatic polyester composite material by modifying the surface of biomass fiber with alkyl ketene dimer, which comprises the following steps: (1) Preparation of AKD emulsion and its effect on the surface of biomass fiber raw material (2) aging treatment of surface-modified fibers; (3) compounding of surface-modified biomass fibers and aliphatic polyester matrix. Hydrophobic treatment of the surface weakens the interfiber hydrogen bonding, reduces agglomeration in the aliphatic polyester matrix, improves the interfacial strength of the composite material, and makes it have more excellent comprehensive properties, especially mechanical properties. The composite material product has a wide range of applications and can be used in household appliances, automobile industry, packaging, daily necessities and other fields. Moreover, the method has low cost and simple process, is conducive to popularization and application, and has great significance for improving the utilization level of biomass raw materials, alleviating the oil resource crisis and protecting the environment.

Owner:SHAANXI HUAHAOXUAN NEW ENERGY TECH DEV CO LTD

A degradable uv gravure embossed sandy ink for gold and silver cardboard

The invention relates to the technical field of ink, and in particular, relates to a degradable UV gravure embossed sand-feeling ink for a gold and silver cardboard material. The ink comprises the following components by the weight percentage: 15%-25% of epoxidized soybean oil acrylate, 10%-15% of acrylate, 15%-25% of 1,6-hexanediol diacrylate, 10%-20% of isobornyl acrylate, 2%-4% of a 184 photoinitiator, 3%-6% of a TPO photoinitiator, 8%-12% of an amine initiator, 3%-5% of sand finish powder, 5%-8% of wax powder, and 1%-3% of an auxiliary agent. The degradable UV gravure embossed sand-feeling ink for a gold and silver cardboard has no solvent and no toxic gas emissions when in use, is environmentally friendly, and has no pollution; the ink after curing has the advantages of strong pattern three-dimensional sense, good adhesion force and good fluidity, can meet the requirements of decorative inks, can be biodegraded after being discarded, meets new concepts of environmental protection, reduces environment pollution, and achieves the purpose of sustainable development.

Owner:HUIZHOU PERFECT CHEM IND CO LTD

Special efficient nucleating agent for lignin grafted polylactic acid as well as preparation method and application of special efficient nucleating agent

PendingCN114874446AIncrease the rate of crystallizationHigh crystallinityPtru catalystCrystal structure

The invention discloses a special efficient nucleating agent for lignin grafted polylactic acid as well as a preparation method and application of the special efficient nucleating agent. The nucleating agent is prepared from the following components in parts by weight: 75-95 parts of polylactic acid, 1-5 parts of lignin, 1-4 parts of a catalyst and 0.3-2 parts of an anti-hydrolysis agent. The special efficient nucleating agent for lignin grafted polylactic acid provided by the invention can greatly improve the crystallization rate and crystallinity of PLA, improves the crystal structure of PLA, does not affect the bio-based degradability of PLA, and can achieve a remarkable effect by adding a small amount of nucleating agent.

Owner:南京塑净新材料科技有限公司

Biodegradable material comprising polyhydroxy fotty acid ester blending polymer

One new kind of biodegradable material with low cost and high machining performance is mixture containing including 3-hydroxy butyrate homopolymer and copolymer of 3-hydroxy butyric acid and non-HB structure hydroxy fatty acid in the weight ratio of 1 / 9 to 9. The copolymer contains at least two random structural units I and II, with the structural unit I accounting for the molar ratio of 10-95 %. The plastic products made of the biodegradable material are also provided.

Owner:SHANTOU F T Z FREE TRADE ZONE LIANYI BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com