Biodegradable material comprising polyhydroxy fotty acid ester blending polymer

A technology for degrading materials and hydroxybutyrate, applied in the field of plastic products, can solve the problem of high production cost, and achieve the effects of reducing production cost, being suitable for processing, and enhancing elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

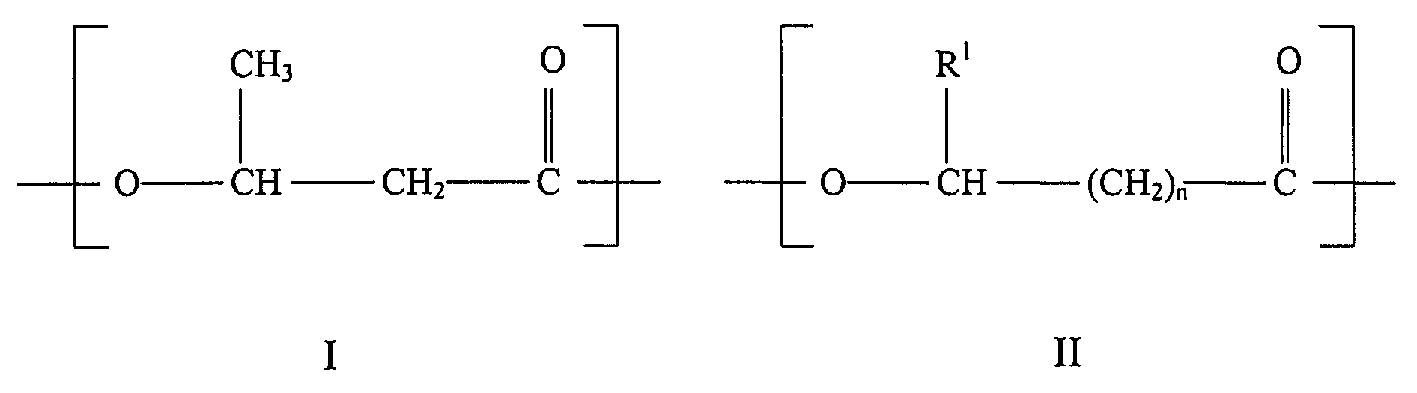

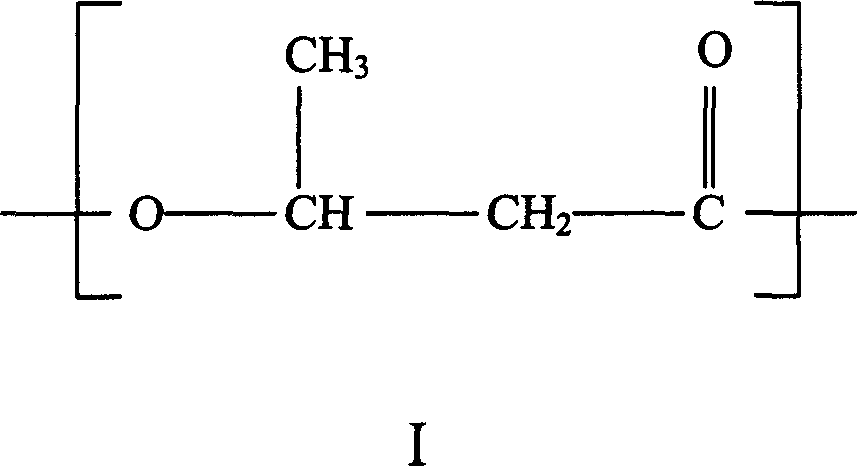

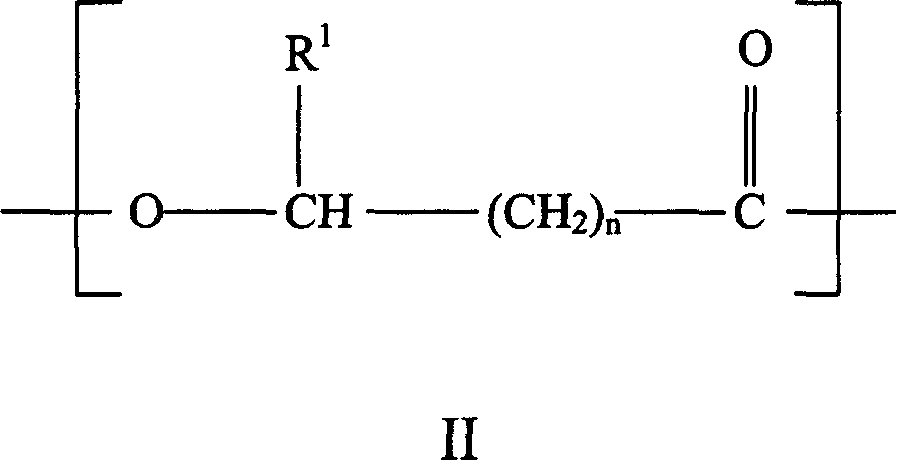

Image

Examples

Embodiment 1

[0040] Blend of PHB + 3-hydroxybutyric acid and 3-hydroxyvaleric acid copolymer (PHBV)

[0041] PHB and PHBV were synthesized by the methods reported in "Chen et al. Biotechnol. Techniques, 1997, 11: 347" and "Chen et al. Antonie van Leewenhoek, 1991, 60: 61", respectively. Weigh 20 grams of powdered PHB and 20 grams of PHBV with 20% 3-hydroxyvaleric acid content, referred to as P(HB-20%HV), and mix thoroughly. The granulation is carried out by a small twin-screw extruder. See Table 1 for the performance comparison of blend PHB+P (HB-20%HV) with homopolymer PHB and copolymer.

[0042] sample

Embodiment 2

[0044] Blend of PHB + 3-hydroxybutyric acid and 3-hydroxyhexanoic acid copolymer (PHBHHx)

[0045] PHB and PHBHHx were synthesized by the methods reported in "Chen et al. Biotechnol. Techniques, 1997, 11:347" and "Chen GQ et al. Appl. Microbiol. Biotechnol., 2001, 57:50", respectively. Weigh 20 grams of powdered PHB and 10 grams of PHBHHx with a 3-hydroxyhexanoic acid content of 15%, referred to as P(HB-15%HHx), and mix thoroughly. The granulation is carried out by a small twin-screw extruder. See Table 2 for the performance comparison of blend PHB+P (HB-15%HHx) with homopolymer PHB and copolymer PHBHHx.

[0046] sample

Embodiment 3

[0048] Blend of PHB+3-Hydroxybutyric Acid and 3-Hydroxydecanoic Acid Copolymer (PHBD)

[0049] PHB and PHBD were synthesized by the methods reported in "Chen et al. Biotechnol. Techniques, 1997, 11: 347" and "Abe et al. Int. J. Biol. Macromol, 1994, 16: 115", respectively. Weigh 20 grams of powdered PHB and 10 grams of PHBD with 8% 3-hydroxydecanoic acid content, referred to as P(HB-8%HD), and mix thoroughly. The granulation is carried out by a small twin-screw extruder. See Table 3 for the performance comparison of blend PHB+P (HB-8%HD) with homopolymer PHB and copolymer PHBD.

[0050] sample

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com