Full-biodegradable composite as well as preparation method and application of full-biodegradable composite

A composite material and biodegradation technology, which is applied in the field of fully biodegradable composite materials and their preparation, can solve the problems of poor compatibility between starch and biodegradable copolyester, poor tear strength, and impact on performance, so as to improve the tear Lower strength, improved tear strength, increased compatibility effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

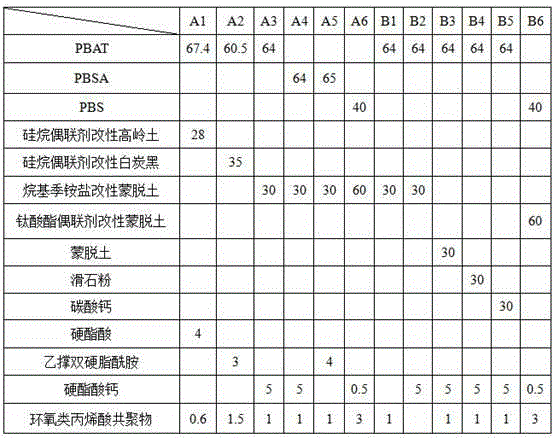

[0050] Preparation of inorganic filler fully biodegradable masterbatch:

[0051] According to the ratio in Table 1, the biodegradable copolyester was first dried in an oven at 80°C for 5 hours; the dried biodegradable copolyester

[0052] Mechanically blend esters, inorganic fillers, lubricants, and compatibilizers in a high-speed mixer for 5 minutes; feed the homogeneously mixed materials in step (2) into a twin-screw extruder for melt plasticization, extrusion, and granulation That is, A1~A6, B1-B6 inorganic filler fully biodegradable masterbatches are obtained;

[0053] The twin-screw extruder is a co-rotating parallel twin-screw extruder, and its set temperature is: Zone 1: 60-90°C, Zone 2: 120-150°C, Zone 3: 140-170°C, Zone 4: 170~190℃, Zone 5: 170~190℃, Zone 6: 170~190℃,

[0054] Zone 7: 170~190℃, zone 8: 170~190℃, zone 9: 170~190℃, head: 170-190℃, screw speed: 300rpm. The screw aspect ratio is 40:1.

[0055] Table 1 A 1~A6, B1-B6 inorganic filler fully biodegradabl...

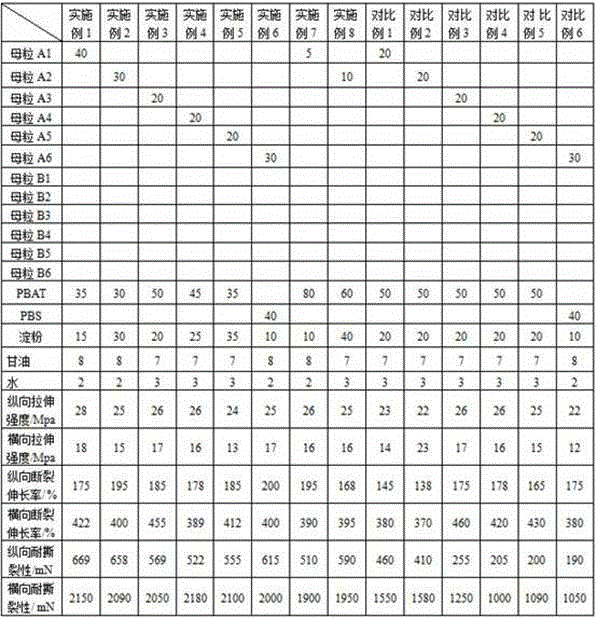

Embodiment 1-8 and comparative example 1-6

[0058] Mix the above-mentioned fully biodegradable masterbatch of inorganic filler with biodegradable copolyester, starch, and plasticizer in a high mixer at room temperature for 5 minutes according to the ratio in Table 2, and then add it to a twin-screw machine for extrusion blending and granulation. The inorganic filler fully biodegradable composite material was obtained. Put the composite material in an extrusion blown film machine, set the screw temperature at 120-160°C, and extrude and blow it into a film with a thickness of 12 microns. The mechanical properties of the film are shown in Table 2.

[0059] Table 2 The composition and performance results of each component of the embodiment and the comparative example

[0060]

[0061] From the comparison of Comparative Example 1 and Example 3, it can be seen that the addition of the lubricant can effectively prevent the agglomeration of the filler and make the filler have higher dispersibility, and the film product obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com