Full biodegradable fiber-reinforced starch foaming tableware and preparation method thereof

A biodegradable, fiber-reinforced technology, applied in tableware, household appliances, applications, etc., can solve the problems that the high foaming ratio of starch cannot be realized, polyvinyl alcohol is not biodegradable, and there is no waterproof and oil-proof treatment for tableware, etc., to achieve shortening molding Cycle time, small foam pore size, good water and oil repellency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

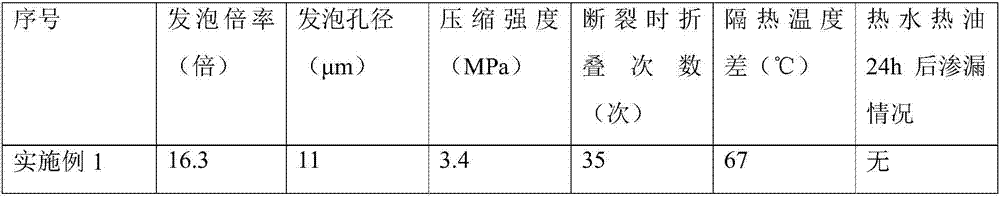

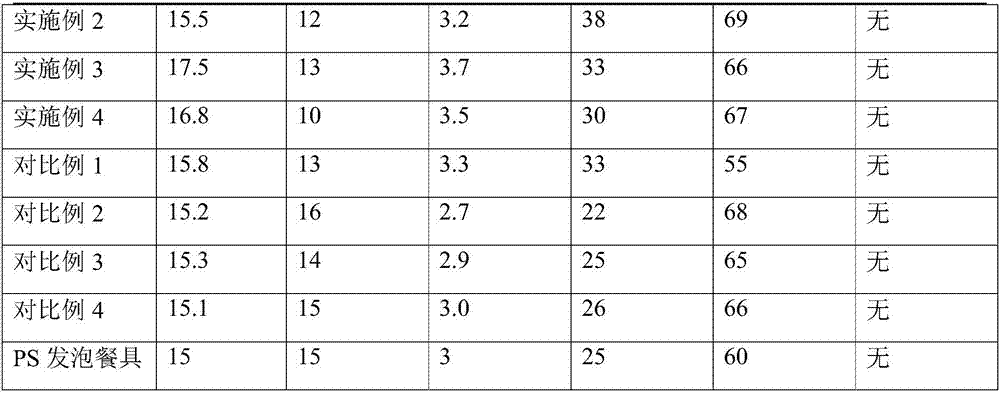

Examples

Embodiment 1

[0046] 50% tapioca starch (50 mesh), 20% polylactic acid short fiber (50D, 25mm), 10% polybutylene succinate powder (100 mesh), 5% 5000 mesh hydrotalcite ZnMg 3 al 2 (OH) 12 CO 3 mH 2 O is added in the mixer successively, stirred at normal temperature for 10 min, then added 3% diethanolamine, stirred at normal temperature for 15 min, finally added 10% foaming agent (water / stearic acid / baking soda=8 / 1 / 1 mass ratio), 2% 100-mesh glyceryl monostearate was stirred and mixed evenly at 40°C, then added to the mold, hot-pressed at 180°C for 40 seconds, and finally sprayed with a polybutylene terephthalate adipate film with a thickness of 10 μm. A completely biodegradable fiber-reinforced starch foam tableware is obtained.

Embodiment 2

[0048] 60% tapioca starch (100 mesh), 15% polylactic acid short fiber (100D, 10mm), 10% polybutylene terephthalate adipate powder (500 mesh), 3% 5500 mesh hydrotalcite ZnMg 3 al 2 (OH) 12 CO 3 mH 2 O is added in the agitator successively, stirred at normal temperature for 10 min, then added 3% triethanolamine, stirred at normal temperature for 15 min, finally added 8% foaming agent (water / palmitic acid / baking soda=6 / 2 / 2 mass ratio), 1 % 50 mesh glycerol monostearate was mixed evenly at 60°C, then added to the mold, hot-pressed at 250°C for 20 seconds, and finally sprayed with a polypropylene carbonate film with a thickness of 20 μm to obtain a completely biodegradable fiber-reinforced starch foam. soak tableware

Embodiment 3

[0050] 82% tapioca starch (150 mesh), 5% polyglycolic acid short fiber (10D, 50mm), 5% polybutylene terephthalate adipate powder (300 mesh), 1% 4500 mesh hydrotalcite ZnMg 3 al 2 (OH) 12 CO 3 mH 2 O is added in the mixer successively, stirred at normal temperature for 10 min, then added 1% monoethanolamine, stirred at normal temperature for 15 min, finally added 5% foaming agent (water / oleic acid / baking soda=7 / 2 / 1 mass ratio), 1 % 150 mesh glyceryl monostearate was stirred and mixed evenly at 50°C, then added to the mold, hot-pressed at 220°C for 60 seconds, and finally sprayed with a polybutylene succinate film with a thickness of 5 μm to obtain a completely biodegradable Fiber reinforced starch foam tableware.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com