A kind of flame-retardant degradable composite material for 3D printing and preparation method thereof

A composite material and 3D printing technology, applied in the field of flame-retardant degradable composite materials and their preparation, can solve problems such as not involving flame-retardant enhanced degradable composite materials, and achieve low cost, high printing accuracy, and excellent flame retardant properties. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

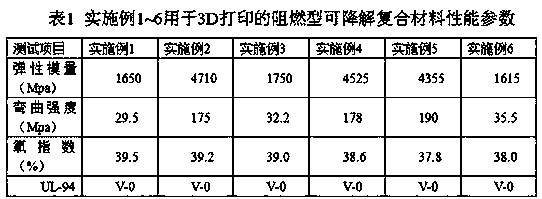

Examples

preparation example Construction

[0038] The invention provides a method for preparing a flame-retardant degradable composite material for 3D printing, including the following steps:

[0039] Pretreatment of reinforcing fiber: firstly, the surface modifier is formulated into a surfactant solution with a mass fraction of 0.2% to 10% through a solvent, and the reinforcing fiber is vacuum-dried at 30°C to 105°C for 1 to 48 hours to obtain absolute dryness Reinforcing fiber; secondly, pour the bone-dry reinforcing fiber into the surfactant solution to prepare a suspension with a mass concentration of 0.1%-10%, stir the suspension for 1 min-60 min, then cool it, and use it Ionized water wash 2-6 times, suction filtration; again, the solid obtained by suction filtration is vacuum-dried at 30℃~105℃ for 1~48 h. The contact angle test proves that the surface of the reinforcing fiber in the suspension has changed from hydrophilic to Hydrophobicity is the reinforced fiber after pretreatment;

[0040] The above-mentioned solv...

Embodiment 1

[0046] The surface hydrophobic treatment of magnesium sulfate whiskers by sodium stearate:

[0047] Firstly, sodium stearate is prepared into a 3% sodium stearate solution with 70% ethanol and 30% water ethanol solution; magnesium sulfate whiskers are vacuum dried at 30℃ for 48 h to obtain absolutely dry magnesium sulfate crystals Must

[0048] Secondly, pour the above-mentioned absolute dry magnesium sulfate whiskers into the sodium stearate solution to prepare a suspension with a mass fraction of 3%; at 90℃, stir the suspension at 50 rpm for 60 minutes and then cool it. , Then wash 6 times with deionized water and filter with suction;

[0049] Once again, the solid obtained by suction filtration was vacuum dried at 30°C for 48 hours. The contact angle test proved that the surface of the magnesium sulfate whiskers in the suspension changed from hydrophilic to hydrophobic to obtain pretreated magnesium sulfate crystals. Must.

[0050] Preparation of intumescent flame retardant syste...

Embodiment 2

[0055] Hydrophobic pretreatment of magnesium sulfate whiskers by sodium stearate:

[0056] Firstly, sodium epistearate was prepared into a 0.2% sodium stearate alcohol solution by methanol, and magnesium sulfate whiskers were vacuum dried at 40°C for 40 h to obtain absolutely dry magnesium sulfate whiskers; The magnesium sulfate whiskers are poured into the sodium stearate alcohol solution to prepare a suspension with a mass concentration of 0.1%, and the magnesium sulfate whisker suspension is stirred at 100 rpm at 80°C for 50 min. Cool, wash 5 times with deionized water, and filter with suction;

[0057] Thirdly, the solid obtained by suction filtration was vacuum dried at 42°C for 41 h, and the contact angle test proved that the surface of the magnesium acid whisker in the suspension changed from hydrophilic to hydrophobic to obtain the pretreated magnesium acid whisker;

[0058] Preparation of intumescent flame retardant system:

[0059] The ammonium polyphosphate and melamine we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com