Anti-static non-woven fabric and preparation method thereof

A non-woven fabric and antistatic technology, which is applied in the manufacture of conductive/antistatic filaments, nonwoven fabrics, textiles and papermaking, etc. It can solve the problem that the flexibility of nonwoven fabrics needs to be further improved and the antistatic performance of polyester materials is reduced. , Limiting the application of polyester materials and other issues, to achieve the effect of high porosity, simple equipment, and excellent filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

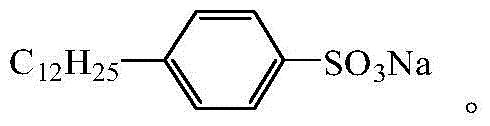

[0033] (1) Weigh 85 parts of polybutylene terephthalate, 10 parts of polycaprolactam (molecular weight: 5000) and 5 parts of sodium dodecylbenzenesulfonate for blending, and then extrude through a twin-screw extruder to produce pellets to obtain an antistatic blend, and the extrusion temperature was 250°C.

[0034] (2) Vacuum-dry the blend particles obtained in step (1) at 80°C for 48 hours to make the moisture content <100ppm; then heat the dried blend particles through a screw extruder, and the melting temperature is 270°C. Extruded into a melt, when the melt is extruded from the spinneret hole of the die, it is blown by a high-pressure hot air flow with a flow rate of 50m / sec and a temperature of 210°C on both sides of the spinneret hole, and the melt of the blend is pulled Stretched into ultra-fine fibers, condensed on the roller receiver with a distance of 5cm from the nozzle, the roller speed of the receiver is 20r / min, self-adhesive into non-woven fabric, after cooling,...

Embodiment 2

[0036] (1) Weigh 90 parts of polyethylene terephthalate, 8 parts of polycaprolactam (molecular weight: 10000) and 2 parts of sodium dodecylbenzenesulfonate for blending, and then extrude through a twin-screw extruder to produce pellets to obtain an antistatic blend, and the extrusion temperature was 230°C.

[0037] (2) Vacuum-dry the blend particles obtained in step (1) at 90°C for 40 hours to make the moisture content <100ppm; then heat the dried blend particles through a screw extruder, the melting temperature is 280°C, Extruded into a melt, when the melt is extruded from the spinneret hole of the die, it is blown by a high-pressure hot air flow with a flow rate of 100m / sec and a temperature of 250°C on both sides of the spinneret hole, and the melt of the blend is pulled Stretched into ultra-fine fibers, condensed on the roller receiver 10cm away from the nozzle, the roller speed of the receiver is 25r / min, self-adhesive into non-woven fabric, after cooling, use a blade to ...

Embodiment 3

[0039] (1) Weigh 95 parts of polytrimethylene terephthalate, 5 parts of polycaprolactam (molecular weight: 20000) and 0.5 part of sodium dodecylbenzenesulfonate for blending, and then extrude through a twin-screw extruder to produce pellets to obtain an antistatic blend, and the extrusion temperature was 230°C.

[0040] (2) Vacuum-dry the blend particles obtained in step (1) at 100°C for 36 hours, so that the moisture content is <100ppm; then heat the dried blend particles through a screw extruder, and the melting temperature is 240°C. Extruded into a melt, when the melt is extruded from the spinneret hole of the die, it is blown by a high-pressure hot air flow with a flow rate of 150m / sec and a temperature of 270°C on both sides of the spinneret hole, and the melt of the blend is pulled Stretched into ultra-fine fibers, condensed on the roller receiver 20cm away from the nozzle, the roller speed of the receiver is 27r / min, self-adhesive into non-woven fabric, after cooling, u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com