Heat-conduction electronic potting adhesive and preparation method thereof

A potting and electronic technology, applied in the directions of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problem that the potting requirements of electronic components cannot be effectively met, the application fields of potting adhesives are limited, spherical fillers Expensive and other problems, to achieve the effect of heat dissipation, improved service life, and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

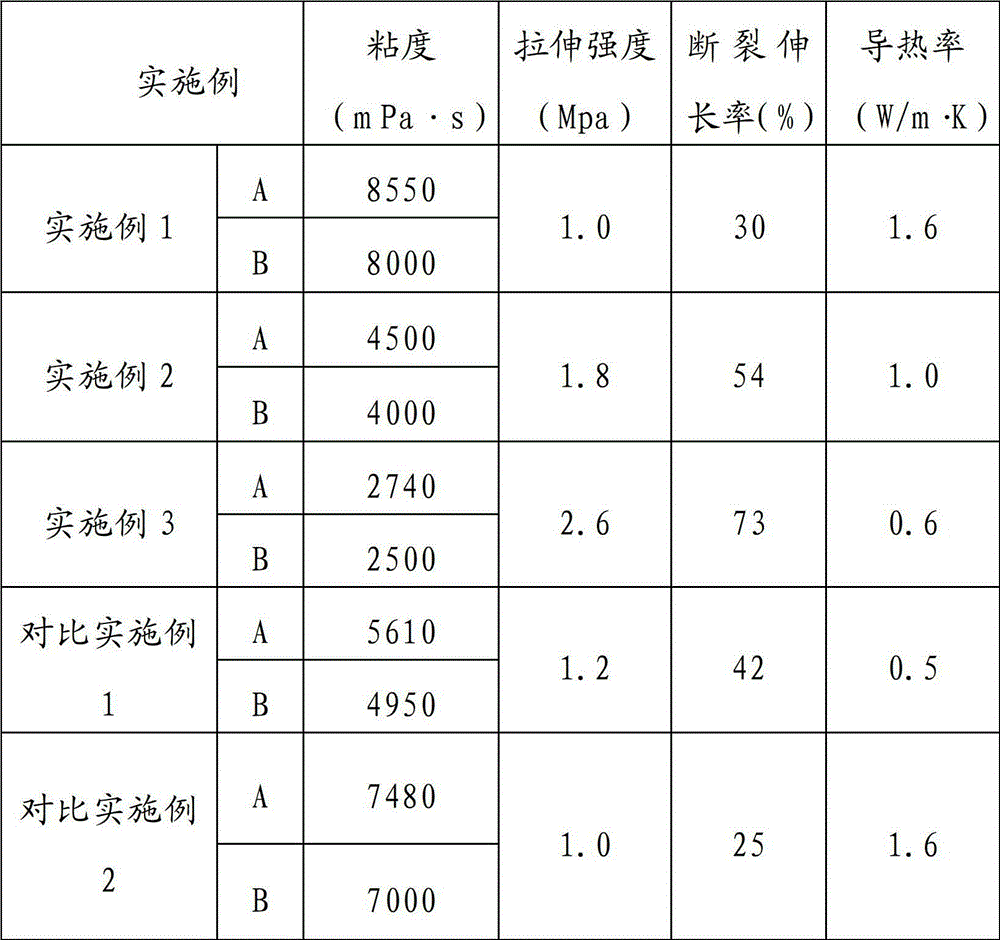

Examples

Embodiment 1

[0035] Put 2560.00g of irregular silica powder with an average particle size of 10μm, 6400.00g of irregular alumina powder with an average particle size of 60μm, and 3840.00g of aluminum hydroxide powder with an average particle size of 20μm in the container , Dilute 25.60g of silane coupling agent γ-aminopropyltriethoxysilane with 512.00g of absolute ethanol, add it to the heat-conducting and flame-retardant powder, stir it evenly, and place it in a ball mill. Put it into a ball mill for ball milling modification. After grinding for 2 hours, take it out and dry it, and continue grinding for 1 hour to obtain a modified heat-conducting and flame-retardant powder.

[0036] Accurately weigh 2592.00 g of vinyl-terminated silicone oil and 12825.60 g of modified heat-conducting and flame-retardant powder, add them to a vacuum kneader in sequence, and knead in vacuum at 120-130° C. for 4 hours to obtain a base material.

[0037] Accurately weigh 6156.80g of base material, 192.00g of...

Embodiment 2

[0042] Put 2305.00g of irregular silicon oxide powder with an average particle size of 5 μm, 3455.00 g of irregular silicon oxide powder with an average particle size of 13 μm, and 3840.00 g of magnesium hydroxide powder with an average particle size of 40 μm in the container, Dilute 48.00g of silane coupling agent γ-(2,3-glycidoxy)propyltrimethoxysilane with 960.00g of absolute ethanol, add it to the heat-conducting and flame-retardant powder, stir evenly, and place it in a ball mill. Put it into a ball mill for ball milling modification. After grinding for 2 hours, take it out and dry it, and continue grinding for 1 hour to obtain a modified heat-conducting and flame-retardant powder.

[0043] Accurately weigh 4,800.00 g of vinyl silicone oil and 9,648.00 g of modified heat-conducting and flame-retardant powder, add them to a vacuum kneader in sequence, and knead in vacuum at 120-130° C. for 3 hours to obtain a base material.

[0044] Accurately weigh 5760.00g of base mater...

Embodiment 3

[0049] Put 1920.00g of irregular silica powder with an average particle size of 2μm, 3200.00g of irregular alumina powder with an average particle size of 20μm, and 1280.00g of titanium oxide powder with an average particle size of 13μm in the container, Dilute 64.00g of silane coupling agent γ-(2,3-glycidoxy)propyltrimethoxysilane with 1280.00g of absolute ethanol, add it to the heat-conducting and flame-retardant powder, stir evenly, and place it in a ball mill. Put it into a ball mill for ball milling modification. After grinding for 2 hours, take it out and dry it, and continue grinding for 1 hour to obtain a modified heat-conducting and flame-retardant powder.

[0050] Accurately weigh 7040.00g of vinyl-terminated silicone oil and 6464.00g of modified heat-conducting and flame-retardant powder, add them to a vacuum kneader in turn, and knead in vacuum at 120-130°C for 3 hours to obtain a base material.

[0051] Accurately weigh 5376.00g of the base material, 928.00g of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com