One-component polyurethane potting adhesive and preparation method thereof

A technology of polyurethane and potting glue, which is applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., and can solve the problems affecting the performance of potting glue, the limited defoaming ability of defoamers, and the hindrance of filler dispersion, etc. problem, to achieve the effect of accelerating the curing speed, high bonding strength, and meeting the requirements of potting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The raw materials are prepared as follows:

[0031] raw material Dosage / g Polyether diol 2000 100 Polyether diol 4000 200 long chain chlorinated paraffins 120 talcum powder 120 Kaolin 200 Neopentyl glycol 3 Diisocyanate MDI 37 Dibutyltin dilaurate 1 Defoamer polyether modified silicone copolymer 1 acetone 20 magnesium oxide 12

[0032] Add polyether glycol 2000, polyether glycol 4000, talc powder, kaolin, long-chain chlorinated paraffin, polyether modified siloxane copolymer to the reaction kettle in sequence, and heat up to 110°C while stirring. Dehydrate for 2 hours, lower the temperature to 80°C, slowly add diisocyanate MDI dropwise, under nitrogen protection, control the reaction speed, keep the temperature for 4 hours, make the -OH reaction in the system complete, then add neopentyl glycol and acetone, and keep the reaction for 3 hours at 80°C. Then add dibutyltin dilaurate and magnesi...

Embodiment 2

[0034] The raw materials are prepared as follows:

[0035] raw material Dosage / g Polyether Triol 3000 150 Polyether diol 4000 210 long chain chlorinated paraffins 150 talcum powder 60 Ground calcium carbonate 400 Trimethylolpropane 3 Diisocyanate MDI 42 Dibutyltin dilaurate 1 Defoamer polyether modified silicone copolymer 1 Dimethyl carbonate 20 magnesium oxide 15

[0036] Add polyether trihydric alcohol 3000, polyether dihydric alcohol 4000, talcum powder, heavy calcium carbonate, long-chain chlorinated paraffin, polyether modified siloxane copolymer in sequence in the reaction kettle, and heat up to 110°C, dehydrate for 2 hours, cool down to 80°C, slowly add diisocyanate MDI dropwise, under nitrogen protection, control the reaction speed, keep warm for 4 hours to make the -OH in the system react completely, then add trimethylolpropane and dimethyl carbonate , keep warm at 80°C for 3 hours, then ...

Embodiment 3

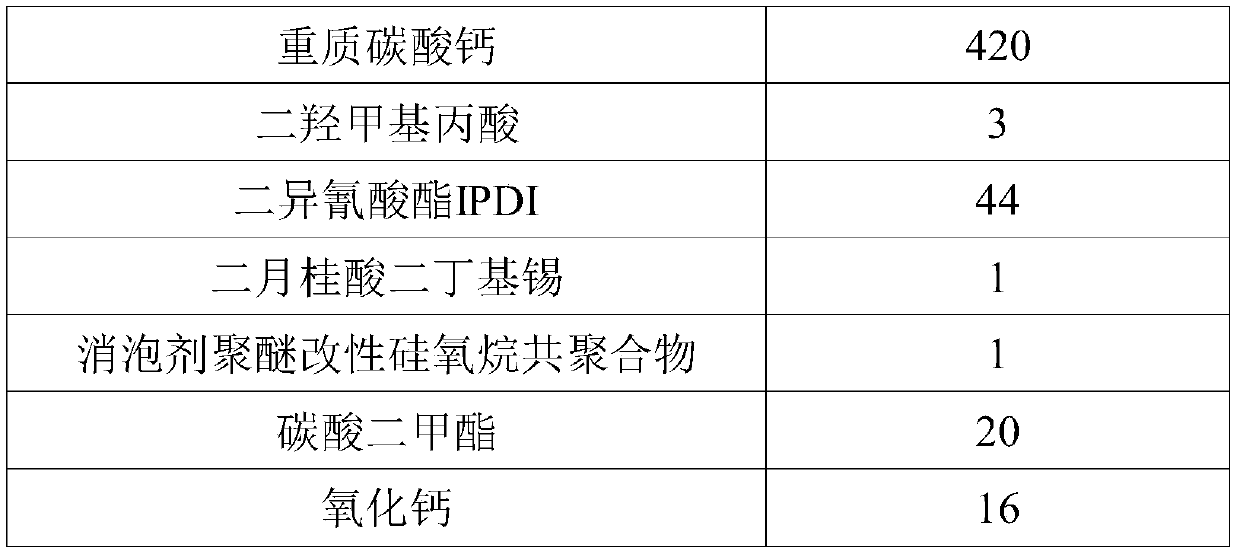

[0038] The raw materials are prepared as follows:

[0039]

[0040]

[0041] Add polyether diol 2000, polyether triol 5000, heavy calcium carbonate, chlorinated palm oil, polyether-modified siloxane copolymer to the reaction kettle in turn, heat up to 110°C while stirring, and dehydrate 2h, cool down to 80°C, slowly add diisocyanate IPDI, nitrogen protection, control the reaction speed, keep warm for 4h, make the -OH reaction in the system complete, then add dimethylol propionic acid, dimethyl carbonate, 80°C Insulate and react for 3 hours, then add dibutyltin dilaurate and calcium oxide in sequence, stir evenly, cool down to 50°C, discharge, and seal for storage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com