Temperature control device for hot melting encapsulation of wiper motor

A technology of temperature control device and motor heating, which is applied in the direction of temperature control, non-electric variable control, control/regulation system, etc. It can solve the problems of hot melt gun damage, hot melt adhesive is not easy to cure, hot melt adhesive is easy to fall off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

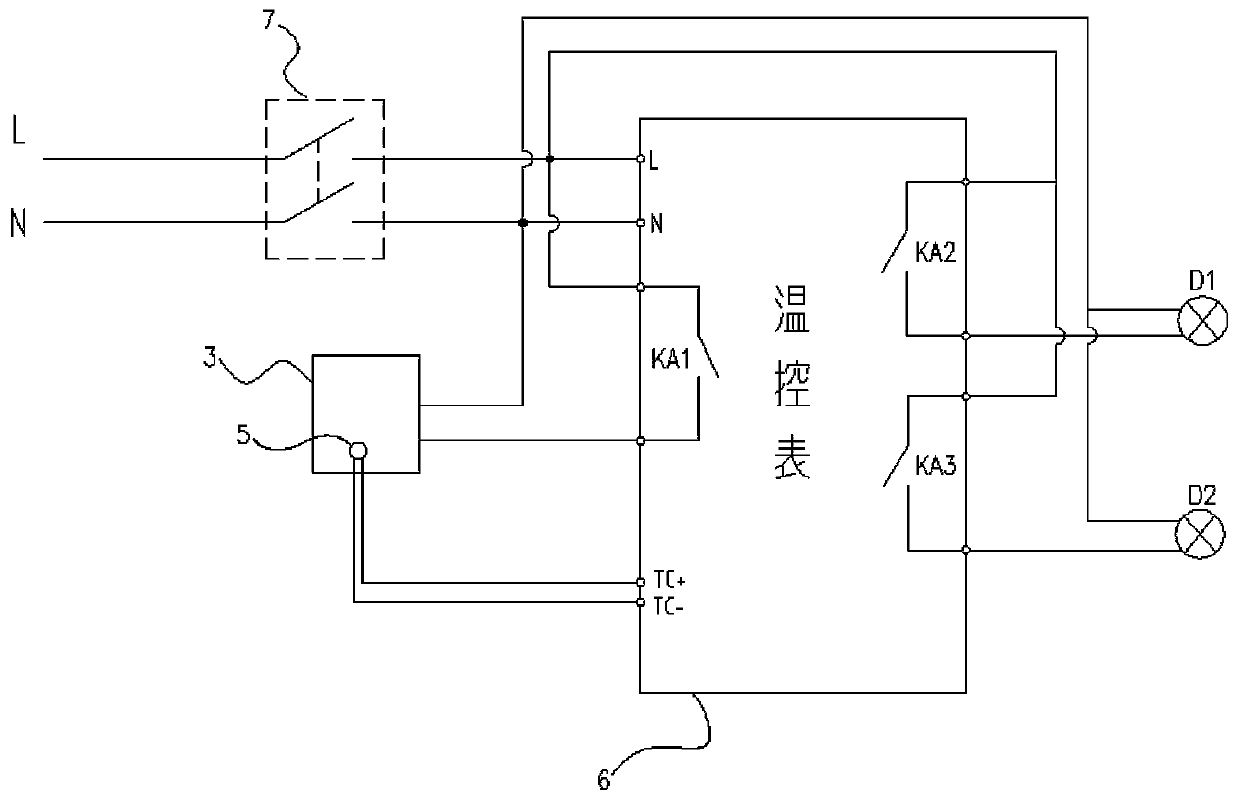

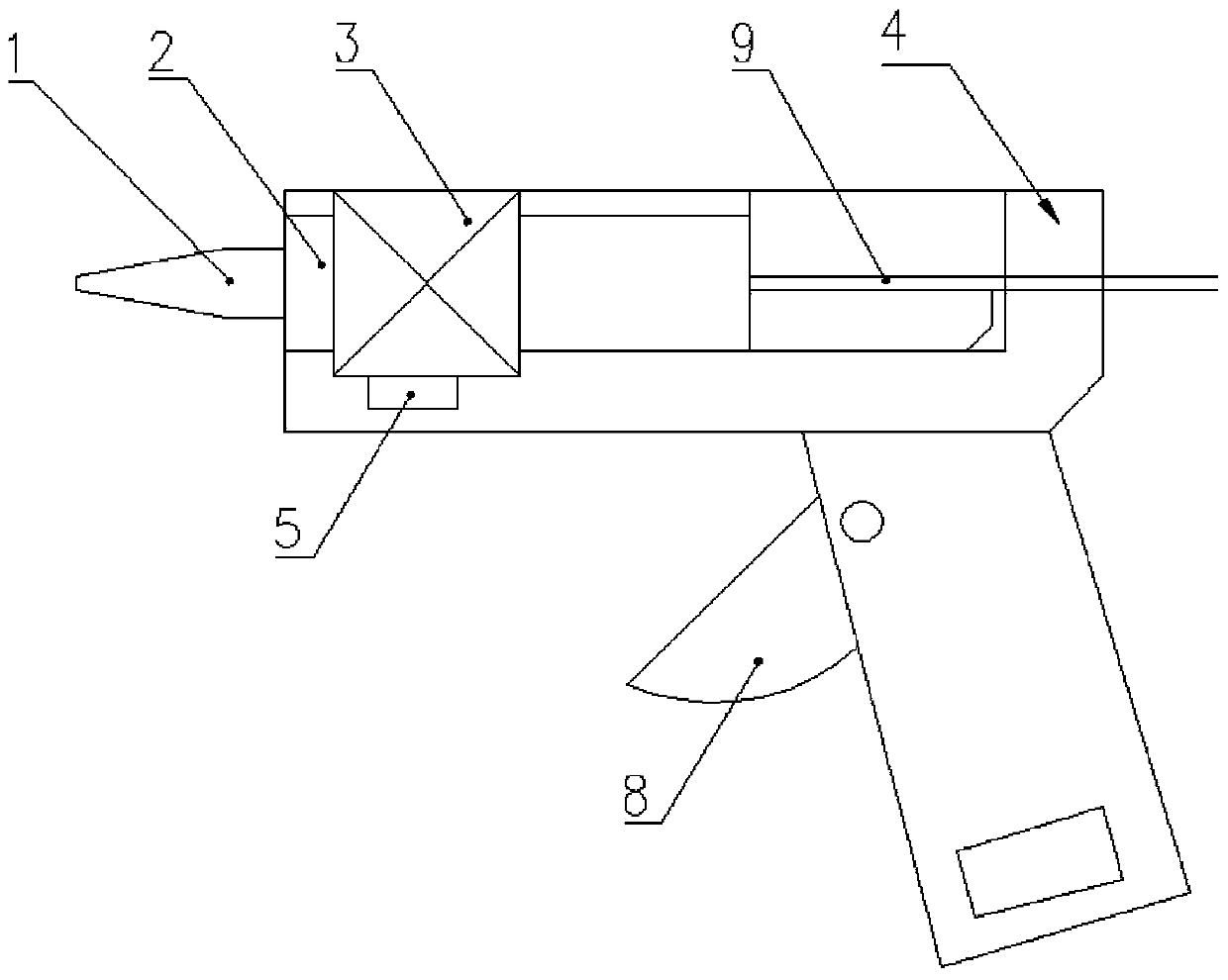

[0015] see Figure 1 to Figure 2 , a temperature control device for hot-melt potting of a wiper motor, comprising a hot-melt glue gun, the hot-melt glue gun includes a nozzle 1, a hot-melt tube 2, a heating coil 3, and the gun nozzle 1 and the hot-melt tube 2 connected, the nozzle 1 of the hot-melt glue gun adopts a copper nozzle or an aluminum alloy nozzle, and the heating coil 3 is wound on the hot-melt pipe 2, and the adhesive strip 9 is pulled from the rear end of the hot-melt glue gun Insert the hot-melt pipe 2, the heating coil 3 wound on the hot-melt pipe 2 generates heat to melt the glue strip 9, and the operator pulls the trigger 8 on the handle of the hot-melt glue gun to make the hot-melt glue flow out from the nozzle 1 , and move the rubber strip 9 toward the gun nozzle 1. A thermocouple 5 is arranged in the gun body 4 of the hot melt glue gun, and the thermocouple 5 is in contact with the heating coil 3. The thermocouple 5 can be connected and fixed with the gun ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com