A kind of water vapor barrier biodegradable polymer film and its preparation and application

A polymer film, biodegradable technology, applied in applications, bio-packaging, flexible coverings, etc., can solve the unclear impact of biodegradable polymer film water vapor barrier performance, the improvement effect of mechanical properties needs to be further strengthened, difficult Use biaxial stretching process and other problems to achieve the effect of improving water vapor barrier ability and mechanical properties, improving water vapor barrier properties and mechanical properties, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the water vapor barrier biodegradable polymer film in the present invention comprises the following steps:

[0037] (1) Blending biodegradable polymers, crosslinking agents, and processing aids (such as blocking agents, titanium dioxide, calcium carbonate, etc.) to obtain special materials for biodegradable polymer films. The biodegradable polymer is polyadipate / terephthalate-butylene glycol ester or a blend of polyadipate / terephthalate-butylene glycol ester and other degradable polymers, and the other The degradable polymer is one of polylactic acid, thermoplastic starch, carbon dioxide-propylene oxide copolymer, polybutylene succinate, polycaprolactone, and polyhydroxybutyrate. The special material for biodegradable polymer film may or may not contain processing aids. Described linking agent is the one in triallyl isocyanurate, triallyl cyanurate, trimethylolpropane trimethacrylate, trimethylolpropane triacrylate, so The added amount of the...

Embodiment 1

[0054] Several water vapor barrier biodegradable polymer films were prepared according to the following steps:

[0055] (1) Dry poly(adipic acid / terephthalic acid-butylene glycol) in a blast drying oven at 50-80°C for 12-24 hours, and then cool to room temperature with cold air. Dry polyadipate / terephthalate-butylene glycol ester resin and triallyl isocyanurate (consumption is 2wt% of polyadipate / terephthalate-butylene glycol ester) in Banburying and blending in the internal mixer, the banburying temperature is 130°C, and the banburying time is 13min, to obtain the special material for biodegradable polymer film.

[0056] (2) The biodegradable polymer film special material obtained in the step (1) is hot-pressed into a 0.2mm thick biodegradable polymer film by a flat vulcanizing machine.

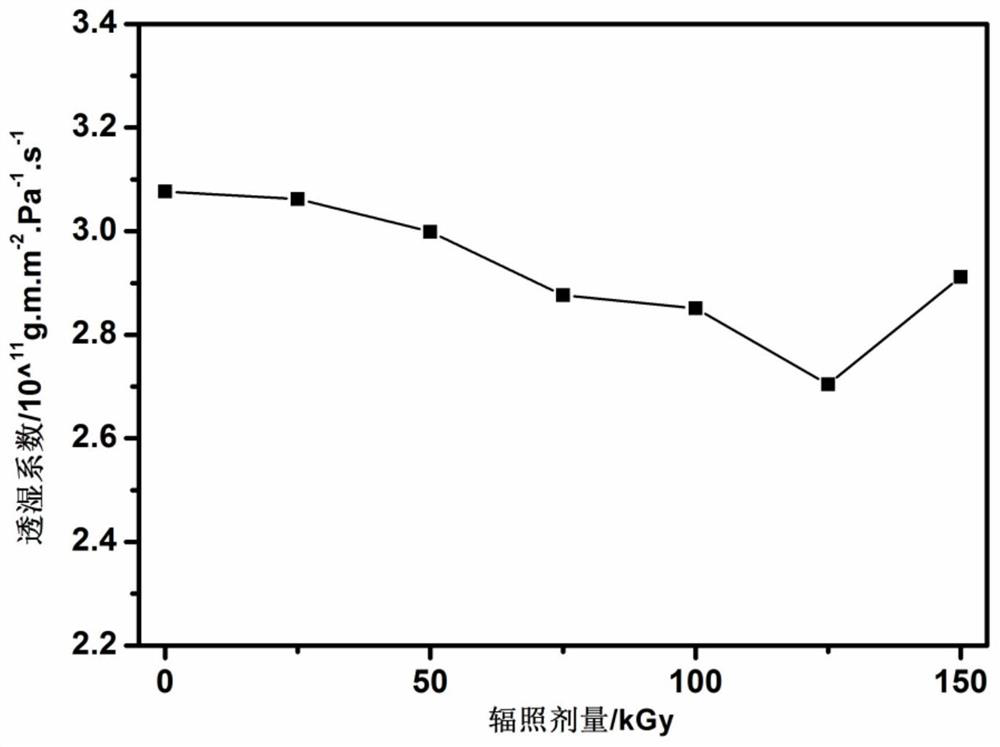

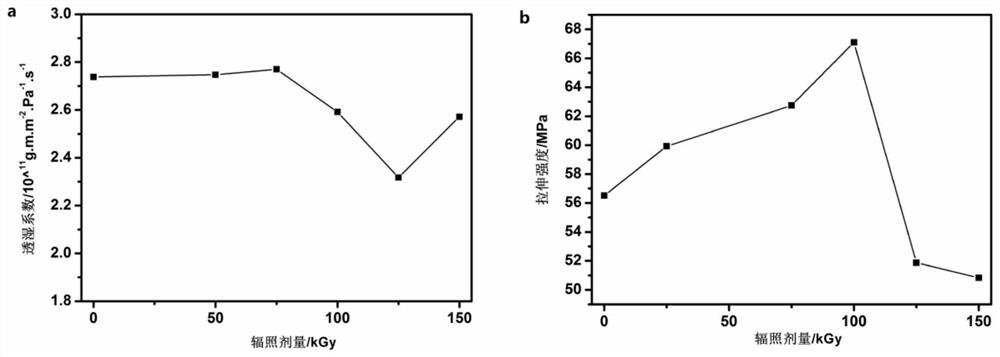

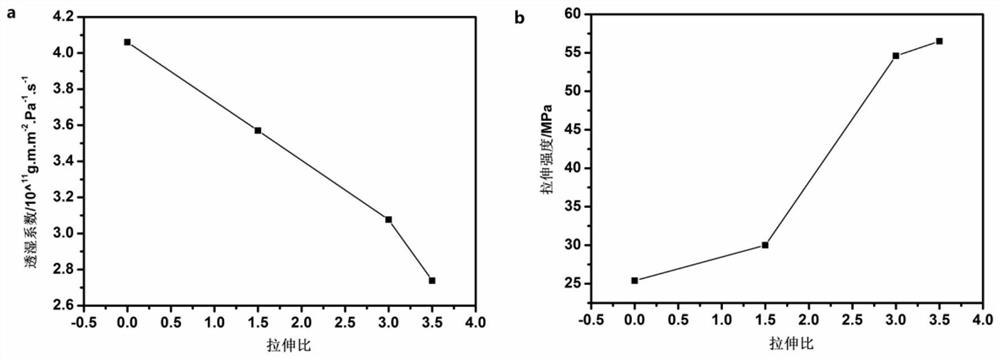

[0057] (3) The biodegradable polymer thick film obtained in step (2) is simultaneously biaxially stretched at 80° C. to obtain a bidirectionally oriented film; the stretching speed is 100 m...

Embodiment 2

[0063] Several water vapor barrier biodegradable polymer films were prepared according to the following steps:

[0064] (1) Dry poly(adipic acid / terephthalic acid-butylene glycol) in a blast drying oven at 50-80°C for 12-24 hours, and then cool to room temperature with cold air. Dry polyadipate / terephthalate-butylene glycol ester resin and triallyl isocyanurate (consumption is 2wt% of polyadipate / terephthalate-butylene glycol ester) in Banburying and blending in the internal mixer, the banburying temperature is 130°C, and the banburying time is 13min, to obtain the special material for biodegradable polymer film.

[0065] (2) The biodegradable polymer film special material obtained in the step (1) is hot-pressed into a 0.2mm thick biodegradable polymer film by a flat vulcanizing machine.

[0066] (3) The biodegradable polymer thick film obtained in step (2) is simultaneously biaxially stretched at 80° C. to obtain a bidirectionally oriented film; the stretching speed is 100 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com