A kind of preparation method of biomass fiber-aliphatic polyester composite material

A technology of biomass fiber and aliphatic polyester, which is applied in the field of preparing aliphatic polyester composite materials, to achieve the effects of improving comprehensive performance, good reinforcement, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A preparation method of biomass fiber-aliphatic polyester composite material, comprising the following steps:

[0037] Step 1, preparation of biomass-based macromolecular coupling agent product:

[0038] Dissolve the biomass-based components in a suitable aprotic solvent to obtain a solution with a mass concentration of 0.1% to 10%, and stir for 1 to 20 minutes under the protection of an inert gas. The molar ratio is dropped into the esterification reaction reagent, and the reaction is stirred at 30-70°C for 8-48 hours; the product after the above-mentioned stirring reaction is precipitated in 2-20 times the volume of deionized water, separated and precipitated, and the biomass-based macromolecular coupling is obtained. agent product;

[0039] Step 2, surface treatment of biomass fibers:

[0040] Continue dissolving the biomass-based macromolecular coupling agent obtained in step 1 in an aprotic solvent to prepare a solution with a mass fraction of 0.5-20%; use the pr...

Embodiment 1

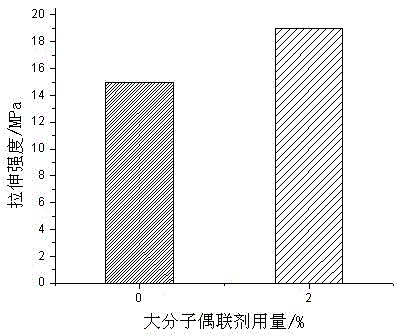

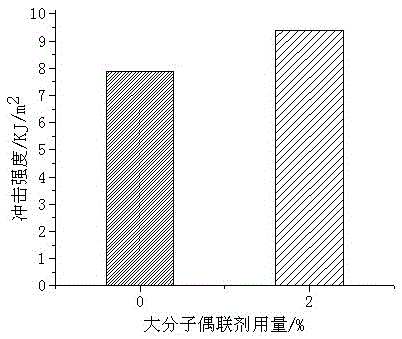

[0048] (1) Synthesis of lignin-based macromolecular coupling agent: dissolve 5 g of kraft lignin in 100 ml of DMF, pass N 2 Stir for 10 minutes under protected conditions, drop in lauroyl chloride with a molar ratio of 1:1.2 reactive groups, stir and react at 50°C for 24 hours, and the obtained product is precipitated in 6 times the volume of deionized water to obtain a lignin-based macromolecular coupling agent product.

[0049] (2) Surface treatment of wood flour: the obtained lignin-based macromolecular coupling agent was dissolved in DMF to prepare a solution with a concentration of 5%. Surface-treat 80-mesh poplar wood powder with the prepared solution, wherein the amount of macromolecular coupling agent relative to the wood powder is 2% by mass ratio, stir in a high-speed mixer at a speed of 2000rpm for 15min, and drum at 100°C Air-dried for 12 hours to obtain surface-treated wood powder.

[0050] (3) Preparation of composite materials: Proportioning materials accordin...

Embodiment 2

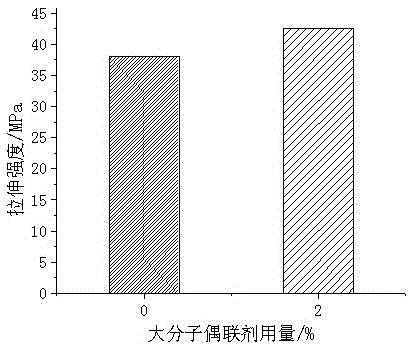

[0053] (1) Synthesis of cellulose-based macromolecular coupling agent: 5g hydroxyethyl cellulose (HEC) was dissolved in 100mlDMF, and passed N 2 Stir under protected conditions for 10 minutes, drop octanoyl chloride at a reactive group molar ratio of 1:1.3, stir and react at 50°C for 24 hours, and the obtained product is precipitated in 8 times the volume of deionized water to obtain a cellulose-based macromolecular coupling agent product.

[0054] (2) Surface treatment of bamboo fibers: the obtained macromolecular coupling agent was dissolved in DMF to prepare a solution with a concentration of 3%. Carry out surface treatment to 80 order bamboo powders with the solution that is made, wherein the consumption of macromolecule coupling agent is 2% with respect to the consumption of bamboo powders by mass ratio, stir 15min with the rotating speed of 2000rpm in high-speed mixer, blast under 100 ℃ Dry for 12h.

[0055] (3) Preparation of composite materials: Proportioning materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com