Method for extracting bioflocculant from excess activated sludge

A biological flocculant and excess sludge technology, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., to achieve the effect of low preparation cost, simple operation process, and good promotion and use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A. The remaining sludge is concentrated to obtain gravity thickened sludge. Adopt A from 2 The sewage treatment plant of the / O treatment process takes back the return sludge of the secondary sedimentation tank as the remaining sludge, puts it in a refrigerator at 4°C within half an hour, and dumps the supernatant after 14 hours, and the gravity obtained after the supernatant is dumped Mix the concentrated sludge evenly. At this time, the gravity concentrated sludge concentration should reach 18.0-20.0g / L, VSS / SS=68.0%-75.0%, and the pH value is 6.5-7.0;

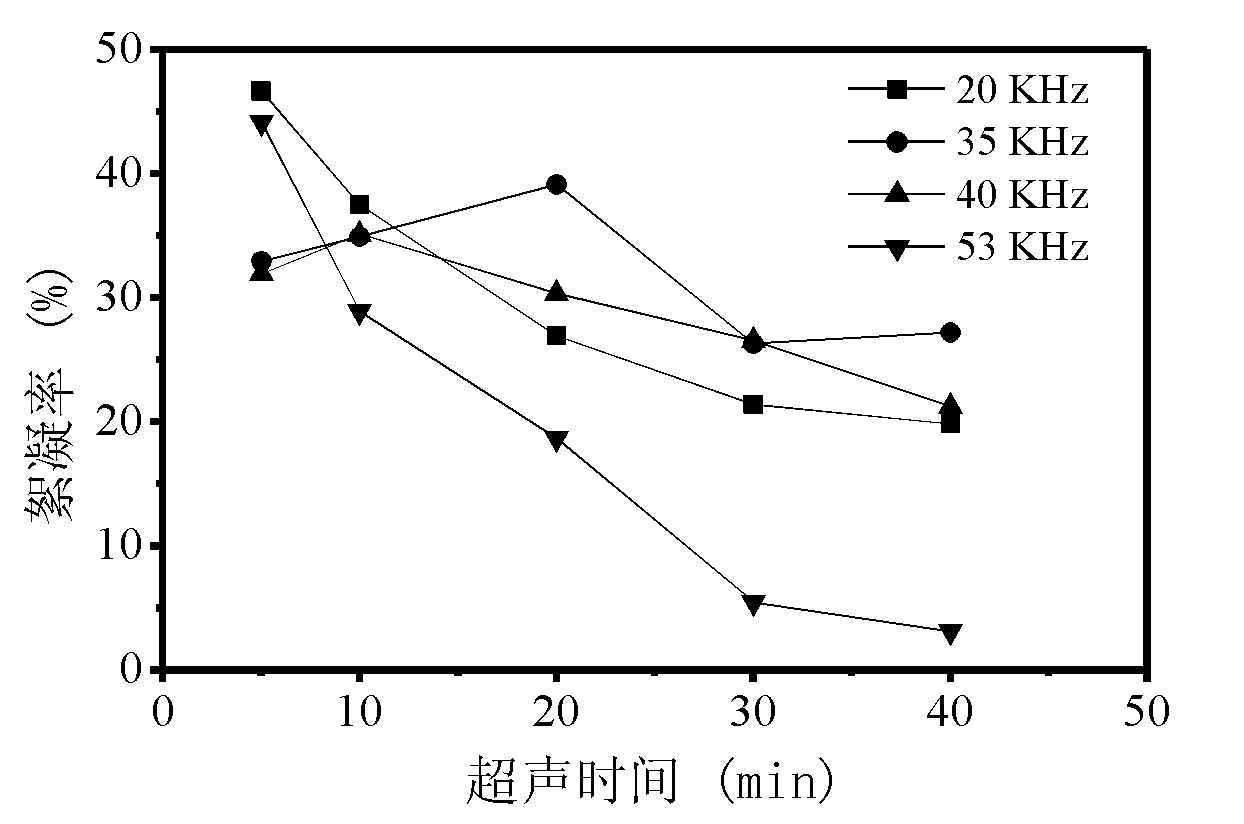

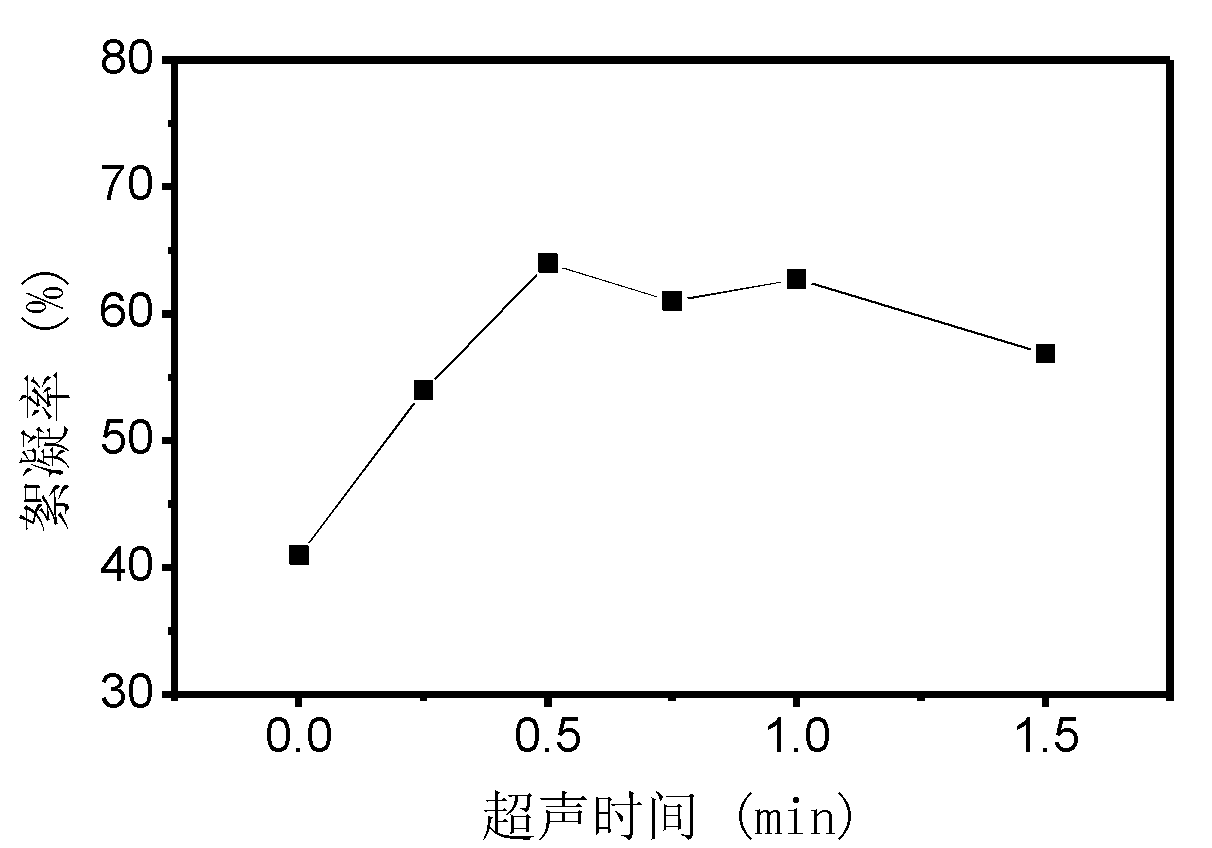

[0023] B. Ultrasonic treatment of gravity thickened sludge to obtain sludge samples. Take out the gravity concentrated sludge obtained in step A from the refrigerator, mix it and put it in a 100ml plastic jar, about 90ml; use a 20KHz ultrasonic cell breaker from Shanghai Shengxi Ultrasonic Instrument Co., Ltd., at a power of 120W Next, select continuous ultrasound mode, 13mm probe, and continue ultrasound for 30s; ...

Embodiment 2

[0027] A. The remaining sludge is concentrated to obtain gravity thickened sludge. Retrieve the return sludge from the secondary settling tank from a sewage treatment plant that adopts a double sludge treatment system process, place it in a refrigerator at 5°C within half an hour, pour off the supernatant after 12 hours, and dump the supernatant Concentrate the sludge by gravity and mix evenly. At this time, the concentration of the sludge by gravity concentration should reach 15.0-16.0g / L, VSS / SS=65.0%-70.0%, and the pH value is 7.0-7.5.

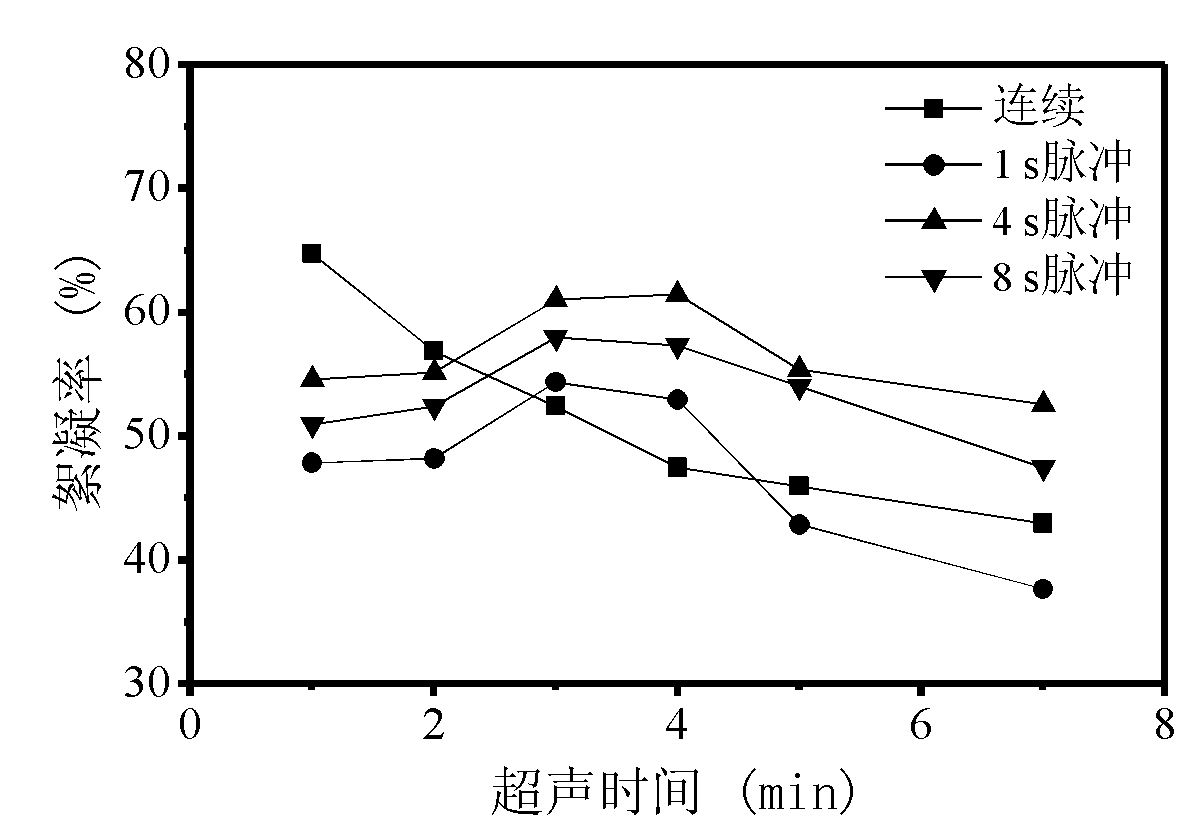

[0028] B. Ultrasonic treatment of gravity thickened sludge to obtain sludge samples. Take out the gravity concentrated sludge obtained in step A from the refrigerator, mix it and put it in a 100ml plastic jar, about 90ml; use a 20KHz ultrasonic cell breaker from Shanghai Shengxi Ultrasonic Instrument Co., Ltd., at a power of 180W Next, choose 1-8 seconds pulsed ultrasound for continuous ultrasound mode, 13mm probe, continuous ultrasound for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com