Completely biodegradable plastic film prepared from straws and preparation method thereof

A biodegradable and plastic film technology is applied in the field of completely biodegradable plastic film prepared by using straw and its preparation field, which can solve the problem of high cost and achieve the effects of good mechanical properties, simple preparation process and easy industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

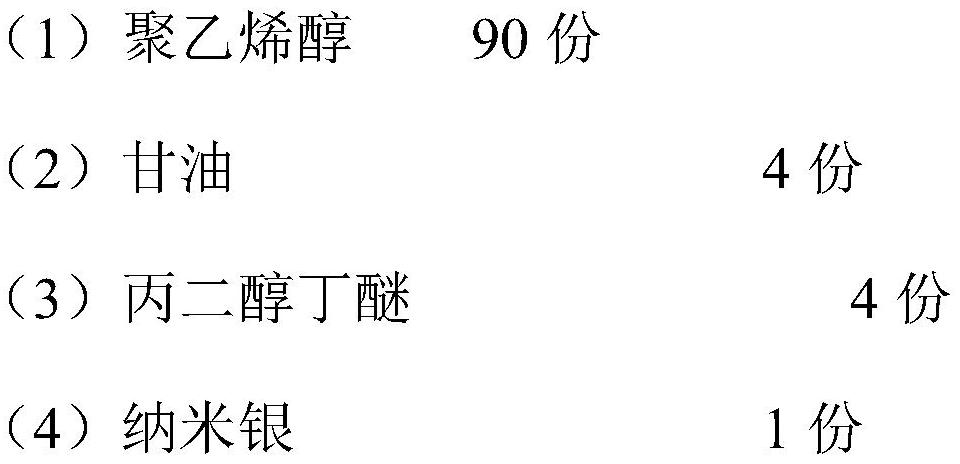

[0044] In this embodiment, the fully biodegradable plastic film comprises the following raw material compositions and parts by weight:

[0045]

[0046]

[0047] The preparation method of the above-mentioned biodegradable material comprises the following steps:

[0048] S1: The dried straw is crushed by ultra-fine crushing technology, and the particle size of the crushed straw is below 10 microns;

[0049] S2: The straw powder and the silane coupling agent were completely mixed and stirred at room temperature for 15 minutes to modify the surface of the straw powder;

[0050] S3: Mix the mixture in step S2 with other raw material components (biodegradable polymer, plasticizing modifier, film forming agent and nano-silver) in a high-speed mixer at 70 ° C for 15 minutes to obtain the prepared mix;

[0051] S4: Add the premix to the single-screw extruder to extrude the film, the extrusion temperature of the blown film is 170°C, and the screw speed is 60r / min;

[0052] S5:...

Embodiment 2

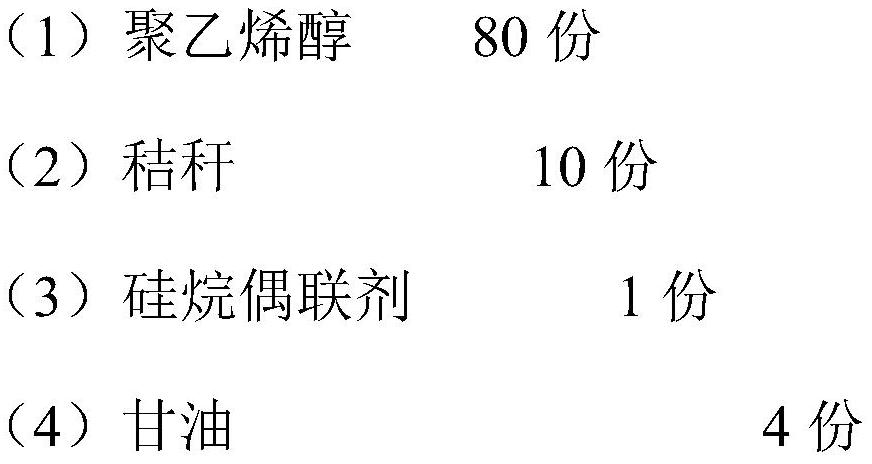

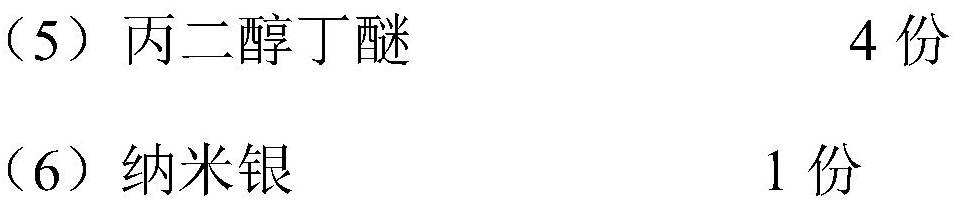

[0054] In this embodiment, the fully biodegradable plastic film comprises the following raw material compositions and parts by weight:

[0055]

[0056] The preparation method of the above-mentioned biodegradable material comprises the following steps:

[0057] S1: The dried straw is crushed by ultra-fine crushing technology, and the particle size of the crushed straw is below 10 microns;

[0058] S2: The straw powder and the silane coupling agent were completely mixed and stirred at room temperature for 15 minutes to modify the surface of the straw powder;

[0059] S3: Mix the mixture in step S2 with other raw material components (biodegradable polymer, plasticizing modifier, film forming agent and nano-silver) in a high-speed mixer at 70 ° C for 15 minutes to obtain the prepared mix;

[0060] S4: Add the premix to the single-screw extruder to extrude the film, the extrusion temperature of the blown film is 170°C, and the screw speed is 60r / min;

[0061] S5: A fully bio...

Embodiment 3

[0063] In this embodiment, the fully biodegradable plastic film comprises the following raw material compositions and parts by weight:

[0064]

[0065] The preparation method of the above-mentioned biodegradable material comprises the following steps:

[0066] S1: The dried straw is crushed by ultra-fine crushing technology, and the particle size of the crushed straw is below 10 microns;

[0067] S2: The straw powder and the silane coupling agent were completely mixed and stirred at room temperature for 15 minutes to modify the surface of the straw powder;

[0068]S3: Mix the mixture in step S2 with other raw material components (biodegradable polymer, plasticizing modifier, film-forming agent and nano-silver) in a high-speed mixer at 70° C. for 15 minutes to obtain the prepared mixture. mix;

[0069] S4: Add the premix to the single-screw extruder to extrude the film, the extrusion temperature of the blown film is 170°C, and the screw speed is 60r / min;

[0070] S5: A f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com