Plant press strip device

A plant and batting technology, applied in the field of special appliances, can solve the problems of poor air permeability of plastic bags, limited seasons of batting, low strength of plastic bags, etc., and achieve the effects of convenient operation, root system protection, and low root system and weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

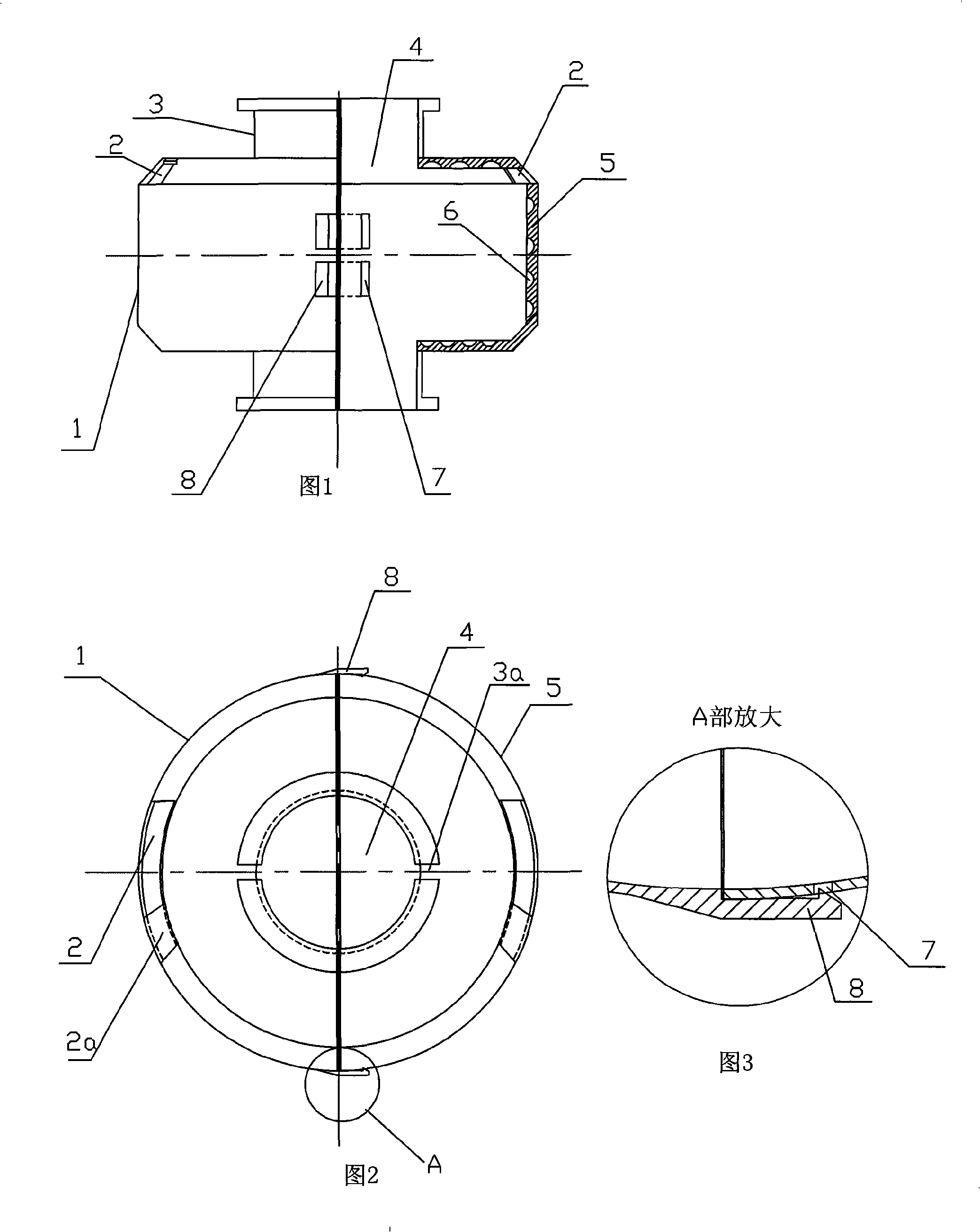

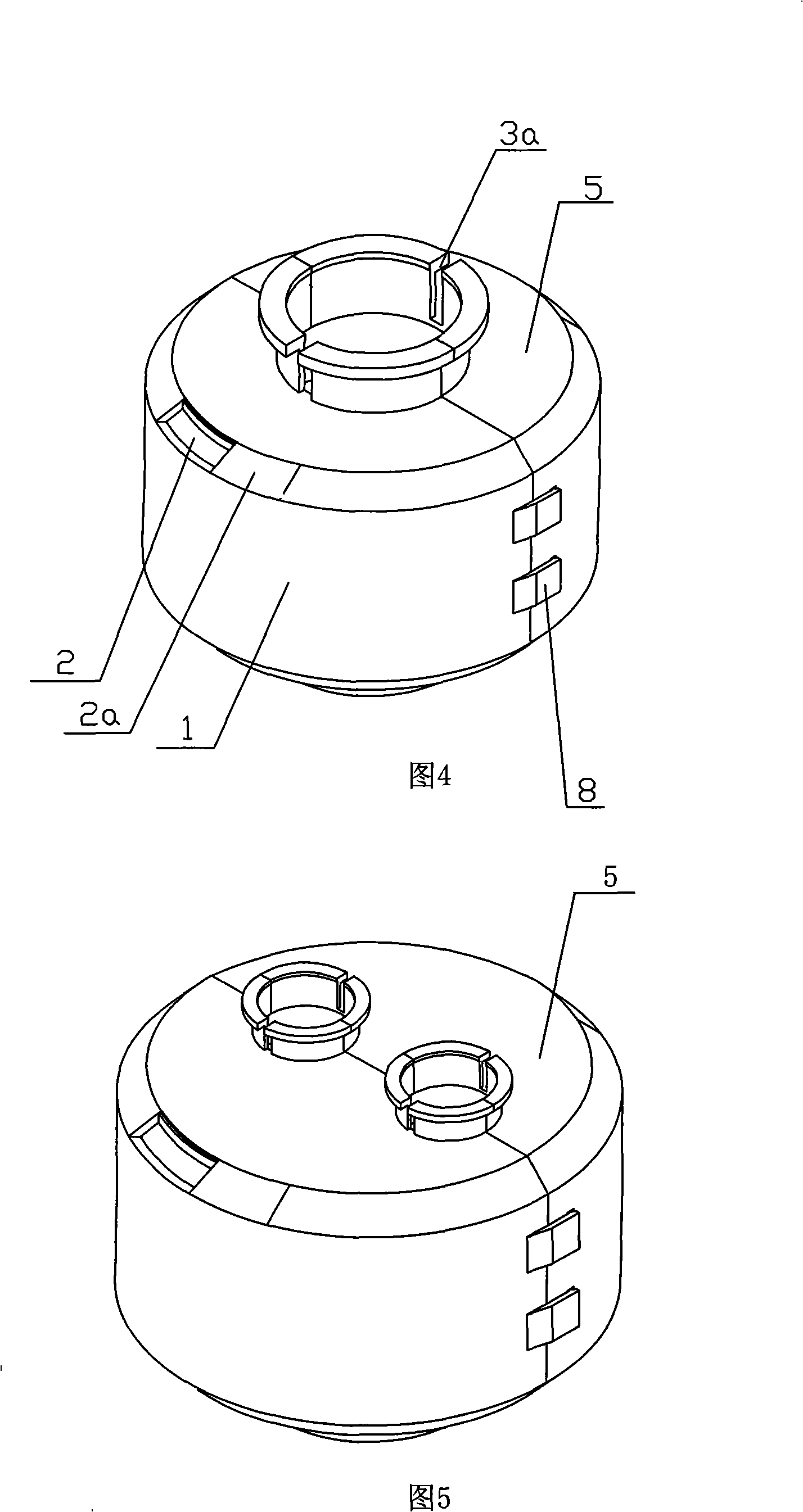

[0032] As shown in Figures 1, 2, 3, and 4, the plant layerer provided by the present invention includes two half-shells 1, 5, which are connected to form a hollow shell through connectors, and each half-shell two ends The half bayonets 4 that are symmetrically matched are respectively provided. Each half bayonet part is provided with a half neck 3 corresponding to the half bayonet. The end of the half neck is provided with a shoulder and a guide groove 3a. The two half necks cooperate to form A neck and bayonet that surrounds and secures the plant branches. The bayonet structure of the plant layering device provided by the present invention can also be made into a double bayonet or even a multiple bayonet structure as shown in FIG. 5 .

[0033] On the basis of the above basic structure, the following technical features can be added:

[0034] Each half-shell is provided with a feeding port 2, and the position of the feeding port is provided with a chute, and a sealing slide 2a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com