Coating composition for transferable laser anti-counterfeiting plate and method for preparing transferable laser anti-counterfeiting plate

A technology for transferring laser and composition, applied in anti-corrosion coatings, chemical instruments and methods, polyurea/polyurethane coatings, etc. , Increase the applicability of the coating, the effect of not easy to acid and alkali corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

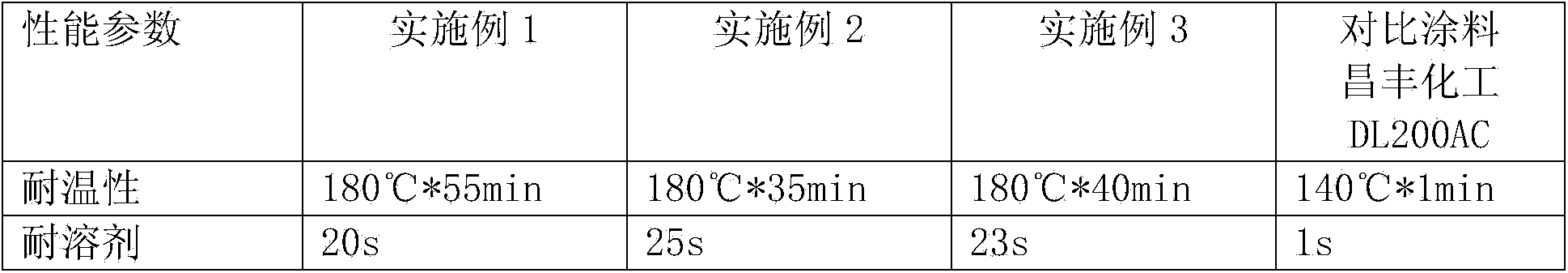

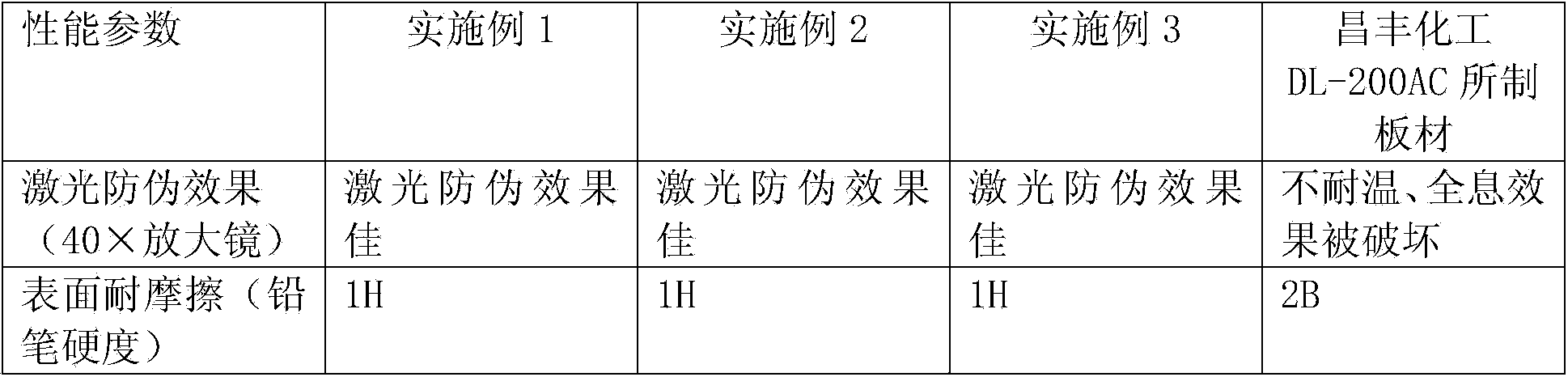

Embodiment 1

[0032] This embodiment relates to a coating composition suitable for transferable laser anti-counterfeiting plates, and its preparation method includes the following steps:

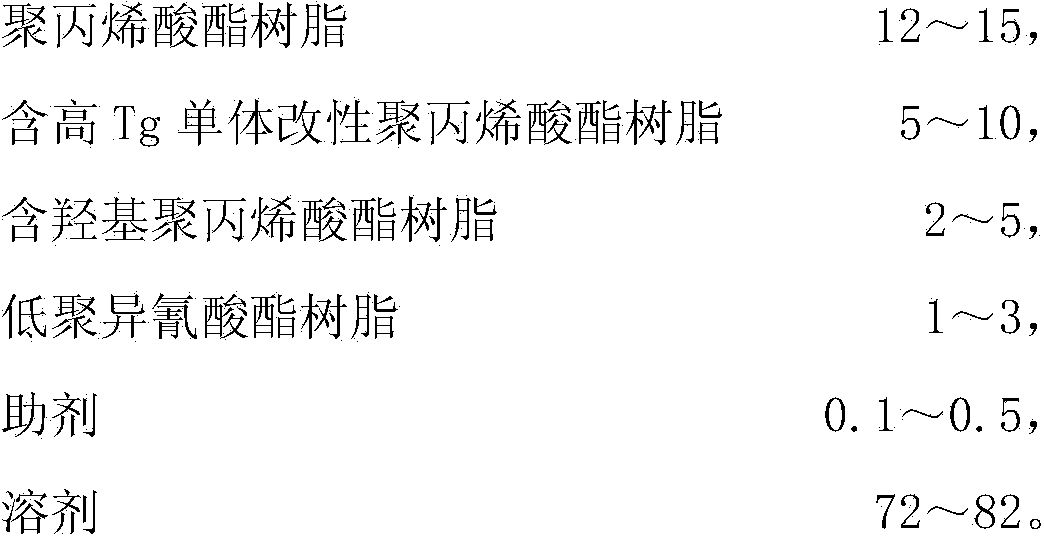

[0033] (1) Prepare raw materials according to the components and parts by weight shown in Table 1:

[0034] (2) Put the solvent in the reaction kettle according to the formula, turn on the stirring device, and mix evenly;

[0035] (3) Put the above four resin components into the reactor, control the stirring rate to be 150rpm, and stir for 1h to fully dissolve the resin components;

[0036] (4) After the resin components are completely dissolved, put the additives into the reaction kettle, control the stirring rate to 150rpm, and wait for 30 minutes until the additives are fully dispersed and evenly, and filter to obtain the final product.

[0037] The above-mentioned leveling agent is modified polysiloxane; the anti-scratch agent is polyether modified silicone.

Embodiment 2

[0039] This embodiment relates to a coating composition suitable for transferable laser anti-counterfeiting plates, and its preparation method includes the following steps:

[0040] (1) Prepare raw materials according to the components and parts by weight shown in Table 1:

[0041] (2) Put the solvent in the reaction kettle according to the formula, turn on the stirring device, and mix evenly;

[0042] (3) Put the above four resin components into the reactor, control the stirring rate to 200rpm, and stir for 5h to fully dissolve the resin components;

[0043] (4) After the resin components are completely dissolved, put the additives into the reaction kettle, control the stirring rate to 100rpm, and wait for 10 minutes until the additives are fully dispersed and evenly, and filter to obtain the final product.

[0044] The above-mentioned leveling agent is modified silicone; the anti-abrasion agent is polyethylene emulsified wax.

Embodiment 3

[0046] This embodiment relates to a coating composition suitable for transferable laser anti-counterfeiting plates, and its preparation method includes the following steps:

[0047] (1) Prepare raw materials according to the components and parts by weight shown in Table 1:

[0048] (2) Put the solvent in the reaction kettle according to the formula, turn on the stirring device, and mix evenly;

[0049] (3) Put the above four resin components into the reactor, control the stirring rate to 200rpm, and stir for 5h to fully dissolve the resin components;

[0050] (4) After the resin components are completely dissolved, put the additives into the reaction kettle, control the stirring rate to 100rpm, and wait for 10 minutes until the additives are fully dispersed and evenly, and filter to obtain the final product.

[0051] The above-mentioned leveling agent is modified polysiloxane; the anti-scratch agent is polyethylene emulsified wax.

[0052] Components and parts by weight of Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com