High-temperature resistant hydrophobic material and preparation method thereof

A technology of hydrophobic materials and high temperature resistance, which is applied in the field of inorganic hydrophobic coatings and high temperature resistant hydrophobic materials prepared on metal surfaces. It can solve the problem that hydrophobic materials cannot be used in high temperature environments above 500 ° C, so as to improve oxidation resistance and excellent mechanical properties. , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments to further understand the purpose, solution and effect of the present invention, but it is not intended to limit the scope of protection of the appended claims of the present invention.

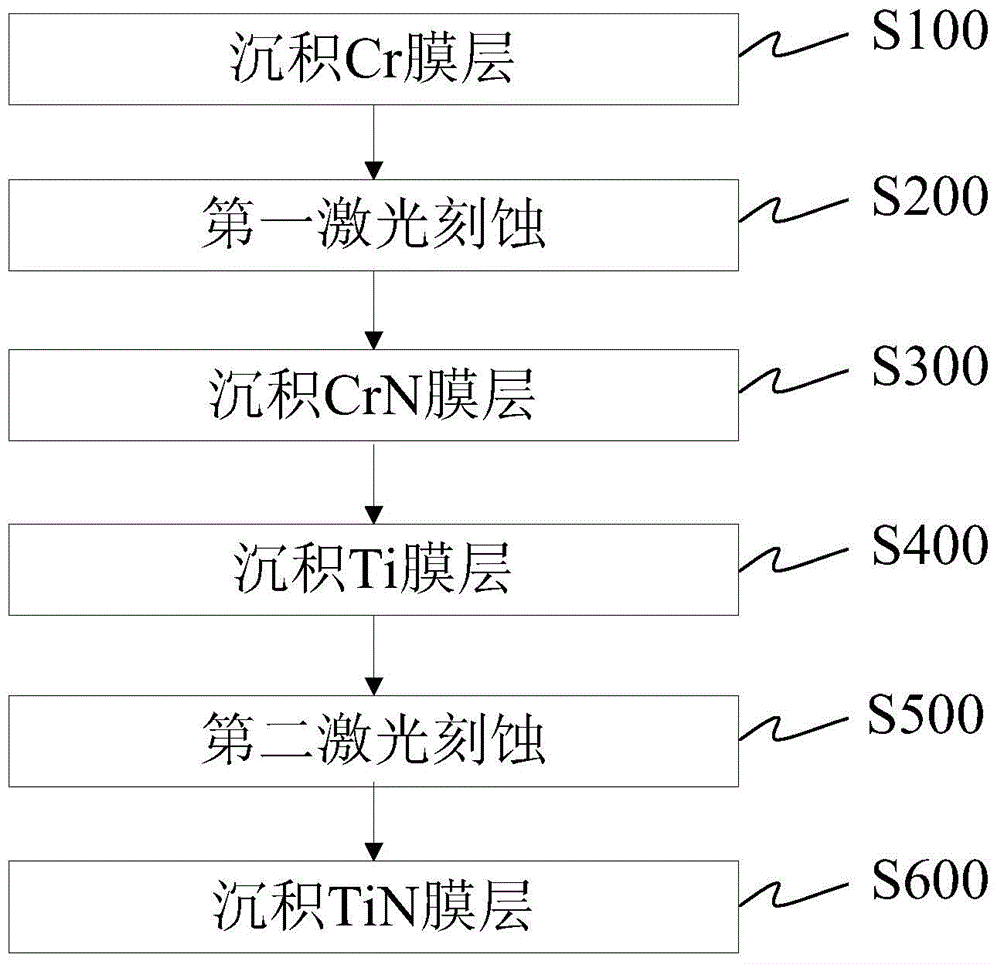

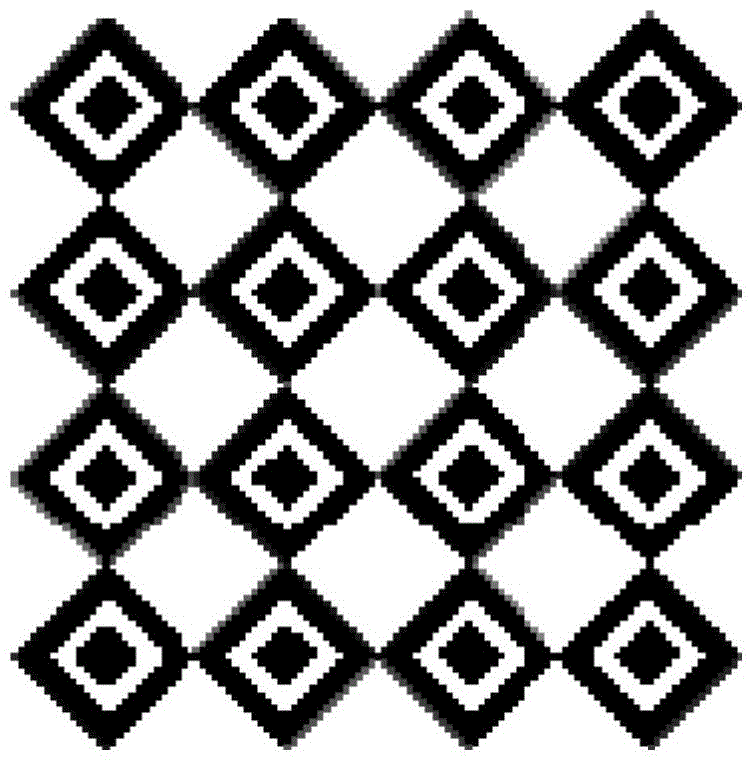

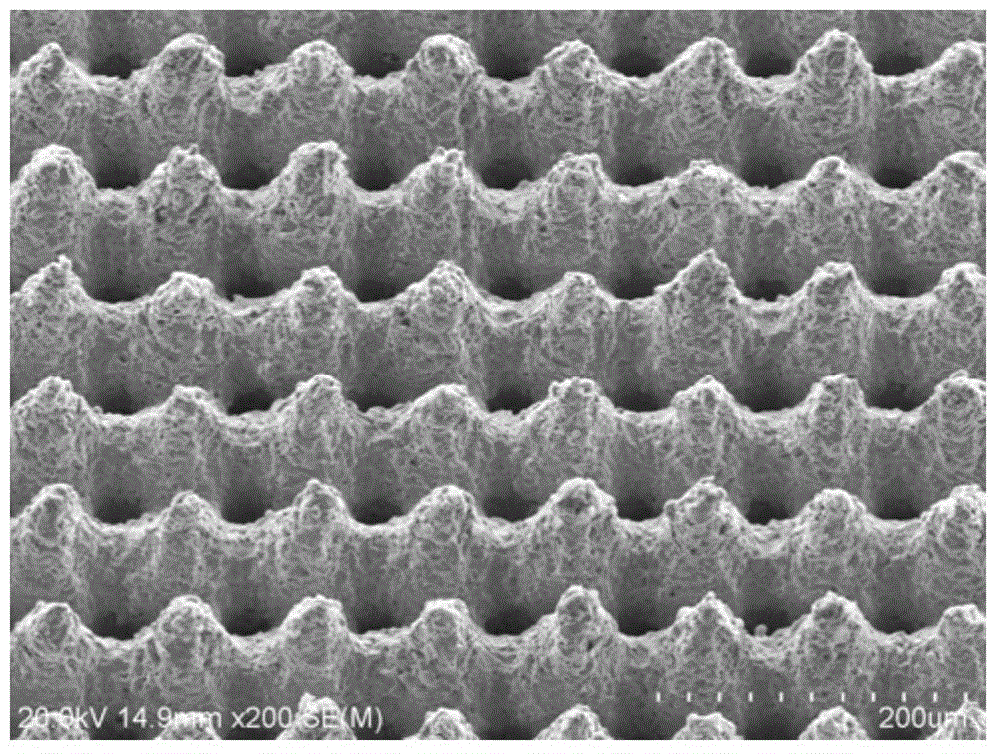

[0031] The invention adopts the magnetic filter cathode vacuum arc discharge technology and the laser etching technology to prepare the hydrophobic functional layer, and the deposited film and the etching texture are carried out at intervals. The magnetic filter cathode vacuum arc discharge deposition coating technology is used to deposit multi-layer composite films on titanium alloys, nickel-based alloys, and copper materials. The magnetic filter cathode vacuum arc discharge coating equipment adopts a multi-arc source cathode target system, and the cathode material is mainly high-purity. Chromium and titanium materials are used to depo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com