Low-alloy high-strength high-impact-energy extra-large special-shaped ring forging and forging method thereof

A low-alloy high-strength, high-impact technology, applied in the field of forging manufacturing, can solve the problems of high temper brittleness, low pass rate, long high temperature time, etc., to improve stability, improve pass rate, and reduce equipment investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A low-alloy, high-strength, high-impact extra-large special-shaped ring forging. In terms of weight percentage, the chemical composition of the low-alloy high-strength steel is: C: 0.11%, Mn: 0.56%, P: 0.006%, S: 0.005%, Si: 0.53%, Cr: 1.45%, Mo: 0.60%, Ni: 0.13%, Cu: 0.07%, V: 0.009%, Nb: 0.032%, Al: 0.025%, Sn: 0.004%, As: 0.01%, Sb: 0.003%, H: 0.8ppm, O: 13ppm, N: 52ppm, J=109%, X=10.1ppm, the balance is Fe and impurities.

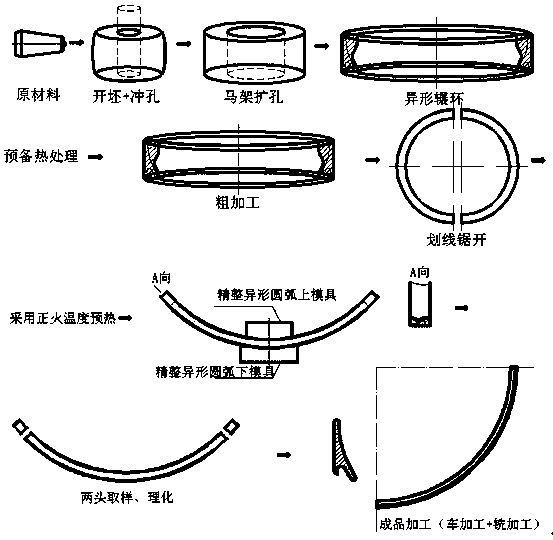

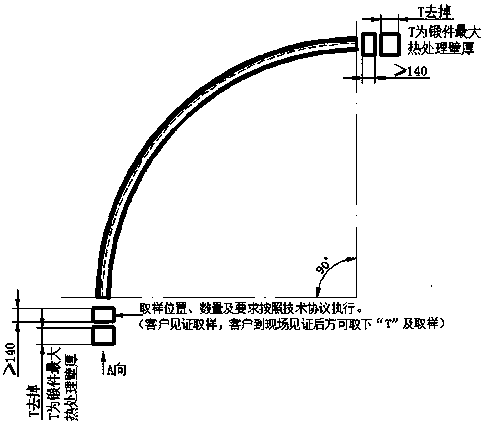

[0049] The special-shaped ring forging is made by the following preparation method:

[0050] Use EBT+LF+VD to make steel ingots, and then forge the steel ingots. The specific steps are as follows:

[0051] a. Sawing machine blanking: cold saw nozzle, according to the blanking specifications of the enterprise, remove the impurities in the tail of the ingot.

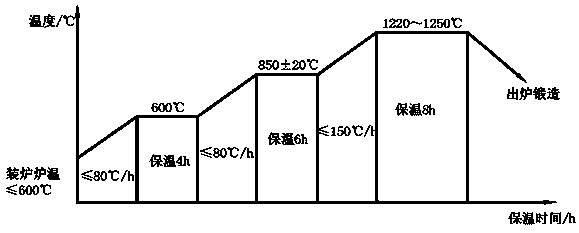

[0052] b. Heating for forging: Put the steel ingot into the gas furnace, and adopt the section heating method for heat treatment, so that the steel ingot is fully heated, reduces the intern...

Embodiment 2

[0065] A low-alloy, high-strength, high-impact energy super-large special-shaped ring forging. The low-alloy high-strength steel includes the following components in terms of weight percentage:

[0066] C: 0.11%, Mn: 0.56%, P: 0.005%, S: 0.005%, Si: 0.53%, Cr: 1.44%, Mo: 0.59%, Ni: 0.12%, Cu: 0.09%, V: 0.009%, Nb: 0.031%, Al: 0.026%, Sn: 0.004%, As: 0.01%, Sb: 0.003%, H: 0.8ppm, O: 12ppm, N: 51ppm, J=109%, X=9.1ppm, balance For Fe and impurities.

[0067] The special-shaped ring forging is made by the following preparation method:

[0068] Use EBT+LF+VD to make steel ingots, and then forge the steel ingots. The specific steps are as follows:

[0069] a. Sawing machine blanking: cold saw nozzle, according to the blanking specifications of the enterprise, remove the impurities in the tail of the ingot.

[0070] b. Heating for forging: Put the steel ingot into the gas furnace, and adopt the section heating method for heat treatment, so that the steel ingot is fully heated, red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com