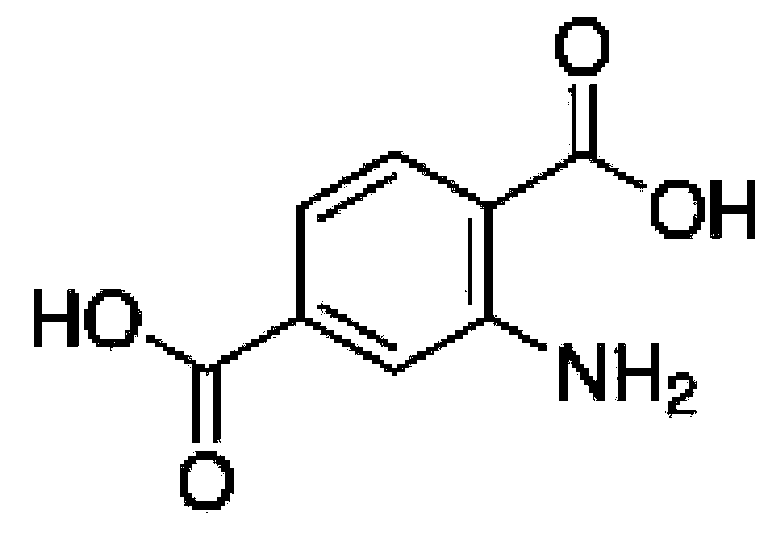

Method for preparing graphite-phase carbon nitride visible-light-induced photocatalyst through copolymerization of 2-aminoterephthalic acid and amine compound

An amino terephthalic acid, graphitic carbon nitride technology, applied in nitrogen and non-metallic compounds, physical/chemical process catalysts, chemical instruments and methods, etc. problems such as low catalytic activity, to achieve the effects of low cost, optimized chemical composition, and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 10 g of urea and 0.5 mg of 2-aminoterephthalic acid were dissolved in 20 mL of deionized water to form a transparent mixed solution, which was stirred and evaporated to dryness in a water bath at 70°C. The resulting mixture was ground evenly in a mortar, added to a 50mL crucible with a cover, and then the crucible was placed in an ash furnace, and the temperature was raised from room temperature to 550 °C at a heating rate of 5 °C / min, kept for 4 hours, and naturally cooled to room temperature . That is, a new type of graphite-phase carbon nitride copolymerized is obtained, and the performance test is to be performed.

Embodiment 2

[0040] 10 g of urea and 1 mg of 2-aminoterephthalic acid were dissolved in 20 mL of deionized water to form a transparent mixed solution, which was stirred and evaporated to dryness in a water bath at 70°C. The resulting mixture was ground evenly in a mortar, added to a 50mL crucible with a cover, and then the crucible was placed in an ash furnace, and the temperature was raised from room temperature to 550 °C at a heating rate of 5 °C / min, kept for 4 hours, and naturally cooled to room temperature . That is, a new type of graphite-phase carbon nitride copolymerized is obtained, and the performance test is to be performed.

Embodiment 3

[0042]10 g of urea and 3 mg of 2-aminoterephthalic acid were dissolved in 20 mL of deionized water to form a transparent mixed solution, which was stirred and evaporated to dryness in a water bath at 70°C. The resulting mixture was ground evenly in a mortar, added to a 50mL crucible with a cover, and then the crucible was placed in an ash furnace, and the temperature was raised from room temperature to 550 °C at a heating rate of 5 °C / min, kept for 4 hours, and naturally cooled to room temperature . That is, a new type of graphite-phase carbon nitride copolymerized is obtained, and the performance test is to be performed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com