Efficient tail gas particle purification system of mining rubber-tyred vehicle

A technology for mining rubber-wheeled vehicles and exhaust particles, which is applied to exhaust devices, mufflers, engine components, etc., can solve the problems of the increase of underground miners and the emission performance of exhaust particles exceeding the standard, and achieves reduction of emissions, enhanced adsorption capacity, The effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

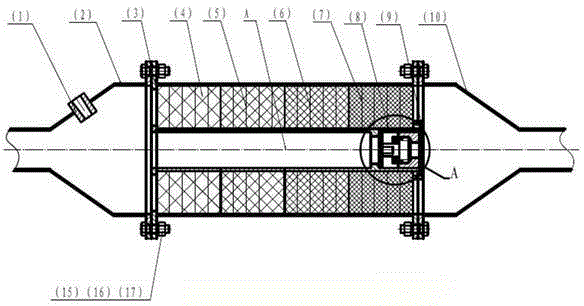

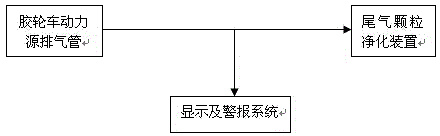

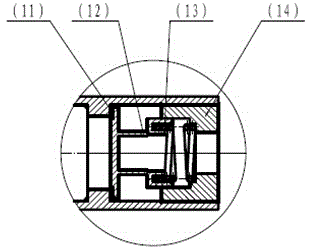

[0030] Such as figure 1 , 2 As shown, a mining rubber-tyred vehicle exhaust particle purification system includes an exhaust pipe 2 and an exhaust tail pipe 10, and also includes an exhaust particle purification device and a display and alarm system. The exhaust particle purification device includes an exhaust safety The device 8 and the exhaust particulate trap A arranged between the exhaust pipe 2 and the exhaust tailpipe 10, the exhaust particulate trap A includes several stages of traps arranged in sequence in the casing 3, each stage The traps are composed of a number of metal foam sheets with different pore diameters and thicknesses of 3-5mm fired by Fe-Cr-Al. The pore diameter of the metal foam sheets in each stage of the trap decreases gradually, and the exhaust particle trap A is internally connected. There is a hollow circular hole, and the exhaust safety device 8 is installed at the tail of the circular hole in the exhaust particle catcher A.

[0031] Such as F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com