High performance cutting pick and manufacturing method thereof

A high-performance, pick technology, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of increased consumption of mining picks, achieve the effects of improving various performances, increasing hardness, and saving mining costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

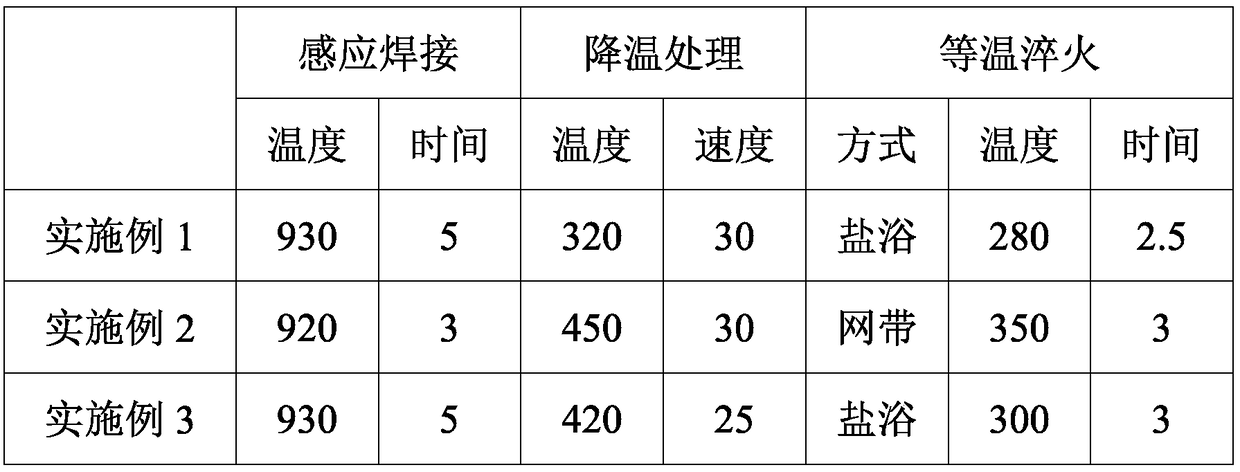

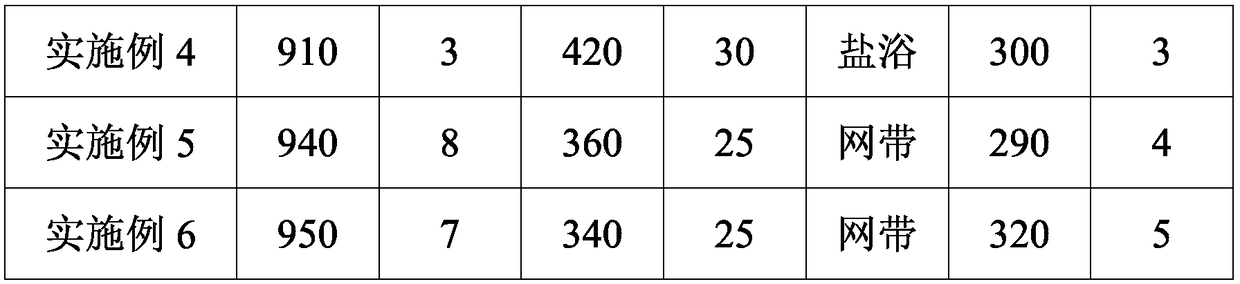

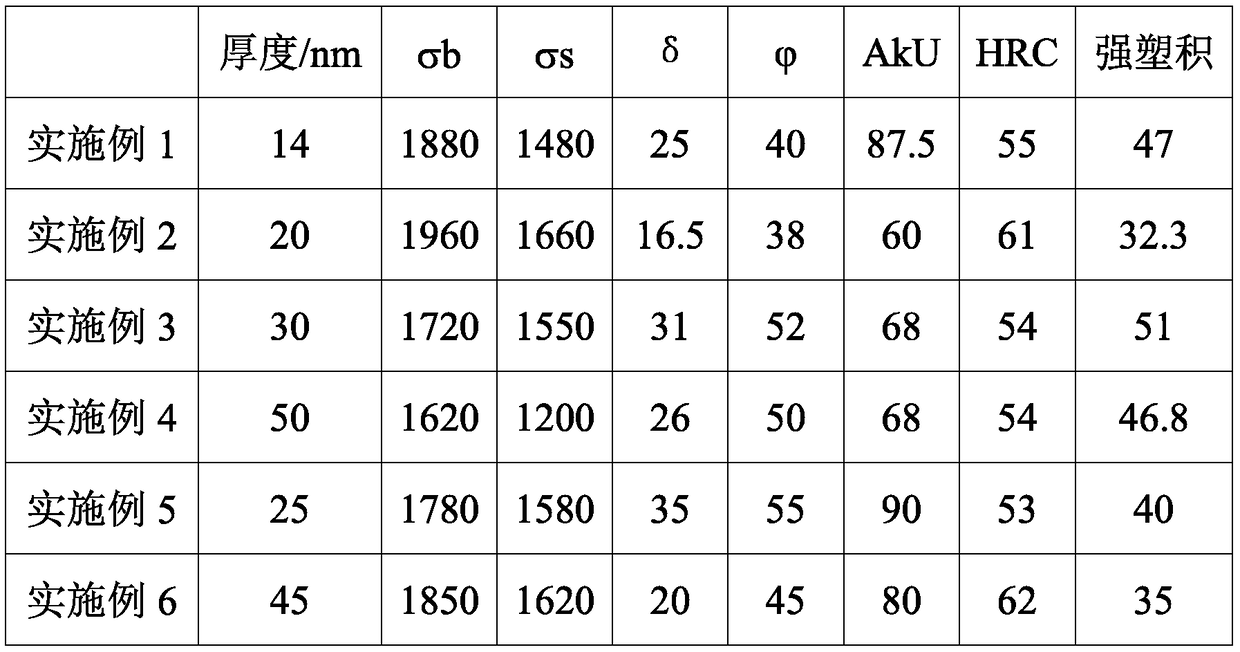

Embodiment Construction

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the content of the present invention will be described in further detail below, and the embodiments are only used to illustrate the present invention, rather than to limit the present invention. The mechanical performance tests of materials in the present invention are all tested according to corresponding national standards.

[0039]The invention provides a high-performance pick, which includes a tooth tip and a tooth body. The tooth tip is made of cemented carbide and welded to the tooth body by medium-frequency induction heating. The tooth body is made of high-strength, high-toughness , Made of wear-resistant steel. The chemical composition of the tooth body is as follows in terms of mass percentage wt%, C: 0.30-0.40, Si: 2.30-2.50, Mn: 2.20-2.60, Cr: 0.80-1.50, Mo: 0.35-0.45, Re: 0.01-0.1, Nb: 0.02-0.04, S<0.01, P<0.01, the rest is Fe. When the Si element in the system...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com