Preparation method of reconstituted tobacco from tobacco stem and tobacco powder

A technology for reconstituted tobacco leaves and tobacco dust, which is applied in the direction of preparation of tobacco, tobacco, application, etc., to achieve the effects of improving physical properties, improving operational performance and effectiveness, and improving surface properties and internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Tobacco stems and tobacco dust used in the experiment were randomly selected from the raw materials produced by Guangdong China Tobacco Industry Co., Ltd., and were commercially available tobacco stems and tobacco dust. Refrigerate the tobacco stems and tobacco powder at 4°C, and pack them into bags to balance the moisture for later use.

[0032] The maceration extraction and refining treatment of tobacco stems and tobacco dust refer to existing routines.

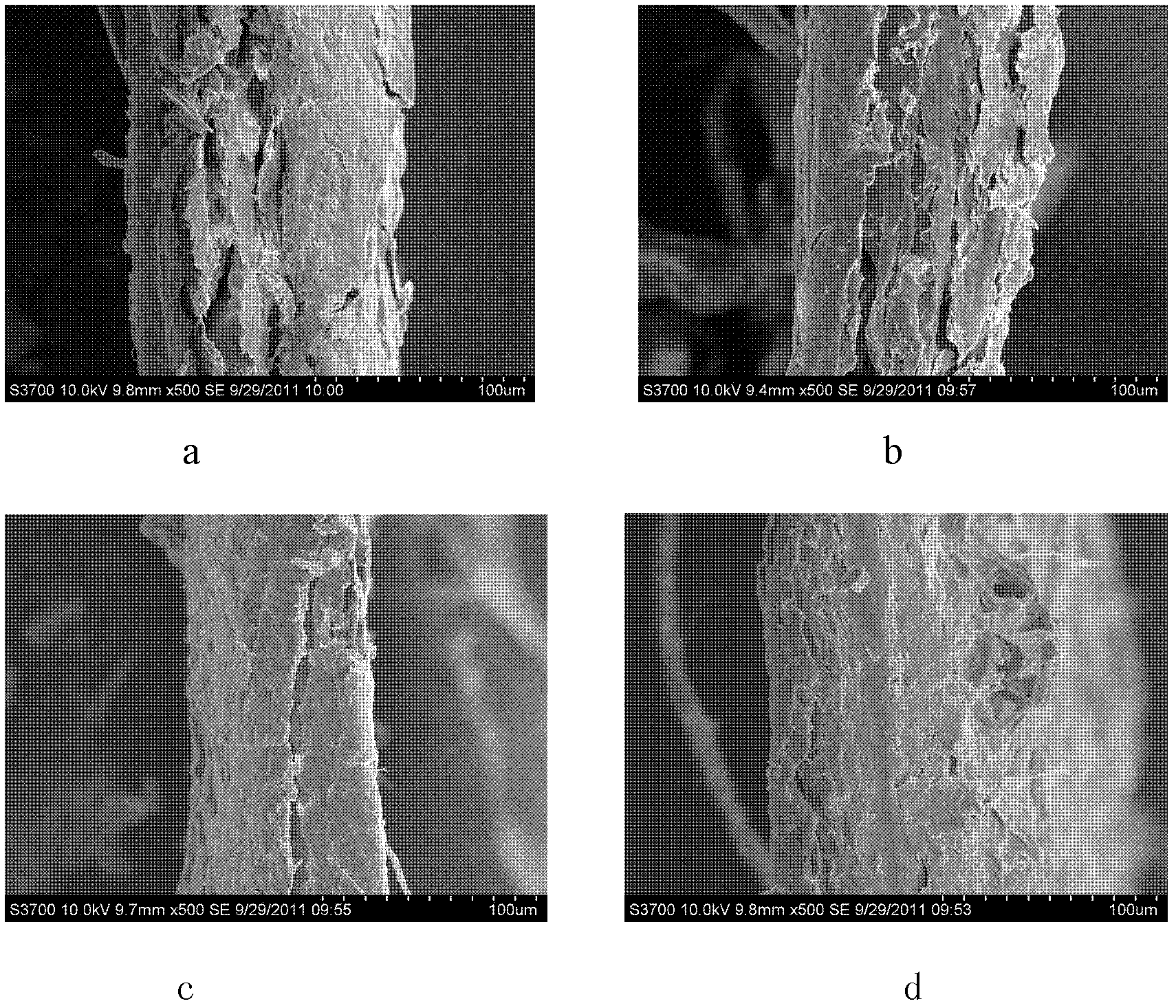

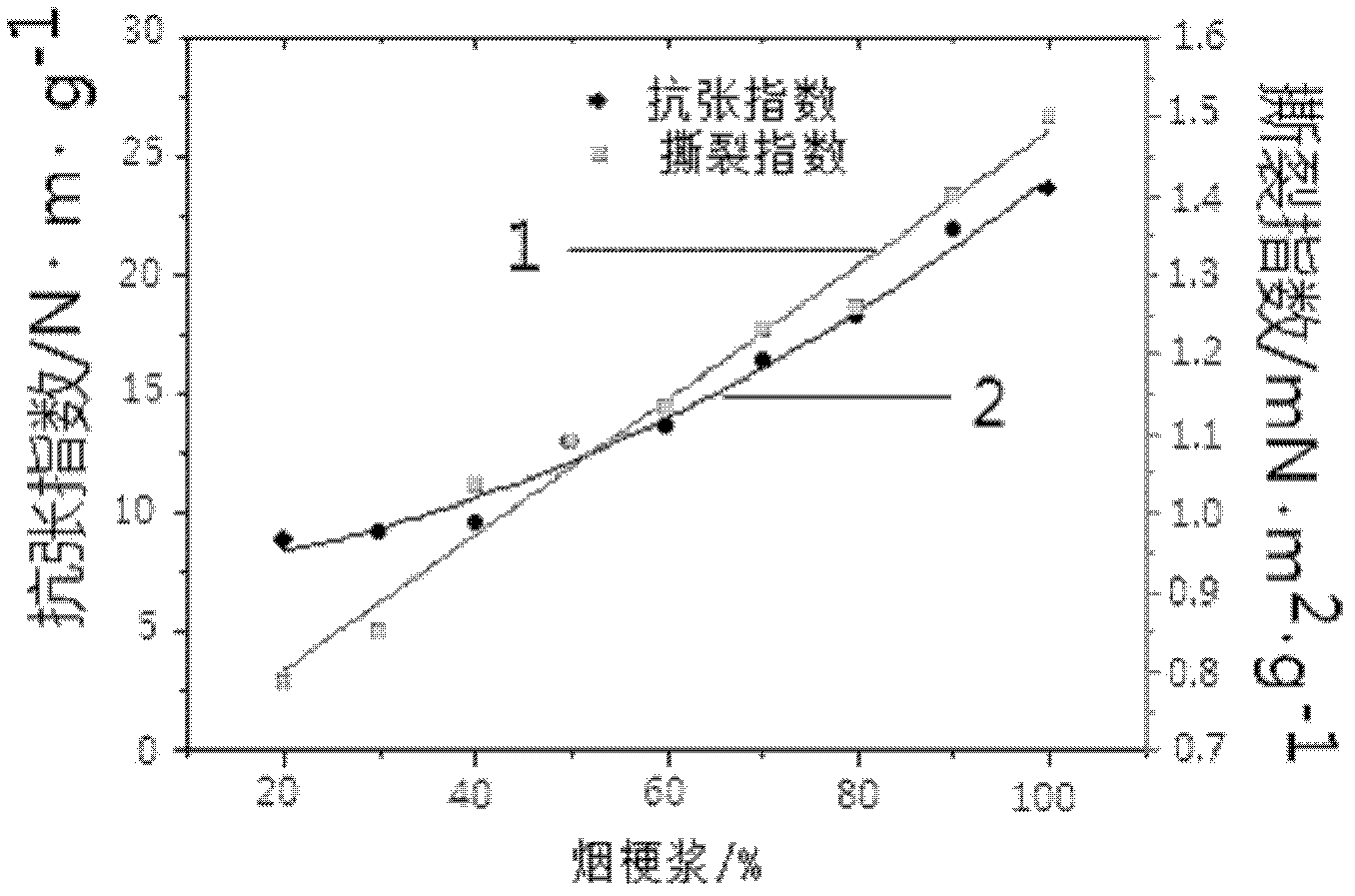

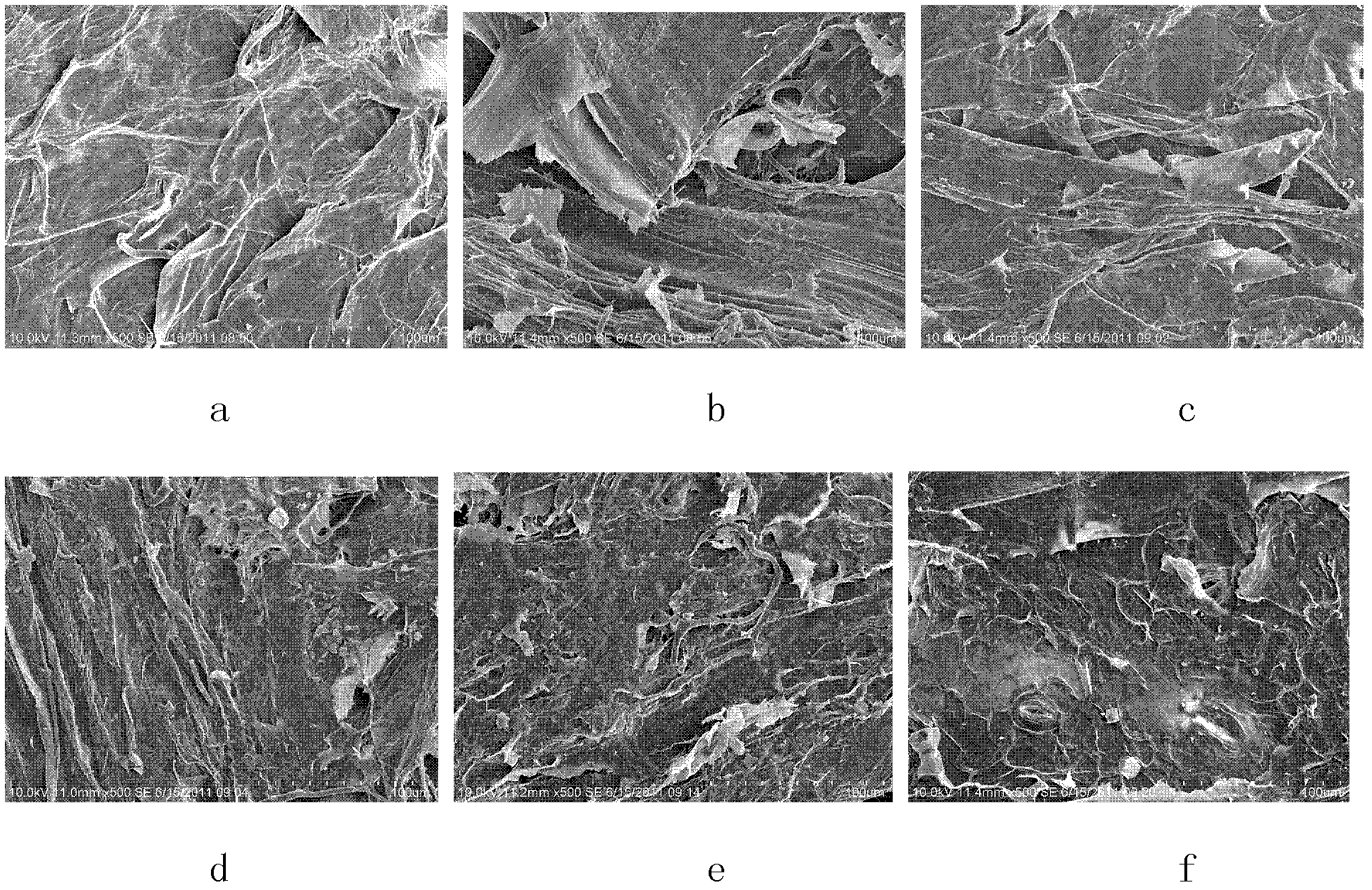

[0033] The pulp after refining is copied by Austrian PTI fast sheet copying machine, and the quantitative is 70g / m 2 For the thin paper base for cigarettes, for the convenience of description, the mass ratio of tobacco stem pulp to tobacco dust pulp used in this embodiment is 7:3. A KRK-2570 square press (Japan KRK Company) was used to press and then dry with different pressing pressures. The drying temperature used in this embodiment was 105°C. The paper sheets were treated under ISO standard constant temperature ...

Embodiment 2

[0061] Example 2 Comprehensive Research on the Preparation Technology of Sheets for Tobacco

[0062] Tobacco stems and tobacco dust used in the experiment were randomly selected from the raw materials produced by Guangdong China Tobacco Industry Co., Ltd., and were commercially available tobacco stems and tobacco dust. Refrigerate the tobacco stems and tobacco powder at 4°C, and pack them into bags to balance the moisture for later use.

[0063] (1) Dipping extraction

[0064] In this example, the single-stage immersion extraction experiment of tobacco stems and tobacco powder was carried out in an electric cooking pot (ordinary type) ZT1-00 / 15L (produced by Xingping Zhongtong Experimental Equipment Co., Ltd.).

[0065] Tobacco stem extraction: The amount of tobacco stems in the pot is 1500g. First add about 10000mL of water into the cooking pot according to the liquid ratio of 1:7 (mass ratio), preheat to 60°C, add the tobacco stems, cover the pot and carry out rotary cooki...

Embodiment 3

[0101] The preparation of embodiment 3 reconstituted tobacco leaves

[0102] Tobacco stems and tobacco dust used in the experiment were randomly selected from the raw materials produced by Guangdong China Tobacco Industry Co., Ltd., and were commercially available tobacco stems and tobacco dust. Refrigerate the tobacco stems and tobacco powder at 4°C, and pack them into bags to balance the moisture for later use.

[0103] (1) extracting tobacco stems and tobacco powder

[0104] Tobacco stems and tobacco dust are extracted by a three-stage countercurrent extraction process, and the schematic diagram of the process flow is shown in the appendix Figure 4shown. Tobacco stems and tobacco powder enter the refining section after the first stage extraction, the second stage extraction and the third stage extraction respectively. The third-stage extraction uses clean water to extract the third-stage extract liquid that enters the second stage countercurrently for immersion extracti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com