A kind of NdFeB permanent magnet material and its preparation method and magnetic field assisted direct casting device

A permanent magnet material, neodymium iron boron technology, applied in the direction of magnetic materials, magnets, magnetic objects, etc., can solve the problems of restricting the application of copper mold casting methods, uneven overall structure of castings, and easy nucleation and growth of grains, etc., to achieve Enhanced corrosion resistance and service life, good mechanical properties, less metallurgical defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

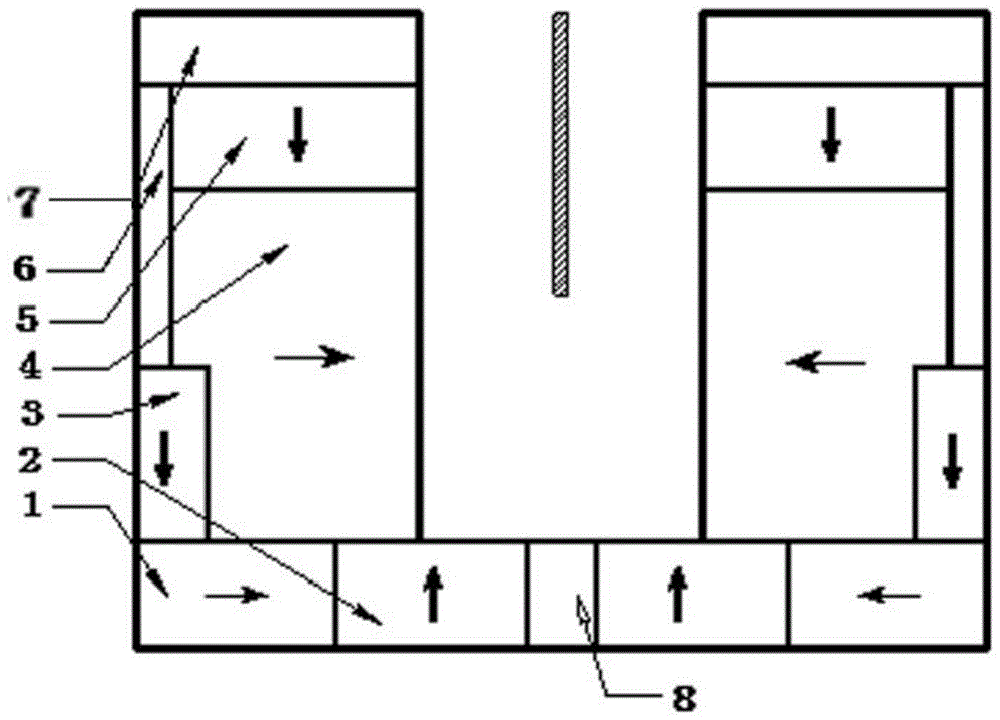

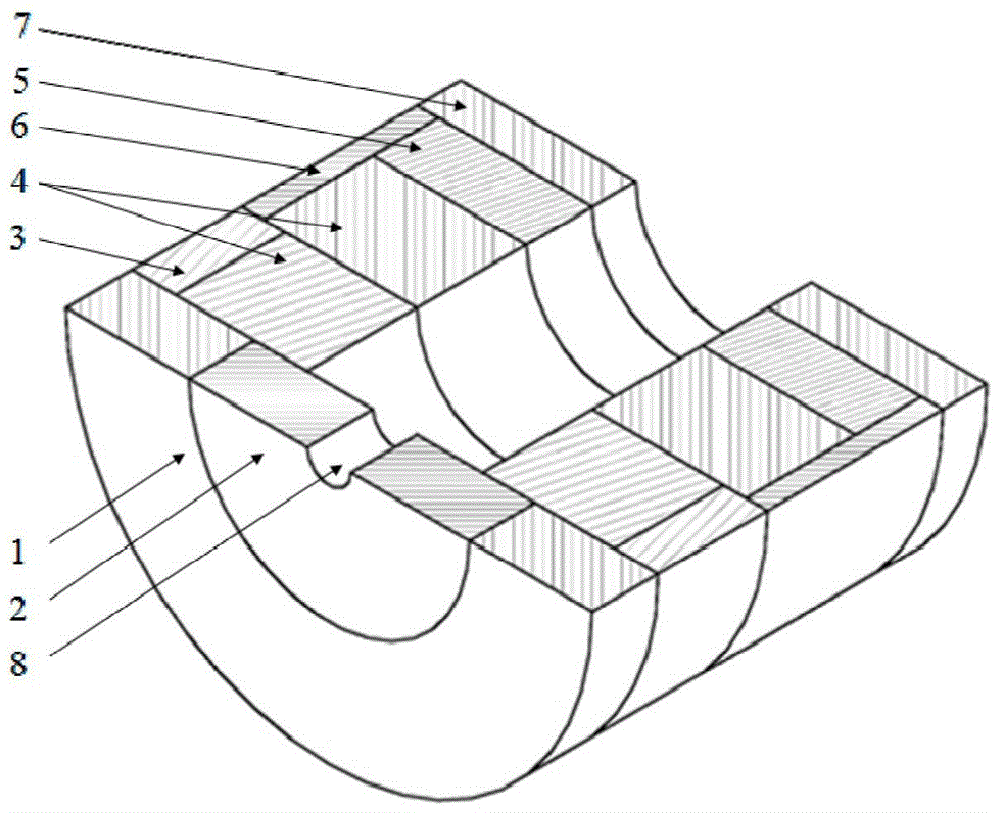

[0036] figure 1 It is a schematic structural diagram of a magnetic field-assisted direct casting device for NdFeB permanent magnet materials, and the arrow in the figure indicates the direction of magnetization. Such as figure 1 , 2As shown, the magnetic field assisted direct casting device of NdFeB permanent magnet materials includes a first repelling magnet 1, a second repelling magnet 2, a magnet guiding magnet 3, a main magnet 4, a control magnet 5, a first soft iron 6 and a second Soft iron 7; Main magnet 4 is the ring-shaped magnet of radial magnetization; Main magnet 4 center is provided with a piece of magnetic field direction and is the second repelling magnet 2 of axially upward disc shape, and the second repelling magnet 2 periphery is provided with There is the circular first repelling magnet 1 of radial magnetization; The first repelling magnet 1 and the second repelling magnet 2 are preferably equal thickness cooperation; The first repelling magnet 1 and the se...

Embodiment 2

[0050] Step 1: Add Nd 35 co 20 Fe 30 al 10 B 5 According to the proportion of (atomic ratio); the total weight of the sample is 10g, of which Nd, Co, Fe, Al, and B are 6.1369g, 1.4327g, 2.0367g, 0.3280, and 0.0657, respectively.

[0051] Step 2: Put the raw materials prepared in Step 1 into the electric arc furnace, and evacuate to 10 ‐3 Pa, after cleaning the furnace with high-purity argon, fill it with high-purity argon at a pressure slightly lower than 1 atmosphere (about 0.1MPa), and repeatedly smelt 5-8 times under the protection of high-purity argon. The melting temperature is 1300-1500°C. The time is 2-3 minutes, and a button-shaped alloy ingot with uniform composition is obtained after cooling.

[0052] Step 3: After simple mechanical crushing of the alloy ingot prepared in Step 2, put it into a quartz tube with a small hole at the lower end, heat it with high-frequency induction, and evacuate to 10 -4 Pa, after cleaning the furnace with high-purity argon, fill i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com